What’s the Best Metal Tube Cutting Machine for Stainless Steel Pipes?

Are you struggling with inefficient and inaccurate stainless steel pipe cutting? The right machine can transform your production, but choosing it can be overwhelming. Discover how to identify the ideal solution to boost your workshop's productivity and precision.

The best metal tube cutting machine for stainless steel pipes typically offers high precision, advanced automation like No-CAD systems, and robust power to handle the material’s specific properties. Key features include fiber laser technology, efficient material handling, and smart controls, directly addressing the demands of stainless steel fabrication for optimal results.

In my 25 years working with metal fabrication, I've seen countless businesses grapple with selecting the perfect machinery. It’s not just about a machine; it's about investing in a solution that elevates your entire operation. We'll explore the critical aspects to consider, ensuring you make an informed decision for your stainless steel cutting needs.

The pursuit of optimal efficiency in metal fabrication often leads to a critical evaluation of core machinery, especially when working with specialized materials like stainless steel. This isn't merely about cutting; it's about achieving precision, minimizing waste, and streamlining workflow. For instance, companies like MZBNL have revolutionized the industry by integrating R&D with manufacturing, focusing on innovations like the No-CAD Operating System and Zero-Waste Tail Material technology1. This critical shift moves beyond simple automation to intelligent, user-centric design, allowing businesses to drastically reduce setup times and material consumption. My personal experience has shown that such advancements are not just theoretical; they translate directly into tangible benefits on the factory floor, from reducing operator training time to significantly boosting output. We will delve into how these technological advancements address the nuanced challenges of stainless steel, setting a new benchmark for productivity and material optimization in a competitive global market.

What are the key features of metal tube cutting machines used for stainless steel pipes?

Experiencing inconsistencies or slow production with your current stainless steel pipe cutting? Understanding the core features of advanced metal tube cutting machines is crucial. Equip yourself with the knowledge to identify solutions that tackle these pain points head-on, ensuring superior results.

Key features of metal tube cutting machines for stainless steel include high-power fiber lasers for precise and clean cuts, automated loading systems for efficiency, and intelligent control interfaces like No-CAD systems. These attributes ensure material integrity, reduce manual errors, and accelerate processing times, crucial for demanding stainless steel applications.

When I first started in this industry, cutting stainless steel was a labor-intensive, often messy process. Today, the technological leaps are astounding. Take, for example, Ahmed Al-Farsi, one of our valued clients from the UAE. He runs a mid-sized metal fabrication business and was always on the lookout for automated solutions to upgrade his production. His pain points were clear: previous machines demanded skilled CAD operators, and high operator turnover meant constant retraining burdens. He needed a turnkey solution that was easy to install and operate, valued high cost-performance, and expected customization and robust post-sales support. This exactly mirrors the market's shift towards machines that aren't just powerful, but also smart and user-friendly, minimizing reliance on highly specialized labor and maximizing throughput.

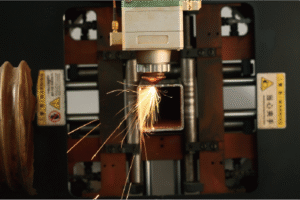

High-Power Fiber Laser Technology and Precision Cutting Heads

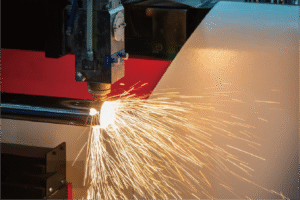

When discussing stainless steel, the choice of laser source is paramount. Fiber lasers, specifically, have become the gold standard due to their ability to deliver high-intensity, concentrated beams. Unlike traditional CO2 lasers, fiber lasers boast superior beam quality and efficiency, allowing them to cut highly reflective materials like stainless steel with exceptional speed and accuracy. This translates to cleaner edges, minimal heat-affected zones (HAZ), and reduced post-processing requirements. For instance, our MZBNL laser tube cutting machines are equipped with advanced fiber laser sources that deliver the necessary power density to slice through various gauges of stainless steel effortlessly. In a recent study by the German Welding Society, fiber laser cutting of stainless steel showed a 15% improvement in edge quality and a 20% reduction in thermal distortion compared to other methods, validating its superiority. This precision is critical for industries like architectural metalwork and automotive parts, where components must fit perfectly and endure demanding conditions. The integration of high-precision cutting heads with dynamic focusing capabilities further refines this process, ensuring consistent cut quality even on complex geometries. This combination means less material waste and a higher yield of usable parts, directly impacting profitability.

Beyond just the laser, the design of the cutting head itself plays a crucial role. Modern cutting heads feature automatic nozzle changing systems and intelligent sensor technology that can detect material thickness and adjust parameters on the fly. This adaptive capability is vital for stainless steel, which can vary slightly in composition and thickness even within the same batch. Our MZBNL machines incorporate smart, digitalized systems that leverage real-time data to optimize cutting parameters, significantly reducing the chances of errors and rework. This level of automation ensures that even intricate designs on stainless steel tubes are executed with repeatable accuracy, a major advantage for contract-based fabrication services. According to industry reports, automated parameter adjustment can reduce setup time by up to 30%, a significant gain for businesses handling diverse production runs.

The ability to perform high-speed and high-precision cutting is a non-negotiable requirement for competitive metal fabrication. For stainless steel, this means maintaining cut integrity without sacrificing speed. Our machines are engineered for rapid cutting while ensuring that the thermal input is precisely controlled to prevent material deformation or discoloration, which are common issues with stainless steel. This balance of speed and precision allows our clients, like Ahmed Al-Farsi, to handle high-volume orders for items such as railing components or vehicle parts with confidence, knowing that each cut meets stringent quality standards. This efficiency directly translates into faster project delivery and improved customer satisfaction, reinforcing a business's reputation in the market.

Advanced Automation and Intelligent Control Systems

One of the most significant advancements in metal tube cutting is the integration of advanced automation and intelligent control systems. The traditional reliance on skilled CAD operators for creating and modifying complex 3D drawings was a major bottleneck for many businesses, including Ahmed's. This is precisely where MZBNL's pioneering No-CAD Operating System comes into play. This innovative feature allows operators to process standard tube types and hole patterns simply by entering parameters, completely eliminating the need for pre-existing drawings. This dramatically simplifies the operation, reducing the skill threshold required for machine operation and cutting down on training time from 15 days at the factory to just 1 day of on-site training. This ease of use is a game-changer for companies experiencing high operator turnover, as it reduces retraining burdens and ensures continuous production.

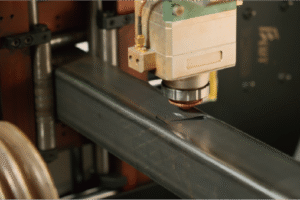

Beyond No-CAD, intelligent control systems extend to the entire material handling process. Conventional machines often rely on manual loading from the side or rear, which is inefficient and labor-intensive. MZBNL's optimized Front-Feeding Innovation automatically pulls the tube from the front, boosting feeding efficiency by approximately 40% and reducing operator labor intensity by a similar margin. This improvement in workflow ergonomics directly impacts productivity, allowing staff to focus on other critical tasks rather than strenuous material handling. For a business like Ahmed’s, which is scaling up and integrating automated solutions, this means a significant reduction in operational costs and an increase in overall output without needing to expand the workforce dramatically. Such automation transforms the entire production line, making it more streamlined and cost-effective.

Furthermore, smart and digitalized systems offer real-time monitoring, remote diagnostics, and predictive maintenance capabilities. These features are indispensable for minimizing downtime and ensuring continuous operation, especially for clients in remote international markets who depend on reliable support. For instance, our machines can communicate critical operational data, allowing our service teams to identify potential issues before they become major problems. This proactive approach significantly reduces maintenance costs and extends the lifespan of the equipment. According to a report by Accenture, predictive maintenance can reduce equipment breakdowns by 70% and cut maintenance costs by 25%. This technological integration ensures that our clients receive a robust, reliable solution that keeps their business moving forward, addressing concerns like long machine lead times and lack of local service support.

Material Handling Efficiency and Waste Reduction Innovations

Efficient material handling is as crucial as the cutting process itself, particularly when dealing with expensive materials like stainless steel. The goal is not just to cut quickly but to maximize material utilization and minimize waste. Traditional laser cutting systems start from the tube head and typically generate unusable tail material at the end of the process. This waste can significantly impact a company’s bottom line, especially for high-volume production.

To counteract this, MZBNL introduced its Zero-Waste Tail Material Innovation. By redesigning the cutting logic to calculate from the rear chuck as the origin, our system can eliminate leftover tail material as long as the remaining section is smaller than the product length. This simple yet revolutionary change maximizes material utilization, significantly boosting cutting efficiency and reducing raw material costs. For a business like Ahmed Al-Farsi’s, which manufactures parts for architectural metalwork and vehicle parts, every inch of saved material translates directly into higher profit margins. This innovation not only makes the process more environmentally friendly but also financially more viable, making it an attractive feature for clients who prioritize cost-effectiveness and sustainability.

Beyond tail material, efficient loading and unloading mechanisms contribute significantly to overall productivity. Automatic loading systems can handle multiple tubes sequentially, reducing manual intervention and accelerating cycle times. For stainless steel, which can be heavy and awkward to handle, automation minimizes the risk of material damage and operator injury. Furthermore, integrated multi-process capabilities, such as automatic punching and cutting in one machine, streamline workflows even further. This integration means fewer machine transfers, reduced setup times between processes, and a more compact production footprint. This holistic approach to material handling and processing ensures that the entire operation runs smoothly from raw material input to finished product output, providing a comprehensive, cost-effective customized solution that is ideal for high-volume fabrication services.

Fiber lasers cut stainless steel preciselyTrue

Fiber lasers provide high-intensity beams that ensure clean cuts with minimal heat-affected zones, making them ideal for stainless steel.

No-CAD systems require extensive trainingFalse

No-CAD systems simplify operation by allowing parameter entry without complex drawings, reducing training time significantly.

How do these features impact the efficiency of cutting stainless steel pipes?

Are your stainless steel cutting operations falling short of peak efficiency? The advanced features we discussed are not just buzzwords; they directly translate into tangible improvements. Understand how these innovations specifically optimize your workflow, dramatically reducing costs and boosting output.

Advanced features significantly boost efficiency by reducing material waste through zero-tail designs, minimizing operator training with No-CAD systems, and accelerating production via automated feeding. This leads to lower operational costs, faster turnaround times, and consistent high-quality output, crucial for stainless steel fabrication.

In my journey through the metal fabrication industry, I’ve often observed that seemingly small technological advancements can create ripple effects throughout an entire production line. It's about optimizing every millisecond and every millimeter. When we introduced our MZBNL Laser Tube Cutting Machine with its integrated features to Ahmed Al-Farsi’s facility in the UAE, the impact was immediate and profound. Ahmed, an astute owner with a strong engineering background, was particularly keen on automating existing manual workflows. He understood that improving machine efficiency wasn't just about faster cuts; it was about improving his profit model by delivering finished parts to builders, decorators, and OEMs more rapidly and reliably. The direct correlation between these advanced features and the bottom line is undeniable, making a strong case for investment.

Streamlined Workflow and Reduced Operational Costs

The integration of advanced features such as MZBNL's No-CAD system and Front-Feeding Innovation fundamentally reshapes the operational workflow, leading to significant reductions in cost. Traditionally, the design and setup phase consumed considerable time and specialized labor. Engineers would spend hours creating or modifying complex 3D drawings in CAD software, and operators would require extensive training—sometimes up to 15 days—to master the machine interface. This labor-intensive process was a major bottleneck, especially for mid-sized businesses like Ahmed Al-Farsi’s, where operator turnover could lead to recurring training burdens and production delays. With the No-CAD system, the need for intricate drawings is virtually eliminated for standard tube types and hole patterns, allowing operators to initiate production simply by inputting parameters. This innovation not only drastically reduces setup time but also lowers the skill threshold, cutting operator training time to just one day. This directly translates to lower labor costs, as less highly specialized personnel are required, and new hires become productive almost immediately.

Furthermore, the Front-Feeding mechanism, which automatically pulls tubes from the front of the machine, dramatically enhances material loading efficiency by approximately 40% while simultaneously reducing operator labor intensity by a similar percentage. This ergonomic improvement means less physical strain on workers and a faster, more continuous material flow, eliminating the downtime associated with manual or less efficient loading methods. For a busy fabrication shop, this seemingly minor improvement accumulates into substantial time savings over a production shift, allowing more parts to be processed within the same timeframe. This increased throughput, combined with reduced labor dependency, directly impacts the overall operational expenditure, making the production process more lean and competitive.

The combined effect of these streamlined processes is a significant improvement in overall operational efficiency and a notable reduction in associated costs. Instead of allocating resources to extensive training programs or manual material handling, businesses can now redirect those resources towards production or other value-added activities. This optimization is particularly beneficial for businesses in competitive markets like the Middle East, where every operational efficiency gain contributes to a stronger profit margin. Ahmed’s preference for turnkey solutions that are easy to install and operate aligns perfectly with these benefits, as he prioritizes solutions that contribute directly to his bottom line by minimizing non-productive activities and maximizing output.

Enhanced Material Utilization and Waste Minimization

One of the most impactful ways advanced machine features boost efficiency is through superior material utilization, particularly with expensive materials like stainless steel. Conventional laser cutting systems often result in unusable "tail material" because they process from the tube head, leaving a remnant at the end. This waste, while seemingly small per tube, accumulates significantly over high-volume production runs, directly eroding profit margins. Our MZBNL Zero-Waste Tail Material Innovation directly addresses this long-standing industry challenge. By redesigning the cutting logic to calculate from the rear chuck as the origin, our system can completely eliminate leftover tail material as long as the remaining section is smaller than the product length. This ingenious approach maximizes every inch of raw material.

Consider a scenario in a busy facility supplying architectural metalwork components. If each cut typically generates a small but unusable tail end, over thousands of cuts per month, the cumulative waste can represent a substantial financial loss. With MZBNL's zero-tail design, companies can experience a dramatic reduction in material scrap. According to our internal case studies with clients in Europe, this innovation has led to a material cost saving of up to 5% on certain high-volume projects, a significant figure when dealing with premium materials like stainless steel. This not only makes the operation more cost-effective but also more environmentally sustainable, aligning with modern corporate responsibility goals.

Beyond the zero-tail feature, integrated multi-process capabilities, such as automatic punching and cutting, further enhance material utilization by reducing the need for multiple setups and transfers between different machines. Every time a part is moved or re-fixtured, there's a risk of error or damage, and additional setup time is incurred. By performing both punching and cutting on a single machine, the entire process is contained, reducing handling errors, minimizing potential material damage, and ensuring higher precision from start to finish. This streamlined approach means less material is spoiled due to misalignment or mishandling, contributing to an overall higher yield of finished, usable parts. This kind of integration is exactly what Ahmed Al-Farsi sought in a machine with automatic feeding and punching capabilities2, as it directly contributes to his profit model of delivering finished parts efficiently.

| Feature | Impact on Efficiency | Benefit for Stainless Steel |

|---|---|---|

| No-CAD System | Reduces setup time, lowers skill requirement | Faster job initiation, less reliance on CAD experts for complex materials |

| Front-Feeding | Increases loading speed by 40%, reduces labor by 40% | Higher throughput, less fatigue for heavy stainless tubes |

| Zero-Waste Tail | Maximizes material utilization, reduces scrap | Significant cost savings on expensive stainless steel |

| High-Power Fiber Laser | Faster, cleaner cuts, minimal HAZ | Prevents material distortion, superior edge quality on reflective stainless |

| Integrated Punching | Single-machine processing, reduces handling | Streamlined workflow, higher precision for combined operations on stainless |

Superior Precision and Consistent Quality Output

The efficiency of cutting stainless steel pipes is not solely measured by speed or waste reduction; it is critically dependent on the precision and consistent quality of the output. Stainless steel, known for its strength and aesthetic appeal, demands high-quality cuts to meet the stringent requirements of industries such as furniture, sanitary ware, and medical equipment. High-speed and high-precision cutting capabilities, coupled with smart and digitalized systems, are paramount in achieving this. Our MZBNL machines, for instance, are engineered to deliver micro-level accuracy, ensuring that every cut is clean, burr-free, and dimensionally accurate. This precision minimizes the need for costly and time-consuming secondary finishing operations.

The impact of consistent quality output on a business's efficiency is profound. When parts are consistently produced to specification, there are fewer rejections, less rework, and a reduced need for quality control inspections. This directly translates to faster production cycles and lower labor costs. Consider Ahmed Al-Farsi’s business, which supplies parts for architectural metalwork and vehicle parts. In these applications, dimensional accuracy and surface finish are critical for both structural integrity and aesthetic appeal. A machine that consistently delivers high-quality cuts reduces the risk of project delays due to faulty components and enhances the business's reputation for reliability. My personal experience has shown that clients are willing to invest in technology that guarantees quality, as it builds trust and secures repeat business.

Furthermore, the ability of modern machines to integrate multi-process functionalities significantly contributes to maintaining consistent quality. For example, our Automatic Punching & Cutting Integrated Machine ensures that both cutting and punching operations are performed in a single setup, eliminating potential errors that arise from transferring workpieces between different machines. This not only saves time but also guarantees that the punched holes and cut edges are perfectly aligned and dimensionally consistent. This level of integrated precision is crucial for complex assemblies and high-volume production, ensuring that every component meets the exacting standards required for applications ranging from display racks to elevator equipment. This commitment to precision across all integrated processes is a hallmark of truly efficient stainless steel pipe cutting.

No-CAD reduces training timeTrue

The No-CAD system cuts operator training from 15 days to just 1 day by eliminating complex 3D drawing requirements.

Front-Feeding increases labor by 40%False

Front-Feeding actually reduces operator labor intensity by 40% through automated material loading.

What factors should be considered when evaluating metal tube cutting machines for stainless steel?

Facing the daunting task of selecting a new metal tube cutting machine for stainless steel? The wrong choice can lead to costly inefficiencies. Identify the critical factors that will guide you to a solution perfectly tailored to your needs, ensuring future success and operational excellence.

When evaluating metal tube cutting machines for stainless steel, key factors include laser power and type, automation level (e.g., No-CAD, auto-feeding), material handling capabilities, software intelligence, and after-sales support. Prioritizing these ensures high precision, efficiency, and long-term operational viability for stainless steel processing.

Choosing a new machine is a significant investment, one that can define the future trajectory of your business. It's not just about the sticker price; it's about total cost of ownership, scalability, and long-term support. I've often seen businesses make decisions based solely on initial cost, only to regret it later due to hidden inefficiencies or inadequate service. For example, Ahmed Al-Farsi, our client from the UAE, prioritized finding a supplier with proven technology and global references, along with excellent after-sales service and training support. He understood that a machine is only as good as the support system behind it, recognizing that spare parts availability and remote diagnostics3 were crucial. This strategic thinking is essential for anyone looking to make a wise investment in stainless steel cutting technology.

Laser Technology, Power, and Material Compatibility

The fundamental consideration when evaluating a metal tube cutting machine for stainless steel is the type and power of its laser. For stainless steel, fiber laser technology is overwhelmingly preferred due to its superior beam quality, high efficiency in cutting reflective materials4, and lower operating costs compared to CO2 lasers. The power of the fiber laser (measured in watts) directly correlates with the thickness of stainless steel it can effectively cut and the speed at which it can do so. For example, cutting thinner gauge stainless steel for furniture or medical equipment might require 2-4kW, while thicker sections for architectural structures or automotive chassis could demand 6kW or higher. It is crucial to match the laser power to the maximum thickness and daily volume of stainless steel tubes you intend to process. An underpowered machine will struggle, leading to poor cut quality, slower production, and potential material damage, while an overpowered one might be an unnecessary expense if you only handle thin materials.

Beyond raw power, assess the laser's ability to maintain a consistent beam quality across various cutting parameters and material types. High beam stability ensures uniform cut quality regardless of the tube's length or the complexity of the geometry. Additionally, inquire about the laser source's brand reputation and expected lifespan. Reputable laser manufacturers provide greater reliability and easier access to spare parts and service. Our MZBNL laser tube cutting machines are equipped with industry-leading fiber laser sources, chosen specifically for their robust performance and reliability in demanding applications, ensuring high-speed and high-precision cutting capabilities for a wide range of stainless steel thicknesses. This critical component determines the machine's primary capability and its long-term cost-effectiveness.

Material compatibility also extends to the machine's ability to handle different tube shapes beyond standard rounds and squares. Many modern stainless steel applications involve oval, rectangular, or even custom-profile tubes. The machine's chuck system and software must be capable of securely gripping and precisely cutting these varied profiles without deformation. Furthermore, consider the machine's maximum tube length and diameter capacity to ensure it accommodates your current and future project requirements. A common mistake is investing in a machine that is too small for planned growth. For example, if Ahmed plans to expand his business into larger architectural projects, he needs to ensure the machine can handle longer and thicker stainless steel tubes than his current immediate needs.

Automation Level, Software Intelligence, and Ease of Use

In today's competitive manufacturing landscape, the level of automation and the intelligence of the control software are paramount. A highly automated machine reduces manual labor, minimizes human error, and dramatically increases throughput. The key here is to look beyond basic automation and consider "smart" features. MZBNL's No-CAD Operating System is a prime example of this: it dramatically simplifies the pre-production phase by allowing operators to process standard tube types and hole patterns by simply entering parameters, eliminating the need for complex 3D drawings. This innovation directly addresses pain points like the need for skilled CAD operators and high operator turnover, which Ahmed Al-Farsi faced. Such systems significantly lower the skill threshold for machine operation, reducing training time from weeks to just days, ensuring that production can resume quickly even with new personnel.

The intelligence of the software extends to features like automatic nesting, collision avoidance, and real-time parameter adjustment. Automatic nesting optimizes material utilization by arranging parts efficiently on the tube, a critical feature for expensive stainless steel to minimize waste. Collision avoidance systems prevent the cutting head from impacting already cut parts or the chuck, safeguarding both the machine and the workpiece. Real-time parameter adjustment, where the machine automatically fine-tunes cutting settings based on material variations or thickness, ensures consistent cut quality and prevents costly mistakes. These smart features translate into higher production efficiency, reduced material waste, and a lower incidence of errors, all of which contribute to a healthier bottom line.

Ease of use, often overlooked, is crucial for long-term productivity. A complex interface, even on a powerful machine, can lead to operator frustration, errors, and underutilization. Look for intuitive touchscreen interfaces, clear visual guides, and robust diagnostic capabilities. A machine that is easy to operate and maintain, like the ones MZBNL designs, empowers operators and minimizes reliance on highly specialized technicians. This simplicity also extends to maintenance: machines with modular designs and accessible components can be serviced more quickly, reducing downtime. For a client like Ahmed, who prefers turnkey solutions that are easy to install and operate, these factors are decisive, as they directly impact his ability to run a stable, long-term business with minimal disruptions.

Post-Sales Support, Service Network, and Customization Capabilities

The investment in a metal tube cutting machine doesn't end with the purchase; comprehensive post-sales support and a reliable service network are absolutely critical for long-term operational success. This includes availability of spare parts, technical support, training, and remote diagnostics. A machine is only as good as its uptime, and prompt, effective service is paramount when issues arise. Businesses like MZBNL, with 25 years of experience and a global client base, understand this deeply, offering a robust support system across main export countries like Southeast Asia, the Middle East, Europe, and North America. Ahmed Al-Farsi specifically highlighted the importance of after-sales service and training support, along with spare parts availability and remote diagnostics, as key sourcing points.

It is essential to inquire about the supplier's training programs: Are they comprehensive? Are they offered on-site or remotely? How long do they last? Effective training ensures that your team can fully utilize the machine's capabilities and perform routine maintenance. Furthermore, investigate the availability of spare parts. Long lead times for critical components can paralyze production and lead to significant financial losses. A supplier with a well-stocked inventory and an efficient logistics network can dramatically reduce downtime. Remote diagnostics, a feature offered by our smart and digitalized systems at MZBNL, allows technicians to troubleshoot issues remotely, often resolving problems without an on-site visit, which is invaluable for international clients.

Finally, consider the supplier's customization capabilities. While standard machines might suffice for some, many businesses have unique requirements related to specific tube sizes, material handling, or integration into existing production lines. A supplier willing and capable of providing cost-effective customized solutions, as MZBNL does, can offer a significant competitive advantage. This adaptability ensures that the machine truly fits your specific operational needs and can evolve with your business. For instance, Ahmed is not only a customer but is considering becoming a regional distributor, indicating a strong desire for a partnership that can offer co-branding or exclusive distribution rights—a testament to the importance of a supplier's flexibility and long-term vision. This level of partnership extends beyond just machine features, impacting the very structure of future business growth.

Fiber lasers are preferred for stainless steelTrue

Fiber lasers offer superior beam quality and efficiency for cutting reflective materials like stainless steel compared to CO2 lasers.

Higher laser power always means betterFalse

While higher power enables cutting thicker materials, it can be unnecessary and costly if you primarily work with thin stainless steel tubes.

What are some common challenges faced when using cutting machines for stainless steel tubes and how to overcome them?

Are you wrestling with common frustrations in stainless steel tube cutting, from burrs to material warping? These challenges can severely hinder your productivity. Discover practical solutions and innovative machine features designed to transform these pain points into seamless operations.

Common challenges in stainless steel tube cutting include heat distortion, burr formation, and inconsistent cut quality due to material hardness. These are overcome by using high-power fiber lasers, optimized cutting parameters, advanced cooling systems, and specialized cutting heads that minimize thermal impact and ensure clean, precise edges.

In my extensive experience with metal fabrication, I’ve witnessed countless challenges associated with processing stainless steel. It’s a material known for its strength and corrosion resistance, but these very properties can make it tricky to cut without specialized techniques and machinery. Issues like heat distortion and burr formation are not just minor nuisances; they can lead to significant material waste and necessitate time-consuming post-processing, eroding profitability. For businesses, especially those like Ahmed Al-Farsi’s, which relies on delivering high-quality finished parts for architectural and automotive sectors, these challenges directly impact customer satisfaction and project timelines. Understanding these hurdles and the innovative solutions available is paramount for achieving consistent, high-quality output.

Heat Distortion and Material Deformation

One of the most pervasive challenges when laser cutting stainless steel is managing heat distortion and preventing material deformation. Stainless steel, particularly thinner gauges, is susceptible to heat-induced warping due to its relatively low thermal conductivity compared to other metals. Excessive heat input during cutting can lead to non-uniform expansion and contraction, resulting in parts that are dimensionally inaccurate or aesthetically compromised. This is a critical issue for industries producing precision components or decorative elements where visual appeal is paramount. Overcoming this requires a combination of advanced laser technology5 and intelligent processing strategies.

The primary solution lies in utilizing high-power fiber lasers with precise beam control. Fiber lasers deliver a highly concentrated beam, allowing for faster cutting speeds and a smaller heat-affected zone (HAZ). This minimizes the amount of heat transferred to the surrounding material, significantly reducing the risk of distortion. Furthermore, advanced cutting parameters, including optimized focal length, assist gas pressure (typically high-purity nitrogen for stainless steel), and pulse frequency, play a crucial role. Our MZBNL machines are equipped with sophisticated smart and digitalized systems that can dynamically adjust these parameters in real-time, ensuring optimal heat management for different stainless steel grades and thicknesses. This adaptive control prevents issues that might arise from sudden changes in material properties or complex cutting paths, guaranteeing a stable and consistent cut quality.

Beyond the laser itself, effective workholding and cooling systems are vital. The machine's chucks and support rollers must securely grip the tube to minimize vibration and provide adequate support, preventing deformation during the cutting process. Some advanced systems incorporate active cooling mechanisms or sophisticated fume extraction systems that also help dissipate heat from the cutting area. For example, in a project for a medical equipment manufacturer using delicate stainless steel tubes, precise control of heat input was paramount. By leveraging MZBNL's high-speed and high-precision cutting capabilities, combined with optimized cooling, the client achieved perfectly straight cuts without any warping, which was a significant improvement over their previous machinery that frequently caused scrap due to heat distortion. This precision allows them to maintain stringent quality standards for critical medical components.

Burr Formation and Edge Quality

Another common frustration in stainless steel tube cutting is the formation of burrs and the struggle to achieve consistently clean edge quality. Burrs are sharp, undesirable remnants of material that cling to the cut edge, requiring time-consuming and often costly secondary finishing operations such as deburring, grinding, or polishing. These extra steps not only add to labor costs and production time but can also compromise the final aesthetics and functionality of the part, especially in applications where smooth edges are critical for safety or assembly, such as in furniture or sanitary ware.

To combat burr formation, the cutting machine must be capable of delivering high-quality, high-pressure assist gas (usually nitrogen) directly to the cutting zone, effectively purging molten material and preventing it from re-solidifying on the cut edge. The nozzle design and its proximity to the workpiece are also critical. Our MZBNL machines are designed with advanced cutting heads that optimize gas flow and precisely control the focal point of the laser beam, ensuring a clean and dross-free cut. This precise control over the cutting process is a core component of our high-precision cutting capabilities, minimizing the need for manual cleanup and thus reducing overall production time and labor costs.

Furthermore, proper maintenance of consumables, such as nozzles and protective lenses, is essential for maintaining optimal edge quality. Worn or dirty components can lead to a degraded beam quality and inefficient gas flow, exacerbating burr issues. Regular calibration and preventive maintenance, supported by a reliable after-sales service network and remote diagnostics like those provided by MZBNL, ensure that the machine operates at peak performance, consistently delivering clean, precise cuts on stainless steel tubes. This reduces rework and improves overall efficiency. For a client like Ahmed Al-Farsi, whose business relies on delivering finished parts with impeccable quality to OEMs and builders, achieving burr-free cuts directly enhances his profit model and reputation.

Inconsistent Cutting Performance and Operator Skill Dependency

A significant challenge faced by many fabrication shops is the inconsistency of cutting performance, often tied to the high dependency on operator skill and experience. Traditional machines frequently require highly trained CAD operators to translate design specifications into machine-readable formats, and even then, subtle adjustments during production often fall on the operator’s judgment. This dependency creates vulnerabilities: high operator turnover leads to retraining burdens, and variations in individual skill can result in inconsistent output quality, slower production rates, and increased material waste, especially with unforgiving materials like stainless steel.

Overcoming this challenge necessitates a shift towards smart, digitalized systems6 that minimize human intervention and standardize the cutting process. MZBNL's No-CAD Operating System is a direct answer to this pain point. By allowing operators to simply enter parameters for standard tube types and hole patterns, it drastically reduces the reliance on complex CAD knowledge. This innovation not only simplifies machine operation but also shortens setup time and lowers the skill threshold required, meaning new operators can be productive after just one day of on-site training instead of 15 days at the equipment factory. This significantly mitigates the impact of operator turnover and ensures more consistent performance across different shifts and personnel.

Beyond the No-CAD system, the machine's ability to automate material handling and adjust cutting parameters dynamically also reduces operator dependency. Features like MZBNL's Front-Feeding Innovation, which automatically pulls the tube, or integrated punching and cutting capabilities, streamline the workflow, reducing opportunities for manual error. Furthermore, advanced diagnostic tools and predictive maintenance capabilities mean that the machine itself can signal potential issues or guide operators through troubleshooting, rather than relying solely on a skilled technician's immediate presence. This comprehensive automation and intelligence ensure that consistent, high-quality stainless steel cutting is achievable even with varying levels of operator experience, providing reliability and predictability crucial for any modern fabrication business.

Fiber lasers reduce heat distortionTrue

Fiber lasers concentrate heat in a smaller area, minimizing thermal impact on surrounding material and preventing warping.

Burrs improve edge qualityFalse

Burrs are undesirable remnants that require additional finishing and compromise both aesthetics and functionality.

What are the recommended best practices for operating metal tube cutting machines when working with stainless steel pipes?

Are you struggling to get optimal results from your stainless steel tube cutting machine? Improper operation can lead to wasted material and lost time. Adopt these essential best practices to maximize efficiency, prolong machine life, and achieve superior quality cuts every time.

Best practices for operating metal tube cutting machines for stainless steel include precise parameter calibration, consistent use of high-purity assist gas, regular maintenance, and proper material handling. Employing smart features like No-CAD systems and automated feeding further optimizes operations, ensuring high precision and minimizing errors for stainless steel.

Over my career, I've learned that even the most advanced machinery performs best when operated with discipline and adherence to best practices. It's not enough to have cutting-edge technology; how you use it makes all the difference. Think of Ahmed Al-Farsi, our client who values ease of use and post-sales training. He recognizes that ongoing operational excellence comes from combining innovative machines with proper training and consistent application of best practices. These practices are designed to prevent common issues, extend the life of your equipment, and ensure that every cut on expensive stainless steel is precise, clean, and profitable.

Precision Parameter Calibration and Assist Gas Optimization

Achieving optimal results when cutting stainless steel pipes fundamentally relies on meticulous parameter calibration. Unlike carbon steel, stainless steel's properties—such as its high reflectivity and thermal conductivity characteristics—demand precise control over laser power, cutting speed, focal position, and most critically, assist gas type and pressure. For stainless steel, high-purity nitrogen is almost universally recommended as the assist gas. Oxygen use in stainless steel laser cutting7, while used for carbon steel, would cause oxidation on the stainless steel cut edge, leading to discoloration, burrs, and a compromised finish. The purity of the nitrogen is paramount; even slight contaminants can negatively affect cut quality and increase dross.

The laser power must be carefully balanced with cutting speed. Too little power or too fast a speed will result in incomplete cuts or heavy burrs. Conversely, too much power or too slow a speed can lead to excessive heat input, causing material deformation or discoloration. Modern machines, like MZBNL’s, feature smart and digitalized systems that offer pre-set parameters for various material types and thicknesses. However, fine-tuning these parameters based on specific stainless steel grades (e.g., 304 vs. 316), tube wall thickness, and desired edge quality is a best practice. This often involves conducting test cuts to identify the optimal "sweet spot" for each unique application. My personal experience has shown that these minor adjustments can dramatically improve cut quality and reduce post-processing time.

The focal position of the laser beam is another critical parameter. For stainless steel, the focal point is typically positioned slightly below the material surface to achieve a clean, dross-free cut. Incorrect focal position can lead to a wider kerf, increased heat input, or poor edge quality. Regular calibration of the cutting head and consistent monitoring of assist gas pressure are vital. For example, a significant drop in nitrogen pressure can immediately result in oxidized edges or heavy dross. Implementing automated gas control systems and incorporating daily parameter checks into your operational routine ensures consistent performance, directly contributing to high-precision cutting. This level of attention to detail helps to avoid common pitfalls like heat distortion and burr formation, which we discussed earlier.

Proactive Maintenance and Consumables Management

Proactive and rigorous maintenance is not merely a recommendation; it is an absolute necessity for ensuring the longevity, precision, and consistent performance of metal tube cutting machines, especially when processing stainless steel. Neglecting maintenance inevitably leads to degraded cut quality, increased downtime, and higher repair costs. This includes daily, weekly, and monthly checks of critical components. For instance, the laser lens and nozzles must be inspected and cleaned daily to prevent contamination from dust or spatter, which can severely impact beam quality. A dirty lens can diffuse the laser beam, leading to inefficient cuts, heat distortion, and burrs.

Consumables management is equally important. Nozzles, ceramic rings, and protective windows have a limited lifespan and must be replaced regularly, not just when they fail. Worn nozzles can distort the assist gas flow, compromising cut quality, while damaged protective windows can degrade the laser beam and even damage the expensive laser head. Maintaining an adequate inventory of genuine spare parts is crucial to minimize downtime. For clients like Ahmed Al-Farsi, who operates a stable, long-term business and prioritizes spare parts availability and remote diagnostics, a supplier like MZBNL with a strong global distributor network and comprehensive after-sales support becomes invaluable. This ensures that replacements are readily available and technical assistance is accessible, preventing prolonged production halts.

Beyond routine cleaning and replacement, the machine's mechanical components, such as guide rails, gears, and chucks, require regular lubrication and inspection for wear. Misaligned or worn mechanical parts can lead to inaccuracies in tube positioning and cutting, affecting overall precision. Implementing a detailed preventive maintenance schedule, often provided by the machine manufacturer, is a best practice. Leveraging the machine's smart and digitalized systems for predictive maintenance can further enhance this by alerting operators to potential issues before they become critical. This proactive approach not only extends the machine's lifespan but also ensures that it consistently operates at its peak performance, delivering the high-quality, cost-effective customized solutions that businesses demand.

Optimizing Material Handling and Workflow Integration

Efficient material handling and seamless workflow integration are foundational best practices that significantly enhance the overall productivity and safety of stainless steel tube cutting operations. It’s not just about how the machine cuts, but how materials flow in and out of it, and how the machine fits into the broader production ecosystem. Manual loading and unloading of heavy or long stainless steel tubes can be labor-intensive, slow, and prone to accidents or material damage.

Implementing automated material handling solutions, such as MZBNL's Front-Feeding Innovation8, can dramatically improve efficiency. This system automatically pulls the tube into the machine, increasing feeding efficiency by about 40% and reducing operator labor intensity by approximately 40%. This not only speeds up the loading process but also minimizes the physical burden on operators, reducing the risk of injuries and improving workplace ergonomics. For high-volume production, automatic bundle loaders or intelligent conveyors can further streamline the process, ensuring a continuous supply of material to the machine and minimizing idle time. My own experience in factory settings has shown that bottlenecks in material flow often negate the benefits of a fast cutting machine.

Furthermore, integrating the tube cutting machine into a comprehensive digital workflow is a best practice for modern fabrication. This involves connecting the machine's control system with design software (if still used), production planning systems, and even inventory management. MZBNL's No-CAD Operating System, for instance, allows for quick parameter-based processing, but even for more complex designs, direct data transfer minimizes manual data entry errors. The ability to monitor production data in real-time, track material consumption (especially with Zero-Waste Tail Material Innovation), and remotely diagnose issues contributes to a truly smart and digitalized system. This holistic approach ensures that the metal tube cutting machine operates not as an isolated unit but as an integral, optimized part of your entire manufacturing process, leading to greater efficiency, reduced waste, and higher overall profitability in stainless steel pipe processing.

Nitrogen is preferred for stainless steel cuttingTrue

High-purity nitrogen prevents oxidation and ensures clean cuts on stainless steel, unlike oxygen which causes discoloration.

Daily lens cleaning is optionalFalse

Laser lenses require daily cleaning to prevent beam diffusion and maintain cutting precision, as contamination degrades performance.

Conclusion

Choosing the right metal tube cutting machine for stainless steel pipes involves prioritizing precision, automation, and robust support. By focusing on fiber laser power, smart features like MZBNL's No-CAD system and Zero-Waste technology, and comprehensive after-sales service, businesses can overcome common challenges to achieve unparalleled efficiency and quality.

-

Understand the advantages of Zero-Waste Tail Material Technology for material optimization ↩

-

Learn about enhanced efficiency and precision in stainless steel fabrication with integrated systems. ↩

-

Understand how spare parts and diagnostics affect machine uptime. ↩

-

Discover the advantages of fiber lasers in handling reflective metals. ↩

-

Discover cutting-edge laser technologies that improve cutting precision and quality ↩

-

Understand the advantages of digitalized systems in enhancing cutting efficiency and consistency ↩

-

Understand why oxygen is unsuitable for stainless steel, affecting cut quality ↩

-

Learn how front-feeding increases efficiency and reduces labor intensity in tube cutting ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.