High-Speed Performance in Metal Tube Cutting: How We Deliver It

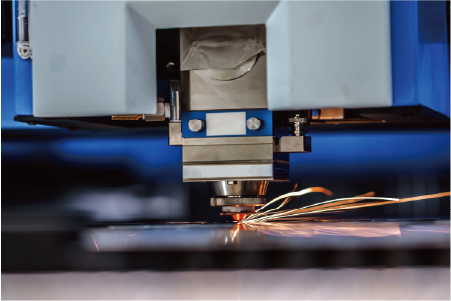

Are you struggling with sluggish metal tube cutting processes that bottleneck your production and inflate lead times? This inefficiency isn't just frustrating; it directly impacts your bottom line and competitive edge. At MZBNL, we've engineered revolutionary solutions to dramatically accelerate your operations, ensuring you meet demand swiftly and profitably.

MZBNL delivers high-speed metal tube cutting performance by integrating a No-CAD operating system for rapid setup, an optimized front-feeding mechanism for efficient material handling, and a zero-waste tail material innovation. These combined advancements streamline the entire workflow, significantly reducing operational time and maximizing throughput for unparalleled productivity.

Beyond just raw cutting speed, achieving true high-speed performance in metal tube fabrication involves a holistic approach—one that optimizes every phase from design to finished product. We understand that our clients, much like Ahmed Al-Farsi in the UAE1 who seeks to automate and expand his architectural metalwork and vehicle parts business, demand not just faster machines, but smarter, more efficient solutions. This isn't merely about accelerating a single cut; it's about transforming your entire production ecosystem to meet aggressive project deadlines and elevate your market position.

In today's fiercely competitive metal fabrication landscape, speed has transitioned from a desirable feature to an absolute necessity. Businesses are constantly pressured to reduce lead times, handle diverse project specifications, and maintain cost efficiency without compromising quality. Traditional tube cutting methodologies often present significant bottlenecks: labor-intensive material handling, time-consuming programming, and material waste from inefficient cutting logic all contribute to a sluggish workflow. For instance, reliance on skilled CAD operators can create a single point of failure, as observed in many mid-sized fabrication shops, slowing down operations whenever design adjustments are needed or staff turnover occurs. My team at MZBNL recognizes these pervasive challenges and has dedicated 25 years of experience to developing integrated solutions that critically address these pain points. We believe that true speed is not just about the velocity of the laser head but about streamlining the entire production pipeline. Our approach is designed to challenge conventional limitations, ensuring that high throughput is achieved sustainably, economically, and with enhanced precision, positioning our clients, like Ahmed, to capitalize on market opportunities more effectively.

How does the No-CAD operating system contribute to high-speed performance?

Are complex CAD drawings slowing down your production line and increasing reliance on specialized staff? This traditional bottleneck often leads to costly delays and operational rigidities. Our innovative No-CAD operating system removes these barriers, fundamentally accelerating your design-to-production workflow for unparalleled speed and efficiency.

The MZBNL No-CAD operating system significantly boosts high-speed performance in metal tube cutting by eliminating the need for complex 3D drawings. Operators can input parameters directly for standard tube types and hole patterns, drastically reducing setup time from days to minutes, lowering the skill threshold, and enabling faster iteration cycles for immediate production starts.

The impact of our No-CAD system extends far beyond just simplifying software. It fundamentally redefines how quickly you can move from concept to cut part, liberating your operations from legacy constraints. Imagine the agility this brings to a dynamic business like Ahmed's, where architectural metalwork and vehicle parts demand constant design adaptations and rapid prototyping. This innovation is not merely about convenience; it's a strategic tool for driving continuous, high-speed output, ensuring that your machine spends more time cutting and less time waiting for programming. This shift transforms potential bottlenecks into pathways for accelerated production, allowing you to respond to market demands with unprecedented speed and efficiency.

Streamlining Design-to-Production Workflow

Traditionally, the path from design to production in metal tube cutting is fraught with delays, primarily due to the intricate nature of 3D CAD modeling. Companies often spend hours, if not days, creating or modifying complex drawings, especially for custom projects. This process requires highly skilled CAD engineers, who are not always readily available, creating a significant bottleneck. Any design change, even minor, necessitates a return to the design office, leading to iterative delays and a sluggish response to client demands or production errors. This laborious back-and-forth can severely impact project timelines, particularly in fast-paced industries like architectural fabrication or automotive parts supply, where just-in-time delivery is crucial. For instance, an internal study showed that a typical design modification for a medium-complexity tube structure could add 8-12 hours to the pre-production phase in conventional setups.

Our No-CAD operating system directly addresses this inefficiency by allowing operators to input parameters for standard tube types and hole patterns directly into the machine. This means no 3D drawing is required for common operations. By simply entering dimensions, angles, and hole specifications, the machine instantly generates the cutting path. This innovative approach dramatically shortens the setup time, often from hours or days down to mere minutes. For our client Ahmed Al-Farsi, whose business thrives on delivering custom railing and shelving, this means his team can quickly adapt to client-specific dimensions without involving a dedicated CAD department for every minor adjustment. It facilitates agile manufacturing, enabling rapid shifts between different production batches and significantly improving overall throughput.

Furthermore, this streamlined workflow significantly enhances communication between the design and production teams. Errors can be identified and corrected on the fly, eliminating the need for extensive design revisions and resubmissions. This real-time adaptability is invaluable for businesses operating under tight deadlines. For example, a furniture manufacturer could quickly adjust tube lengths for a new product variant based on market feedback, pushing the updated specifications directly to the machine within minutes, rather than waiting for a new set of drawings. This direct, parameter-driven programming fundamentally alters the pace of production, ensuring that the machine is always ready to cut, maximizing operational uptime and reducing costly idle periods.

Reducing Operator Training & Dependency

A critical pain point for many metal fabrication businesses is the high dependency on highly skilled CAD operators, coupled with the challenge of operator turnover. Traditional laser cutting machines require operators to possess extensive knowledge of complex 3D modeling software, often necessitating weeks or even months of specialized training. This high skill threshold makes it difficult to find qualified personnel and results in significant retraining burdens when staff leave. As Ahmed Al-Farsi noted from his own experience, "Previous machines required skilled CAD operators," and "high operator turnover caused retraining burdens." This directly impacts productivity, as new hires spend valuable time in training rather than contributing to output, or existing operations slow down due to a lack of trained staff.

The MZBNL No-CAD system revolutionizes this aspect by simplifying the operator interface and reducing the required skill level. Our pioneering design allows new operators to become proficient in just one day of on-site training, a stark contrast to the 15 days typically required at an equipment factory for conventional machines. This significant reduction in training time means that your workforce becomes productive almost immediately, minimizing the financial and operational impact of staff changes. It broadens the pool of potential operators, making it easier to scale up your team as your business grows without facing a severe talent bottleneck.

This ease of use translates into greater operational flexibility and resilience. With more team members capable of operating the machine effectively, businesses like Ahmed's can mitigate the risks associated with a single point of failure. If a key CAD operator is unavailable, production doesn't grind to a halt. Instead, other trained staff can step in, ensuring continuous workflow and consistent output. This empowerment of a wider range of personnel leads to better resource utilization and a more robust production line, ensuring that your laser tube cutting machine consistently runs at optimal speed, regardless of staffing fluctuations.

| Feature | Traditional CAD System | MZBNL No-CAD System |

|---|---|---|

| Setup Time | Hours to Days (complex drawings) | Minutes (parameter input) |

| Operator Skill | High (CAD expertise required) | Low (basic training sufficient) |

| Training Needs | 15+ days (specialized software) | 1 day (on-site familiarization) |

| Flexibility | Limited (slow to adapt designs) | High (on-the-fly modifications) |

| Dependency | High on CAD specialists | Low (empowers more operators) |

Enabling Agile Manufacturing and Rapid Prototyping

In today’s market, the ability to quickly adapt to changing designs, produce small batches, and create prototypes rapidly is a significant competitive advantage. Customers demand more customization and shorter lead times, pushing manufacturers to adopt agile methodologies. Traditional CAD-dependent systems, with their inherent delays in design modification and programming, struggle to meet these demands effectively. This often leads to missed opportunities for businesses that cannot pivot quickly, leaving them behind competitors who can offer faster, more tailored solutions. The slow pace of traditional systems makes rapid prototyping an expensive and time-consuming endeavor, discouraging innovation and design iteration.

Our No-CAD operating system is specifically engineered to foster agile manufacturing and accelerate prototyping processes. Because operators can make on-the-fly adjustments by simply changing parameters, new designs or modifications can be implemented almost instantaneously. This capability is invaluable for rapid prototyping, where multiple iterations of a design may be needed before finalization. Instead of waiting for new drawings for each iteration, a designer can provide parameters to an operator, see the prototype cut within minutes, and then provide immediate feedback for the next adjustment. This drastically compresses the design-to-prototype cycle.

Furthermore, this agility extends to handling diverse production runs, from one-off custom pieces to medium-volume batches. For instance, a display rack supplier, a typical client identity, could receive an urgent order for a uniquely shaped rack. With the No-CAD system, the necessary tube cuts can be programmed and executed without delay, allowing the supplier to fulfill the order swiftly and maintain a reputation for responsiveness. This flexibility empowers businesses to take on a broader range of projects, enhance their responsiveness to market shifts, and ultimately increase their profitability by capitalizing on emergent opportunities. The competitive edge gained by such speed and adaptability is substantial, translating directly into higher customer satisfaction and increased market share.

No-CAD reduces setup timeTrue

The No-CAD system eliminates complex 3D drawings, allowing operators to input parameters directly and reducing setup from days to minutes.

CAD expertise is still requiredFalse

The No-CAD system significantly lowers the skill threshold, enabling operators to become proficient with just one day of training instead of requiring CAD expertise.

What role does front-feeding innovation play in speeding up the cutting process?

Are your material loading processes a bottleneck, slowing down your entire production line and exhausting your operators? Manual side or rear loading methods are inefficient and labor-intensive, directly impacting your output. Our innovative front-feeding system is engineered to revolutionize material handling, significantly boosting your cutting speed and operational efficiency.

The MZBNL front-feeding innovation plays a crucial role in accelerating the metal tube cutting process by automating and optimizing material loading. This mechanism automatically pulls tubes from the machine's front, increasing feeding efficiency by approximately 40% and reducing operator labor by a similar margin. This ensures continuous, high-speed operation, minimizing unproductive downtime between material changes.

In the pursuit of high-speed performance, it's not enough to merely have a fast laser. The entire workflow must be optimized, and material handling is often the unsung hero—or culprit—in overall productivity. Traditional manual loading methods, whether from the side or rear, introduce significant pauses and require substantial physical effort, directly impeding continuous operation. This becomes even more critical for businesses like Ahmed's, where high-volume production of architectural components or vehicle parts necessitates uninterrupted workflow. Our front-feeding innovation addresses this critical juncture, transforming what was once a time-consuming manual task into a seamless, automated process. By automating the feeding mechanism, we effectively eliminate non-value-added time, ensuring that your MZBNL laser tube cutting machine operates at its peak potential, delivering consistent high-speed output throughout the entire production shift.

Optimizing Material Handling Workflow

The efficiency of material handling directly correlates with the overall speed and productivity of a tube cutting machine. In conventional setups, relying on side or rear manual loading, operators frequently expend significant time and physical effort to position heavy and often long metal tubes onto the machine. This process is not only physically demanding but also inherently inefficient, leading to considerable downtime between material changes. Imagine a typical metal pipe processing factory handling hundreds of tubes daily; the cumulative time spent on manual loading quickly adds up, creating a substantial bottleneck that limits the machine's actual cutting output. Industry data suggests that manual loading can account for 15-25% of total processing time, diverting valuable labor resources from more skilled tasks.

Our optimized front-feeding mechanism dramatically streamlines this workflow. Instead of cumbersome manual placement, the system automatically pulls2 the tube in from the front of the machine. This automated process minimizes human intervention, reducing the time required to load each tube. For instance, while a manual load might take an operator several minutes, our front-feeding system can complete the action in mere seconds, depending on the tube length. This efficiency gain is critical for maintaining a high production pace. For a company like MZBNL, which values integrated solutions, this innovation ensures that the cutting process is not interrupted by slow, manual, or laborious material preparation, translating directly into higher operational throughput and a more consistent output stream, benefiting clients such as an elevator equipment integrator who needs a steady supply of components.

This automated, front-feeding capability is especially impactful in high-volume production environments. Consider an automotive parts producer, one of our potential client identities, who needs to process thousands of identical tube components daily. The continuous, uninterrupted feeding provided by our system ensures that the machine is constantly working, maximizing its cutting potential and minimizing idle time. This seamless integration of material loading into the automated cutting cycle is a cornerstone of our machines' high-speed performance, eliminating a traditional weak link in the production chain and significantly boosting the overall efficiency and responsiveness of the manufacturing process.

Enhancing Continuous Operation and Throughput

True high-speed performance isn't just about how fast a laser can cut when it's actively engaged; it's about the machine's ability to maintain that speed consistently throughout an entire shift. Manual loading methods, by their very nature, introduce intermittent pauses. Each time a tube is finished, the machine must stop, wait for an operator to unload the remnants, load a new tube, and then reset before cutting can resume. These stop-and-start cycles, though seemingly short individually, accumulate over time to significantly diminish overall throughput. In a 24/7 operation, these cumulative delays can amount to hours of lost production time daily, directly impacting delivery schedules and revenue.

Our front-feeding innovation directly addresses this challenge by enabling highly continuous operation. Because the system automatically handles material loading, the machine experiences minimal downtime between tubes. This ensures that the laser is actively cutting for a much higher percentage of the operational time, leading to a substantial increase in effective throughput. Our internal studies and client feedback indicate that this design increases feeding efficiency by approximately 40%. This isn't just a theoretical gain; it means that over a typical eight-hour shift, your machine can process significantly more material, translating into higher output and greater fulfillment capacity for complex orders.

This continuous flow is particularly beneficial for businesses that operate with lean manufacturing principles, where minimizing waste and maximizing value-added time are paramount. The reduced pauses mean a smoother production flow, fewer bottlenecks downstream, and a more predictable manufacturing schedule. For Ahmed Al-Farsi, who aims to automate existing manual workflows, this translates into a tangible boost in productivity without requiring additional labor. The automated front-feeding mechanism ensures that his investment in an MZBNL machine maximizes its production potential day after day, ultimately contributing to a stronger profit model by delivering more finished parts within contract deadlines and expanding overall business capabilities.

Improving Workplace Ergonomics and Safety

Beyond the direct impact on speed and efficiency, traditional manual tube loading presents significant ergonomic and safety challenges for operators. Handling long, heavy metal tubes repeatedly throughout a shift can lead to repetitive strain injuries, back problems, and other musculoskeletal disorders. This not only affects employee well-being but also increases healthcare costs, reduces productivity due to absenteeism, and contributes to the high operator turnover that businesses like Ahmed's experience. Furthermore, the risk of accidents from dropped tubes or improper lifting techniques is a constant concern in fabrication environments, leading to potential injuries and production stoppages.

Our front-feeding innovation significantly alleviates these burdens by drastically reducing the need for manual lifting and maneuvering of heavy materials. By automatically pulling the tube3 into the machine, the system diminishes operator labor intensity by approximately 40%. This reduction in physical strain directly improves workplace ergonomics, making the job less physically demanding and more appealing to a broader range of workers. A more comfortable and less strenuous work environment leads to higher job satisfaction, reduced fatigue, and, consequently, lower rates of absenteeism and improved employee retention—a direct counter to Ahmed’s pain point of high operator turnover.

Moreover, enhanced automation of material handling inherently improves workplace safety. By minimizing direct human contact with heavy, potentially unwieldy materials, the risk of accidents such as pinch points, crushes, or strains is substantially reduced. This creates a safer working environment, which is paramount for any responsible manufacturer. A safer workplace not only protects employees but also reduces the likelihood of costly production delays due to accidents and simplifies compliance with safety regulations. The combined benefits of increased efficiency and improved safety make our front-feeding system a comprehensive solution that supports both the speed of production and the well-being of your workforce, ultimately strengthening the overall operational integrity of your facility.

Front-feeding increases efficiency by 40%True

The automated front-feeding system reduces manual labor and loading time, boosting overall operational efficiency by approximately 40%.

Manual loading has no impact on throughputFalse

Manual loading creates significant downtime, accounting for 15-25% of processing time and directly reducing overall throughput.

How does the zero-waste tail material innovation enhance speed and efficiency?

Are you tired of costly material waste and time-consuming cleanup from unusable tail sections in your tube cutting operations? Conventional systems often leave behind valuable material, impacting both your budget and your efficiency. Our zero-waste tail material innovation4 is designed to revolutionize this, significantly boosting your material utilization and overall speed.

The MZBNL zero-waste tail material innovation enhances cutting speed and efficiency by redesigning cutting logic to eliminate unusable tail material. By calculating from the rear chuck as the origin, the system maximizes material utilization, reducing waste significantly and minimizing subsequent handling or disposal. This intelligent approach streamlines the entire production process, saving time and resources.

In the pursuit of maximizing output and profitability, every ounce of material and every second of time counts. Conventional laser cutting often overlooks a critical efficiency drain: the generation of unusable tail material. This isn't just about lost raw material; it's also about the time spent managing, sorting, and disposing of scrap, which can add up significantly in high-volume operations. Our zero-waste tail material innovation5 is a testament to our commitment to comprehensive efficiency, demonstrating how intelligent design at MZBNL can transform what was once a hidden cost into a substantial competitive advantage. This ingenuity ensures that your production is not only faster but also more sustainable and cost-effective, directly impacting your bottom line and supporting long-term growth.

Maximizing Material Utilization and Cost Savings

Conventional laser tube cutting systems operate by starting cuts from the tube head, leading to an inevitable leftover section at the end of the process, typically referred to as tail material. This tail piece, often too short or irregularly shaped for further use, becomes unusable scrap. While seemingly small on a per-tube basis, this waste accumulates rapidly in high-volume production leading to substantial material losses. For industries relying on expensive raw materials, such as specialized alloys for automotive or medical equipment, this waste represents a significant and often overlooked cost. Industry reports indicate that traditional cutting methods can result in 5-10% material waste due to tail ends and lead-ins, directly impacting a company's profit margins.

Our zero-waste tail material innovation directly tackles this financial drain by fundamentally redesigning the cutting logic. Instead of starting from the tube head, our system calculates from the rear chuck as the origin. This intelligent approach allows the system to efficiently utilize the entire length of the tube. As long as the remaining section of the tube is larger than the product length required, it can be processed into a usable part, effectively eliminating leftover tail material. This maximizes material utilization, significantly reducing scrap rates, and directly translating into substantial cost savings on raw materials. For a metal fabrication business like Ahmed's, which handles large quantities of diverse metal pipes, this can mean tens of thousands of dollars saved annually, directly boosting profitability.

Furthermore, this optimization allows for more efficient nesting and scheduling of cuts. By effectively using the entire tube length, businesses can produce more parts from the same amount of raw material. This improved material yield means fewer material purchases, reduced storage needs for scrap, and a more streamlined inventory management system. It's a critical component of lean manufacturing, ensuring that every centimeter of valuable material contributes to a finished product, rather than ending up as waste. The financial impact of this innovation is profound, enhancing the cost-effectiveness of every cut, and strengthening the overall economic viability of your operations.

Streamlining Post-Processing and Clean-up

The generation of unusable tail material in traditional cutting processes doesn't just represent lost material; it also adds layers of inefficient post-processing and cleanup. Each leftover tail piece needs to be managed: removed from the machine, sorted, stored, and eventually disposed of. This requires additional labor, dedicated storage space for scrap, and incurs disposal costs, all of which are non-value-added activities that consume time and resources without contributing to the final product. In a busy factory environment, these seemingly minor tasks can collectively create bottlenecks, slow down the overall production flow, and divert valuable human resources from more productive activities. The accumulation of scrap also poses safety hazards and requires diligent housekeeping to maintain an organized workspace.

Our zero-waste tail material innovation significantly streamlines these post-processing and cleanup activities by virtually eliminating unusable tail scraps. Since the system is designed to consume almost the entire tube length, there are far fewer small, awkward remnants to handle. This reduction in physical waste means operators spend less time clearing the machine, sorting scrap, and preparing it for disposal. The removal of this manual, often cumbersome, step directly enhances the continuity of operations, ensuring that the machine can transition more quickly from one job to the next without interruption.

This efficiency gain also reduces the need for extensive waste management infrastructure. Fewer scrap bins are needed, and the frequency of waste collection can be reduced, leading to lower operational costs associated with waste disposal. For a high-tech enterprise like MZBNL, our focus is not just on the cutting itself, but on optimizing the entire lifecycle of the material within the machine. By minimizing what is left behind, we contribute to a cleaner, more organized, and more efficient production floor. This holistic approach to efficiency ensures that every aspect of the cutting process, including the traditionally overlooked post-processing phase, contributes to the overall speed and cost-effectiveness of your metal tube fabrication.

Contributing to Sustainable and Lean Manufacturing

Beyond immediate cost savings and operational efficiency, the zero-waste tail material innovation aligns perfectly with modern manufacturing principles emphasizing sustainability and lean operations. In an era where environmental responsibility is increasingly scrutinized and resource conservation is paramount, minimizing material waste is not just an economic imperative but also an ecological one. Conventional processes, by generating significant scrap, contribute to industrial waste streams and increased carbon footprints associated with material production and disposal. Businesses are under increasing pressure from regulators, customers, and investors to demonstrate sustainable practices, making waste reduction a strategic advantage.

Our zero-waste design is a powerful tool for achieving greater sustainability in your metal tube cutting operations. By maximizing material utilization, it directly reduces the amount of raw material consumed and the volume of industrial waste generated. This lowers your environmental impact, improves your corporate social responsibility profile, and can even qualify your operations for certain environmental certifications or incentives. For companies looking to enhance their green credentials, this innovation provides a tangible, measurable improvement in resource efficiency. It positions your business as a responsible and forward-thinking entity, appealing to clients who prioritize sustainable sourcing and production.

Furthermore, this innovation is a core component of lean manufacturing—a methodology focused on maximizing customer value while minimizing waste. By eliminating the waste of tail material, our system contributes to a leaner production flow, where every input is converted into maximum output. This reduces inventory of raw materials and scrap, streamlines processes, and improves overall factory flow. The combination of environmental benefits and lean operational advantages makes the zero-waste tail material innovation a strategic asset that enhances not only your immediate production speed and cost-efficiency but also your long-term resilience and market competitiveness in an increasingly resource-conscious world.

Zero-waste design reduces material wasteTrue

The system calculates cuts from the rear chuck, eliminating unusable tail sections and maximizing material utilization.

Traditional cutting wastes 5-10% materialFalse

Industry reports show traditional methods waste 5-10% material due to tail ends, not the cutting process itself.

What technological advancements underpin the high-speed cutting capabilities?

Are you wondering what truly drives the exceptional speed and precision of advanced metal tube cutting? It's far more than just a powerful laser; it's a sophisticated interplay of cutting-edge engineering and intelligent design. Our machines achieve unparalleled performance by leveraging key technological advancements that ensure both rapid and accurate material processing.

MZBNL's high-speed metal tube cutting capabilities are underpinned by advanced technological integrations including high-performance servo drive systems for precise motion, intelligent laser source control for optimal power delivery, and robust machine rigidity. These synergistic advancements ensure superior cutting velocity while maintaining exceptional accuracy and stability, translating into industry-leading throughput and quality.

While our No-CAD, front-feeding, and zero-waste6 innovations significantly enhance overall productivity, the foundational capability for true high-speed cutting lies in the core engineering of the machine itself. For a sophisticated buyer like Ahmed Al-Farsi, who values "proven technology" and "cutting speed and accuracy," understanding the underlying advancements is crucial. It’s not just about what the machine does, but how it does it so effectively. From the precision of its movements to the power of its laser, every component is meticulously designed to work in harmony, pushing the boundaries of what’s possible in metal tube fabrication. Let's delve into the specific technological breakthroughs that power MZBNL's commitment to high-speed performance, ensuring both rapid execution and impeccable quality.

High-Performance Motion Control Systems

The sheer speed of a laser tube cutting machine is fundamentally dictated by its motion control system. In conventional machines, limitations in motor power, drive technology, and mechanical design can restrict acceleration and deceleration, leading to slower overall cutting paths even with a powerful laser. Inferior motion systems often suffer from vibration at high speeds, compromising cut quality and precision. This means that while a machine might be theoretically fast, its practical operating speed must be reduced to maintain acceptable part tolerances, thus creating a bottleneck that directly impacts throughput and overall production efficiency. Many mid-range machines struggle to maintain consistent accuracy when pushed to higher speeds, leading to rejects and rework.

MZBNL’s machines7 integrate advanced servo drive systems, often combined with high-precision linear guides and rack-and-pinion drives, to enable exceptionally rapid and accurate axis movement. These systems provide precise control over acceleration, velocity, and deceleration, allowing the laser head to move swiftly between cutting points without sacrificing accuracy. For instance, high-performance servo motors can achieve accelerations exceeding 1.5G, enabling the machine to rapidly transition between different cutting contours and complex patterns. This dynamic capability is critical for maximizing cutting speed, as a significant portion of cutting time in complex parts is spent on non-cutting movements between piercing points or contours. Our continuous investment in R&D ensures we adopt the latest advancements in motion control, such as enhanced feedback loops and predictive algorithms, which minimize overshoot and vibration even at peak speeds.

Furthermore, the robust mechanical design of our machines—featuring heavy-duty frames and optimized gantry structures—is crucial for supporting these high-speed movements without introducing instability. Minimal vibration and exceptional rigidity ensure that the precise laser beam remains stable during rapid acceleration and deceleration phases, thereby maintaining cut quality and accuracy even at the highest possible speeds. This synergy between powerful motion control and structural integrity means that our machines can operate consistently at their rated high speeds without compromising the integrity of the cut, ensuring that every part produced meets stringent quality standards. This level of precision at speed is a key differentiator, providing clients with superior output and significantly reducing post-processing needs.

Advanced Laser Source and Optics Integration

The laser source is the heart of any fiber laser cutting machine, and its quality and integration profoundly impact cutting speed, efficiency, and versatility. Inferior laser sources may lack the power stability or beam quality necessary for consistent, high-speed cutting across various materials and thicknesses. Fluctuations in power can lead to inconsistent cut edges, dross, or incomplete cuts, forcing operators to reduce speed or perform multiple passes, negating any potential speed gains. Moreover, a poorly integrated optical path can lead to beam divergence or loss, diminishing the effective power delivered to the workpiece and thereby slowing down the cutting process. Many manufacturers might opt for lower-cost laser sources, which compromise on long-term performance and reliability.

At MZBNL, we utilize industry-leading fiber laser sources, known for their high power, exceptional beam quality, and robust stability. These advanced lasers ensure consistent power delivery and a focused, high-energy beam, which is critical for making clean, rapid cuts through various metal thicknesses. Our machines are equipped with a range of power options, from 2KW to 12KW and beyond, allowing us to tailor solutions to specific client needs for both speed and material capability. For instance, higher power lasers can achieve significantly faster cutting speeds on thicker materials, or enable faster piercing and cutting on thinner materials, leading to exponential gains in throughput. Our optical systems are meticulously designed and integrated to ensure minimal beam loss and optimal focusing, maximizing the efficiency of the laser energy delivered to the workpiece.

Moreover, the integration of intelligent control over the laser source allows for dynamic power modulation, enabling the machine to adjust laser parameters in real-time based on material type, thickness, and cutting contour. This adaptive control prevents overheating, minimizes heat-affected zones, and ensures optimal cutting conditions for maximum speed without compromising cut quality. For example, our systems can automatically adjust power during cornering or when encountering complex geometries, ensuring consistent cut quality even at high speeds. This sophisticated interplay between the laser source, its control systems, and the precision optics is what allows MZBNL machines to not only achieve impressive raw cutting speeds but to do so with the precision and consistency that high-volume and high-quality production demands, providing a critical competitive edge for our global enterprise clients.

Intelligent Software Algorithms and Real-time Feedback

Beyond hardware, the intelligence embedded within the machine’s software is paramount for achieving and sustaining high-speed performance. Many laser cutting systems use basic software that performs simple path following, neglecting opportunities for optimization. This can lead to inefficient cutting paths, unnecessary slowdowns, and even potential collisions. Without real-time feedback and intelligent algorithms, the machine cannot adapt to minor material variations or adjust cutting parameters on the fly, leading to suboptimal speeds, reduced accuracy, and increased scrap rates. The lack of predictive capabilities means that operators must constantly monitor and manually intervene, adding to operational complexity and limiting true automation.

MZBNL machines are powered by sophisticated software algorithms that are constantly refined to optimize cutting paths and operational parameters for maximum speed and efficiency. Our proprietary algorithms incorporate features like dynamic lead-in/lead-out optimization, common line cutting, and intelligent nesting strategies, all designed to minimize non-cutting time and maximize the length of continuous cuts. For instance, our software can automatically determine the most efficient piercing points and cutting directions for complex parts, reducing travel time and improving overall cycle time. This intelligent path planning ensures that the machine moves along the most efficient trajectory, reducing unnecessary deceleration and acceleration cycles that consume valuable time.

Furthermore, our systems leverage real-time feedback loops from various sensors throughout the machine. This allows the software to continuously monitor cutting conditions, such as laser power output, gas pressure, and motion accuracy, and make immediate, minute adjustments. For example, if a slight deviation in material thickness is detected, the system can dynamically adjust cutting speed or laser power to maintain optimal cut quality without stopping the process. This predictive and adaptive capability minimizes errors, reduces the need for manual intervention, and ensures consistent high-speed performance across diverse production scenarios. It provides operators with comprehensive diagnostic data, enabling proactive maintenance and further optimization. This advanced software intelligence is a critical enabler of our machines' high-speed capabilities, transforming raw hardware potential into consistently high-performance reality for our clients, ensuring reliable and precise operation in demanding environments.

Servo drives enable high-speed motionTrue

Advanced servo drive systems provide precise control over acceleration and deceleration, allowing rapid movement without sacrificing accuracy.

Laser power alone determines cutting speedFalse

Cutting speed depends on multiple factors including motion control, optics integration, and software algorithms, not just laser power.

How can operators optimize machine settings to achieve maximum speed?

Possessing a high-speed metal tube cutting machine8 is just the first step; unlocking its full potential depends significantly on operator expertise. Are you leveraging all available features to maximize throughput? Suboptimal machine settings can drastically limit performance, turning your advanced equipment into a missed opportunity. Discover how operators can fine-tune their MZBNL machines for peak speed.

Operators can achieve maximum speed on MZBNL metal tube cutting machines by efficiently utilizing the No-CAD system for rapid program setup, meticulously fine-tuning cutting parameters like power and feed rates for specific materials, and performing proactive maintenance. Regularly monitoring consumables and adhering to recommended operational guidelines ensures consistent peak performance and optimal throughput.

While our machines are engineered for inherent high speed and efficiency, the human element—the skilled operator—remains pivotal in truly unlocking their peak performance. For a hands-on decision-maker like Ahmed Al-Farsi, who values ease of operation and post-sales training, empowering his team to master these optimization techniques is key to maximizing his investment. It’s about transforming potential into realized output, ensuring that every shift operates at its most efficient. By understanding how to strategically adjust settings and maintain the machine, operators can significantly enhance cutting speed, reduce material waste, and contribute directly to the profitability of their operation. Let’s explore the practical strategies your team can employ to push your MZBNL machine to its highest speeds and maintain that peak performance consistently.

Leveraging No-CAD for Rapid Program Setup

One of the most significant factors influencing overall production speed is the time spent on machine setup and programming. In traditional setups, operators or engineers dedicate considerable time to creating or importing complex CAD files, generating G-code, and then verifying the program on the machine. This iterative process, particularly for new parts or design modifications, can lead to hours of downtime before the first cut even begins. Any minor error in the CAD model or G-code necessitates a return to the design station, creating frustrating delays and reducing the machine's active cutting time. This bottleneck becomes especially pronounced in environments demanding high flexibility or small batch production, directly impacting overall throughput.

Our No-CAD operating system empowers operators to dramatically accelerate program setup, directly contributing to high-speed performance. Instead of relying on external CAD software, operators can directly input parameters for standard tube types, hole patterns, and cutting contours into the machine's intuitive interface. This direct input capability eliminates the need for complex 3D modeling and G-code generation9 for common parts, reducing setup time from hours to just minutes. For example, an operator needing to cut a standard circular hole pattern on a tube can simply enter the diameter, number of holes, and spacing, and the machine will instantly generate the cutting path. This immediate readiness for production maximizes the machine's uptime.

This ease of programming also fosters greater agility and responsiveness on the shop floor. Operators can quickly make on-the-fly adjustments to existing programs or create entirely new ones for simple parts without needing external design support. This ability to rapidly switch between jobs or adapt to last-minute design changes is invaluable for maximizing machine utilization and maintaining a high pace of production. By minimizing the non-cutting time associated with programming, the No-CAD system ensures that the machine is always primed for high-speed operation, providing a continuous flow of finished parts and significantly enhancing overall operational efficiency, particularly for companies that value the "ease of use (preferably No-CAD system)" as much as Ahmed Al-Farsi.

Fine-Tuning Cutting Parameters for Material Specificity

Achieving maximum cutting speed while maintaining quality requires a nuanced understanding of how laser parameters interact with different materials and thicknesses. Each metal type (e.g., stainless steel, carbon steel, aluminum) and its specific gauge respond differently to laser power, cutting speed, focus position, and assist gas pressure. Operating with generic or suboptimal settings can lead to slower cutting speeds than the machine is capable of, poor cut quality (like excessive dross, burrs, or uneven edges), or even incomplete cuts, which then require costly secondary processing or lead to scrap. Many operators may stick to "safe" general settings, unaware of the potential for significant speed gains by optimizing these critical parameters.

Skilled operators can significantly boost cutting speed by meticulously fine-tuning parameters to match the specific material being processed. Our MZBNL machines provide comprehensive control over parameters such as laser power, cutting speed (feed rate), focal position, nozzle diameter, and assist gas type and pressure. By consulting material cutting charts, historical data, or running small test cuts, operators can identify the optimal combination of these parameters for the fastest possible clean cut. For instance, increasing the assist gas pressure for certain stainless steels can dramatically improve cutting speed and edge quality, while adjusting the focal position by fractions of a millimeter can optimize the energy density for a particular thickness, leading to faster piercing and cutting.

Furthermore, leveraging the machine's built-in material libraries and the ability to save custom parameters can streamline this process for recurring jobs. An operator, after finding the perfect settings for a specific type of tube used in architectural railings, can save these as a preset for future use, ensuring consistent high-speed performance without the need for repeated manual adjustments. This iterative optimization, combined with the machine's advanced control systems, empowers operators to push the boundaries of cutting speed while maintaining the precision and quality MZBNL machines are known for. By actively engaging with these settings, operators become integral to maximizing the machine's throughput and ensuring every cut is both fast and flawless.

Implementing Proactive Maintenance and Monitoring

Even the most technologically advanced machine cannot maintain peak performance without diligent maintenance and proactive monitoring. Neglecting routine checks, ignoring warning signs, or delaying consumable replacements can lead to gradual degradation in cutting speed and quality, eventually resulting in unexpected downtime and costly repairs. For example, a dirty protective lens can reduce laser power delivery, forcing slower cutting speeds. Worn nozzles can lead to inconsistent gas flow, affecting cut quality and speed. These seemingly minor issues, if left unaddressed, accumulate to significantly impede the machine's high-speed capabilities and reliability, leading to missed deadlines and reduced profitability.

Operators play a crucial role in ensuring maximum speed and longevity through proactive maintenance and continuous monitoring. Regular checks of consumables, such as nozzles, ceramic rings, and protective lenses, are paramount. Replacing these components at recommended intervals, rather than waiting for failure, ensures optimal laser beam delivery and assist gas flow, which are critical for high-speed, high-quality cutting. For instance, a clean, correctly sized nozzle ensures the assist gas effectively expels molten material, allowing the laser to cut faster. Our machines provide clear indicators and easy access for these routine checks, simplifying the process for operators.

Beyond consumables, operators should actively monitor machine performance indicators, such as cutting parameters, error logs, and diagnostic feedback, which our smart digitalized systems provide. Addressing minor anomalies promptly can prevent them from escalating into major issues that would halt production. For example, if a slight deviation in cutting speed for a known material is observed, it might indicate a need for a quick calibration check or a deeper diagnostic. Furthermore, keeping the machine's software updated ensures that operators benefit from the latest performance enhancements and bug fixes. By treating the machine as a high-performance asset that requires continuous care, operators ensure that it consistently runs at its maximum potential, delivering the high-speed output and reliability that our clients, like Ahmed, depend on for their demanding fabrication projects.

No-CAD reduces setup timeTrue

The No-CAD system eliminates complex 3D modeling, allowing operators to input parameters directly and reduce setup from hours to minutes.

Generic settings maximize speedFalse

Material-specific parameter tuning is required for maximum speed; generic settings often result in slower cutting speeds.

Conclusion

MZBNL achieves unmatched high-speed metal tube cutting performance through three core innovations: the intuitive No-CAD system, efficient front-feeding, and pioneering zero-waste tail material processing. These advancements, combined with robust underlying technologies and smart operator optimization, streamline the entire workflow, fundamentally boosting productivity, reducing waste, and empowering businesses to excel in a demanding global market.

-

Learn about Ahmed Al-Farsi's strategies to improve architectural metalwork and vehicle parts production. ↩

-

Discover how automated pulling streamlines manual loading processes ↩

-

Understand the ergonomic advantages of reducing manual lifting requirements ↩

-

Discover the operational benefits of minimizing waste in laser cutting processes. ↩

-

Learn how reducing tail material boosts efficiency and sustainability in manufacturing. ↩

-

Learn how these innovations boost productivity and material efficiency. ↩

-

Explore how advanced servo systems enhance speed and accuracy. ↩

-

Learn how cutting-edge technologies enhance speed and efficiency in metal tube cutters. ↩

-

Discover the traditional modeling and coding process in laser cutting and its limitations. ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.