What is a 3D Tube Laser Cutter? Features & Applications

Struggling with slow, inaccurate, and wasteful tube processing? Traditional methods are holding your business back, costing you time and money while limiting your design capabilities. You need a better way to manufacture.

A 3D tube laser cutter is an advanced machine that uses a multi-axis laser head to perform complex cuts, holes, and bevels on metal tubes. It boosts production efficiency by up to 80%, minimizes material waste, and reduces operator training from weeks to a single day.

As the General Manager of MZBNL, I've seen firsthand how this technology transforms factory floors. It's not just a new machine; it's a new way of thinking about production. So, let's dive deeper into what this technology is, where it's used, and how you can successfully implement it in your own operations.

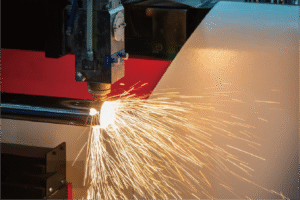

What is 3D Tube Laser Cutting Technology?

You hear the term "3D laser cutting," but it's not always clear how it's different from standard 2D cutting. This confusion can prevent you from seeing the immense competitive advantage it offers your business.

3D tube laser cutting technology uses a sophisticated, multi-axis laser head to cut metal tubes from any angle in a single operation. Unlike 2D cutting, it creates beveled edges for perfect welds, complex joints, and intricate patterns on various tube profiles without manual intervention.

Let's dive deeper. Traditional manufacturing requires multiple steps: sawing a tube to length, moving it to a drill press for holes, then to a milling machine for slots or end-shaping. Each step adds time, introduces the potential for error, and requires a skilled operator. A 3D tube laser cutter consolidates all these processes into one automated cycle. Its 5-axis or 6-axis head[^1] can move and tilt to cut any feature imaginable, including weld-ready beveled edges that drastically reduce downstream assembly time.

At MZBNL, we took this a step further because we saw that the biggest barrier wasn't the hardware, but the software.

The MZBNL No-CAD System

I remember a client, a furniture manufacturer, who was hesitant to invest. He told me, "Eric, I don't have CAD engineers on my team. How can we run such a complex machine?" This is a common fear. So, we developed our No-CAD system[^2]. It allows an operator with no programming experience to start producing complex parts within a single day. By simplifying the interface, we made the technology accessible to everyone, not just specialists. This directly tackles the industry's skilled labor shortage and reduces your long-term operational costs.

Where are 3D Tube Laser Cutters Used Today?

You understand the technology is powerful, but you might wonder if it's a fit for your specific industry. Without seeing clear applications, you could be missing out on a significant opportunity to get ahead of your competition.

3D tube laser cutters are critical in automotive for chassis parts, furniture for complex frames, medical equipment for high-precision components, and architectural projects for unique structures. Their versatility makes them indispensable for any industry that processes metal tubes for high-value applications.

Let's dive deeper. The flexibility of 3D laser cutting has opened up new possibilities across many sectors. Here are a few examples from our 4,000+ clients worldwide.

- Automotive and Motorcycle Parts: Manufacturers use our machines to produce everything from chassis components and roll cages to exhaust systems. The ability to cut perfect bevels ensures stronger, more consistent welds, which is critical for safety and performance.

- Furniture and Sanitary Ware: I visited a client in the high-end furniture business who used our machine to create complex joints that flowed seamlessly into their designs. They eliminated several welding and grinding steps, cutting their assembly time by over 40% and improving the final look of their product.

- Fitness and Medical Equipment: These industries demand absolute precision and clean finishes. Our laser cutters produce burr-free parts for fitness machines and high-precision components for medical devices, where accuracy is non-negotiable.

- Architectural Decoration: Architects love the design freedom. With 3D laser cutting, they can design complex, artistic metal structures for building facades, staircases, and support beams that would be impossible or prohibitively expensive to create with traditional methods.

What are the Challenges of Implementing a 3D Tube Laser Cutter?

Investing in powerful new technology like this can feel like a big risk. The fear of high upfront costs, a steep learning curve for your team, and potential disruption to your production line can make any manager hesitate.

The primary challenges of implementing a 3D tube laser cutter are the initial capital investment, the perceived operational complexity requiring skilled programmers, and the difficulty of integrating the machine into an existing workflow. These hurdles often create fear of a slow ROI.

Let's dive deeper into these very real concerns. I've spoken with hundreds of business owners, and these three issues come up every time. First, the initial investment is significant. This isn't a small purchase, and the price tag can be intimidating. Second is the skills gap. Traditionally, running a 3D laser required a programmer who could work with complex CAD/CAM software. Finding and retaining this talent is expensive and difficult. Many plant managers worry that their existing workforce won't be able to adapt, leading to a long and painful training period. Third is the fear of disruption. How do you integrate this advanced machine into a workflow that has run the same way for years? The worry is that the installation and learning phase will cause costly downtime, hurting your delivery schedules and frustrating your team. These are not small problems, and ignoring them is a mistake.

How Can You Overcome These Implementation Challenges?

You see the challenges, but you need a clear strategy to overcome them. Without a practical plan, the risks can seem too large, preventing you from making a decision that could secure the future of your business.

Overcome implementation challenges by focusing on technology designed for simplicity, like MZBNL's No-CAD system that reduces training to one day. Analyze the long-term ROI from labor and material savings, not just the initial cost, and choose a partner who provides end-to-end support.

Let's dive deeper. At MZBNL, we have built our entire business model around solving these exact problems for our clients. We don't just sell machines; we provide complete solutions.

Tackling the Skills Gap with Simple Technology

Our answer to the skills gap is our innovative No-CAD system. We intentionally designed the user interface to be intuitive. An operator doesn't need to understand G-code or 3D modeling. They can use our pre-built library of shapes or simple input parameters to start cutting immediately. We guarantee that a new operator can be fully trained and productive in a single day. This removes the biggest operational hurdle and empowers your existing team.

Focusing on Total Cost of Ownership

Instead of just looking at the purchase price, we help our clients calculate the Total Cost of Ownership (TCO). A 3D laser cutter is an investment that pays for itself. We factor in the massive savings from reduced labor costs, higher throughput, and less material waste. For example, our Zero-Waste cutting technology ensures you use the entire length of the tube, often saving clients thousands of dollars a month on materials alone. When you see the full picture, the ROI becomes clear and compelling.

How Can You Optimize Your 3D Tube Laser Cutter's Performance?

You have the machine, but you want to ensure you are getting the absolute maximum return from your investment. Just running the machine isn't enough; leaving performance and efficiency on the table is the same as leaving money on the table.

To optimize your cutter, implement automated loading/unloading systems, use intelligent software to nest parts and minimize waste, and stick to a strict preventive maintenance schedule. Features like MZBNL's Front-Feeding and Zero-Waste technology are designed specifically for peak optimization.

Let's dive deeper. Getting the most from your machine comes down to a few key strategies that we help all our clients implement. It's about maximizing uptime and minimizing waste.

Smart Material Handling and Automation

Every minute the laser isn't cutting is a minute you're losing money. That's why we developed our Front-Feeding system. It allows for continuous loading of raw material, dramatically reducing idle time between jobs. This simple feature can increase overall throughput by 15-20% on its own. It automates a slow, manual process and keeps your production flowing smoothly.

Eliminating Material Waste

Material is one of your biggest costs. Our Zero-Waste tailing feature[^3] is a game-changer. Traditional cutters often leave a significant, unusable piece of the tube at the end. Our machine is engineered to use the entire stock, reducing the final tailing to almost zero. For a company processing thousands of tubes a month, this translates into a direct and substantial saving on their bottom line.

Preventive Maintenance

Finally, a machine is only as reliable as its maintenance schedule. We provide all our clients with a clear, simple checklist for daily, weekly, and monthly maintenance. Simple tasks like cleaning the nozzle, checking the lens, and ensuring the beam is aligned prevent costly downtime and ensure the machine delivers perfect cuts every single time.

Conclusion

A 3D tube laser cutter is a transformative technology that offers unmatched precision, speed, and versatility. While the initial cost and perceived complexity can be challenges, MZBNL solves these with user-friendly innovations like our No-CAD system and efficiency-focused features that deliver a rapid, measurable return on investment.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.