Bir Metal Boru Kesme Makinesi Birden Fazla Boru Şeklini İşleyebilir mi?

Mevcut makinelerinizle çeşitli boru şekillerini verimli bir şekilde kesmekte zorlanıyor musunuz? Farklı boru tipleri için sürekli yeniden takımlama ve karmaşık programlama, üretkenliği ciddi şekilde sınırlayabilir ve işletme maliyetlerini artırabilir. Çeşitli üretim ihtiyaçlarınıza zahmetsizce uyum sağlayan tek bir makine hayal edin.

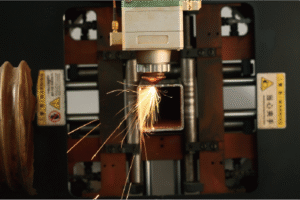

Modern metal boru kesme makineleri, özellikle de gelişmiş yazılıma, uyarlanabilir aynalama sistemlerine ve çok eksenli yeteneklere sahip olanlar, yuvarlak, kare, dikdörtgen ve hatta düzensiz profiller dahil olmak üzere çok çeşitli boru şekillerini gerçekten işleyebilir. Bu çok yönlülük, üretim esnekliğini önemli ölçüde artırır.

Metal imalatının dinamik dünyasında, çok yönlülük artık bir lüks değil, bir gerekliliktir. Kendim de bir imalatçı olarak, verimlilik veya hassasiyetten ödün vermeden gelişen üretim taleplerine uyum sağlayabilen ekipmanlara duyulan acil ihtiyacı anlıyorum. Bu, operasyonlarınızı sınırlamakla değil, güçlendirmekle ilgilidir.

Tek bir makinede birden fazla boru şeklini işleme tutkusu genellikle geleneksel üretimin teknik gerçekleriyle çarpışır. Görünüşte basit olsa da, makineleri farklı geometrilere uyarlamak, programlama karmaşıklığından malzeme işleme ve bitmiş ürün kalitesine kadar her şeyi etkileyen karmaşık bir zorluk sunar. BAE'deki Ahmed Al-Farsi'ninki gibi sayısız imalat işletmesinin, her bir benzersiz boru profili için ayrı makineler bulundurmanın veya uzun kurulum sürelerine katlanmanın verimsizliğiyle boğuştuğunu gördük. Buradaki eleştirel düşünce, yalnızca teknik kabiliyetin ötesine geçmekte; arıza süresinin ekonomik sonuçlarını, operatör beceri gereksinimlerini ve uzun vadeli yatırım getirisini kapsamaktadır. Sektör raporları sürekli olarak şunu vurgulamaktadır üreti̇mde çevi̇kli̇k1çok yönlü makineler tarafından yönlendirilen, rekabet gücü için önemli bir farklılaştırıcıdır. O halde, tek bir makinenin evrensel boru kesme vaadini gerçekten yerine getirebilmesini sağlayarak, istek ve pratik uygulama arasındaki bu boşluğu nasıl doldurabiliriz?

Tek bir makine kullanarak birden fazla boru şeklini keserken ne gibi zorluklar ortaya çıkıyor?

Makineniz farklı boru şekilleri arasında sorunsuzca geçiş yapamadığında üretim darboğazlarıyla mı karşılaşıyorsunuz? Programlamadan fiziksel kuruluma kadar çeşitli geometrileri ele almanın karmaşıklığı genellikle önemli duruş sürelerine yol açar. Bu çok yönlülük eksikliği, operasyonel verimliliğinizi ciddi şekilde engelleyebilir.

Tek bir makinede birden fazla boru şeklinin kesilmesi, karmaşık programlama, sık sık yeniden takımlama, malzeme taşıma zorlukları, çeşitli profillerde hassasiyeti koruma ve tutarlı kalite ve verimlilik elde etmek için operatörler için yüksek beceri gereksinimlerini yönetme gibi zorluklar sunar.

Ahmed gibi müşteriler de dahil olmak üzere yüzlerce metal imalatçısıyla çalışma deneyimimden yola çıkarak, farklı görevler için yeterli donanıma sahip olmayan makinelerden kaynaklanan hayal kırıklıklarına ilk elden tanık oldum. Tek noktadan çözüm hayali çoğu zaman pratik sınırlamalardan oluşan bir duvara çarpıyor ve sorunsuz olması gereken iş akışını bir dizi sinir bozucu duraklamaya ve maliyetli hatalara dönüştürüyor. Bu sadece teknik engellerle ilgili değildir; kârlılığınızı, proje zaman çizelgelerinizi ve hatta ekibinizin moralini etkiler. Bu zorlukları doğrudan ele alan yenilikçi çözümlerin değerini gerçekten takdir etmek ve yatırımınızın gerçekten karşılığını almasını sağlamak için bu zorlukları incelememiz gerekir.

Programlama ve Kurulumun Karmaşıklığı

Yuvarlak, kare, dikdörtgen veya daha karmaşık özel profiller gibi farklı boru şekillerinin tek bir makinede işlenmesi, geleneksel olarak programlama süresi ve operatör uzmanlığı için önemli bir yatırım gerektirir. Her yeni şekil, özel kesme yolları, malzeme kalınlığı ve türü için telafi ve genellikle karmaşık fikstür ayarlamaları gerektirir. Ahmed Al-Farsi'nin önceki kurulumunu düşünün: Ekibi, farklı bir boru şekli içeren her yeni proje için karmaşık 3B çizimler oluşturmak veya değiştirmek için yetenekli CAD operatörlerine ihtiyaç duyma yüküyle sık sık karşılaşıyordu. Bu sadece bir rahatsızlık değildi; önemli ölçüde üretken olmayan saatlere dönüşüyor, teslim sürelerini artırıyor ve proje teslimatlarını geciktiriyordu. 2022 yılında yapılan bir üretim araştırmasından elde edilen veriler, geleneksel makinelerin kullanıldığı çok şekilli kesim işlemlerinde programlama ve kurulumun toplam iş süresinin 30%'sini oluşturduğunu göstererek büyük bir verimsizliğin altını çizdi.

Ayrıca, bağlama basıncından kesme hızına ve gücüne kadar her bir şekil için makine parametrelerini manuel olarak ayarlama işlemi, yüksek bir insan hatası riskini beraberinde getirir. Küçük yanlış hesaplamalar bile malzeme israfına, yeniden çalışmaya ve hatta makinenin hasar görmesine yol açabilir. Bu yinelemeli deneme yanılma süreci, özellikle de yüksek değerli malzemelerle çalışırken hem zaman alıcı hem de pahalıdır. MZBNL'nin sözleşmeye dayalı imalat hizmetlerinde faaliyet gösteren müşterileri gibi işletmeler için israfı en aza indirmek ve verimi en üst düzeye çıkarmak kârlılık için çok önemlidir. Son derece uzmanlaşmış operatörlere olan geleneksel bağımlılık, Ahmed'in yaşadığı "yüksek operatör devri, yeniden eğitim yüklerine neden oldu" sorununu da daha da kötüleştiriyor, çünkü bu tür bir uzmanlığı bulmak ve elde tutmak rekabetçi bir işgücü piyasasında giderek zorlaşıyor.

Kesme ve delme işlemlerinin aynı makinede birleştirilmesi gibi çoklu işlem entegrasyonu düşünüldüğünde bu zorluk daha da artmaktadır. Her bir proses, her bir benzersiz boru şekli için farklı eksenler ve takımlar arasında hassas senkronizasyon gerektiren başka bir programlama karmaşıklığı katmanı ekler. Akıllı, uyarlanabilir bir sistem olmadan, operatörlerin birden fazla yazılım arayüzü ve manuel ayarlamalarla uğraşması gerekir, bu da daha fazla gecikmeye ve hata potansiyelinin artmasına neden olur. Değişkenlerin bu karmaşık etkileşimi, geleneksel makinelerin neden gerçekten çok yönlü olmakta zorlandığının ve işletmeleri her boru şekli için özel ekipmanlara ittiğinin altını çizmektedir ki bu da maliyetli ve alan yoğun bir çözümdür.

Malzeme Taşıma ve Mekanik Sınırlamalar

Programlamanın ötesinde, çeşitli boru şekillerinin fiziksel olarak taşınması ve sabitlenmesi, tek bir makine için önemli mekanik zorluklar ortaya çıkarır. Geleneksel bağlama sistemleri genellikle başta yuvarlak borular olmak üzere belirli geometriler için tasarlanmıştır. Bu sistemleri kare, dikdörtgen veya oval boruları yüksek hızlı kesim sırasında deformasyon veya kayma olmadan güvenli bir şekilde tutacak şekilde uyarlamak için ya hantal manuel ayarlamalar, her şekil için özel fikstürler ya da gerekli çok yönlülükten yoksun özel aynalar gerekir. Çeşitli projelerle uğraşan bir metal imalat işletmesi için bu, yeniden takımlama için sürekli kesintiler anlamına gelir.

Besleme mekanizmasının kendisi de bir darboğaz haline gelebilir. Eski tasarımlarda yaygın olan yandan veya arkadan manuel yüklemeye dayanan makineler, farklı boru uzunlukları ve şekilleri arasında geçiş yaparken doğal olarak daha az verimlidir. Her değişiklik, malzeme hasarını veya hatalı kesimleri önlemek için hassas hizalama ve dikkatli besleme gerektirir. Bu emek yoğun süreç sadece verimliliği düşürmekle kalmaz, aynı zamanda operatör yorgunluğunu ve işyeri yaralanmaları riskini de artırır. MZBNL'nin de kabul ettiği gibi, "Geleneksel makineler yandan veya arkadan manuel yüklemeye dayanırken," bu yaklaşım, çeşitli boru türleri arasında hızlı geçişler gerektiren modern üretim talepleri için ölçeklenebilir değildir.

Ayrıca, bazı makinelerin yapısal rijitliği ve eksen kinematiği, dairesel olmayan profillerin kesilmesiyle ilgili gerilimler ve hareketler için optimize edilmemiş olabilir. Bir makine öncelikle yuvarlak borular için tasarlandığında, kare veya dikdörtgen profillere uygulanması, makinenin gerekli dinamik stabiliteye sahip olmaması durumunda titreşimin artmasına, kesme hassasiyetinin azalmasına veya bileşenlerin erken aşınmasına neden olabilir. Bu durum genellikle bir değiş tokuşla sonuçlanır: ya makine farklı şekillerde optimumun altında performans gösterir ya da her bir özel ihtiyaç için özel, daha az çok yönlü makineler satın alınır ve sermaye harcamaları artar. Bu nedenle, zorluk sadece kesimle ilgili değil, makinenin uzun ömürlülüğünden veya çıktı kalitesinden ödün vermeden bir dizi şekil boyunca tutarlı, yüksek hassasiyetli kesimle ilgilidir.

| Mücadele Alanı | Geleneksel Makine Sınırlamaları | Üretim Üzerindeki Etkisi |

|---|---|---|

| Programlama Karmaşıklığı | Yetenekli CAD operatörleri, her şekil için manuel veri girişi gerektirir. | Yüksek arıza süresi, artan teslim süreleri, kıt yeteneklere bağımlılık. |

| Yeniden Ayarlama / Kurulum Süresi | Manuel fikstür değişiklikleri, farklı geometriler için yavaş ayarlamalar. | Azaltılmış verim, önemli ölçüde üretken olmayan saatler. |

| Malzeme Taşıma | Verimsiz manuel yükleme, adaptif olmayan bağlama sistemleri. | Operatör yorgunluğu, malzeme deformasyonu, besleme hataları. |

| Hassasiyet ve Kalite | Çeşitli profillerde, titreşimlerde toleransı korumada zorluk. | Artan hurda oranları, yeniden işleme, tutarsız ürün kalitesi. |

| Operatör Beceri Bariyeri | Çeşitli işlemler ve sorun giderme için kapsamlı eğitim gereklidir. | Yüksek eğitim maliyetleri, personel değişiminde zorluk, daha yüksek ücretler. |

Beceri Açığı ve Eğitim Yükü

Geleneksel makinelerde çok şekilli kesimden kaynaklanan en büyük zorluklardan biri, operatörler arasında yarattığı önemli beceri açığı ve bunun işletmeler üzerindeki eğitim yüküdür. Çeşitli boru şekilleri için sürekli manuel ayarlamalar ve karmaşık programlama gerektiren karmaşık makinelerin çalıştırılması, genellikle kapsamlı ve zaman alıcı eğitimlerle edinilen yüksek düzeyde teknik yeterlilik gerektirir. Ahmed Al-Farsi'nin deneyimi bu sıkıntılı noktanın altını çiziyor: "Önceki makineler yetenekli CAD operatörleri gerektiriyordu" ve "yüksek operatör devri yeniden eğitim yüküne neden oluyordu." Bu sadece anekdotsal bir sorun değil; Ulusal İmalatçılar Birliği'nin yakın tarihli bir raporu, şirketlerin 60%'sinin ileri imalat rolleri için gerekli becerilere sahip çalışanlar bulmakta zorlandığını vurguladı.

Yüksek vasıflı personele olan bu bağımlılık, doğrudan daha yüksek işçilik maliyetleri ve personel değişimine karşı artan kırılganlık anlamına gelir. Deneyimli bir operatör ayrıldığında, yeni işe alınanların gerekli tüm boru şekillerinde makineyi etkin bir şekilde kullanabilmeleri için genellikle haftalar hatta aylar süren uzun eğitim dönemlerinden geçmeleri gerektiğinden, bilgi açığı üretimi ciddi şekilde aksatabilir. Bu durum, üretkenliğin azalması ve eğitime sürekli yatırım yapılması gibi kısır bir döngüye yol açarak inovasyon veya genişleme için kullanılabilecek kaynakların başka yöne aktarılmasına neden olur. Ayrıca, üretimin artırılması bu tür uzmanlaşmış daha fazla kişinin bulunması ve eğitilmesi anlamına geldiğinden, bir şirketin hızlı ölçeklendirme yeteneğini de sınırlar.

Ayrıca, makinelerin farklı şekiller için sürekli olarak yeniden yapılandırılmasının zorlu doğası, özellikle sıkı teslim tarihleri altında operatör yorgunluğuna ve potansiyel hatalara yol açabilir. Bu insan unsuru, çeşitli üretim çalışmalarında tutarlı kalite ve verimliliğin sürdürülmesinde kritik bir değişken haline gelir. Sonuç olarak, geleneksel çok şekilli kesim makineleriyle ilişkili beceri açığı ve eğitim yükü sadece anlık çıktıyı etkilemekle kalmaz; bir üretim işletmesinin uzun vadeli sürdürülebilirliğini ve büyüme potansiyelini etkileyerek sektörü kullanım kolaylığına ve otomatik uyarlanabilirliğe öncelik veren çözümlere doğru iter.

Modern makineler birden fazla boru şeklini keserDoğru

Çok eksenli özelliklere sahip gelişmiş boru kesme makineleri, uyarlanabilir sistemler aracılığıyla yuvarlak, kare, dikdörtgen ve düzensiz profilleri işleyebilir.

Farklı şekilleri programlamak basittirYanlış

Her yeni boru şekli, geleneksel kurulumlarda iş süresinin 30%'sini oluşturan kesme yollarının ve malzeme telafilerinin karmaşık bir şekilde programlanmasını gerektirir.

Neden bazı makineler farklı boru şekillerini etkili bir şekilde kesmekte zorlanıyor?

Bazı kesme makinelerinin çeşitli boru şekillerinin üstesinden gelirken neden yetersiz kaldığını hiç merak ettiniz mi? Bunun nedeni genellikle sorunsuz adaptasyonu engelleyen temel tasarım sınırlamalarıdır. Bu zorluklar verimliliği ve işinizin ihtiyaç duyduğu çok yönlülüğü doğrudan etkiler.

Birçok makine, sabit bağlama mekanizmaları, uyarlanabilir programlamadan yoksun katı yazılımlar ve tek bir geometri için optimize edilmiş mekanik tasarımlar nedeniyle çeşitli boru şekilleriyle mücadele etmektedir. Bu sınırlamalar verimsizliğe, hassasiyetin azalmasına ve farklı profiller için manuel müdahalenin artmasına neden olur.

Bir makine üreticisi olarak, sektörün ve bununla birlikte çok yönlülük beklentilerinin geliştiğine tanık oldum. Bir makinenin çok şekilli kesimle mücadele etmesinin altında yatan nedenler genellikle makinenin temel mimarisinden, yani makinenin yeteneklerini tanımlayan unsurlardan kaynaklanıyor. Bu sadece bir özellik ekleme meselesi değildir; bütünsel bir tasarım felsefesiyle ilgilidir. Bu sınırlamaları anlamak, gerçekten çok yönlü makineleri gerçeğe dönüştüren ve MZBNL'nin küresel müşterileri gibi işletmeler için manzarayı değiştiren devrim niteliğindeki gelişmeleri takdir etmenin ilk adımıdır. Şimdi birçok sistemi geride tutan teknik suçlulara bakalım.

Tasarım ve Yazılım Sağlamlığı

Birçok metal boru kesme makinesinin farklı boru şekillerinde zorlanmasının başlıca nedenlerinden biri, doğal tasarımları ve yazılım sertlikleridir. Geleneksel makineler genellikle belirli bir boru tipi (tipik olarak yuvarlak) düşünülerek tasarlanır ve bu da aynalar, kılavuzlar ve kesme kafaları gibi mekanik bileşenlerini bu tekil geometri için optimize eder. Kare, dikdörtgen veya oval borular işlenmeye çalışıldığında, bu sabit tasarımlar yetersiz kalır ve yanlış bağlama, yanlış hizalama veya düzensiz kesme gibi sorunlara yol açar. Mükemmel dairesel kavrama için tasarlanan aynalar, dairesel olmayan boruları deforme edebilir veya yeterli stabilite sağlayamayarak hatalı kesimlere ve hatta yüksek hızlı işlemler sırasında malzeme kaymasına neden olabilir.

Bu mekanik katılığı tamamlayan şey, yazılımın esnek olmamasıdır. Eski kontrol sistemleri her yeni boru şekli ve kesim deseni için ayrı bir programlama gerektiriyor. Bu da Ahmed Al-Farsi'nin deneyimlediği gibi, operatörlerin her varyasyon için karmaşık 3D çizimleri manuel olarak oluşturması veya uyarlaması için "yetenekli CAD operatörlerine ihtiyaç duyduğu" anlamına geliyor. Bu tür yazılımlar, boru boyutlarının ve istenen delik modellerinin basit girişine dayalı olarak parametreleri otomatik olarak ayarlamak için sezgisel, uyarlanabilir zekadan yoksundur. Bu durum, uyarlanabilir olmayan yazılımların karmaşık şekiller arasında geçiş yaparken programlama süresini 50%'ye kadar artırabildiğine dikkat çeken 2021 tarihli bir sektör analizinde vurgulandığı gibi, son derece zaman alıcı bir kurulum sürecine yol açıyor.

Dahası, birçok geleneksel makinede entegre çok eksenli kontrolün olmaması, düzensiz şekiller üzerinde karmaşık kesimler gerçekleştirme yeteneklerini kısıtlamaktadır. Kare bir boru üzerindeki basit bir düz kesim yönetilebilir olsa da, karmaşık konturlar, eğimler veya entegre delme işlemleri, birden fazla eksenin hareketini aynı anda ve yüksek hassasiyetle koreograflayabilen gelişmiş bir yazılım gerektirir. Bu düzeyde gelişmişlik olmadan operatörler ikincil işlemler yapmak veya tasarımdan ödün vermek zorunda kalır, bu da makinenin çeşitli projeler için genel kullanımını ve verimini ciddi şekilde sınırlar.

Sıkıştırma ve Besleme Mekanizmalarındaki Sınırlamalar

Bir metal boru kesme makinesinin birden fazla boru şeklini işlemedeki etkinliği büyük ölçüde bağlama ve besleme mekanizmalarına bağlıdır. Birçok geleneksel makine, öncelikle belirli boru çapları ve şekilleri için tasarlanmış aynalar veya mengeneler kullanır, bu da onları geniş bir geometri yelpazesi için uygunsuz veya verimsiz hale getirir. Örneğin, yuvarlak borular için optimize edilmiş dört çeneli bir ayna, ince duvarlı dikdörtgen bir boru üzerinde sabit, deforme olmayan bir kavrama sağlamakta zorlanabilir ve bu da titreşimlere, kaymaya veya ezilmeye yol açabilir. Bu da sık sık manuel ayarlamalar, çenelerin değiştirilmesi ve hatta her yeni boru şekli için özel aparatlar gerektirir ki bu da doğrudan önemli bir duruş süresi ve artan iş yoğunluğu anlamına gelir.

Ayrıca, geleneksel besleme sistemleri genellikle manuel yüklemeye veya çeşitli boru boyutlarını ve şekillerini sorunsuz bir şekilde ele almak için uyarlanabilir zekadan yoksun daha az sofistike otomatik süreçlere dayanır. MZBNL'nin öncülük ettiği gibi, "Geleneksel makineler yandan veya arkadan manuel yüklemeye dayanırken", bu yaklaşım doğası gereği daha az verimlidir ve sürekli değişen boru türleri karışımıyla uğraşırken hatalara daha yatkındır. Manuel bir sistem için çok ağır veya çok uzun olan ya da sabit tasarımlı bir besleyici tarafından uygun şekilde desteklenmeyen bir boru, yanlış hizalamaya, malzeme hasarına ve hatta güvenlik tehlikelerine yol açabilir. Bu yokluk "Önden Beslemeli İnovasyon2" ifadesi, boru tipindeki her değişiklik için verimlilikten ödün verildiği anlamına gelir.

Bu eski mekanizmalarda akıllı geri bildirim sistemlerinin bulunmaması da mücadelelerine katkıda bulunmaktadır. Borunun hassas konumunu, şeklini ve potansiyel deformasyonunu gerçek zamanlı olarak algılayabilen sensörler olmadan, makine otomatik olarak telafi edemez veya sıkıştırma kuvvetini veya besleme hızını ayarlayamaz. Kapalı döngü kontrolünün olmaması, operatörlerin sürekli olarak izlemesi ve müdahale etmesi gerektiği anlamına gelir ki bu da yüksek hacimli, çok şekilli üretim için sürdürülemez bir durumdur. Kapsamlı insan müdahalesi olmadan çeşitli boru şekillerinin otomatik olarak yüklenememesi, doğru bir şekilde kelepçelenememesi ve sorunsuz bir şekilde beslenememesi, birçok geleneksel makinenin gerçek çok yönlülüğünü ve üretkenliğini sınırlayan temel bir kusurdur.

Uyarlanabilir Teknolojilerin Yokluğu

Birçok makinenin çeşitli boru şekillerini etkili bir şekilde kesmesini engelleyen kritik bir faktör, modern uyarlanabilir teknolojilerin olmamasıdır. Eski sistemler tipik olarak, değişen malzeme özelliklerine, et kalınlıklarına veya standart olmayan boru şekillerindeki beklenmedik düzensizliklere otomatik olarak uyum sağlamak için gerekli olan gelişmiş sensörlerden, gerçek zamanlı geri bildirim döngülerinden ve akıllı kontrol algoritmalarından yoksundur. Bu uyarlanabilirlik olmadan, operatörlerin telafi değerlerini manuel olarak girmesi veya test kesimleri yapması gerekir, bu da kurulum sürelerini önemli ölçüde uzatır ve malzeme israfını artırır. Bu durum, MZBNL'nin kesintisiz adaptasyon için tasarlanmış "akıllı ve dijitalleştirilmiş sistemleri" ile tam bir tezat oluşturmaktadır.

Dahası, entegre bir "No-CAD İşletim Sistemi İnovasyonu "nun olmaması büyük bir engeldir. Geleneksel makineler, küçük değişiklikler veya yeni standart boru tipleri için bile operatörleri karmaşık 3D çizimler için tasarım ofisine dönmeye zorlamaktadır. Bu verimsiz iş akışı, yeni boru şekli gereksinimlerine hızlı adaptasyonu temelden engelleyerek üretim çevikliğini doğrudan etkileyen bir darboğaz yaratır. BNL'nin sisteminin izin verdiği gibi standart boru tipleri ve delik desenleri için parametreleri basitçe girme yeteneği, beceri eşiğini ve kurulum süresini önemli ölçüde azaltarak çok yönlülük için bir oyun değiştiricidir.

Son olarak, birçok makinenin sıkıntısı, farklı şekillerde, özellikle de genellikle kullanılamayan kuyruk malzemesi için malzeme kullanımını en üst düzeye çıkaramamaları nedeniyle daha da artmaktadır. Boru başından kesmeye başlayan geleneksel sistemler, kaçınılmaz olarak kullanılamaz bir kalıntı bırakmaktadır. Kesme mantığının arka aynadan hesaplandığı "Sıfır Atık Kuyruk Malzemesi İnovasyonu "nun olmaması, boru şekli ne olursa olsun malzemenin boşa harcanması anlamına gelir. Bu verimsizlik, özellikle pahalı özel alaşımlar veya özel profiller söz konusu olduğunda zamanla daha da artar. Bu tür uyarlanabilir, atık azaltıcı teknolojilerin entegrasyonu, çok yönlü, yüksek performanslı bir makineyi, modern çok şekilli metal imalatının taleplerini karşılamakta zorlanan bir makineden gerçekten ayıran şeydir.

Sabit sıkıştırma şekil çok yönlülüğünü sınırlarDoğru

Geleneksel makinelerde belirli şekiller için tasarlanmış aynalar kullanılır ve bu da standart olmayan profilleri keserken dengesizliğe neden olur.

Ayarlamalar için her zaman CAD gereklidirYanlış

MZBNL gibi modern sistemler, standart boru modifikasyonları için CAD olmadan parametre girişine izin verir.

Makine tasarımındaki yenilikler farklı boru şekillerinin işlenmesini nasıl sağlıyor?

Son teknoloji makine tasarımının her türlü boru şeklini işlemek için geleneksel sınırlamaları nasıl aştığını merak ediyor musunuz? Çığır açan yenilikler, çok yönlülükte devrim yaratarak tek makinelerin çeşitli geometrilere sorunsuz bir şekilde uyum sağlamasına olanak tanıyor. Gerçek esneklik bu şekilde tasarlanır.

Gelişmiş No-CAD işletim sistemleri, son derece uyarlanabilir çok çeneli aynalama mekanizmaları ve gerçek zamanlı geri bildirimli entegre akıllı yazılım dahil olmak üzere makine tasarımındaki yenilikler, metal boru kesme makinelerinin çok çeşitli boru şekillerini yüksek hassasiyet ve minimum kurulumla verimli bir şekilde işlemesini sağlar.

Metal imalat teknolojisinin gelişimine derinden dahil olan biri olarak, makine tasarımındaki ilerlemelerin devrim niteliğinde olduğunu rahatlıkla söyleyebilirim. MZBNL olarak Ar-Ge'ye önemli yatırımlar yaptık ve hedeflenen yeniliklerin bir makinenin yeteneklerini katı uzmanlıktan akışkan çok yönlülüğe nasıl dönüştürebileceğine ilk elden tanık olduk. Bunlar yalnızca artımlı iyileştirmeler değil; makinelerin malzemelerle etkileşim biçiminde temel değişimlerdir ve bir zamanlar birden fazla özel ekipman parçası gerektiren şeyleri tek bir sistemin gerçekleştirmesini sağlar. Ahmed Al-Farsi gibi vizyoner müşteriler de dahil olmak üzere dünya çapındaki imalatçılara karmaşık projeleri benzeri görülmemiş bir kolaylıkla kucaklamaları için güç veren belirli tasarım yeniliklerini inceleyelim.

No-CAD İşletim Sistemi ve Parametre Tabanlı İşleme

Çeşitli boru şekillerinin işlenmesini sağlayan en dönüştürücü tasarım yeniliklerinden biri, MZBNL'nin öncü No-CAD Sistemi ile özetlenen akıllı, parametre tabanlı işletim sistemlerinin geliştirilmesidir. Geleneksel olarak, karmaşık ve hatta standart boru şekillerinin işlenmesi karmaşık 3D CAD çizimleri gerektiriyordu. Bu, boru şeklindeki her yeni tasarım veya varyasyon için (ister yuvarlaktan kare profile geçilsin, isterse sadece delik desenleri değiştirilsin) operatörlerin bir tasarım ofisine dönmesi, çizimleri oluşturması veya değiştirmesi ve ardından bunları makinenin kontrol sistemine aktarması gerektiği anlamına geliyordu. Bu süreç inanılmaz derecede verimsiz ve zaman alıcıydı, yüksek verim ve hızlı prototipleme hedefleyen işletmeler için büyük bir darboğaz görevi görüyordu.

Ancak No-CAD Sistemi bu zahmetli süreci tamamen atlar. Karmaşık çizimlere dayanmak yerine, operatörlerin standart boru tiplerini ve delik modellerini doğrudan makinenin arayüzüne belirli parametreleri girerek işlemesine olanak tanır. Örneğin, bir operatör bir "kare boru" profili seçebilir, kenar uzunluğunu ve et kalınlığını girebilir, ardından istenen delik çapını, konumunu ve miktarını belirleyebilir. Sistemin akıllı algoritmaları daha sonra optimum kesme yolunu ve makine parametrelerini gerçek zamanlı olarak otomatik olarak oluşturur. Bu yenilik, kullanım kolaylığını önemli ölçüde artırarak makineyi daha geniş bir operatör yelpazesi için erişilebilir hale getiriyor ve gereken beceri eşiğini önemli ölçüde düşürüyor. Daha önce "yetenekli CAD operatörleri" ve "yeniden eğitim yüküne neden olan yüksek operatör devri" ihtiyacıyla boğuşan Ahmed Al-Farsi, 15 günlük kapsamlı fabrika eğitimi ihtiyacını yalnızca tek bir günlük yerinde eğitime indirgediği için bunu özellikle çekici bulacaktır.

Bu parametre tabanlı yaklaşım, geometrinin karmaşıklığını basit, kullanıcı dostu girdilere dönüştürdüğü için çok şekilli çok yönlülük için çok önemlidir. Bu, yuvarlak bir borudan dikdörtgen bir boruya, hatta özel bir oval boruya kadar farklı boru şekilleri arasında geçiş yapmanın karmaşık tasarım çalışmaları yerine veri girişi meselesi haline geldiği anlamına gelir. Bu sadece kurulum süresini kısaltmakla kalmaz, aynı zamanda manuel çizim ve programlama ile ilişkili insan hatasını da neredeyse ortadan kaldırır. Bu tür sistemler, yaygın şekil ve desenlerin önceden programlanmış kütüphanelerini içererek süreci daha da hızlandırır. Bunun etkisi çok büyüktür: artan operasyonel çeviklik, azalan işçilik maliyetleri ve farklı üretim taleplerine hızla uyum sağlama yeteneği, tek bir makinenin benzeri görülmemiş çeşitlilikteki boru profillerini yüksek hassasiyetle işlemesini mümkün kılmaktadır.

Gelişmiş Uyarlanabilir Parçalama ve Besleme Sistemleri

Akıllı yazılımın ötesinde, çok yönlü bir boru kesme makinesinin mekanik kalbi, gelişmiş uyarlanabilir ayna ve besleme sistemlerinde yatar. Geleneksel makineler genellikle, tipik olarak yuvarlak olan belirli bir boru şekli için optimize edilmiş sabit veya manuel olarak ayarlanabilen aynalara dayanır. Kare, dikdörtgen veya düzensiz profiller sabitlenmeye çalışıldığında, bu aynalar ya malzemeyi deforme eder, dengesiz kavrama sağlar ya da zaman alıcı manuel ayarlamalar ve özel, şekle özgü aparatların kullanılmasını gerektirir. Bu durum, farklı boru geometrileri arasında geçiş yaparken verimliliği ve hassasiyeti önemli ölçüde engeller.

Ancak modern yenilikçi tasarımlar, çok çeşitli boru şekillerine uyacak şekilde kavrama kuvvetini ve konumunu otomatik olarak ayarlayabilen çok çeneli uyarlanabilir aynalar içerir. Bu aynalar genellikle gelen borunun profilini algılayan ve optimum, deforme olmayan kelepçeleme sağlamak için makinenin kontrol sistemiyle iletişim kuran akıllı algılama özelliklerine sahiptir. Bu sadece yüksek hızlı kesim sırasında üstün stabilite sağlamakla kalmaz, aynı zamanda operatörlerin artık her farklı şekil için aynaları manuel olarak yeniden yapılandırması gerekmediğinden kurulum süresini de en aza indirir. Bu otomasyon seviyesi, "kurulumu ve kullanımı kolay anahtar teslim çözümlere" öncelik veren ve "mevcut manuel iş akışlarını otomatikleştirmek" isteyen Ahmed's gibi işletmeler için kritik önem taşıyor.

Ayrıca, yenilikçi besleme mekanizmaları, örneğin MZBNL'nin optimize edilmiş Önden Beslemeli İnovasyonu3çeşitli boru şekilleri için malzeme işlemede devrim yaratır. Geleneksel sistemler genellikle her yeni boru tipi için önemli ölçüde manuel çaba ve hassas hizalama gerektiren daha az verimli yandan veya arkadan yükleme kullanırken, önden besleme boruyu otomatik olarak önden çeker. Bu tasarım verimliliği önemli ölçüde artırarak besleme verimliliğini yaklaşık 40% artırır ve operatörün iş gücü yoğunluğunu yaklaşık 40% azaltır. Bu, özellikle farklı boru şekillerinin ve uzunluklarının bir karışımını işlerken hayati önem taşır, çünkü darboğazlar olmadan sürekli ve hassas malzeme akışı sağlar. Akıllı ayna ve otomatik, uyarlanabilir besleme sistemlerinin kombinasyonu, tek bir makinenin farklı boru geometrileri arasında, yüklemeden kelepçelemeye ve kesmeye kadar benzersiz bir hız ve doğrulukla sorunsuz bir şekilde geçiş yapabileceği anlamına gelir.

Entegre Akıllı Kontrol ve Sıfır Atık Mantığı

Farklı boru şekillerinin tek bir makinede işlenmesini sağlayan en önemli unsur, MZBNL'nin Sıfır Atık Kuyruk Malzemesi gibi yenilikler de dahil olmak üzere gerçek zamanlı geri bildirim, tahmine dayalı analitik ve gelişmiş kesme mantığı içeren akıllı kontrol sistemlerinin entegrasyonudur. Bu sistemler önceden programlanmış yolları uygulamanın ötesine geçerek malzemeye ve kesme işlemine gerçek zamanlı olarak akıllıca uyum sağlar, çeşitli geometrilerde optimum performans sağlar ve israfı en aza indirir. Geleneksel lazer kesim sistemleri, boru şekli ne olursa olsun, tipik olarak boru başından başlar ve özellikle uzun bir borudan birden fazla kısa parça keserken, işlemin sonunda genellikle kullanılamaz kuyruk malzemesi oluşturur. Bu da önemli ölçüde malzeme kaybına yol açarak karlılığı etkiler.

MZBNL'nin Sıfır Atık Kuyruk Malzemesi İnovasyonu, başlangıç noktası olarak arka aynadan hesaplama yaparak kesme mantığını temelden yeniden tasarlar. Bu, kalan bölüm ürün uzunluğundan daha küçük olduğu sürece sistemin artık kuyruk malzemesini ortadan kaldırmasına olanak tanır ve ister yuvarlak, ister kare veya dikdörtgen olsun, herhangi bir boru şekli için malzeme kullanımını en üst düzeye çıkarır. Bu akıllı optimizasyon, özellikle "yüksek maliyet-performans oranına" değer veren ve operasyonel giderleri azaltmaya çalışan işletmeler için maliyet etkinliği açısından çok önemlidir. Basit bir boru kesme işlemi, böyle bir sistemle malzeme kullanım oranlarının geleneksel 85-90%'den yaklaşık 99%'ye sıçradığını görebilir ve zaman içinde önemli tasarruflar sağlayabilir.

Dahası, modern akıllı kontrol sistemleri farklı boru şekilleri için otomatik yerleştirme, gerçek zamanlı malzeme geri bildirimine dayalı dinamik güç ayarlamaları ve hatta öngörücü bakım uyarıları gibi özellikler içerir. Örneğin, sistem dikdörtgen bir borunun malzemesinde hafif bir anormallik tespit ederse, kaliteyi korumak için lazer gücünü veya kesme hızını otomatik olarak ayarlayabilir, oysa eski bir makine sadece güç vererek potansiyel olarak kusurlu bir kesime neden olabilir. Bu sistemler, kesme işlemlerini sanal olarak simüle edebilir ve herhangi bir malzeme tüketilmeden önce çeşitli şekillerdeki karmaşık kesimlerin önceden doğrulanmasına olanak tanır. Bu akıllı, entegre kontrol seviyesi, tek bir makinenin yalnızca çeşitli boru şekillerini kesebilmesini değil, aynı zamanda bunu maksimum verimlilik, minimum atık ve tutarlı, yüksek hassasiyetle yapabilmesini sağlayarak onu modern metal imalatı için gerçekten çok yönlü ve vazgeçilmez bir varlığa dönüştürür.

No-CAD sistemleri CAD çizimlerini ortadan kaldırırDoğru

No-CAD işletim sistemleri, karmaşık 3D CAD çizimlerine ihtiyaç duymadan parametre tabanlı işlemeye izin vererek verimliliği önemli ölçüde artırır.

Sabit mandrenler farklı boru şekillerinin üstesinden gelirYanlış

Geleneksel sabit aynalar belirli şekillerle sınırlıyken, modern uyarlanabilir çok çeneli aynalar çeşitli geometriler için otomatik olarak ayarlanır.

Çeşitli boru şekilleri için makine performansını optimize etmeye yönelik hangi çözümler mevcut?

Makinenizin sınırlarını zorlamak ve her boru şekli için performansını gerçekten optimize etmek mi istiyorsunuz? Doğru stratejiler ve teknolojik entegrasyonlar, benzeri görülmemiş çok yönlülük ve verimliliğin kilidini açabilir. Daha azıyla yetinmeyin; üretim hatlarınızı güçlendirin.

Çeşitli boru şekilleri için makine performansının optimize edilmesi, otomatik parametre ayarı için gelişmiş yazılımdan yararlanmayı, hızlı değiştirilebilir takım sistemlerini dahil etmeyi, kapsamlı operatör eğitimi uygulamayı, öngörücü bakımdan yararlanmayı ve belirli çok şekilli üretim ihtiyaçlarına göre uyarlanmış özelleştirilmiş makine çözümleri aramayı içerir.

Sahada optimize edilmiş çözümlerin dönüştürücü gücüne tanık olduktan sonra, sadece birden fazla boru şeklini işleyebilen bir makineye sahip olmanın yeterli olmadığını anladım. Gerçek değer, her kesimin hassas, her işlemin verimli ve her geçişin sorunsuz olmasını sağlayarak ondan maksimum performans elde etmekte yatıyor. Bunun için teknolojik öngörü, en iyi operasyonel uygulamalar ve sağlam destek sistemlerinin stratejik bir karışımı gerekir. Bu, Ahmed Al-Farsi'nin iş akışlarını otomatikleştirerek ve "yüksek maliyet-performans oranı" çözümleri talep ederek yapmaya çalıştığı gibi, potansiyeli kâra dönüştürmekle ilgilidir. Bu yüksek performans seviyesine ulaşmanın yollarını keşfedelim.

Özelleştirme ve Modülerlik

Çeşitli boru şekillerinde makine performansını optimize etmek için en etkili çözümlerden biri, makine tasarımında özelleştirme ve modülerliğe odaklanmaktır. Herkese uyan tek bir yaklaşım yerine, aşağıdaki gibi önde gelen üreticiler MZBNL4 makinelerin çok şekilli kesim yeteneklerini geliştirmek için belirli modüllerle yapılandırılabildiği veya yükseltilebildiği özel çözümler sunar. Bu, farklı profil türleri için tasarlanmış bir dizi ayna sistemi arasından seçim yapmayı (örneğin, hızlı bir şekilde değiştirilebilen özel kare boru aynaları veya daha geniş bir kavrama aralığına sahip evrensel uyarlanabilir aynalar) veya özellikle uzun veya ağır dairesel olmayan borular için optimize edilmiş özel besleme sistemlerini seçmeyi içerebilir. Önemli olan, makinenin yeteneklerini müşterinin çeşitli üretim talepleriyle tam olarak eşleştirmektir.

Ahmed Al-Farsi gibi işleri mimari metal işleri ve araç parçalarına kadar genişleyen bir müşteri için "otomatik besleme ve delme özelliklerine sahip bir Lazer Boru Kesme Makinesi" ve "özelleştirme ve satış sonrası eğitim/destek" çok önemlidir. Modüler bir yaklaşım, makinesinin başlangıçta birincil ihtiyaçları için yapılandırılabileceği (örneğin, korkuluklar için yuvarlak ve kare borular), ancak daha sonra tamamen yeni bir makine gerektirmeden özel araç bileşenleri için oval borular gibi daha karmaşık veya düzensiz şekilleri işlemek için ek modüller veya yazılım özellikleri ile kolayca yükseltilebileceği anlamına gelir. Bu ölçeklenebilirlik, ilk yatırımı korur ve uzun vadeli uyarlanabilirlik sağlar.

Ayrıca, özelleştirme yazılıma kadar uzanır. Çeşitli boru şekilleri için optimizasyon, genellikle müşterinin niş ürünlerine özgü benzersiz malzemeler veya zorlu toleranslar için kesme parametrelerine ince ayar yapabilen ısmarlama programlama veya algoritma ayarlamalarını içerir. Örneğin, bir müşteri sıklıkla belirli bir alaşımdan kalın duvarlı dikdörtgen borular işliyorsa, makine üreticisi ısı bozulmasını en aza indiren ve kenar kalitesini en üst düzeye çıkaran önceden optimize edilmiş kesme reçeteleri sağlayabilir. Donanım modülerliğini yazılım esnekliğiyle birleştiren bu özel optimizasyon seviyesi, makinenin sadece farklı şekilleri kesebilmesini değil, aynı zamanda her profil için en yüksek performansı sunarak ve daha yüksek genel üretkenliğe ve ürün kalitesine önemli ölçüde katkıda bulunarak bu konuda mükemmel olmasını sağlar.

Kapsamlı Operatör Eğitimi ve Beceri Geliştirme

En gelişmiş makinelerde bile insan uzmanlığı, çeşitli boru şekilleri için performansı optimize etmede kritik bir faktör olmaya devam etmektedir. Bu nedenle, kapsamlı operatör eğitimi ve sürekli beceri geliştirme vazgeçilmez çözümlerdir. MZBNL gibi yenilikler No-CAD Sistemi5 Öğrenme eğrisini önemli ölçüde azaltarak, operatörlerin makinenin yeteneklerini, sorun giderme prosedürlerini ve farklı geometriler için en iyi uygulamaları tam olarak anlamasını sağlamak, potansiyelini en üst düzeye çıkarır. Bu, temel operasyonel eğitimin ötesine geçerek malzeme bilimi, çeşitli profiller için kesme dinamikleri ve şekiller arasında geçiş yaparken verimli iş akışı yönetiminin anlaşılmasını da kapsar.

"Yüksek operatör devrinin yeniden eğitim yüküne neden olduğu" Ahmed Al-Farsi için basitleştirilmiş, etkili eğitim vurgusu özellikle önemlidir. MZBNL'nin "operatörler artık ekipman fabrikasında 15 gün geçirmek yerine sadece 1 günlük yerinde eğitime ihtiyaç duyuyor" sözü doğrudan bu sorunlu noktaya hitap ediyor. Bu kolaylaştırılmış eğitim, No-CAD sisteminin pratik ve uygulamalı olarak kullanılmasına ve farklı boru şekilleri için parametrelerin hızlı ve doğru bir şekilde nasıl girileceğinin anlaşılmasına odaklanmaktadır. Böylesine verimli bir eğitim, operatörlerin çeşitli üretim çalışmalarını güvenle yönetmelerini sağlayarak kurulum hatalarını azaltır ve çalışma süresini en üst düzeye çıkarır.

İlk eğitimin ötesinde, tazeleme eğitimleri, gelişmiş atölye çalışmaları ve bilgi tabanına erişim yoluyla sürekli beceri geliştirme, operatörlerin yeni özelliklerle güncel kalmasını ve tekniklerini optimize etmesini sağlar. Bu, çok şekilli projeler için gelişmiş yerleştirme stratejileri veya uzaktan tanılama ve sorun giderme araçlarının nasıl kullanılacağı konusunda eğitimi içerebilir. İşletmeler, işgücüne yatırım yaparak son teknoloji makinelerinin her zaman en yüksek verimlilikte çalışmasını sağlar ve bu da işin daha hızlı tamamlanmasına, daha az malzeme israfına ve tüm boru şekillerinde tutarlı bir şekilde yüksek kaliteli çıktı elde edilmesine yol açar. Beceri geliştirmeye yönelik bu bütünsel yaklaşım, operatörleri yalnızca makine kullanıcıları olmaktan çıkarıp optimizasyon sürecinin ayrılmaz parçaları haline getirerek işletmenin kârlılığına ve rekabet gücüne doğrudan katkıda bulunur.

Kestirimci Bakım ve Uzaktan Teşhis

Çeşitli boru şekilleri için makine performansını gerçekten optimize etmek amacıyla, gelişmiş uzaktan tanılama ile birlikte sağlam bir kestirimci bakım stratejisi uygulamak çok önemlidir. Farklı geometrilerin kesilmesi genellikle makine bileşenleri üzerinde farklı baskılar oluşturur. Örneğin, kalın duvarlı kare bir borunun kesilmesi, ince duvarlı yuvarlak bir borunun kesilmesinden farklı olarak belirli parçaları aşındırabilir. Proaktif bakım yapılmadığı takdirde bu farklılıklar beklenmedik arızalara yol açabilir ve özellikle Ahmed Al-Farsi'ninki gibi son teslim tarihleri sıkışık olan işletmeler için üretim programlarını ve genel verimliliği önemli ölçüde etkileyebilir.

Kestirimci bakım, makine bileşenlerinin sağlığını gerçek zamanlı olarak izlemek için sensörleri ve veri analizlerini kullanır. Titreşim, sıcaklık, motor akımı veya kesme kafası performansındaki küçük değişiklikleri tespit ederek olası sorunları büyük arızalara dönüşmeden önce işaret edebilir. Birden fazla boru şeklini işleyen bir makine için bu, sistemin belirli işlemlerin (örneğin, dikdörtgen borularda karmaşık profillerin kesilmesi) belirli parçalarda hızlandırılmış aşınmaya neden olup olmadığını belirleyebileceği ve acil bir arızaya tepki vermek yerine planlı duruş süresi boyunca planlı bakıma izin verebileceği anlamına gelir. Bu, planlanmamış arıza sürelerini önemli ölçüde azaltır ve kritik bileşenlerin ömrünü uzatarak tüm boru tiplerinde tutarlı yüksek performans sağlar.

Uzaktan teşhis, üreticilerin veya servis teknisyenlerinin makine verilerine uzaktan erişmesine olanak tanıyarak bu optimizasyonu daha da geliştirir. Bir operatör yeni bir boru şekline geçerken bir sorunla karşılaşırsa, bir destek ekibi genellikle yerinde bir ziyaret yapmadan sorunu teşhis edebilir ve hatta çözebilir. Bu özellik, "satış sonrası hizmet ve eğitim desteğine" ve "uzaktan tanılamaya" değer veren BAE'deki Ahmed gibi uluslararası müşteriler için paha biçilmezdir. Teknik sorunların hızlı bir şekilde çözülmesini sağlar, üretimdeki kesintileri en aza indirir ve makinenin coğrafi mesafeden bağımsız olarak her boru şekli için en yüksek verimlilikte çalışmaya devam etmesini garanti eder. Bu proaktif bakım ve hızlı uzaktan destek karışımı, potansiyel darboğazları sürekli üretkenliğe dönüştürür.

Modüler makineler çeşitli boru şekillerine uyum sağlarDoğru

Modüler tasarımlar, farklı profilleri verimli bir şekilde işlemek için aynalar ve besleme sistemleri gibi bileşenlerin hızlı bir şekilde değiştirilmesine olanak tanır.

Operatör eğitimi minimum 15 gün sürerYanlış

No-CAD gibi modern sistemler, kolaylaştırılmış arayüzler ve odaklanmış talimatlar sayesinde operatör eğitimini sadece 1 güne indirebilir.

Operatörler birden fazla boru şekli için makine kullanırken hangi en iyi uygulamaları takip etmelidir?

Makinenizin çok yönlülüğünde ustalaşmak ve tüm boru şekillerinde en yüksek performansı sağlamak mı istiyorsunuz? Verimliliği en üst düzeye çıkarmak ve hassasiyeti korumak için belirli en iyi uygulamalara bağlı kalmak çok önemlidir. Kendinizi ve üretiminizi güçlendirin.

Operatörler, farklı boru şekilleri için makine performansını optimize etmek ve tutarlı kaliteyi sağlamak için kapsamlı üretim öncesi planlama, akıllı yazılım özelliklerinden yararlanma, farklı şekillere göre uyarlanmış düzenli kalibrasyon ve bakım, hassas malzeme kullanımı ve sürekli öğrenme gibi en iyi uygulamaları takip etmelidir.

Bir makine üreticisi olarak benim bakış açımdan, en gelişmiş ekipmanın bile ancak onu çalıştıran operatörler kadar iyi olduğunu biliyorum. MZBNL'nin yenilikleri arasında No-CAD Sistemi6 Makinelerimizi son derece kullanıcı dostu hale getirirken, çok şekilli kesimde ustalaşmak temel işlemlerden daha fazlasını gerektirir; iş akışına disiplinli bir yaklaşım ve incelikli en iyi uygulamaların anlaşılmasını gerektirir. Bu, özellikle Ahmed Al-Farsi gibi bitmiş parçaların hassasiyetle teslim edilmesine güvenen müşteriler için güçlü teknolojiyi tutarlı, yüksek kaliteli çıktılara dönüştürmekle ilgilidir. İşlediğiniz her bir boru şeklinde makinenizin performansını yükseltecek temel alışkanlıkları ve prosedürleri inceleyelim.

Kapsamlı Üretim Öncesi Planlama ve Malzeme Hazırlığı

Birden fazla boru şekli için makine kullanan operatörler için en önemli en iyi uygulamalardan biri, kapsamlı üretim öncesi planlama ve titiz malzeme hazırlığıdır. Herhangi bir kesme işlemine başlamadan önce, özellikle de farklı boru geometrileri arasında geçiş yaparken, operatörler iş özelliklerini titizlikle gözden geçirmelidir. Bu, her bir boru şeklinin tam boyutlarının (örneğin yuvarlak için dış çap ve et kalınlığı, kare/dikdörtgen için kenar uzunlukları ve et kalınlığı), malzeme türünün ve gerekli kesim modellerinin doğrulanmasını içerir. Bu ilk inceleme, olası tutarsızlıkların veya zorlukların kesim sürecini etkilemeden önce belirlenmesine yardımcı olarak maliyetli hataları ve malzeme israfını azaltır.

Ayrıca planlama, özellikle farklı şekillerde birden fazla parça üretecek uzun borular için malzeme kullanımının optimize edilmesini içermelidir. Operatörler, birden fazla parça tasarımını (farklı şekiller için bile) tek bir boru üzerinde verimli bir şekilde düzenlemek ve hurda malzemeyi en aza indirmek için makinenin yerleştirme özelliklerinden yararlanmalıdır. MZBNL'nin Sıfır Atık Kuyruk Malzemesi İnovasyonu7 burada önemli bir yardımcıdır, çünkü kesim mantığının arka aynadan hesaplanmasına olanak tanıyarak artık kuyruk malzemesini neredeyse ortadan kaldırır. Operatörler, pahalı malzemenin her santimetresinin hesaba katılmasını sağlamak için bu özelliği tam potansiyeliyle kullanacak şekilde eğitilmelidir. Örneğin, Ahmed'in ekibi mimari korkuluklar için kare borulardan oluşan bir parti üretip daha sonra araç parçaları için yuvarlak borulara geçtiğinde, dikkatli bir yerleştirme her ikisini de minimum atıkla sürekli bir iş akışına entegre edebilir.

Malzeme hazırlığı da aynı derecede hayati önem taşır. Bu, tüplerin temiz olmasını, lazer kesim işlemini engelleyebilecek veya optiklere zarar verebilecek pas, döküntü veya aşırı yağlayıcı içermemesini sağlamayı içerir. Borular ayrıca, özellikle taşıma sırasında deformasyona daha yatkın olan dairesel olmayan profillerde besleme sorunlarını veya hatalı kesimleri önlemek için düz ve belirtilen toleranslar dahilinde olmalıdır. Makineye dikkatli yükleme de dahil olmak üzere malzemenin doğru şekilde taşınması, tüplerin hasar görmesini veya yanlış hizalanmasını önler; bu da özellikle ağır veya uzun, düzensiz şekilli borularla çalışırken zor olabilir. Kapsamlı planlama ve hazırlık için harcanan birkaç dakika, makinenin her boru şekli için en iyi performansı göstermesini sağlayarak saatlerce süren yeniden işleme ve önemli malzeme maliyetlerinden tasarruf sağlayabilir.

Düzenli Kalibrasyon ve Önleyici Bakım

Birden fazla boru şeklini işleyen makineler için düzenli kalibrasyon ve proaktif önleyici bakım, tartışmasız en iyi uygulamalardır. Farklı boru geometrileri, makine bileşenleri üzerinde farklı gerilimlere ve aşınma modellerine yol açabilir. Örneğin, sıkıştırma çeneleri ince duvarlı dikdörtgen bir boru ile sağlam bir yuvarlak boruyu sabitlerken farklı basınçlara maruz kalabilir. Tüm şekillerde tutarlı ve yüksek hassasiyetli kesim, makinenin eksenlerinin, aynalarının ve lazer kafasının mükemmel şekilde kalibre edilmesini gerektirir. Operatörler, aynaların doğru şekilde kavradığından, lazer hizalamasının hassas olduğundan ve tüm hareketli parçaların aşırı oynama olmadan sorunsuz çalıştığından emin olmak için üreticinin önerdiği şekilde günlük veya haftalık kontroller yapmalıdır.

Önleyici bakım basit kontrollerin ötesine geçer; hareketli parçaların planlı yağlanmasını, optik bileşenlerin temizlenmesini ve yıpranan parçaların zamanında değiştirilmesini içerir. Bu proaktif yaklaşım, makinenin çeşitli üretim taleplerine uyum sağlaması gerektiğinde özellikle yıkıcı olan küçük sorunların büyük arızalara dönüşmesini önler. Ahmed'inki gibi "yedek parça bulunabilirliğine ve uzaktan arıza teşhisine" önem veren bir işletme için, üreticinin bakım programına uyulması makinenin uzun ömürlü olmasını ve tutarlı performans göstermesini sağlar. Bakımın ihmal edilmesi kesim kalitesinin düşmesine, malzeme israfının artmasına ve duruş süresinin uzamasına yol açarak, çeşitli ürün portföyü ile çalışırken karlılığı ciddi şekilde etkileyebilir.

Ayrıca operatörler, çok şekilli kesime özgü olası sorunların işaretlerini tanıyacak şekilde eğitilmelidir. Örneğin, bir kare boru kesiminde bir tarafta tutarlı bir eğim görülürken diğer tarafta görülmüyorsa bu durum aynanın kavrama kuvvetiyle ilgili bir kalibrasyon sorununa veya kesme kafasında dairesel olmayan profil nedeniyle daha da kötüleşen bir hiza bozukluğuna işaret ediyor olabilir. Operatörler bu gözlemleri belgeleyerek ve bakım ekiplerine derhal ileterek optimum makine performansının sürdürülmesinde çok önemli bir rol oynar. Düzenli, şekilden bağımsız kalibrasyon ve özenli önleyici bakım, makinenin her boru şekli için güvenilir, yüksek kaliteli kesimler yapmasını sağlayarak çalışma süresini ve yatırım getirisini en üst düzeye çıkarır.

Akıllı Özelliklerden ve Sürekli Öğrenmeden Yararlanma

Birden fazla boru şekli için makineleri kullanırken performansı gerçekten optimize etmek için operatörler makinenin akıllı özelliklerinden tam olarak yararlanmalı ve sürekli öğrenmeyi taahhüt etmelidir. MZBNL'ninkiler gibi modern lazer boru kesme makineleri, gelişmiş dijital sistemler, sezgisel arayüzler ve çok yönlülüğü artırmak için tasarlanmış özelliklerle donatılmıştır. Operatörler, manuel geçici çözümlere veya modası geçmiş yöntemlere başvurmak yerine, çok çeşitli standart ve hatta özel boru şekilleri için parametreleri nasıl hızlı bir şekilde gireceklerini anlayarak No-CAD İşletim Sisteminin her yönüne aşina olmalıdır. Bu, karışık boru şekli partileri için otomatik yerleştirme ve sapmaları anında belirleyebilen gerçek zamanlı süreç izleme gibi özellikleri keşfetmeyi içerir.

Örneğin, makine, malzeme kalınlığı veya iç gerilime ilişkin gerçek zamanlı geri bildirime dayalı olarak lazer gücünü ve hızını ayarlayan uyarlanabilir kesme parametrelerine sahipse, operatörler bu işlevleri nasıl etkinleştireceklerini ve izleyeceklerini bilmelidir. Bu, optimum kesim kalitesi sağlar ve örneğin ince duvarlı yuvarlak bir borudan sağlam bir dikdörtgen profile geçerken israfı en aza indirir. Kombine kesme ve delme işlemlerine olanak tanıyan entegre "çoklu işlem entegrasyonu" özelliği de operatörlerin maksimum verimlilik ve hassasiyet elde etmek için farklı boru şekilleri için optimum sıraları ve parametreleri anlamasını gerektirir. Operatörler bu akıllı özellikleri kullanarak çok yönlü bir makineyi akıllıca kontrol edilen bir üretim merkezine dönüştürür.

Son olarak, sürekli öğrenme çok önemlidir. Metal imalat teknolojisi alanı, düzenli olarak ortaya çıkan yazılım güncellemeleri, yeni işlevler ve geliştirilmiş en iyi uygulamalarla sürekli olarak gelişmektedir. Operatörler üreticiler tarafından sağlanan sürekli eğitimlere aktif olarak katılmalı, çevrimiçi forumlara katılmalı ve güncellenmiş belgeleri incelemelidir. Bölgesel bir distribütör olmayı bile düşünen Ahmed için, teknolojik anlayışın ön saflarında yer almak, ekibinin makinelerinden her zaman maksimum potansiyeli elde edebilmesini sağlıyor. Operatörler yeni özellikleri benimseyerek, gelişmiş tanılama mesajlarını anlayarak ve iş akışlarını uyarlayarak makinelerinin akla gelebilecek her boru şekli için sürekli olarak yüksek kaliteli, verimli çıktılar sunmasını sağlayabilir ve işletmenin pazardaki rekabet avantajını sağlamlaştırabilir.

Üretim öncesi planlama israfı azaltırDoğru

Kapsamlı planlama ve malzeme hazırlığı, özellikle birden fazla boru şeklini keserken malzeme kullanımını optimize etmeye ve hurdayı en aza indirmeye yardımcı olur.

Kalibrasyon sadece yıllık olarak gereklidirYanlış

Hassasiyeti korumak ve değişen aşınma modellerini hesaba katmak için birden fazla boru şeklini kullanırken düzenli kalibrasyon (günlük/haftalık) şarttır.

Sonuç

Tek bir metal boru kesme makinesi, MZBNL'nin No-CAD sistemi, uyarlanabilir aynalar ve akıllı kontrol gibi yenilikler sayesinde birden fazla boru şeklini gerçekten işleyebilir. Bu gelişmeler, geleneksel sınırlamaların üstesinden gelerek gelişmiş çok yönlülük, verimlilik ve malzeme kullanımı sunmakta ve nihayetinde Ahmed's gibi işletmelerin çeşitli imalat pazarlarında gelişmesini sağlamaktadır.

-

Üretim çevikliğinin maliyet tasarrufu ve pazara daha hızlı yanıt verme gibi avantajlarını keşfedin. ↩

-

Önden besleme inovasyonunun verimliliği nasıl artırdığını ve manuel çabayı nasıl azalttığını keşfedin ↩

-

Gelişmiş malzeme taşıma ve bunun üretkenlik üzerindeki etkisi hakkında bilgi edinin ↩

-

Çok şekilli kesim yeteneklerini geliştirmeye yönelik özel çözümler hakkında bilgi edinin ↩

-

No-CAD Sisteminin birden fazla boru şekli için eğitimi ve çalışmayı nasıl basitleştirdiğini anlayın ↩

-

Bu sistemin kullanıcı dostu makine kullanımındaki avantajı hakkında bilgi edinin ↩

-

Bu yeniliğin atıkları nasıl azalttığını ve malzeme kullanımını nasıl iyileştirdiğini keşfedin ↩

Sorularınız mı var veya daha fazla bilgiye mi ihtiyacınız var?

Kişiselleştirilmiş yardım ve uzman tavsiyesi için bizimle iletişime geçin.