Tüp Lazer Kesim Makinelerinde Kuyruk Atığı Azaltımını Anlama

Are you struggling with excessive material waste and soaring production costs in your tube laser cutting operations? The hidden culprit might be inefficient tail material handling. This common challenge can significantly impact your bottom line, but I've dedicated MZBNL's innovations to finding a smarter way forward.

Tail waste reduction in tube laser cutting refers to strategies and technologies aimed at minimizing unusable material left at the end of a tube. By optimizing cutting logic and machine design, manufacturers can significantly enhance material utilization, reduce scrap, and lower operational expenses, ultimately boosting overall efficiency.

tail waste impact in tube laser cutting1 has been witnessed firsthand at MZBNL. From small workshops to large-scale enterprises, this overlooked inefficiency chips away at profitability. Let's delve into how innovative solutions can transform your production, turning wasted material into saved resources and increased revenue, ultimately giving you a competitive edge.

For years, the industry often accepted tail waste as an inevitable byproduct of tube laser cutting. However, embracing critical thinking, we at MZBNL questioned this assumption. While traditional methods frequently prioritize processing speed, they often overlook the cumulative financial drain of discarded material over thousands of cuts. Consider a factory like Ahmed Al-Farsi’s in the UAE, actively expanding into architectural metalwork and vehicle parts supply. Even a small percentage of material waste per tube accumulates rapidly, directly impacting project profitability. material costs in metal fabrication2 can constitute a significant portion, sometimes up to 60%, of total production expenses. Therefore, any reduction in waste directly translates to substantial savings and improved margins. My team and I have dedicated MZBNL's R&D efforts to challenging these conventional approaches, developing cutting-edge solutions that redefine efficiency and material utilization, helping our clients like Ahmed achieve better financial outcomes.

What is the issue of tail waste in tube laser cutting machines?

Are you puzzled by the exact nature of "tail waste" in your tube laser cutting operations? This seemingly minor issue often leads to significant material losses and operational headaches. Understanding its definition is the first step towards unlocking substantial cost savings and improving your production line's sustainability.

Tail waste in tube laser cutting refers to the unusable, short segment of material remaining at the end of a tube after all desired parts have been cut. This remnant is often too small or improperly clamped for further processing, leading to its disposal and contributing to material costs and environmental impact.

Knowing what tail waste is crucial, but recognizing its pervasive impact is even more critical. Ahmed Al-Farsi, a successful business owner in the UAE with over 100 staff, once shared his frustration with me regarding the seemingly small pieces of tube material piling up in his scrap bins. He realized that while each individual piece was insignificant, their cumulative volume over a month represented a considerable financial drain. This isn't just about throwing away material; it's about the lost potential, the reduced profitability, and the environmental footprint of inefficiency. The challenge lies not only in identifying the waste but in understanding tail waste's impact on productivity3 and material utilization across the entire production cycle, demanding a proactive approach to optimize every millimeter of costly raw material. My goal at MZBNL is to empower businesses like Ahmed's to overcome this challenge effectively.

Defining the "Uncut Remnant" and Its Economic Impact

Tail waste fundamentally refers to the portion of the tube that cannot be fully processed by the laser cutting machine’s chuck system, typically due to clamping limitations or safety clearances at the end of the cutting path. In conventional designs, once the cutting head reaches the end of the tube, a certain length, often ranging from 100mm to 300mm or even more depending on the machine’s design and the tube diameter, becomes unusable. This "uncut remnant" is then discarded. From an economic perspective, this is pure loss. Consider a manufacturer producing 100,000 components annually from tubes. If each tube yields 150mm of unusable tail material, and a typical tube length is 6 meters, this translates to thousands of meters of wasted raw material over a year. For a mid-sized factory like Ahmed’s, dealing with diverse projects from architectural railings to automotive parts, the accumulated cost can be substantial. For example, if a ton of steel tubing costs $800, and a 5% waste rate occurs due to tail ends, that’s $40 per ton directly lost, which quickly escalates to tens of thousands of dollars annually across a high-volume operation.

The impact isn't just monetary; it affects operational efficiency and sustainability. Processing waste material requires energy, labor for handling, and disposal costs, none of which contribute to the final product. Businesses are increasingly scrutinizing every aspect of their operations, and this includes material utilization. My conversations with clients, especially those in regions with strict environmental regulations or high material costs, consistently highlight the need for solutions that not only cut parts but also maximize the value from every piece of raw material. This critical perspective moves beyond simply "making a part" to "optimizing the entire material lifecycle" within the fabrication process.

The Cumulative Effect of Seemingly Small Losses

While an individual piece of tail waste might appear insignificant, its cumulative effect over time, especially in high-volume production, is staggering. For instance, if a company processes 1,000 tubes per day, and each tube has a 200mm tail waste, that's 200 meters of material lost daily. Over a year, this equates to 50,000 meters of wasted tubing – enough to build significant structures or hundreds of thousands of small components. This is precisely the pain point Ahmed Al-Farsi discussed with me. His company's expanding projects, from large-scale architectural frameworks to intricate vehicle parts, mean a continuous demand for tube processing. The challenge wasn't just about the occasional scrap; it was about the constant, predictable loss that eroded his profit margins. He recognized that traditional machines, which always left a tail, were inherently inefficient for his business model.

This cumulative loss also extends beyond material costs to affect production scheduling and inventory management. Businesses might have to order more raw material than necessary to account for waste, leading to higher inventory holding costs and potentially longer lead times. Furthermore, the disposal of these metal scraps isn’t free; it involves labor for collection, storage space, and often transportation costs to recycling facilities. A critical analysis reveals that the "small" tail waste creates a ripple effect throughout the entire supply chain and production ecosystem. My team at MZBNL understood that addressing this required a fundamental shift in machine design and cutting logic, moving beyond incremental improvements to a truly innovative solution that challenged established industry norms.

The MZBNL Innovation: Redefining "Zero Waste"

At MZBNL, we developed our "Zero-Waste Tail Material Innovation" precisely to address this fundamental flaw in traditional tube laser cutting. Unlike conventional systems that start cutting from the tube head and generate unusable tail material at the end, our redesigned cutting logic calculates from the rear chuck as the origin. This allows the system to eliminate leftover tail material as long as the remaining section is smaller than the product length. This revolutionary approach maximizes material utilization and dramatically boosts cutting efficiency. For a client like Ahmed, who prioritizes high cost-performance ratio and automation, this feature directly translates into tangible savings and increased competitiveness.

This table illustrates the potential savings for a typical customer processing 500 tubes per day:

| Metric | Traditional System (200mm Tail Waste) | MZBNL Zero-Waste System | Savings / Improvement |

|---|---|---|---|

| Tail Waste per Tube | 200 mm | 0-X mm (minimal) | Significant Reduction |

| Annual Waste (500 tubes/day) | 25,000 meters | < 500 meters | > 98% reduction |

| Material Cost Savings | $X (high) | $Y (low) | Substantial |

| Production Efficiency | Standard | Enhanced | Higher Output |

| Scrap Disposal Costs | Present | Minimal | Near Elimination |

The critical implication here is not just about reducing waste, but about enabling a more sustainable and profitable manufacturing model. By eliminating what was once deemed an unavoidable byproduct, MZBNL empowers businesses to achieve greater resource efficiency and reduce their environmental footprint, aligning perfectly with modern industry demands for sustainable practices. This innovative thinking underpins MZBNL's commitment to delivering tailored solutions that truly solve our clients' deep-seated operational pain points, setting us apart in the global metal fabrication machinery market.

Tail waste reduces profitabilityDoğru

Even small tail waste accumulates significantly over time, directly impacting material costs and operational efficiency.

Tail waste is unavoidableYanlış

Innovative solutions like MZBNL's Zero-Waste system demonstrate tail waste can be virtually eliminated through optimized machine design.

What causes tail waste in these cutting processes?

Have you ever wondered why your tube laser cutting machine inevitably leaves behind unusable tail material? Understanding the root causes of tail waste is crucial for any business aiming to optimize its operations and minimize costly material losses. Let's explore the technical limitations and operational factors contributing to this common industry challenge.

Tail waste in tube laser cutting is primarily caused by the limitations of machine chucks and clamping mechanisms, which require a certain length of material for stable gripping and rotation. Additionally, safety clearances, optical path stability, and traditional programming logic that prioritizes front-end processing also contribute to these unusable remnants.

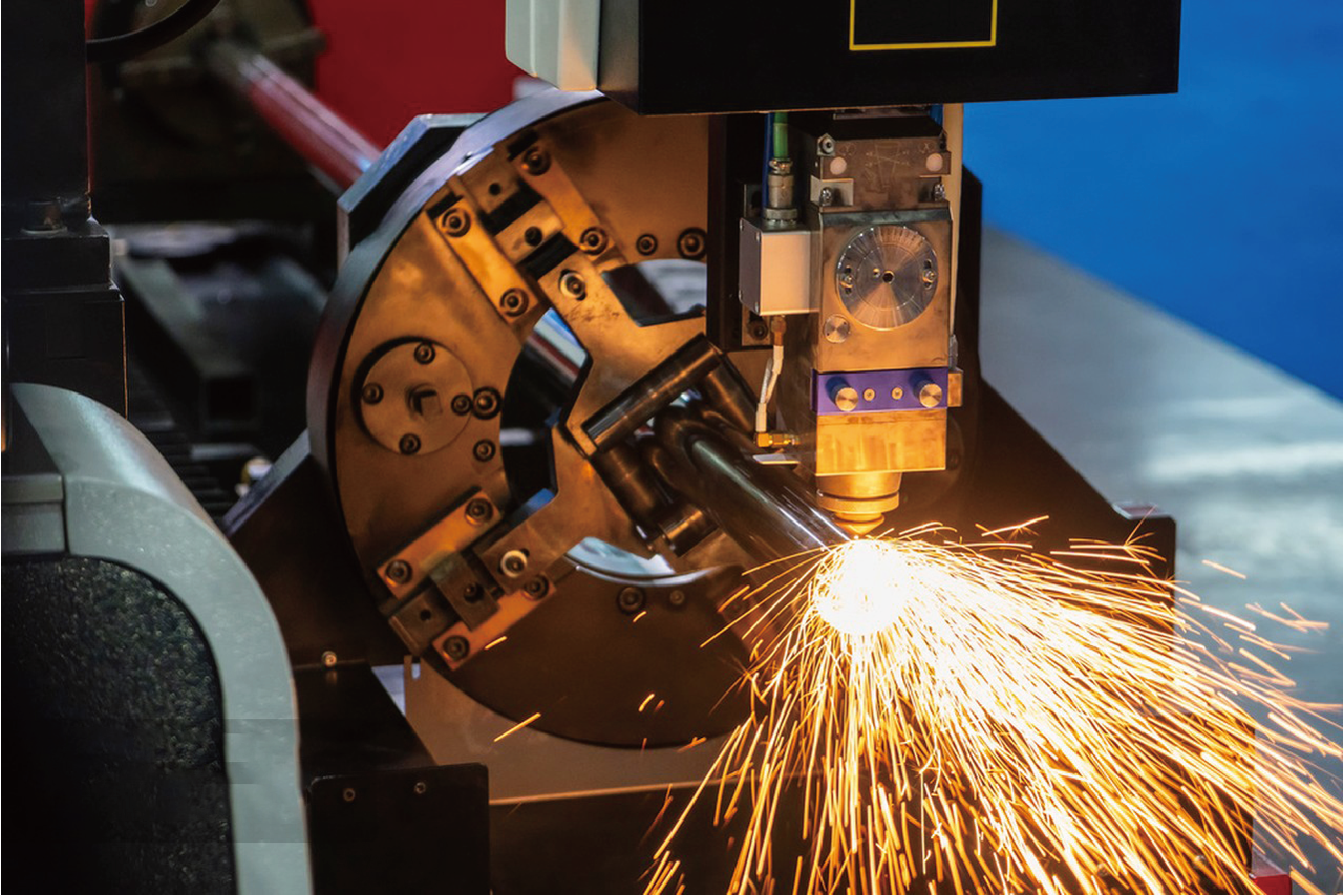

Delving deeper into the 'why' behind tail waste reveals a combination of mechanical constraints and outdated programming methodologies. My conversations with engineers and factory owners, including those at Ahmed Al-Farsi’s facility in the UAE, often highlight the frustration of these seemingly unavoidable losses. While some argue that these limitations are simply "how machines work," I believe that's where innovation truly steps in. Traditional machine designs necessitate a certain amount of material within the chuck for secure rotation and accurate cutting, meaning the very end of the tube becomes inaccessible. This inherent design constraint has long been accepted as a necessary evil, but at MZBNL, we challenged this assumption, recognizing that overcoming these limitations was key to unlocking a new level of efficiency and profitability for our clients. We needed to fundamentally rethink the entire cutting process.

Mechanical Constraints and Clamping Limitations

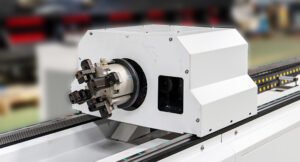

The primary technical cause of tail waste lies in the mechanical design of traditional tube laser cutting machines, specifically their chuck systems. To ensure stable rotation and precise cutting, the tube must be securely gripped by the chucks, often one at the front and one at the rear. This gripping action requires a minimum length of material to be contained within the chuck jaws. As the cutting process progresses towards the end of the tube, there comes a point where the remaining length is too short to be safely and effectively held by the chuck, or it falls within the 'dead zone' required for chuck movement or laser head clearance. For instance, if a machine requires 150mm for secure clamping, then the last 150mm of every tube becomes inaccessible for cutting, regardless of whether a part could theoretically fit there. This structural limitation is inherent to many conventional designs.

Furthermore, some machines utilize multiple chucks that move along the tube. While this can extend the cutting range, it still leaves a certain amount of material between the moving chucks and the end of the tube that cannot be processed. These limitations are not arbitrary; they are critical for maintaining cutting accuracy, preventing vibrations, and ensuring operator safety. However, accepting them as immutable presents a barrier to true material optimization. This is a challenge Ahmed Al-Farsi has explicitly sought to overcome, as his diverse product portfolio means even short remnants could potentially yield valuable, smaller components if only they could be processed. He specifically requested machines capable of maximizing every inch of raw material, a demand MZBNL was uniquely positioned to meet with our advanced technological approach.

Traditional Programming Logic and Operational Practices

Beyond mechanical constraints, conventional programming logic and operational practices4 also contribute significantly to tail waste. Many older laser cutting software systems are designed to initiate cuts from the front of the tube and proceed sequentially towards the rear. This "front-first" approach means that as the material length diminishes, the system naturally leaves the remaining short segment at the end of the process. This programming bias often doesn't account for the potential to utilize smaller, residual lengths, assuming that any material below a certain threshold is unusable. This is often due to the complexity of re-nesting or re-orienting parts for short remnants. The operational practice of discarding these tails is therefore built into the workflow, creating an embedded inefficiency.

This mindset overlooks the opportunity to integrate advanced nesting algorithms that can strategically place smaller parts at the end of the tube, or to re-evaluate the cutting origin. For example, if a machine could cut from the rear chuck forward, or if it could process the entire tube length by shifting the origin, a significant amount of waste could be avoided. This is a critical point of divergence between traditional and advanced systems. My experience has shown that many businesses, even those investing in new machinery, don't critically examine their software's default behaviors, often missing out on substantial material savings. This is why MZBNL’s "Zero-Waste Tail Material Innovation" is not just a hardware upgrade but a fundamental shift in programming logic.

Overcoming the "Unavoidable" with MZBNL's Innovation

At MZBNL, we fundamentally challenged the notion that tail waste is "unavoidable." Our "Zero-Waste Tail Material Innovation" directly addresses both mechanical and programming limitations. We redesigned the cutting logic to calculate from the rear chuck as the origin. This allows the system to effectively 'pull' the tube and cut from the back, utilizing nearly the entire length of the material. As long as the remaining section is smaller than the product length, our system can eliminate leftover tail material by integrating it into the last possible cut. This innovative approach maximizes material utilization and dramatically boosts cutting efficiency. For Ahmed Al-Farsi, this means his Laser Tube Cutting Machine with automatic feeding and punching capabilities can now deliver more finished parts from the same amount of raw material, directly impacting his profit model for contract-based fabrication services.

The impact of this innovation is profound. Instead of simply accepting an industry standard of 100mm to 300mm of waste per tube, our clients can achieve near-zero waste for many operations. This not only reduces material costs but also decreases the volume of scrap to be managed and disposed of, contributing to a cleaner, more sustainable manufacturing process. This forward-thinking design, which integrates multi-process capabilities, offers a comprehensive solution for businesses seeking to automate and optimize their existing manual workflows. It positions MZBNL as a leader in delivering truly cost-effective customized solutions that challenge the status quo of metal fabrication, offering a significant competitive advantage to our global enterprise clients.

Chuck limitations cause tail wasteDoğru

Traditional tube laser cutting machines require minimum material length for stable gripping, creating unavoidable waste at tube ends.

All tail waste is unusableYanlış

With advanced programming and machine design, tail material can often be utilized for smaller components rather than being wasted.

How does tail waste affect overall production efficiency and material costs?

Have you ever considered the ripple effect of tail waste beyond just discarded material? Its impact extends far beyond the scrap bin, significantly eroding overall production efficiency and driving up material costs. Understanding these compounding effects is vital for any manufacturer committed to lean operations.

Tail waste negatively affects production efficiency by increasing material consumption, necessitating more frequent material handling, and reducing output per tube. It directly elevates material costs through unused remnants, adds to waste disposal expenses, and indirectly impacts profitability by tying up capital in excess inventory and inefficient processes.

The consequences of tail waste are far more insidious than simply throwing away a few inches of metal. From my discussions with manufacturers globally, including potential clients like Ahmed Al-Farsi in the UAE, it's clear that the cumulative impact of these "small" losses can undermine the entire production pipeline. It's not just about the raw material; it's about the labor involved in handling scrap, the energy wasted in processing it, and the lost opportunity to produce more parts from the same input. This inefficiency creates bottlenecks, increases operational overheads, and directly eats into profit margins, making businesses less competitive. My experience at MZBNL has taught me that addressing tail waste5 is not just about environmental responsibility; it's a strategic imperative for financial health and operational excellence, directly impacting the bottom line.

Direct Financial Drain: Material and Disposal Costs

The most immediate and obvious impact of tail waste is the direct financial drain it imposes through material costs. Every centimeter of unusable material represents raw capital literally thrown away. For high-volume producers, this adds up alarmingly quickly. Let's revisit Ahmed Al-Farsi's business, which regularly processes various tube sizes for architectural elements and automotive components. If his team processes, say, 10,000 meters of tubing monthly, and a traditional machine yields 5% tail waste, that’s 500 meters of material lost. At an average cost of $2-$5 per meter for specialized steel tubing, this could mean $1,000-$2,500 in direct material loss each month, totaling $12,000-$30,000 annually. This figure escalates significantly for more expensive or specialized alloys.

Beyond the cost of the material itself, there are the associated disposal costs. While metal scrap can be recycled, the process isn't free. It involves labor for collecting, sorting, and transporting the scrap, as well as potential fees charged by recycling facilities or lost revenue from less-than-optimal scrap prices. These seemingly minor overheads, when combined with the direct material loss, create a substantial recurring expense that directly reduces profitability. Companies often overlook these "hidden" costs, assuming they are unavoidable. However, a critical analysis, which I often conduct with our prospective clients, reveals that these expenses are often significantly higher than anticipated, providing a compelling case for investing in technologies that minimize waste. My team at MZBNL recognized this direct financial burden as a critical problem that needed a novel solution.

Reduced Overall Production Efficiency

Tail waste doesn't just cost money; it also impacts overall production efficiency in several ways. Firstly, it means that for every full tube loaded, a portion of its potential output is lost. This effectively reduces the "yield" per raw material stick. To meet production targets, more tubes must be purchased and processed, which translates to increased material handling, more loading/unloading cycles, and higher energy consumption per finished part. For a high-speed operation, even minor increases in cycle times due to waste management can accumulate into significant delays. Consider a scenario where a machine needs to produce 10,000 parts. If each tube yields one less part due to tail waste, the machine must process significantly more tubes, leading to extended run times, increased wear and tear on components, and higher electricity usage.

Secondly, managing tail waste adds non-value-added steps to the production process. Operators must clear the discarded remnants from the machine, transport them to scrap bins, and manage their disposal. These are tasks that consume valuable labor time which could otherwise be used for productive activities like quality control, machine maintenance, or preparing the next batch of raw materials. This aspect of inefficiency was particularly important for Ahmed Al-Farsi, whose business aims to automate existing manual workflows. His goal is to reduce operator labor intensity and increase overall productivity, making solutions like MZBNL's "Front-Feeding Innovation"6 and "Zero-Waste Tail Material Innovation" highly attractive because they directly address these operational bottlenecks. The shift from side/rear manual loading to optimized front-feeding, for instance, boosts efficiency by 40% and reduces operator labor intensity by 40%, demonstrating MZBNL's holistic approach to improving production efficiency.

Impact on Competitive Advantage and Sustainability

In today's competitive global market, every incremental saving and efficiency gain contributes to a stronger competitive advantage. Businesses that can produce parts with less material waste inherently have lower per-unit costs, allowing them to offer more competitive pricing or achieve higher profit margins. For instance, if MZBNL's Zero-Waste Tail Material Innovation helps a company reduce its material consumption by 5%, this directly translates to a 5% cost advantage on raw materials compared to competitors using traditional methods. This is particularly crucial for contract-based fabrication services like Ahmed’s, where bids are often tight and material costs are a major factor. The ability to quote more competitively, especially in markets like Southeast Asia and the Middle East, where MZBNL actively exports, can win new contracts and expand market share.

Moreover, sustainability is no longer just a buzzword; it's a strategic imperative for businesses, especially those seeking long-term stability and positive public image. Reducing tail waste aligns perfectly with environmental goals by minimizing resource consumption and decreasing the carbon footprint associated with material production and waste disposal. Companies adopting such practices can leverage their "green" credentials to appeal to environmentally conscious clients and meet increasingly stringent regulatory requirements. This dual benefit of financial gain and environmental responsibility positions companies like MZBNL, and by extension, our clients, as industry leaders committed to future-proof manufacturing. It shows a commitment to not just producing, but to producing smartly and responsibly.

Tail waste increases material costsDoğru

Unused remnants and disposal expenses directly raise material costs, as shown in the example of $12,000-$30,000 annual loss.

Tail waste improves efficiencyYanlış

Tail waste actually reduces efficiency by requiring more material handling and creating non-value-added work for operators.

What solutions exist to minimize or eliminate tail waste in tube laser cutting?

Are you searching for effective ways to combat the persistent problem of tail waste in your tube laser cutting operations? While the challenge is widespread, innovative solutions do exist that can dramatically minimize or even eliminate these costly remnants. Let's explore the cutting-edge approaches transforming material utilization in the industry.

Solutions to minimize tail waste in tube laser cutting primarily involve advanced machine designs with optimized chuck systems, intelligent nesting software, and innovative cutting logic. These technologies allow for closer-to-zero tail processing, maximizing material utilization by rethinking how tubes are clamped and cut from their very end.

For decades, the industry accepted a certain amount of tail waste as an unavoidable byproduct of tube laser cutting. However, at MZBNL, I firmly believe that stagnation in the face of inefficiency is not an option. My team and I have dedicated significant R&D to challenging these norms, specifically focusing on solutions that push the boundaries of what's possible in material utilization. We recognized that true innovation wasn't just about faster cuts; it was about smarter cuts. For clients like Ahmed Al-Farsi, who value high cost-performance and efficient turnkey solutions, a machine that truly eliminates waste becomes a powerful asset. Let me share how MZBNL’s patented innovations have transformed this challenge into a competitive advantage for our clients globally.

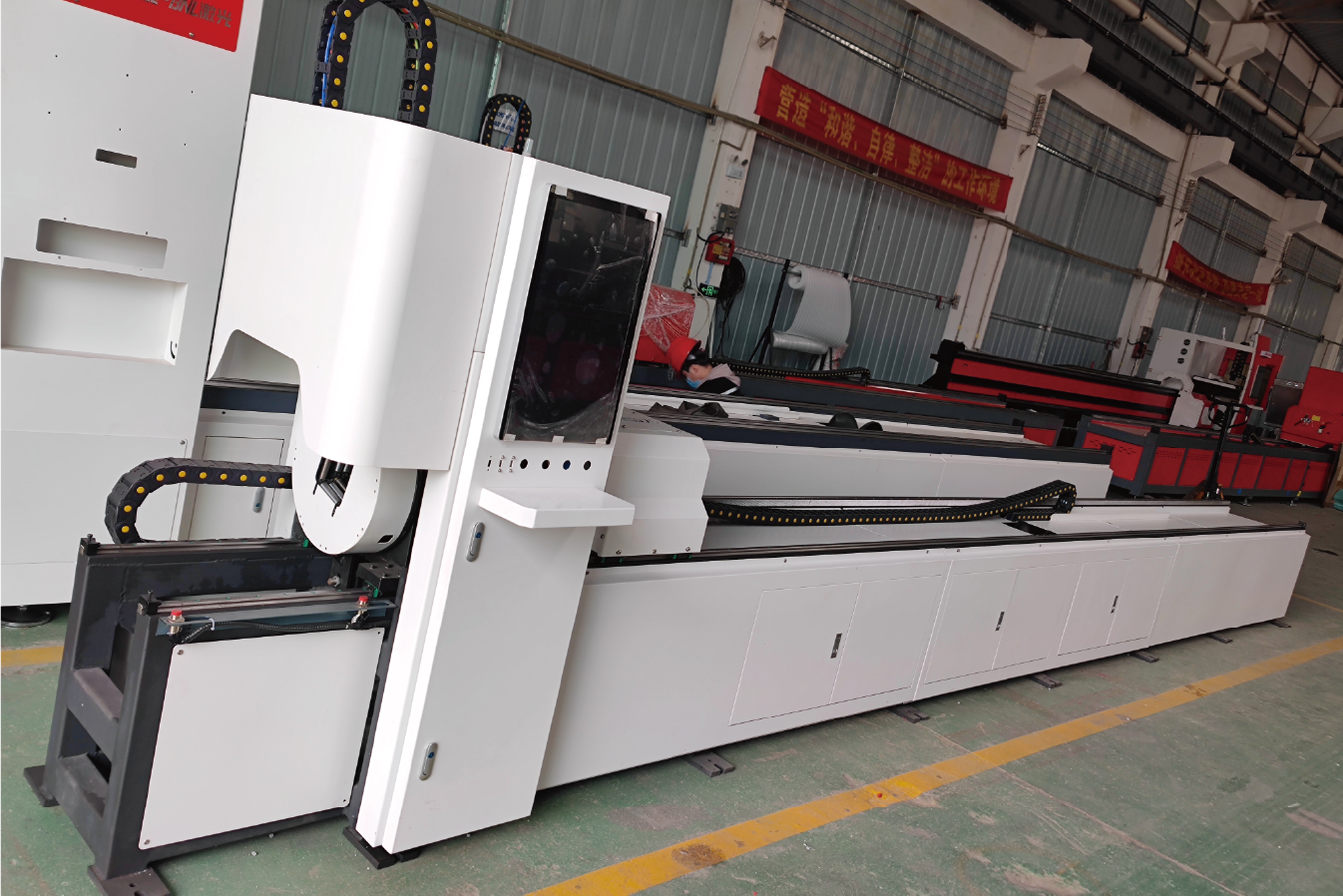

Advanced Chuck Systems and Machine Design Innovations

One of the most impactful solutions to minimize tail waste lies in the evolution of machine design, particularly regarding chuck systems7. Traditional designs necessitate a substantial "dead zone" for chuck clamping and movement, rendering a significant portion of the tube ends unusable. However, advanced machines now incorporate designs that dramatically reduce this dead zone. For instance, some modern systems feature "zero tail" chuck designs where the rear chuck can travel closer to the cutting head, or even pass through it, allowing almost the entire length of the tube to be processed. This is fundamentally different from conventional fixed chucks.

For example, MZBNL's "Zero-Waste Tail Material Innovation" directly addresses this mechanical limitation. My team engineered a system where the cutting logic calculates from the rear chuck as the origin, enabling the system to effectively process material right up to the very end. This means the machine can cut as long as the remaining section is greater than or equal to the product length, eliminating the previously inevitable leftover tail material. This design requires robust, high-precision chucks that maintain stability even when gripping very short lengths, a feature MZBNL has perfected over our 25 years of experience in metal fabrication. Such technological advancements result in real, quantifiable savings; reducing tail waste from 200mm to less than 10mm per tube means over 95% reduction in remnant material for many operations. This level of precision and material optimization sets a new industry standard.

Intelligent Nesting Software and Cutting Path Optimization

Beyond physical machine design, sophisticated software plays a crucial role in minimizing tail waste. Intelligent nesting software is designed to optimize part placement on the raw material, aiming to maximize material utilization and minimize scrap. For tube cutting, this means not just fitting parts onto a tube, but strategically arranging them to ensure the absolute last piece of usable material is extracted. Traditional nesting might leave a short, awkward end, but advanced software can dynamically adjust8 to fill those small gaps.

MZBNL integrates smart and digitalized systems into our machines, which includes highly optimized nesting algorithms. These algorithms don't just consider the main production parts; they can also identify and nest smaller, auxiliary components (like spacers, washers, or even short legs for furniture) into what would traditionally be tail waste. This multi-process integration is key. Furthermore, our systems, particularly with the No-CAD Operating System innovation, allow for on-the-fly parameter entry for standard tube types and hole patterns, eliminating the need for complex 3D drawings. This dramatically improves ease of use and shortens setup time, but also enables operators to quickly adapt to small remnant pieces, effectively utilizing them without complex re-programming. This level of flexibility and intelligence in our software is what empowers our clients to turn potential waste into valuable products, a critical feature for businesses seeking custom solutions and quick turnaround times.

Strategic Operational Practices and MZBNL's Approach

While machine innovations and software are paramount, strategic operational practices also contribute to tail waste reduction. This includes meticulous inventory management to ensure optimal tube lengths are used for specific jobs, minimizing the creation of unnecessarily long remnants. It also involves training operators to understand the economic impact of waste and empowering them with the tools to reduce it. However, the most effective operational solution comes from machines that fundamentally change the cutting process.

MZBNL’s three major innovations work in concert to address tail waste comprehensively:

- No-CAD System Innovation: Simplifies operation, enabling efficient utilization of all material. Operators can quickly process standard tube types, allowing for agile use of shorter tube remnants without complex CAD work. This reduces the skill threshold, meaning operators need only 1 day of training instead of 15, directly impacting efficient setup for varied jobs and less waste from errors.

- Front-Feeding Innovation: While primarily enhancing efficiency and reducing labor intensity by 40%, this also indirectly supports waste reduction by allowing for more consistent and controlled material flow, reducing errors that can lead to unusable sections.

- Zero-Waste Tail Material Innovation: This is our direct solution, recalculating cutting from the rear chuck as the origin. This groundbreaking logic allows the system to eliminate leftover tail material, maximizing material utilization. For Ahmed Al-Farsi, this means his "Laser Tube Cutting Machine with automatic feeding and punching capabilities" is a turnkey solution that inherently optimizes material use, directly impacting his profitability in architectural metalwork and vehicle parts. By embracing these integrated solutions, businesses can move beyond minimizing waste to truly eliminating it, achieving unprecedented levels of material efficiency and operational excellence.

Zero tail chucks reduce dead zonesDoğru

Advanced chuck systems allow processing material right up to the tube end by minimizing clamping dead zones.

Traditional nesting leaves no wasteYanlış

Conventional nesting often leaves short unusable ends, while intelligent software can utilize these remnants.

What are the best practices for optimizing tail waste reduction in cutting operations?

Are you ready to implement the most effective strategies for minimizing tail waste in your tube laser cutting processes? Beyond investing in advanced machinery, adopting key best practices can further optimize material utilization, dramatically boosting your profitability and operational efficiency. Let's explore how.

Best practices for optimizing tail waste reduction include investing in advanced zero-tail technology, implementing smart nesting and production planning, ensuring precise machine calibration, and fostering operator training. These combined approaches maximize material utilization, reduce scrap, and enhance overall efficiency in tube laser cutting operations.

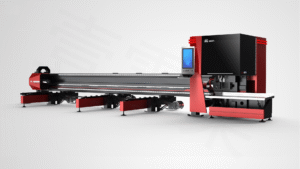

While MZBNL’s innovative machines, like our Automatic Punching & Cutting Integrated Machine, provide the technological foundation for near-zero tail waste, the journey to true optimization extends into how a factory operates. My discussions with successful clients, including those considering long-term partnerships like regional distribution, consistently highlight the importance of integrating technology with sound operational strategies. It's about creating a holistic ecosystem where every decision contributes to maximum material utilization and efficiency. For a business like Ahmed Al-Farsi's, where custom fabrication services and high cost-performance are paramount, these best practices are not just suggestions; they are critical pathways to sustainable growth and maintaining a competitive edge in demanding markets like the Middle East. Let's explore how to truly unlock the full potential of your cutting operations.

Adopting Advanced Zero-Tail Technology and Integrated Systems

The most fundamental best practice for optimizing tail waste reduction is to invest in machinery equipped with advanced "zero-tail" technology. This is not merely an optional feature; it is a critical component for achieving maximum material utilization. Traditional machines, regardless of how well they are operated, are inherently limited by their chuck designs and cutting logic, leading to unavoidable tail remnants. Therefore, the first step is to upgrade to systems engineered to address tail waste9. MZBNL's "Zero-Waste Tail Material Innovation" is a prime example of such technology. By recalculating the cutting origin from the rear chuck, our machines can process material right up to the last millimeter, effectively turning what was once waste into usable product.

For a high-volume facility or one dealing with expensive materials, the return on investment for such technology is remarkably fast. Consider a factory producing thousands of furniture components or architectural elements. Even a small percentage reduction in material waste per tube, compounded over thousands of tubes annually, results in substantial savings. Furthermore, integrating machines with multi-process capabilities, such as MZBNL's Automatic Punching & Cutting Integrated Machine, streamlines operations. This integration means that once the tube is loaded, both cutting and punching can occur without additional handling, minimizing potential errors and maximizing throughput. The seamless flow from raw material to finished part, with minimal waste, epitomizes modern manufacturing efficiency and offers a critical competitive advantage.

Implementing Smart Production Planning and Nesting Strategies

Beyond machine capabilities, intelligent production planning and advanced nesting strategies are crucial best practices for optimizing tail waste. This involves using sophisticated software to plan how parts are laid out on a tube to minimize unused sections. It goes beyond simple "fitting" to strategic nesting strategies in tube cutting10 that account for variable part sizes, material types, and potential remnant utilization. For instance, if a job requires many short pieces, the nesting software should be able to group these towards one end of the tube, leaving a longer, more usable remnant at the other end for future jobs, rather than multiple short, unusable tails.

MZBNL's smart and digitalized systems, complemented by our No-CAD Operating System, facilitate this best practice. Our systems allow for high-speed and high-precision cutting with easy operation. This ease of use means that production planners can quickly adjust to changing demands, and operators can implement optimized nesting patterns without extensive CAD training. For example, if a specific project for Ahmed Al-Farsi's architectural metalwork business requires several short tube sections, our system can efficiently nest them to utilize the tube length optimally, minimizing the final tail. This capability ensures that even if a small remnant is left, it's either truly unusable or strategically created to be useful for a subsequent, smaller part order. This level of granular control over material usage differentiates efficient operations from those that merely "cut and discard."

Continuous Monitoring, Calibration, and Operator Training

Finally, ongoing operational excellence is achieved through continuous monitoring, precise machine calibration, and comprehensive operator training. Even the most advanced machinery requires consistent attention to maintain optimal performance and waste reduction. Regular calibration ensures the chucks grip precisely and the laser path remains accurate, preventing cutting errors that can lead to scrap. Monitoring material usage metrics, such as "material consumption per unit output" or "waste percentage," provides critical data for identifying areas for improvement.

Furthermore, training operators is paramount. While MZBNL machines are easy to operate and require only 1 day of on-site training for our No-CAD system, understanding the principles of waste reduction empowers operators to make informed decisions. They should be aware of how their actions impact material utilization and encouraged to identify opportunities for further optimization. For instance, knowing how to best load tubes, minimize material handling, and verify cut accuracy can significantly reduce errors and, consequently, waste. Ahmed Al-Farsi values post-sales training and support, recognizing that a well-trained team maximizes the value of advanced equipment. By combining MZBNL's cutting-edge technology with these best practices, businesses can achieve unparalleled levels of material efficiency, reinforcing their competitiveness and long-term sustainability in the metal fabrication industry.

Zero-tail technology reduces wasteDoğru

Advanced zero-tail technology like MZBNL's innovation can process material up to the last millimeter, dramatically reducing tail waste.

Traditional machines eliminate tail wasteYanlış

Traditional machines are limited by their chuck designs and cutting logic, making tail remnants unavoidable without zero-tail technology.

Sonuç

Embracing innovations like MZBNL's zero-waste tail material system is crucial for modern metal fabrication. By redefining traditional cutting logic, businesses can significantly reduce material waste, enhance profitability, and boost operational efficiency. This proactive approach not only addresses immediate cost concerns but also positions companies like Ahmed's for sustainable growth and a competitive edge in global markets.

-

Discover how tail waste affects profitability in tube laser cutting operations ↩

-

Explore the cost implications of material expenses in metal fabrication ↩

-

Understand the broader impact of tail waste on productivity and material efficiency ↩

-

Discover how software limitations contribute to material inefficiency and how to overcome them ↩

-

Discover the strategic importance of waste management in manufacturing. ↩

-

Understand how front-feeding boosts productivity and reduces labor intensity. ↩

-

Learn about the evolution in chuck systems for efficient cutting. ↩

-

Understand the software's impact on maximizing material usage. ↩

-

Discover how modern systems minimize tail waste in cutting processes for better efficiency ↩

-

Understand how nesting strategies optimize material use and reduce waste in cutting operations ↩

Sorularınız mı var veya daha fazla bilgiye mi ihtiyacınız var?

Kişiselleştirilmiş yardım ve uzman tavsiyesi için bizimle iletişime geçin.