How Metal Tube Cutting Machines Drive the Shift to Smart Manufacturing

Many manufacturers struggle with outdated processes, leading to inefficiencies and high costs. This prevents them from truly competing in today's fast-paced market. Embrace smart manufacturing1, a transformation where advanced metal tube cutting machines are central.

Smart manufacturing leverages advanced technologies like AI, IoT, and automation to create highly efficient and adaptive production systems. Metal tube cutting machines are pivotal, integrating seamlessly into these digital ecosystems by providing precise, automated, and data-driven fabrication, fundamentally shifting traditional processes towards intelligent, interconnected operations.

The journey towards intelligent production isn't merely about adopting new tools; it's a paradigm shift. As someone deeply involved in this transformation at MZBNL, I've witnessed firsthand how embracing smart technologies can revolutionize operations. Let's delve into this evolution and understand the profound impact these machines have.

For years, the manufacturing sector has grappled with the delicate balance between efficiency, cost-effectiveness, and adaptability. The concept of Industry 4.02 emerges as a critical response, representing the fourth industrial revolution. This isn't just about automating tasks; it's about creating an interconnected ecosystem where machines communicate, data drives decisions, and production processes are self-optimizing. From my perspective at MZBNL, where we’ve pioneered solutions for 25 years, I've seen how this shift is propelled by the integration of advanced machinery. Consider how companies like Ahmed Al-Farsi's metal fabrication business in the UAE constantly seek to upgrade efficiency and expand into architectural metalwork, are at the forefront of this adoption. They face the immediate challenge of high operator turnover and the need for skilled CAD operators, pushing them towards turnkey, intelligent solutions. The critical inquiry isn't merely "how to cut metal" but "how to cut metal smarter," integrating real-time data from the shop floor with enterprise-level planning to predict maintenance, optimize material usage, and reduce lead times. This holistic approach, driven by innovations in tube cutting, is reshaping the entire value chain.

What is the historical background of smart manufacturing?

Understanding smart manufacturing feels complex without context. Without this historical grounding, its true impact can be underestimated. Let's trace its origins, revealing how past industrial revolutions paved the way for today's interconnected factories.

Smart manufacturing's roots trace back through several industrial revolutions: from mechanization (Industry 1.0) and mass production (Industry 2.0) to automation (Industry 3.0), finally culminating in the interconnected, data-driven systems of Industry 4.0, which emphasizes cyber-physical systems, IoT, and AI for real-time optimization.

The path to smart manufacturing has been a progressive evolution, each industrial revolution building upon the last to enhance productivity, reduce labor, and create entirely new capabilities. My journey with MZBNL over 25 years has allowed me to witness firsthand the acceleration of this transformation. I recall a time when manual processes dominated, and even early automation felt revolutionary. However, the true leap forward came with the digital age, transforming isolated machines into interconnected systems. This continuous drive for innovation is what defines our industry, pushing us beyond simple automation towards genuinely intelligent production environments where machines anticipate needs and optimize autonomously. Understanding this journey is crucial to appreciating the current state and future potential of our manufacturing capabilities.

The evolution of manufacturing is a tale of relentless innovation, driven by humanity's desire for greater efficiency and output. Understanding the historical context of smart manufacturing helps us appreciate the depth of today's advancements.

From Steam to Cyber-Physical Systems: A Brief Timeline

The journey begins with Industry 1.0, marked by the introduction of steam power and mechanization in the late 18th century. Water and steam powered the first weaving looms and railroads, fundamentally transforming agricultural societies into industrial ones. This era brought about the factory system, centralizing production and laying the groundwork for modern industrial organization.

Next came Industry 2.0 in the late 19th and early 20th centuries, fueled by electricity and the concept of mass production. Henry Ford's assembly line, powered by electric motors, exemplified this era. The division of labor became highly specialized, leading to unprecedented output volumes and standardized products. It was about making things faster and cheaper, reaching a broader consumer base.

The advent of electronics and information technology ushered in Industry 3.0 in the latter half of the 20th century. This revolution saw the introduction of Programmable Logic Controllers (PLCs), computers, and robotics, enabling the automation of individual machines and processes. This period dramatically reduced human intervention in repetitive tasks, improving precision and consistency. However, these systems often operated in silos, lacking true interconnectivity. For instance, early CNC tube cutting machines, while precise, required extensive manual programming and data input for each job, a challenge that Ahmed Al-Farsi's team often faced with their older equipment, highlighting the isolated nature of these systems.

Finally, we arrive at Industry 4.0, or smart manufacturing, which leverages cyber-physical systems, the Internet of Things (IoT), cloud computing, and artificial intelligence. This paradigm shift connects machines, systems, and people in real-time, allowing for autonomous decision-making, predictive maintenance, and highly customized production. Instead of just automating tasks, it creates an intelligent, self-optimizing ecosystem. For instance, at MZBNL, our No-CAD system is a direct result of this evolution; operators no longer need 15 days of factory training for complex 3D drawings but can start cutting after just one day of on-site training by simply entering parameters – a testament to the intuitive, smart design principles.

Key Enablers and Drivers for Smart Manufacturing Adoption

The transition to smart manufacturing isn't just a technological leap; it's driven by compelling economic and operational imperatives. One primary enabler is the exponential growth in data analytics and processing power. With IoT sensors embedded in machines like our laser tube cutters, vast amounts of data—from cutting speeds and material consumption to machine health and production throughput—can be collected and analyzed in real-time. This real-time insight allows for unprecedented optimization, identifying bottlenecks, predicting equipment failures before they occur, and fine-tuning parameters for maximum efficiency. For a client like Ahmed, who prioritizes reliability and uptime, this predictive capability translates directly into reduced downtime and consistent project delivery. Research by McKinsey & Company suggests that companies adopting Industry 4.0 technologies can achieve up to a 30% reduction in operating costs and a 10-20% increase in productivity.

Another critical driver is the increasing demand for customization and personalization. Consumers and B2B clients alike are moving away from mass-produced, generic items towards unique, tailor-made solutions. Smart factories, with their agile and reconfigurable production lines, are uniquely positioned to meet this demand without sacrificing efficiency or incurring prohibitive costs. This flexibility is crucial for businesses like Ahmed's, which expands into diverse areas like architectural metalwork and vehicle parts, requiring highly adaptable fabrication capabilities. Furthermore, the globalization of supply chains and intensifying competition compel manufacturers to seek new competitive advantages. Companies cannot afford to be slow, wasteful, or inefficient. Smart manufacturing provides that edge by enabling higher quality at lower costs and faster delivery times. For example, while sourcing from China, Germany, and Turkey, Ahmed specifically seeks suppliers with proven technology and global references, indicating a preference for solutions that align with cutting-edge global manufacturing standards.

Societal and Environmental Impacts of This Evolution

Beyond economic drivers, smart manufacturing also addresses significant societal and environmental concerns. From a labor perspective, the shift mitigates the impact of an aging workforce and the shortage of skilled labor in traditional manufacturing roles. While some fear job displacement, the reality is a transformation of roles: repetitive, dangerous tasks are automated, freeing human workers to focus on higher-value activities such as system oversight, data analysis, innovation, and strategic decision-making. MZBNL's No-CAD system directly tackles Ahmed's pain point of high operator turnover and the retraining burden, significantly lowering the skill threshold required for operation and allowing his existing staff to become productive much faster. This not only enhances job satisfaction but also creates new, more intellectually stimulating opportunities.

Environmentally, smart manufacturing offers immense potential for sustainability. By optimizing processes, reducing waste, and improving resource utilization, smart factories can significantly lower their ecological footprint. Features like MZBNL's Zero-Waste Tail Material Innovation exemplify this; by redesigning the cutting logic to utilize the remaining tube section, we maximize material utilization, which not only saves costs but also drastically reduces scrap metal. This aligns with global efforts towards a circular economy and responsible resource management. Data-driven energy management systems can also monitor and reduce energy consumption in real-time, contributing to a greener industrial landscape. The ability to produce only what is needed, when it is needed, with minimal waste, stands in stark contrast to the often wasteful practices of traditional mass production. This holistic benefit, encompassing economic, social, and environmental dimensions, underscores why smart manufacturing is not just a trend but a fundamental necessity for the future of industry.

Smart manufacturing is Industry 4.0True

Smart manufacturing represents the fourth industrial revolution (Industry 4.0), characterized by interconnected, data-driven systems using IoT and AI.

Industry 1.0 used electricityFalse

Industry 1.0 was powered by steam and water, not electricity. The use of electricity marked the beginning of Industry 2.0.

How are metal tube cutting machines integrated into current manufacturing processes?

The integration of advanced machinery into existing workflows often seems daunting. Without clear integration strategies, the full potential of these investments remains untapped. Discover how metal tube cutting machines seamlessly merge into modern manufacturing, enhancing efficiency from concept to completion.

Modern metal tube cutting machines are integrated through digital connectivity, linking CAD/CAM software, ERP systems, and automated material handling. They act as precise, high-speed fabrication hubs, receiving digital designs, optimizing cut paths, and often performing multiple processes like punching simultaneously, becoming central to agile and efficient production lines.

The seamless integration of advanced machinery is a cornerstone of smart manufacturing. My experience with MZBNL, spanning two and a half decades, has shown me that the true power of a machine isn't just in its individual capability, but in its ability to communicate and cooperate with other systems. We've moved beyond standalone machines to networked solutions where information flows freely. Consider how crucial this is for clients like Ahmed, who needs a turnkey solution that is easy to install and operate, and critically, integrates smoothly into his existing workflows. It’s about transforming a discrete step into a continuous, data-driven process, ensuring that every cut is not only precise but also part of a larger, optimized production strategy. This interconnectedness allows for unparalleled responsiveness and efficiency throughout the entire manufacturing chain.

Integrating advanced metal tube cutting machines into contemporary manufacturing processes goes far beyond simply replacing an old saw. It’s about creating a harmonious, intelligent ecosystem where machines, software, and human expertise converge to optimize every stage of production.

Seamless Data Flow: From Design to Production Floor

At the heart of modern integration is the seamless flow of data. In traditional setups, design (CAD), manufacturing planning (CAM), and execution were often disparate processes, requiring manual data transfer and re-entry, which introduced errors and delays. In contrast, today’s smart metal tube cutting machines are designed for deep integration with digital ecosystems. This begins with direct CAD/CAM connectivity, where complex 3D models and cutting instructions are transferred directly from design software to the machine's control system. For example, our MZBNL No-CAD system3 takes this a step further by allowing standard tube types and hole patterns to be processed simply by entering parameters, eliminating the need for complex 3D drawings altogether. This innovation dramatically reduces the design-to-production cycle, saving considerable time and reducing the skill threshold.

Furthermore, these machines are increasingly connected to broader Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES). This connection allows for real-time order processing, material tracking, and production scheduling. When a new order comes in, the ERP system can automatically allocate resources, retrieve relevant designs, and push cutting tasks directly to the tube cutting machine. The machine, in turn, provides real-time feedback on its progress, material consumption, and machine status back to the MES, enabling managers to monitor production, identify bottlenecks, and make data-driven adjustments on the fly. For a business like Ahmed's, which operates with 100+ staff and plans to automate existing manual workflows, this level of integration means that an order for custom railings can move from sales inquiry to cut parts with minimal human intervention in between, significantly boosting overall operational efficiency.

This digital thread ensures that every component is tracked, every process is optimized, and every decision is informed by accurate, real-time data. It transitions manufacturing from a series of isolated steps to a continuous, interconnected flow, where consistency and traceability are paramount.

Automated Material Handling and Multi-Process Integration

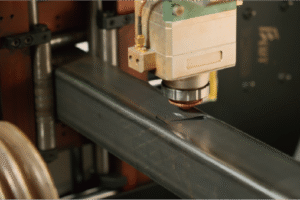

Another critical aspect of integration is the advent of automated material handling systems. Manual loading of long, heavy metal tubes is not only labor-intensive and slow but also poses significant safety risks. Modern tube cutting machines are often paired with automated loading and unloading systems, ranging from bundle loaders to robotic arms. Our MZBNL Front-Feeding Innovation4 is a prime example; while traditional machines rely on side or rear manual loading, our optimized front-feeding mechanism automatically pulls the tube in, increasing feeding efficiency by about 40% and reducing operator labor intensity by approximately 40%. This not only accelerates throughput but also frees up operators to manage multiple machines or perform higher-value tasks, addressing Ahmed’s concern about operator turnover and improving workplace ergonomics.

Beyond material handling, advanced tube cutting machines are embracing multi-process integration. Historically, tube processing involved separate machines for cutting, punching, drilling, and deburring. This led to multiple setups, increased handling, and cumulative errors. However, integrated machines now combine these functions. For instance, our Automatic Punching & Cutting Integrated Machine5 allows for laser cutting and punching within a single setup. This significantly reduces lead times, improves precision by eliminating transfer errors between machines, and minimizes floor space requirements. A company like Ahmed’s, producing both architectural metalwork and automotive parts, benefits immensely from a machine that can perform complex cuts and precise holes on a single piece of tube without additional handling, ensuring consistent quality across diverse product lines and reducing the need for multiple specialized machines.

The consolidation of processes streamlines the production line, creating a lean and efficient workflow. This 'one-stop' processing capability is a game-changer for manufacturers seeking to optimize their footprint and maximize throughput with minimal retooling.

Real-Time Monitoring, Predictive Maintenance, and Quality Control

The most advanced integration features revolve around real-time monitoring, predictive maintenance, and integrated quality control. Through embedded sensors and IoT connectivity, modern tube cutting machines continuously collect data on their performance—everything from laser power and cutting speed to temperature, vibration, and material usage. This data is fed into analytics platforms that provide operators and managers with real-time insights. For example, a dashboard might show the current production rate, machine status, or upcoming maintenance needs.

This continuous monitoring enables predictive maintenance, moving away from reactive (fix it when it breaks) or preventive (fix it on a schedule) approaches. By analyzing operational data, the system can predict when a component is likely to fail or when performance will degrade, allowing maintenance to be scheduled proactively, during non-production hours. This drastically reduces unexpected downtime, a major pain point for manufacturers. For Ahmed, who experienced long machine lead times affecting project delivery, the ability to anticipate and prevent breakdowns is invaluable, ensuring continuous operation and on-time fulfillment of contracts.

Furthermore, some machines incorporate in-process quality control systems. Vision systems or laser scanners can verify cut dimensions and hole positions immediately after processing, identifying deviations early. If an issue is detected, the machine can automatically adjust parameters or flag the part for inspection, preventing defective parts from moving further down the production line. This level of integrated quality assurance ensures higher product quality and reduces waste. Our Zero-Waste Tail Material Innovation6, by optimizing cuts from the rear chuck, not only saves material but also inherently improves efficiency, allowing for a higher first-pass yield. This combination of real-time insights, proactive maintenance, and integrated quality checks makes modern metal tube cutting machines not just tools, but intelligent contributors to a truly smart manufacturing environment.

| Feature Area | Traditional Approach | Smart Manufacturing Integration | Benefit to Customer (e.g., Ahmed) |

|---|---|---|---|

| Design-to-Cut | Manual CAD drawings, separate CAM, manual data entry, high skill req. | No-CAD/Direct CAD/CAM integration, automated parameter input, digital twin | Faster setup (1 day training vs 15), reduced errors, lower skill threshold, agile production for custom orders. |

| Material Feeding | Manual loading (side/rear), labor-intensive, slow, safety risks | Automated front-feeding systems, robotic loaders | 40% increased efficiency, 40% reduced labor intensity, enhanced safety, higher throughput. |

| Process Steps | Separate cutting, punching, drilling, deburring machines, multiple setups | Multi-process integrated machines (e.g., cutting & punching) | Reduced lead times, improved precision (no transfer errors), less floor space, versatility for varied product lines (railings, auto parts). |

| Maintenance | Reactive (break-fix) or Time-based Preventive | Predictive maintenance via IoT sensors & data analytics | Drastically reduced unexpected downtime, higher machine uptime, timely project delivery. |

| Waste Management | Unusable tail material, manual sorting | Zero-Waste Tail Material Innovation, optimized nesting | Maximize material utilization, reduced scrap costs, enhanced sustainability. |

Modern tube cutters connect to ERP systemsTrue

Advanced machines integrate with enterprise software for real-time order processing and material tracking.

Manual loading is safer than automatedFalse

Automated material handling systems reduce safety risks associated with manual loading of heavy tubes.

What challenges do traditional manufacturing methods face in today's industry?

Traditional manufacturing, once robust, now struggles with new market realities. These outdated methods lead to inefficiencies, stifle innovation, and hamper competitiveness. Let's uncover the critical challenges forcing a paradigm shift towards smarter operations.

Traditional manufacturing methods face significant challenges including high labor costs, reliance on skilled manual operators, inconsistent quality due to human error, lengthy production cycles, and limited flexibility for customization. They also struggle with inefficient resource utilization, lack of real-time data for decision-making, and difficulty scaling to meet fluctuating market demands.

Having worked in metal fabrication for 25 years, I’ve seen the industry evolve from largely manual processes to increasingly automated ones. This firsthand experience, particularly at MZBNL, highlights the stark contrast between traditional methods and the demands of modern manufacturing. While older approaches had their place, they are simply no longer sustainable in a globalized, rapidly changing market. The pressures from increasing competition, escalating material costs, and the need for greater agility are forcing every business, including our client Ahmed Al-Farsi in the UAE7, to critically re-evaluate their operational frameworks. He knows that relying solely on traditional methods would hinder his ability to expand into new markets like architectural metalwork and vehicle parts, which demand precision, speed, and cost-effectiveness. It's clear that sticking to the old ways is not just inefficient; it's a direct threat to long-term viability and growth.

The industrial landscape has transformed dramatically, exposing the inherent limitations and vulnerabilities of traditional manufacturing methods. What once sufficed or even thrived, now struggles under the weight of new economic pressures, technological advancements, and evolving customer expectations.

Labor-Intensive Processes and the Skills Gap

One of the most persistent challenges facing traditional manufacturing is its reliance on manual, labor-intensive processes and the concurrent widening skills gap. Many conventional workshops still depend heavily on skilled operators for tasks such as manual loading, precise measurement, setup, and quality inspection. While craftsmanship is valuable, human labor is inherently prone to variability, fatigue, and error, directly impacting consistency and throughput. This dependence also translates into higher operating costs, especially in regions with rising wages. The average manufacturing labor cost8 can vary significantly, from approximately $5 per hour in some developing economies to over $40 per hour in highly developed nations, making manual processes unsustainable for global competitiveness.

Compounding this is the global shortage of skilled labor. Experienced machinists, welders, and technicians are retiring faster than new talent can be trained to replace them. This creates a bottleneck in production, leads to higher operator turnover – a specific pain point Ahmed Al-Farsi faced with his previous machines, causing retraining burdens – and can result in significant delays and quality issues. Traditional training programs often take months, if not years, to produce a truly proficient operator. This bottleneck stifles growth and innovation, making it incredibly difficult for companies to scale operations or adapt to new production demands efficiently. My team at MZBNL heard countless stories from clients whose production lines were crippled by just one skilled operator leaving, underscoring the urgency for less skill-dependent solutions.

Moreover, the high demand for skilled CAD operators for complex 3D drawings, as seen in Ahmed’s previous challenges, exemplifies how specialized knowledge can become a single point of failure. Without a readily available pool of such talent, businesses are left vulnerable, impacting their ability to take on new, intricate projects or innovate quickly.

Inefficiency, Waste, and Lack of Flexibility

Traditional manufacturing methods are often characterized by significant inefficiency and waste. Processes that involve multiple setups, manual transfers between machines, and sequential operations inherently introduce opportunities for error, material waste, and lost time. For example, in conventional tube cutting, the generation of "tail material"9 – unusable tube ends – is a common issue, leading to a substantial waste of expensive raw materials. Industry estimates suggest that material waste in metal fabrication can range from 5% to 15% depending on the process, directly impacting profitability. This isn't just about material; it's also about energy consumption and the environmental footprint of excess production and scrap.

Another critical limitation is the lack of flexibility and agility. Traditional production lines are typically designed for mass production of standardized items. Reconfiguring these lines for small batches, custom orders, or design changes is often time-consuming, expensive, and disruptive. This inflexibility puts manufacturers at a severe disadvantage in today's market, where customers demand rapid customization and personalized products. For Ahmed Al-Farsi, who is actively expanding his business in architectural metalwork and vehicle parts, the inability to pivot quickly between diverse projects and product specifications with his older equipment directly impacted his competitive edge. The long machine lead times he experienced meant delayed project delivery, risking client satisfaction and future contracts.

Furthermore, the absence of real-time data collection and analysis means that inefficiencies often go unnoticed or are only discovered after the fact, making continuous improvement a reactive rather than a proactive process. This lack of insight prevents optimization, contributing to higher operational costs and reduced responsiveness to market shifts.

Quality Inconsistency and Limited Scalability

The inherent human element in traditional manufacturing, while offering a degree of versatility, often leads to quality inconsistency. Manual measurements, adjustments, and inspections are subject to human error, fatigue, and individual skill levels. This can result in variations in product quality, higher scrap rates, and the need for extensive post-production quality control, which adds cost and time. For instance, inconsistencies in punching or cutting accuracy can lead to costly rework or, worse, defective products reaching the market, damaging a company's reputation. A fabrication business like Ahmed's, which earns by delivering finished parts to builders and OEMs, cannot afford even minor quality discrepancies, as they impact contract fulfillment and future business.

Finally, limited scalability is a major constraint. Expanding production with traditional methods often means simply adding more machines and more skilled labor, a linear growth model that quickly hits bottlenecks. The process isn't optimized for exponential growth, and each addition brings its own set of management complexities, training burdens, and potential for inconsistencies. This makes it challenging for companies to quickly ramp up production during peak demand or to take on larger, more complex contracts. In contrast to smart manufacturing, where a single, highly integrated machine can often replace multiple traditional machines and processes, conventional methods struggle to adapt to rapid market changes without significant capital expenditure and operational overhauls. This inability to scale efficiently directly impacts a company's ability to capitalize on new market opportunities or withstand economic downturns.

Traditional manufacturing has high labor costsTrue

The article states that labor costs range from $5 to $40 per hour, making manual processes unsustainable for global competition.

Traditional methods are better for customizationFalse

The text explains that traditional production lines lack flexibility and struggle with custom orders, putting manufacturers at a disadvantage.

How do metal tube cutting machines provide solutions to these challenges?

The challenges of traditional manufacturing demand transformative solutions. Without modern tools, businesses risk falling behind competitors. Discover how advanced metal tube cutting machines directly address these pain points, driving efficiency, reducing waste, and empowering smart factories.

Modern metal tube cutting machines solve traditional manufacturing challenges by automating labor-intensive tasks, reducing the need for highly skilled operators with features like No-CAD systems, minimizing material waste through optimized cutting logic, and ensuring consistent high precision. Their integrated multi-process capabilities enhance efficiency and flexibility, providing real-time data for informed decisions and superior quality control.

My 25 years at MZBNL have been a testament to continuous innovation, always focused on solving the real-world problems manufacturers face. We've dedicated ourselves to developing technologies that not only meet current industry demands but also anticipate future needs. The transition from traditional methods to intelligent, automated solutions isn't merely an upgrade; it's a strategic imperative that directly addresses the pain points we just discussed. I recall many conversations with clients, much like Ahmed Al-Farsi, who expressed frustration over retraining burdens and inconsistent quality. This is precisely why we've poured our expertise into creating machines that deliver tangible, measurable benefits, transforming challenges into competitive advantages and laying the groundwork for a truly smart and sustainable manufacturing future.

The emergence of advanced metal tube cutting machines is not merely an incremental improvement but a revolutionary leap that directly addresses and overcomes the fundamental challenges plaguing traditional manufacturing. These machines are engineered to be the bedrock of smart factories, offering solutions that span from labor efficiency to material optimization and quality control.

Overcoming Labor Challenges and the Skills Gap

The most immediate and impactful solution provided by modern metal tube cutting machines is the dramatic reduction in reliance on highly skilled manual labor and the mitigation of the skills gap. Traditionally, operating sophisticated machinery required extensive training, often spanning months or even years, to master complex CAD drawings and machine operation. Our MZBNL No-CAD Operating System directly tackles this by allowing operators to process standard tube types and hole patterns simply by entering parameters. This revolutionary approach means operators now only need 1 day of on-site training instead of 15 days at the equipment factory10, significantly lowering the skill threshold and training burden. This directly alleviates the high operator turnover and retraining issues that Ahmed Al-Farsi faced, ensuring his team can become productive almost immediately.

Furthermore, the integration of automation, such as our Front-Feeding Innovation, drastically reduces the physical labor intensity. While traditional machines necessitate manual side or rear loading, our system automatically pulls the tube from the front. This not only increases feeding efficiency by about 40% but also reduces operator labor intensity by approximately 40%. This translates into fewer staff required for heavy-duty tasks, allowing existing personnel to be redeployed to higher-value activities like quality supervision, process optimization, or even managing multiple machines. For a business with 100+ staff like Ahmed’s, optimizing human capital by reducing strenuous tasks and skill dependency directly contributes to increased productivity per employee and improved workplace safety, ensuring stable operations even amidst a fluctuating labor market.

The shift means less time spent on mundane, repetitive tasks and more on strategic oversight, transforming the workforce from machine operators to system managers. This paradigm shift makes manufacturing careers more appealing and sustainable in the long run.

Enhancing Efficiency and Eliminating Waste

Modern metal tube cutting machines are designed for unparalleled efficiency and waste reduction, directly combating two of the most significant drawbacks of traditional methods. One of the most significant innovations in this regard is our Zero-Waste Tail Material Innovation. Conventional systems often leave unusable "tail material" at the end of a tube, leading to significant material waste and increased costs. MZBNL redesigned the cutting logic to calculate from the rear chuck as the origin, allowing the system to eliminate leftover tail material as long as the remaining section is smaller than the product length. This innovative approach maximizes material utilization, effectively turning what was once scrap into usable product. For businesses dealing with high volumes of expensive raw materials, this can translate into cost savings of 5-10% or more on material expenses alone, a critical factor for maintaining profit margins.

Beyond material waste, these machines optimize time and energy consumption. High-speed and high-precision cutting capabilities mean that jobs are completed much faster and with fewer errors, leading to higher throughput. For example, a traditional saw might take minutes to cut a tube, while a laser cutter can complete it in seconds with superior edge quality, requiring no post-processing like deburring. This efficiency gain, coupled with multi-process integration (like our Automatic Punching & Cutting Integrated Machine), means that what once required multiple machines and setups—cutting, punching, drilling—can now be done in one continuous operation. This streamlines the production line, reduces bottlenecks, and minimizes handling, translating into significantly shorter lead times for finished parts. Ahmed Al-Farsi, constantly striving for efficient project delivery, would find this holistic solution invaluable for his contract-based fabrication services.

The reduction in process steps also naturally leads to a reduction in energy consumption per finished part, contributing to a greener and more cost-effective operation.

Achieving Unprecedented Quality and Scalability

Perhaps one of the most compelling solutions offered by advanced tube cutting machines is the ability to deliver unprecedented levels of quality and consistency, coupled with superior scalability. Unlike manual processes prone to human error, automated laser cutting machines achieve micron-level precision, ensuring every cut is identical and meets exact specifications. This vastly reduces the incidence of defects, rework, and scrap, thereby improving the first-pass yield and overall product quality. For clients like Ahmed, who deliver finished parts to demanding industries like automotive and architectural decoration, this consistent quality is non-negotiable and directly impacts his reputation and ability to secure future contracts. The machine’s ability to perform complex cuts and intricate patterns with consistent accuracy across thousands of parts removes the variability associated with manual skilled operations.

In terms of scalability, these machines are inherently designed for higher throughput and easier replication. Instead of adding more labor-dependent traditional machines, a single advanced tube cutting machine can often outperform several older units. Their digital nature means that production parameters and designs can be easily replicated across multiple machines, or even across different factory locations, ensuring consistent output globally. The ease of operation, as highlighted by our No-CAD system, means that scaling up production is less about finding and training a vast new skilled workforce and more about deploying additional intelligent units. This agility allows businesses to respond rapidly to fluctuations in market demand, taking on larger orders or adjusting production volumes without prohibitive operational overhauls. Ahmed, who is considering becoming a regional distributor, would find this scalability and the ability to consistently deliver high-quality products across a wide range of projects to be critical advantages for business expansion and maintaining a competitive edge in his market.

No-CAD systems reduce training timeTrue

The No-CAD system allows operators to process standard tube types with just 1 day of training instead of 15 days, significantly lowering the skill threshold.

Front-feeding increases labor intensityFalse

Front-feeding innovation actually reduces operator labor intensity by about 40% by automating tube loading compared to manual side/rear loading.

What are the technology suggestions for leveraging these machines in smart manufacturing?

Investing in advanced machines is one thing; leveraging them effectively in smart manufacturing is another. Without a clear strategy, their full potential remains untapped. Explore key technological suggestions to maximize the value of metal tube cutting machines within a truly smart factory ecosystem.

To fully leverage metal tube cutting machines in smart manufacturing, integrate them with robust IoT platforms for real-time data, utilize AI-driven analytics for predictive maintenance and process optimization, implement advanced robotics for automated handling, and ensure seamless connectivity with ERP/MES systems. Prioritize intuitive interfaces and remote diagnostic capabilities for operational efficiency.

Having worked closely with countless manufacturers, including forward-thinking clients like Ahmed Al-Farsi, I've observed that simply acquiring cutting-edge machinery isn't enough. The true transformation lies in how these powerful tools are integrated and utilized within a broader smart manufacturing framework. It’s about creating an intelligent, responsive ecosystem. At MZBNL, our 25 years of experience have taught us that the key to unlocking maximum value is a strategic approach to technology adoption. This involves not just hardware but also software, connectivity, and a commitment to continuous improvement, ensuring that every investment contributes to a cohesive, optimized production environment. Let's explore the critical technological suggestions that can elevate metal tube cutting machines from standalone assets to central pillars of your smart factory.

Leveraging metal tube cutting machines within a smart manufacturing paradigm requires a holistic technological strategy that extends beyond the machine itself to encompass data, connectivity, and advanced intelligence. It's about building an interconnected ecosystem where every component contributes to optimized performance.

Embrace Data-Driven Intelligence and IoT Integration

At the core of smart manufacturing is data, and the first critical suggestion is to fully embrace data-driven intelligence through robust IoT integration. Modern metal tube cutting machines, like those developed by MZBNL11, are equipped with numerous sensors that generate vast amounts of operational data – everything from laser power consumption and cutting speed to material usage, machine health diagnostics, and production output. However, this data is only valuable if it can be collected, transmitted, and analyzed effectively. Implementing a dedicated IoT platform allows for real-time data capture from the machine to a central cloud or edge computing system. This means that parameters like spindle RPM, temperature fluctuations, and material feed rates are not just static figures but dynamic insights. For instance, collecting data on the wear patterns of a cutting head can inform a precise replacement schedule, far more accurate than time-based maintenance.

This real-time data then becomes the fuel for AI-driven analytics and machine learning algorithms. These algorithms can identify subtle patterns that human operators might miss, predicting potential machine failures before they occur (predictive maintenance), optimizing cutting paths for maximum material utilization, or even suggesting adjustments to cutting parameters for improved quality or speed. For a client like Ahmed Al-Farsi, who experiences pain points with equipment lacking local service support and long lead times, the ability to remotely diagnose issues and proactively schedule maintenance through data insights is invaluable. Remote diagnostics and spare parts availability, which Ahmed prioritizes, become seamless when machines are continuously reporting their status. A report by Deloitte12 estimates that predictive maintenance can reduce machine downtime by 5-10% and maintenance costs by 10-40%. This proactive approach shifts factories from reactive problem-solving to anticipatory optimization, ensuring consistent uptime and output.

Furthermore, this data enables closed-loop feedback systems. If a quality issue is detected (e.g., through an integrated vision system), the data can be fed back to the machine’s control system to automatically adjust parameters for subsequent cuts, ensuring continuous self-correction and optimal output. This continuous learning and adaptation are hallmarks of a truly smart system.

Implement Advanced Automation and Multi-Machine Integration

The second critical suggestion involves pushing the boundaries of automation beyond just the cutting process itself, focusing on advanced automation and seamless multi-machine integration. While our MZBNL Front-Feeding Innovation already significantly automates material loading, consider integrating industrial robots or automated guided vehicles (AGVs) for tube handling throughout the entire production line – from raw material storage to finished part retrieval. This robotic integration further reduces manual labor, enhances safety, and ensures consistent material flow, particularly beneficial for a business like Ahmed's that has 100+ staff and aims to automate existing manual workflows. For example, a robot could automatically load tubes from a storage rack, feed them into the cutting machine, and then transfer the cut parts to a sorting station or the next processing step (e.g., bending or welding), all without human intervention.

Beyond physical automation, prioritize vertical and horizontal integration of systems. Vertically, this means linking the tube cutting machine’s control system directly with higher-level ERP (Enterprise Resource Planning) and MES (Manufacturing Execution Systems). This allows for seamless transfer of production orders, real-time tracking of job progress, and automated inventory management. Horizontally, it involves connecting the tube cutting machine with other machines on the shop floor – for instance, a laser tube cutter sharing data with a laser sheet cutter or a welding robot. This connectivity enables coordinated production, where the output of one machine automatically triggers the next step in the manufacturing process. For Ahmed, whose business spans architectural metalwork and vehicle parts, this multi-process integration is key. If a customer orders a complex metal structure, the ERP system can automatically schedule parts for both tube and sheet cutting, ensuring all components are ready simultaneously, avoiding bottlenecks.

This comprehensive automation and integration transform individual machines into interconnected workstations, creating a cohesive and highly efficient production flow that can dynamically respond to production demands and changes, reducing overall cycle times by up to 20-30%.

Prioritize User-Centric Design, Training, and Cybersecurity

Finally, to truly leverage these machines, a three-pronged approach focusing on user-centric design, comprehensive training, and robust cybersecurity is essential. Firstly, despite the advanced technology, the interface must remain intuitive and user-friendly. Our MZBNL No-CAD System is a testament to this, simplifying complex operations to parameter entry, dramatically reducing training time from 15 days to just 1 day. This focus on ease of use ensures that even as machines become more sophisticated, they remain accessible to operators, combating the skills gap and minimizing retraining burdens. Intuitive dashboards with clear visualizations of production data, machine status, and maintenance alerts empower operators to manage effectively rather than just operate. Ahmed's preference for turnkey solutions that are easy to install and operate aligns perfectly with this principle.

Secondly, while machines reduce the need for highly skilled manual labor, they elevate the need for new skills in system management, data interpretation, and troubleshooting. Comprehensive training programs, often provided by suppliers like MZBNL, are crucial. This training should cover not just machine operation but also basic data analysis, predictive maintenance interpretation, and network troubleshooting. This empowers the workforce to evolve alongside the technology, turning them into proactive managers of intelligent systems. This addresses Ahmed's expectation of post-sales training and support, ensuring his staff is well-equipped to maximize the machine's capabilities and leverage its smart features.

Thirdly, as manufacturing systems become increasingly interconnected, cybersecurity becomes paramount. Protecting operational technology (OT) networks from cyber threats is as crucial as protecting IT networks. Implementing robust firewalls, intrusion detection systems, regular software updates, and employee training on cybersecurity best practices are non-negotiable. A breach could lead to production downtime, data theft, or even physical damage to machinery. Ensuring secure remote access for diagnostics and support, a feature Ahmed might value, requires stringent security protocols. By investing in these areas – user-friendly design, continuous learning for the workforce, and proactive cybersecurity – companies can fully harness the power of advanced metal tube cutting machines, transforming them into resilient, productive, and future-proof assets within their smart manufacturing ecosystem.

IoT enables predictive maintenanceTrue

IoT integration allows real-time machine data analysis to predict failures before they occur, reducing downtime by 5-10%.

Automation eliminates all human laborFalse

While automation reduces manual tasks, it creates new needs for skilled operators to manage and interpret smart systems.

Conclusion

Metal tube cutting machines are central to smart manufacturing, transforming traditional pain points into competitive advantages. Through innovations like No-CAD and Zero-Waste, they enhance efficiency, reduce costs, and improve quality. Embracing these technologies and strategic integration is key for manufacturers, like our client Ahmed, to thrive in the evolving global industry.

-

Learn the fundamentals and benefits of smart manufacturing and its current industrial applications ↩

-

Discover the technological advancements and frameworks that define Industry 4.0 ↩

-

Understand the benefits of bypassing complex drawings for efficiency ↩

-

Explore how front-feeding boosts efficiency and safety ↩

-

Find out how multiple processes are integrated for precision and speed ↩

-

See how zero-waste design maximizes material use ↩

-

Learn more about Ahmed Al-Farsi's role and challenges in modern manufacturing ↩

-

Discover how labor costs impact manufacturing competitiveness globally ↩

-

Understand how tail material affects efficiency and cost in manufacturing ↩

-

Discover how reduced training improves workforce readiness and productivity ↩

-

Discover how MZBNL machines integrate with smart manufacturing systems ↩

-

Learn about predictive maintenance benefits and effects on production costs ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.