Tube Laser Cutting Process: From Raw Material to Finished Part with Zero Waste?

Struggling with material waste eating into your profits? This inefficiency slows down your entire production line. I believe achieving a near-zero waste process is the key to unlocking new levels of profitability.

Yes, a zero-waste tube laser cutting process is achievable. It combines smart raw material preparation, streamlined machine setup with No-CAD systems, and innovative cutting logic like MZBNL's Zero-Waste Tail Material technology, which eliminates the final remnant and maximizes material use from start to finish.

I've visited hundreds of factories over the years, and one thing always stood out: the pile of scrap tail material next to the cutting machine. It was accepted as a necessary cost of doing business. But today, technology has changed the game. This "cost" is now pure, recoverable profit. Let me walk you through how we've transformed the entire workflow, from a raw tube to a perfect, finished part, without leaving a trace of waste behind. It's a journey toward ultimate efficiency that I think will redefine your expectations.

How to prepare raw materials for laser tube cutting?

Poorly prepared tubes cause cutting errors and jams. These mistakes lead to scrap, production delays, and even equipment damage. Proper preparation is the foundation for a smooth and accurate cutting operation.

To prepare raw materials, you must first inspect tubes for straightness, surface defects, and correct dimensions. Then, clean any oil, rust, or contaminants. Finally, load the tubes into the machine's feeding system, ensuring they are correctly aligned for automated processing and optimal cutting results.

When I talk to clients, I always stress that the process begins long before the laser ever fires. The old saying "garbage in, garbage out" is especially true here. A high-performance machine can't compensate for a bent or dirty tube.

The Foundation of a Perfect Cut

The quality of your raw material directly impacts everything downstream. Here's a breakdown of what we advise our partners to focus on:

- Visual and Dimensional Inspection: Before anything else, check the tubes. Are they straight? A bowed tube can cause the chuck to lose its grip or feed incorrectly, leading to inaccurate cuts. Use calipers to verify the outer diameter and wall thickness against the job specifications.

- Surface Cleaning: The laser needs a clean surface to work effectively. Oil, grease, rust, or even heavy scale can interfere with the laser beam, causing incomplete cuts or a poor-quality edge finish. A simple cleaning process can prevent countless headaches.

- Efficient Loading: This used to be a labor-intensive step. Today, automation is a game-changer. Our Front-Feeding Mechanism is a perfect example. It automates the loading of entire bundles of tubes, increasing feeding efficiency by around 40% and reducing operator fatigue. It presents each tube perfectly, ensuring a consistent starting point for the cutting process. This isn't just about speed; it's about creating a reliable, repeatable workflow that minimizes human error.

What are the initial setup steps for a laser tube cutting machine?

Complex machine setup is a major production bottleneck. It demands highly skilled operators and extensive training, which slows down your entire operation. Modern machines, however, are designed to simplify this process dramatically.

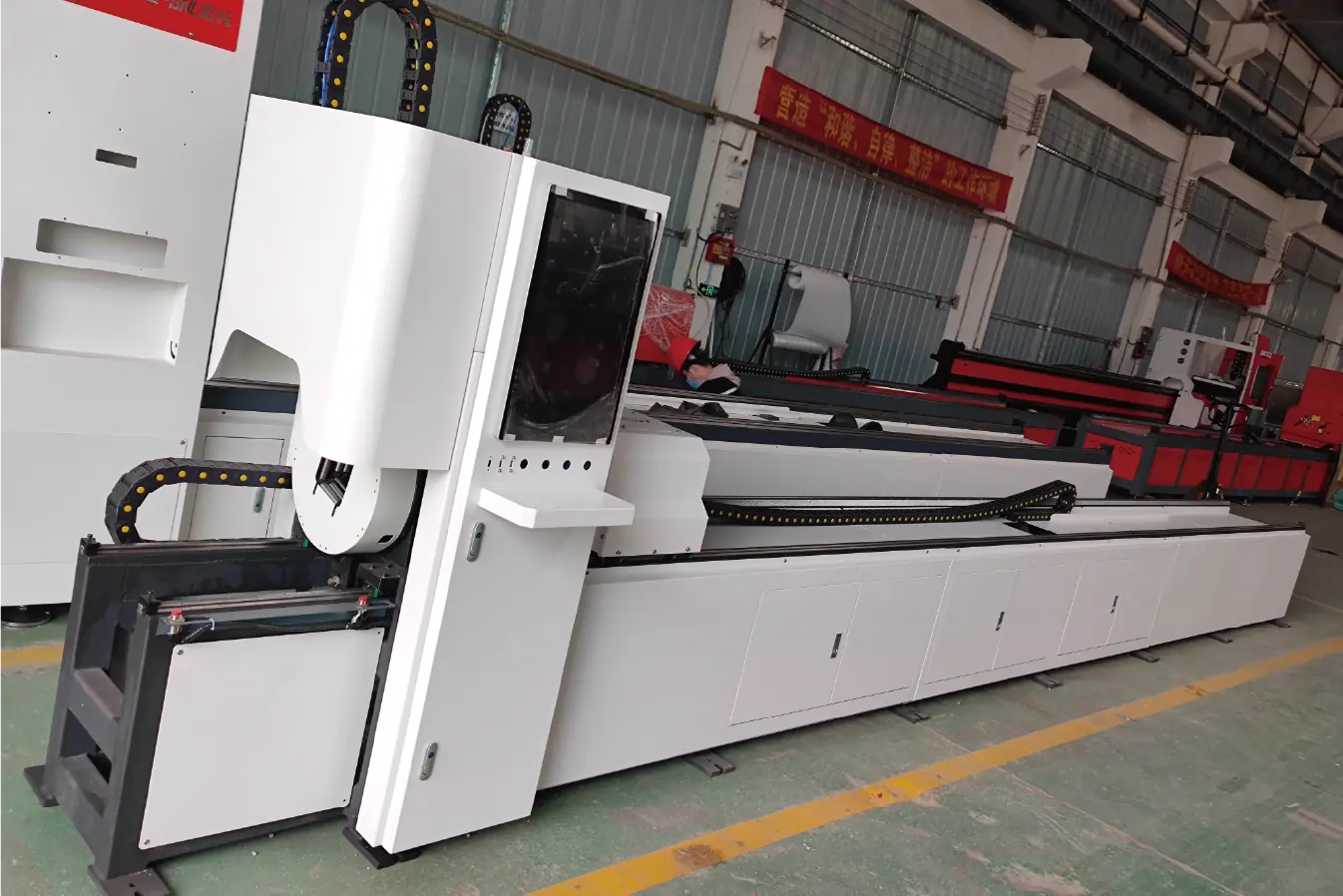

Initial setup involves loading the cutting program and inputting material parameters. With advanced systems like MZBNL's No-CAD technology, operators can simply enter dimensions for standard tubes, bypassing 3D drawings. The machine then automatically calibrates the laser head and chucks for production.

I remember a client in the furniture industry telling me their biggest challenge wasn't cutting speed, but the time it took to switch between jobs. They needed a trained engineer to program every new part. We showed them a better way, and it changed their business.

From Complex Programming to Simple Parameters

The setup phase is where modern technology truly shines, turning a complex engineering task into a simple operational step. The goal is to get you from "idea" to "first cut" as quickly as possible.

1. The Old Way vs. The New Way

Traditionally, cutting any tube required a 3D model created in software like SolidWorks. An engineer would have to draw the part, export it as a specific file type, and then import it into the machine's software. This process was slow and required a specialist. Our No-CAD System completely eliminates this step for standard parts. If you're cutting holes or angles into standard round, square, or rectangular tubes, your operator can input the parameters—like tube length, hole diameter, and position—directly into the machine's interface. What used to take an engineer hours now takes an operator minutes.

2. Reducing Training from 15 Days to 1 Day

This simplification has a massive impact on training. I've seen it firsthand. We've taken the on-site training time required for a new operator from an industry-standard of 15 days down to just one day. This allows our clients to be more flexible with their workforce and get new machines into full production almost immediately. It democratizes the technology, putting the power of advanced manufacturing into the hands of the people on the factory floor. This shift towards smart, digitalized systems is a core principle of lean manufacturing[^1] and is essential for staying competitive.

How does the cutting process ensure zero waste of materials?

Tail material waste has always been an accepted, hidden cost in tube processing. But this "cost" is pure lost profit, adding up to thousands of dollars over time. Innovative cutting logic can eliminate it entirely.

A zero-waste process is achieved by redesigning the cutting logic. Instead of leaving a dead zone at the end of the tube, MZBNL's Zero-Waste Tail Material technology uses a rear chuck to advance the tube fully, allowing the laser to cut the entire length without unusable remnants.

For years, the last 80-120mm of every single tube was thrown away. It was a physical limitation of how machines were designed, with a "dead zone" between the front and rear chucks. We looked at that scrap pile and saw an opportunity for innovation.

Turning Waste into Revenue

This is the heart of the zero-waste revolution. It’s not just about being environmentally conscious; it's a powerful economic strategy. The evolution towards resource optimization is a direct response to market pressures, especially in sectors like automotive parts and metal furniture where material costs are a significant portion of the final product price.

| Feature | Traditional Cutting | MZBNL Zero-Waste Cutting |

|---|---|---|

| Tail Material | 80mm - 120mm of waste per tube | 0mm waste |

| Material Utilization | ~95-98% | 100% |

| Mechanism | Rear chuck cannot feed past the front chuck | Rear chuck moves through the front chuck |

| Financial Impact | Constant loss of raw material cost | Maximized ROI on every tube purchased |

Our Zero-Waste Tail Material technology is a patented solution that rethinks the process. We designed the machine so the rear chuck can pass completely through the front chuck, feeding the very last section of the tube into the cutting area. This means you can use 100% of a 6-meter tube. For a factory processing thousands of tubes a day, the savings are astronomical. This isn't just an incremental improvement; it is a paradigm shift that positions manufacturers as leaders in both efficiency and sustainability.

How to handle and inspect finished parts for quality assurance?

A perfectly cut part means nothing without proper quality assurance. A single bad component can compromise an entire assembly, costing you time, money, and your reputation. A systematic inspection process guarantees product integrity.

Handle finished parts carefully to prevent scratches or damage. Quality assurance involves visual inspection for burrs and surface finish, then dimensional checks with calipers or gauges to verify accuracy against the original design specifications. Automated unloading systems help ensure careful handling.

The beauty of high-precision laser cutting is that the parts coming off the machine are incredibly consistent. However, "trust but verify" is a motto I live by in manufacturing. A simple, fast QA check is the final gatekeeper that ensures only perfect products reach your customer.

Guaranteeing Perfection in Every Part

While our machines produce parts with an accuracy of ±0.05mm, a robust quality assurance (QA) process is still essential. It provides the final confirmation that every part meets the required standard before moving to the next stage of production.

Here are the key inspection points we recommend:

- Automated Unloading: The first step in quality is preventing damage. Many of our machines feature automated unloading and sorting systems. These mechanisms gently receive the cut part and place it in a designated container, preventing the scratches and dings that can occur with manual handling or simply dropping parts into a bin.

- Visual Inspection: The quickest check is visual. An operator should look at the cut edge. Is it smooth? Is there any dross or burr? Modern fiber lasers produce a very clean edge, but a quick visual scan can immediately flag any potential issues with gas pressure or cutting speed.

- Dimensional Verification: This is the most critical step. Using digital calipers, micrometers, or custom-made gauges, the operator should verify key dimensions. This includes the length of the part, the diameter and position of holes, and the angle of miter cuts. This check confirms that the machine setup and cutting execution were flawless.

This systematic process doesn't have to be slow. By integrating it into the workflow, you create a culture of quality that builds trust and reliability into your brand.

What are the post-processing steps to finalize the product?

Cut parts are rarely ready for immediate use in an assembly. Additional steps like deburring, cleaning, or welding add time and labor costs to your workflow. Integrating these processes can dramatically streamline production.

Post-processing finalizes a product for assembly or finishing. Common steps include deburring to remove sharp edges, cleaning to remove residue, and potentially tapping or welding. Many parts also require surface treatments like painting, powder coating, or plating for durability and aesthetics.

The ideal manufacturing line is a continuous flow, not a series of disconnected stops. The goal of post-processing should be to add value, not just to fix issues from the previous step. That's why we believe in integrating as many functions as possible.

From Cut Part to Final Product

While our high-speed, high-precision laser cutters produce parts with minimal burrs, the final application often dictates the necessary post-processing steps. A part for medical equipment has different requirements than one for industrial racking.

Common Post-Processing Stages

- Deburring and Cleaning: Even a small burr can be a safety hazard or prevent a perfect fit during assembly. Light deburring, either manually or with automated equipment, ensures smooth edges. This is followed by cleaning to prepare the surface for the next step.

- Secondary Operations: Many parts require additional mechanical work. This can include tapping threads into holes, bending the tube into a specific shape, or welding it to other components to create a larger assembly.

- Surface Finishing: This final step is both protective and aesthetic. Depending on the product's end-use, it might involve painting, powder coating for a durable finish, or plating (like chrome or zinc) for corrosion resistance and a high-end look.

At MZBNL, we push for process integration. For example, our Automatic Punching & Cutting Integrated Machine can perform multiple operations in one cycle. By combining processes, you reduce material handling, save floor space, and shorten the overall production time from raw material to a fully finished product. This philosophy of multi-process integration is the next frontier in achieving true operational efficiency.

Conclusion

The journey from a raw tube to a finished part has been revolutionized. By focusing on smart material preparation, simplified No-CAD setup, and groundbreaking Zero-Waste cutting technology, a highly efficient, cost-effective, and sustainable process is no longer a future goal—it's a present-day reality for modern manufacturers.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.