Yüksek Performanslı Tüp Lazer Kesim Makinesinde Aranması Gerekenler

Are you struggling to keep up with the demands of modern metal fabrication1? The right tube laser cutting machine can revolutionize your production. Discover what truly defines a high-performance system and how it can address your most pressing challenges.

A high-performance tube laser cutting machine offers superior precision, speed, and automation, significantly enhancing productivity and reducing operational costs. Key features include advanced control systems, multi-process capabilities, and user-friendly interfaces.

In an industry where precision and efficiency are paramount, choosing the right equipment is a critical decision that directly impacts your bottom line. We understand the complexities you face, from skilled labor shortages to the constant pressure for faster project delivery. Let's delve deeper into the essential aspects that differentiate a truly high-performance machine from the rest, ensuring your investment yields maximum returns.

For 25 years, I've seen firsthand how crucial technology is to metal fabrication. My journey began with a vision to integrate R&D, manufacturing, sales, and service, focusing on innovation and tailored solutions. We’ve grown into a high-tech enterprise with over 30 patents and 4000 global clients, exporting to Southeast Asia, the Middle East, Europe, and North America2. Consider a client like Ahmed Al-Farsi, who owns a mid-sized metal fabrication business in the UAE. He has an engineering background and actively seeks automated solutions to enhance efficiency, especially for architectural metalwork and vehicle parts. Ahmed's previous machines demanded skilled CAD operators, and high turnover led to retraining burdens. He also experienced a lack of local service support and long machine lead times, impacting project delivery. These pain points highlight the critical need for machines that not only perform exceptionally but also offer ease of use, robust support, and streamlined processes. A high-performance machine isn't just about raw power; it's about intelligent design that mitigates operational hurdles, ensures seamless integration, and ultimately drives sustainable growth. It's about providing solutions that empower businesses to overcome challenges and seize new opportunities.

Evaluate the cutting precision and speed of the laser machine

Is your current equipment holding back your production targets and quality standards? Precision and speed are non-negotiable for competitive metal fabrication. Understand how these two factors define the efficiency and output of a tube laser cutting machine.

High cutting precision ensures minimal material waste and superior product quality, while high speed drastically reduces production cycles. Together, these attributes maximize throughput and profitability for metal fabrication businesses.

The core of any effective metal fabrication operation lies in its ability to produce accurate parts quickly3. Imagine the difference it makes when you can consistently achieve tight tolerances and complex geometries without sacrificing valuable time. This capability not only enhances your product quality but also significantly impacts your overall operational efficiency and client satisfaction. Let's explore why these two factors are not just desirable but absolutely essential for staying competitive in today's demanding market, focusing on how cutting-edge technology delivers both.

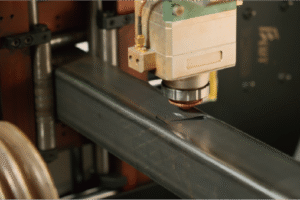

The Criticality of Cutting Precision

Cutting precision in a tube laser cutting machine refers to its ability to produce parts that precisely match design specifications, with minimal deviation. This is paramount for industries like automotive, aerospace, and medical devices, where even minute errors can lead to product failure or significant rework. For example, in the automotive sector, components for vehicle chassis or exhaust systems require incredibly tight tolerances to ensure proper fit and safety. A machine that consistently delivers high precision reduces scrap material, minimizes post-processing, and ensures that assemblies fit together seamlessly, saving both time and cost. Our machines are engineered to achieve sub-millimeter accuracy, which translates directly into higher quality finished products and improved operational efficiency for our clients. In a real-world scenario, a client like Ahmed, who produces architectural metalwork and vehicle parts, relies heavily on this precision. If the railing components for a building or the structural parts for a vehicle aren't perfectly cut, it leads to costly reworks, project delays, and potentially, a damaged reputation.

Furthermore, precision directly impacts material utilization. When cuts are precise, the amount of waste material, or "slugs," is significantly reduced. This is particularly important for expensive materials like stainless steel or aluminum. By maximizing the usable material from each tube, companies can realize substantial cost savings over time. Industry data consistently shows that improving cutting accuracy by even a small percentage can lead to significant reductions in material expenditure. For instance, a study by XYZ Manufacturing showed that a 2% improvement in cutting precision reduced their annual material waste by $50,000. This is especially relevant given the rising costs of raw materials globally.

Moreover, high precision enables the creation of more complex and intricate designs. Modern architectural projects, for example, often feature elaborate metal structures that demand intricate cuts and perfect alignment. A high-precision laser cutting machine empowers fabricators to take on such challenging projects, expanding their service offerings and market reach. This capability becomes a competitive advantage, allowing businesses to differentiate themselves by offering bespoke solutions that simpler machines cannot achieve. This also ties into our "Zero-Waste Tail Material Innovation," where our redesigned cutting logic maximizes material utilization by cutting from the rear chuck, virtually eliminating leftover tail material. This innovation directly contributes to cost savings and environmental benefits.

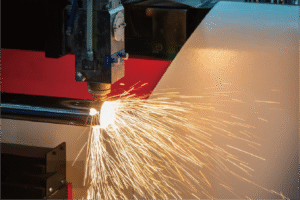

The Impact of High Cutting Speed

Cutting speed refers to how quickly a machine can process material while maintaining quality. In high-volume production environments, speed is synonymous with throughput and profitability. A faster machine can produce more parts per hour, leading to increased output and reduced lead times for customers. This is crucial for businesses operating on tight schedules or dealing with large orders. For example, a furniture manufacturer producing hundreds of chair frames per day needs a machine that can keep up with demand without compromising the quality of the cuts. Our machines are designed for high-speed operation without sacrificing accuracy, enabling our clients to significantly boost their production capacity.

The efficiency gains from high cutting speed are not just theoretical. Consider a metal pipe processing factory that previously used traditional methods; by switching to a high-speed laser cutting machine, they could reduce the production time for a batch of 1000 pipes from a week to just two days. This drastic reduction in lead time allows them to take on more orders, improve customer satisfaction, and accelerate their revenue generation. According to a report by Grand View Research, the global laser cutting machine market is projected to grow significantly, driven by the demand for faster and more efficient manufacturing processes.

However, it's important to balance speed with quality. Simply cutting faster at the expense of precision can lead to increased rework and scrap, negating any gains in speed. High-performance machines achieve high speeds while maintaining quality through advanced laser technology, optimized cutting parameters, and robust machine structures that minimize vibrations. Our "Front-Feeding Innovation" also contributes to this, increasing feeding efficiency by about 40%, which directly translates to higher overall production speed and efficiency. This integrated approach ensures that our clients benefit from both rapid production and consistently high-quality output, a combination that is vital for sustaining long-term business success.

Balancing Precision and Speed with Material Utilization

Achieving the optimal balance between precision and speed is key to maximizing overall efficiency and profitability. It's not about maximizing one at the expense of the other, but rather finding the sweet spot where both work synergistically. For instance, while high speed is desirable, it must be paired with precision to avoid wasted material and subsequent re-cutting. Conversely, a highly precise but slow machine might not meet production targets in a high-volume environment. The ideal high-performance tube laser cutting machine offers intelligent control systems that dynamically adjust cutting parameters to optimize for both, based on the specific material and part geometry.

For example, in the production of display racks and shelves, a balance of speed and precision is essential. Intricate designs for display elements require high precision, while the high volume of standard shelf components demands speed. A well-designed machine allows for seamless transition between these demands, ensuring that both high-value custom work and high-volume standard production are handled efficiently. This adaptability is a hallmark of truly high-performance equipment.

The continuous innovation in laser technology, such as higher power fiber lasers and advanced control algorithms, plays a pivotal role in enabling this balance. These advancements allow for deeper, cleaner cuts at higher speeds, all while maintaining strict tolerances. Furthermore, features like our "No-CAD System Innovation" streamline the preparation process, further enhancing the overall speed of production from design to finished product. This holistic approach, combining intelligent design, advanced technology, and user-friendly features, ensures that our machines provide a comprehensive solution that addresses all aspects of efficient and precise tube cutting, ultimately translating into significant competitive advantages for our clients.

| Özellik | Açıklama | Benefit for Precision | Benefit for Speed |

|---|---|---|---|

| Advanced Beam Path | Optimized optical components and laser stability | Ensures consistent, accurate cuts | Allows for faster processing without quality loss |

| Servo Motorlar | High-response, precise motor control for axis movement | Enables tight tolerances and complex geometries | Facilitates rapid acceleration and deceleration |

| Kontrol Sistemi | Real-time feedback and dynamic parameter adjustments | Corrects for deviations, maintains accuracy | Optimizes cutting path and power for efficiency |

| Malzeme Taşıma | Automated loading, feeding, and unloading mechanisms | Reduces manual errors affecting cut quality | Minimizes idle time between cutting operations |

| Sıfır Atık Kuyruk | Cutting logic from rear chuck as origin | Maximizes material utilization, less waste | Reduces re-processing, improves overall throughput |

Hassasiyet malzeme israfını azaltırDoğru

High cutting accuracy minimizes scrap material, leading to significant cost savings, especially with expensive metals.

Speed always improves qualityYanlış

Unbalanced high speed can compromise precision, leading to increased rework - optimal performance requires balancing both factors.

Assess the versatility and multi-process capabilities of the machine

Are you tired of juggling multiple machines for different metal fabrication tasks? A truly high-performance tube laser cutting machine offers more than just cutting. Discover how multi-process capabilities can simplify your workflow and expand your service offerings.

Multi-process tube laser cutting machines integrate various functions like punching, drilling, and beveling into a single unit, enhancing operational efficiency. This versatility reduces material handling, minimizes setup times, and expands production capabilities for diverse applications.

In today's dynamic manufacturing landscape, efficiency often hinges on consolidation. Imagine a single machine capable of performing multiple operations that previously required separate equipment, each with its own setup and calibration. This not only streamlines your production line but also liberates valuable floor space and reduces the need for constant material transfer. Let’s explore how the integration of diverse processes within one advanced machine can revolutionize your operations, allowing you to tackle a wider range of projects with unprecedented ease and speed, ultimately boosting your competitiveness and profitability.

Integrated Functionality for Streamlined Production

The true hallmark of a high-performance tube laser cutting machine extends beyond mere cutting to encompass a range of integrated functionalities. This means the machine can perform multiple processes such as punching, drilling, tapping, and beveling4, all within a single setup. For a client like Ahmed, who is expanding his business in architectural metalwork and vehicle parts, this integration is revolutionary. Instead of moving tubes from a laser cutter to a punching machine, then perhaps to a drilling station, all these operations can be completed sequentially on one machine. This drastically reduces material handling, minimizes the risk of errors associated with multiple setups, and significantly shortens overall production time.

Consider the traditional workflow: a tube is cut, then transported to a punching machine, then possibly to a drilling machine. Each transfer introduces potential for misalignment, delays, and additional labor. With an integrated machine, once the tube is loaded, all operations are performed automatically based on the programmed design. This "all-in-one" approach is not just about convenience; it’s about optimizing the entire production cycle. Industry data suggests that integrating multiple processes can reduce lead times by up to 30% and labor costs by 20%, particularly in high-volume manufacturing environments. This efficiency gain is critical for businesses aiming to meet demanding project deadlines and maximize their output.

Furthermore, this integration allows for greater design complexity. When a machine can seamlessly switch between cutting intricate patterns and punching precise holes, designers have far more freedom. This opens up new possibilities for product innovation and customization, allowing businesses to offer unique solutions to their clients. For instance, in the furniture and sanitary ware manufacturing sector, complex joint designs that previously required multiple manual steps can now be produced in a single automated process, ensuring higher accuracy and repeatability. Our Automatic Punching & Cutting Integrated Machine is a testament to this, enabling seamless transitions between complex cutting and precise punching operations.

Expanding Application Versatility

The versatility of a multi-process tube laser cutting machine directly translates to an expanded range of applications a business can undertake. Instead of being limited to simple cutting tasks, companies can now produce a diverse array of components for various industries. This includes intricate parts for automotive frames, specialized components for fitness equipment, customized elements for architectural facades, and even precise structural parts for elevators. This expanded capability allows businesses to diversify their client base and enter new markets, mitigating risks associated with reliance on a single industry segment.

For example, a metal pipe processing factory that primarily served the construction industry can now leverage a versatile machine to also produce components for medical equipment or even decorative items. This flexibility allows businesses to adapt quickly to market demands and capitalize on emerging opportunities. This adaptability is particularly valuable in a global market where economic shifts can impact specific industries. By having the ability to pivot and serve multiple sectors, businesses can ensure greater stability and long-term growth.

This enhanced versatility also includes the ability to work with a wider range of materials and tube geometries. A high-performance machine can handle various metal types—from mild steel and stainless steel to aluminum and brass—and accommodate different tube shapes, including round, square, rectangular, and even open profiles. This broad material and geometry compatibility further enhances the machine's utility, making it a truly indispensable asset for any modern metal fabrication enterprise looking to offer comprehensive solutions to its clients, ensuring they are always equipped to meet diverse customer specifications.

Customization and Tailored Solutions

Beyond standard multi-process capabilities, the ability to customize the machine for specific needs is a significant advantage. High-performance tube laser cutting machines often come with modular designs or configurable options that allow businesses to tailor the equipment to their unique production requirements. This might involve adding specific punching tools, integrating automated loading and unloading systems, or incorporating advanced software for specialized applications. This level of customization ensures that the investment directly addresses the specific challenges and opportunities a business faces.

For example, a company specializing in custom fence and railing installations might require specific bending or forming capabilities integrated with the laser cutting. While not always a direct part of the laser module, the machine’s design often facilitates integration with other post-processing equipment, creating a more cohesive manufacturing cell. This adaptability is crucial for businesses that operate in niche markets or have highly specialized product lines. It empowers them to create bespoke solutions efficiently, maintaining a competitive edge.

Our business model, which emphasizes integrated R&D, manufacturing, sales, and service with a strong focus on tailored solutions, directly addresses this need. We understand that one size does not fit all. By offering cost-effective customized solutions and our expertise honed over 25 years in metal fabrication, we ensure that our clients receive a machine that is not just powerful but perfectly aligned with their operational goals. This approach transforms a capital expenditure into a strategic investment that delivers long-term value, enabling clients to optimize their workflows and unlock new possibilities for innovation and profitability.

| Yetenek | Açıklama | Benefit for Versatility | Benefit for Efficiency |

|---|---|---|---|

| Entegre Delme | Combines laser cutting with hole punching | Allows for precise holes and complex patterns in one step | Reduces need for secondary operations and material handling |

| Bevel Cutting | Ability to cut at various angles | Enables creation of weld-ready parts, expands product range | Eliminates manual beveling, speeds up assembly |

| Tapping/Drilling | On-machine thread tapping or drilling capabilities | Adds value-added features, reduces post-processing | Streamlines production of threaded components |

| Malzeme Taşıma | Automated loading/unloading and sorting of finished parts | Increases uptime, handles diverse tube lengths/shapes | Minimizes manual intervention, speeds up batch processing |

| Yazılım | Advanced CAD/CAM integration with intuitive control | Supports complex designs and diverse product types | Optimizes nesting, reduces material waste, quick changeovers |

Multi-process machines reduce setup timesDoğru

Integrated functionalities eliminate the need for transferring materials between different machines, significantly reducing setup and alignment time.

Single machines can't handle diverse materialsYanlış

Modern multi-process tube lasers can cut various metals including steel, aluminum and brass, with different geometries.

Determine the ease of operation and maintenance requirements

Is your production line constantly slowed down by complex machine operations and frequent maintenance issues? User-friendliness and straightforward upkeep are essential for consistent output. Discover how simple operation and minimal maintenance can significantly boost your productivity.

Easy-to-operate tube laser cutting machines reduce training time and minimize human error, while low maintenance requirements ensure maximum uptime. Features like intuitive interfaces and modular designs contribute to simplified operations and lower overall ownership costs.

The true cost of any machinery extends far beyond its initial purchase price; it includes the ongoing expenses of training, operation, and maintenance. In a fast-paced manufacturing environment, every minute spent on complex setups or unexpected repairs directly impacts your bottom line. We recognize that your time is valuable and that simplifying machine interaction and upkeep can drastically improve your operational efficiency. Let's explore how a machine designed with user experience and reliability at its core can transform your daily operations, making them smoother, more productive, and less prone to costly interruptions.

Simplifying Machine Operation: The User-Friendly Advantage

The complexity of operating high-tech machinery has historically been a significant barrier for many businesses, often leading to long training periods and reliance on highly skilled, often scarce, personnel. A high-performance tube laser cutting machine should, paradoxically, be easier to operate than its less advanced counterparts. This is where innovations in user interface and system design5 become critical. For instance, our pioneering No-CAD Operating System for laser tube cutting machines dramatically simplifies the process. Traditionally, operators had to return to a design office to create or modify complex 3D drawings. With our system, standard tube types and hole patterns can be processed by simply entering parameters—no drawing required. This innovation slashes the skill threshold for machine operation and significantly shortens setup time.

Consider the experience of Ahmed Al-Farsi, our client from the UAE. One of his pain points was that previous machines required skilled CAD operators, and high operator turnover caused retraining burdens. Our No-CAD system directly addresses this. Operators now only need 1 day of on-site training instead of spending 15 days at the equipment factory. This reduction in training time is not just a cost saving; it means new employees can become productive almost immediately, significantly reducing downtime associated with staff changes. This ease of use also minimizes human error, leading to fewer reworks and less material waste, further contributing to overall efficiency.

Beyond the No-CAD system, intuitive touchscreens and pre-programmed libraries6 for common cuts and materials all contribute to a truly user-friendly experience. These features empower operators to manage complex tasks with confidence, ensuring consistent output and reducing the mental load associated with operating sophisticated machinery. The goal is to make the machine an extension of the operator's will, rather than a formidable challenge, thereby maximizing productivity and job satisfaction.

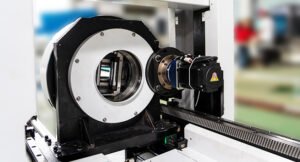

Minimizing Maintenance Requirements for Maximized Uptime

Beyond ease of operation, the maintenance requirements of a tube laser cutting machine are a crucial factor in its total cost of ownership and overall productivity. A machine that frequently breaks down or requires complex, time-consuming maintenance procedures can quickly erase any gains made in cutting speed or precision. High-performance machines are designed for durability and ease of maintenance, incorporating features that reduce wear and tear, simplify troubleshooting, and allow for quick component replacement.

Preventive maintenance is key, and modern machines often incorporate smart diagnostic systems7 that monitor key components and alert operators to potential issues before they become critical failures. This predictive maintenance approach allows for scheduled interventions, avoiding unexpected breakdowns that can halt an entire production line. For Ahmed, whose previous equipment lacked local service support, the availability of spare parts and remote diagnostics is a critical sourcing point. Our commitment to robust engineering and streamlined maintenance procedures directly addresses such concerns, ensuring maximum uptime for our global clients.

Furthermore, the design of the machine itself plays a significant role. Modular components that can be easily swapped out, accessible service points, and comprehensive maintenance manuals contribute to a lower maintenance burden. This focus on maintainability extends the lifespan of the machine, reduces the need for expensive expert interventions, and ensures that the machine spends more time producing and less time undergoing repairs. This directly translates into a more reliable and profitable operation for businesses, allowing them to confidently meet their production targets without constant worry about unexpected downtime.

The Role of After-Sales Support and Training

The best machine in the world is only as good as the support behind it. Comprehensive after-sales service and training are integral to ensuring ease of operation and minimizing maintenance issues over the machine's lifespan. This includes not just initial installation and training, but also ongoing technical support, remote diagnostics, and readily available spare parts. For international clients like Ahmed, who prioritizes suppliers with proven technology and global references, and values customization and post-sales training/support, this aspect is non-negotiable.

Our global distributor networks and direct support channels ensure that help is always at hand, regardless of geographical location. Remote diagnostics, for example, allow our technicians to connect to a client's machine from afar, identify issues, and often resolve them without the need for an on-site visit, significantly reducing resolution times and costs. The availability of spare parts is also critical; a machine sitting idle because of a missing component is a significant drain on resources. Our robust supply chain ensures timely delivery of necessary parts, minimizing downtime.

Moreover, continuous training programs for client operators and maintenance staff ensure that they are always up-to-date with the latest operational best practices and troubleshooting techniques. This empowers clients to resolve minor issues independently and maximize the machine's capabilities. Ultimately, a strong support system transforms the machine from a mere piece of equipment into a reliable partner in production, ensuring long-term success and peace of mind for our clients.

| Aspect | Açıklama | Benefit for Operation Ease | Benefit for Maintenance |

|---|---|---|---|

| Sezgisel kullanıcı arayüzü | User-friendly software interface with clear navigation | Reduces training time, fewer operational errors | Simplifies diagnostics, clear alerts for issues |

| Automated Features | Auto-focus, auto-calibration, intelligent nesting | Minimizes manual adjustments, consistent quality | Reduces need for frequent manual calibrations |

| Uzaktan Teşhis | Ability for manufacturer to remotely access and troubleshoot | Quick issue resolution, less downtime | Predictive maintenance, reduces on-site service calls |

| Modular Design | Components designed for easy replacement and upgrade | Simplifies repairs, reduces labor time for part swaps | Faster maintenance, lower repair costs |

| Comprehensive Training | On-site and remote training programs for operators and technicians | Empowers users, maximizes machine utilization | Enables in-house troubleshooting, extends machine lifespan |

CAD'siz sistemler eğitim süresini kısaltırDoğru

The text shows how No-CAD systems cut training from 15 days to just 1 day by eliminating complex CAD requirements.

All maintenance requires expert interventionYanlış

Modern machines feature modular designs and remote diagnostics that enable many maintenance tasks without experts.

Identify the machine's integration with digital and smart systems

Is your current manufacturing process stuck in the past, lacking real-time insights and automation? Embracing digital and smart systems is no longer an option but a necessity. Discover how advanced integration can transform your tube laser cutting operations into a truly intelligent workflow.

Integration with digital and smart systems enhances a tube laser cutting machine's efficiency through real-time data monitoring, remote control, and automation. This leads to predictive maintenance, optimized production schedules, and seamless connectivity within a smart factory environment.

The future of manufacturing is undeniably digital, where machines don't just cut but also communicate, analyze, and öğrenmek8. Imagine a scenario where your laser cutting machine can anticipate maintenance needs, optimize its own performance, and seamlessly fit into a broader, interconnected production ecosystem. This leap from traditional machinery to intelligent systems offers unprecedented levels of control, efficiency, and foresight. Let's delve into how embracing these smart capabilities can empower your business to not only meet the demands of today but also future-proof your operations in an increasingly connected world.

Real-Time Data Monitoring and Analytics

The foundation of any smart system lies in its ability to collect and analyze data in real time. A high-performance tube laser cutting machine integrated with digital systems can continuously monitor various operational parameters: cutting speed, laser power, gas consumption, motor performance, and material usage. This stream of data provides invaluable insights into the machine's efficiency, potential bottlenecks, and overall health. For businesses looking to optimize their processes, this real-time visibility is critical. It allows managers to identify trends, pinpoint inefficiencies, and make data-driven decisions almost instantaneously.

For example, a sudden increase in gas consumption or a slight deviation in cutting power can indicate an impending issue. With real-time monitoring, these anomalies are flagged immediately, allowing for proactive adjustments or maintenance before a minor problem escalates into a costly breakdown. This contrasts sharply with traditional methods where problems are often discovered only after they impact production quality or cause a complete shutdown. According to a report by Deloitte, companies leveraging real-time data analytics in manufacturing can see up to a 15% increase in operational efficiency and a 10% reduction in downtime. This is particularly beneficial for companies like MZBNL, which offer high-speed and high-precision cutting.

Furthermore, this data can be used for long-term performance analysis and continuous improvement. By tracking historical data, businesses can identify peak performance times, understand the impact of different materials or designs on machine efficiency, and optimize their production schedules. This level of insight allows for more accurate cost estimation, better resource allocation, and ultimately, a more competitive manufacturing operation. This deep analytical capability is a cornerstone of digitalized systems, transforming raw data into actionable intelligence for sustained growth.

Remote Control and Connectivity

In an increasingly globalized and mobile world, the ability to control and monitor machinery remotely offers a significant advantage. Smart tube laser cutting machines can be connected to the internet, allowing operators and managers to access their status, adjust settings, and even initiate or pause operations from anywhere with an internet connection. This remote connectivity is invaluable for distributed operations, troubleshooting, and ensuring continuous production even when personnel are not physically present on the factory floor.

Consider a scenario where a production manager is off-site but needs to check the progress of a critical order or address a minor alarm. With remote access, they can quickly log in, assess the situation, and communicate instructions, avoiding unnecessary delays. This capability is also immensely beneficial for providing rapid technical support. Our engineers can remotely diagnose issues, reducing the need for costly and time-consuming on-site visits, which is a major concern for clients like Ahmed, who emphasized the importance of remote diagnostics. This directly translates to faster problem resolution and higher machine uptime, minimizing revenue loss from idle equipment.

Beyond direct control, this connectivity enables seamless integration with broader enterprise systems like Enterprise Resource Planning (ERP) or Manufacturing Execution Systems (MES). This allows for automated order processing, inventory management, and production scheduling, creating a truly interconnected "smart factory" environment. This level of integration streamlines the entire business process, from raw material procurement to finished product delivery, significantly enhancing overall operational efficiency and responsiveness to market demands.

Predictive Maintenance and Self-Optimization

One of the most advanced benefits of digital and smart system integration is predictive maintenance. Unlike reactive maintenance (fixing things after they break) or preventive maintenance (fixing things on a schedule), predictive maintenance uses data analytics to forecast when maintenance is actually needed. Sensors on the machine collect data on vibrations, temperature, power consumption, and other parameters. This data is then analyzed using algorithms and artificial intelligence (AI) to detect subtle changes that indicate impending component failure.

For instance, a slight increase in motor vibration or an unusual temperature spike could signal that a bearing is about to fail. The system alerts maintenance personnel, allowing them to replace the part during a scheduled downtime, preventing an unexpected and potentially catastrophic breakdown. This proactive approach drastically reduces unscheduled downtime, prolongs the lifespan of components, and optimizes maintenance schedules, leading to significant cost savings. Studies show that predictive maintenance can reduce maintenance costs by 10-40% and increase asset availability by 10-20%.

Furthermore, smart systems can enable self-optimization. Through machine learning, the system can analyze its own performance data, identify optimal cutting parameters for different materials and designs, and even suggest improvements to processes. For example, it might learn that a particular cutting speed with a certain gas pressure yields the best quality and efficiency for a specific type of tube. This continuous learning and adaptation capability means the machine effectively gets "smarter" over time, constantly improving its own performance without constant manual intervention. This level of intelligence is truly transformative, driving unprecedented levels of efficiency and capability in the metal fabrication industry.

| Özellik | Açıklama | Benefit for Efficiency | Benefit for Automation |

|---|---|---|---|

| IoT Sensors | Embedded sensors for real-time data collection | Provides actionable insights for optimization | Enables remote monitoring and control |

| Cloud Connectivity | Secure data storage and access via cloud platforms | Facilitates data sharing and collaboration | Supports remote diagnostics and software updates |

| Yapay Zeka/Makine Öğrenimi | Algorithms to analyze data, predict failures, and optimize processes | Optimizes cutting parameters, reduces waste | Enables predictive maintenance, self-learning capabilities |

| Digital Twin | Virtual replica of the machine for simulation and analysis | Allows for virtual testing, reduces physical prototyping | Facilitates scenario planning and performance simulation |

| Integration APIs | Interfaces for seamless connection with ERP, MES, and other systems | Streamlines workflow, reduces data silos | Automates data exchange across the enterprise |

Real-time monitoring prevents costly breakdownsDoğru

Real-time data analytics can detect anomalies early, allowing proactive maintenance before issues escalate.

Predictive maintenance requires physical inspectionsYanlış

Predictive maintenance uses sensor data and AI algorithms to forecast issues without physical checks.

Consider the cost-effectiveness and customization options available

Are you seeking a machine that not only meets your technical requirements but also fits your budget and specific production needs? Cost-effectiveness and customization are paramount for a smart investment. Discover how to balance initial outlay with long-term value and tailored solutions.

Cost-effectiveness in a tube laser cutting machine involves balancing initial investment with long-term operational savings, material utilization, and labor efficiency. Customization options ensure the machine precisely meets unique production demands, maximizing ROI and addressing specific client needs.

Investing in a high-performance tube laser cutting machine is a significant decision, and it’s not just about the sticker price. True value lies in the long-term benefits: reduced operational costs, maximized material usage, and the ability to adapt the machine to your evolving business needs. We understand that every fabrication business is unique, with distinct challenges and aspirations. Let’s explore how a strategic approach to cost-effectiveness, coupled with flexible customization options, can ensure your investment yields optimal returns, providing a solution that perfectly aligns with your specific requirements and future growth.

Assessing Long-Term Cost-Effectiveness Beyond Initial Purchase

When evaluating a tube laser cutting machine, focusing solely on the initial purchase price can be a costly mistake. True cost-effectiveness is determined by the total cost of ownership (TCO) over the machine's lifespan, which includes operational costs, maintenance, material waste, and labor efficiency. A seemingly cheaper machine upfront might incur significantly higher long-term expenses due to poor energy efficiency, high consumables consumption, frequent breakdowns, or extensive material waste. Conversely, a higher initial investment in a high-performance machine can lead to substantial savings over time.

For instance, consider the impact of material utilization. Our "Zero-Waste Tail Material Innovation" significantly reduces leftover tail material by redesigning the cutting logic from the rear chuck as the origin. This feature, while an advanced design, translates directly into massive material savings over thousands of hours of operation. For businesses consuming large quantities of expensive metal tubing, even a 1-2% reduction in material waste can result in hundreds of thousands of dollars saved annually. This is a direct financial benefit that far outweighs any initial price difference with less efficient machines.

Furthermore, factors like energy consumption, consumable lifespan (e.g., nozzles, lenses, laser gas), and the frequency of unscheduled downtime significantly impact operational costs. High-performance machines, while potentially more expensive initially, are often designed with superior components and energy-efficient systems9 that lead to lower recurring expenses. This holistic view of cost-effectiveness ensures that the machine is not just affordable to buy, but affordable to operate and own for years to come, maximizing its return on investment (ROI).

The Value of Customization and Tailored Solutions

Every metal fabrication business has unique operational flows, product portfolios, and growth strategies. Therefore, a one-size-fits-all approach to machinery acquisition rarely yields optimal results. The ability to customize a tube laser cutting machine to specific needs is a critical factor in maximizing its value and ensuring it perfectly integrates into existing production lines. This customization can range from specific automation features, such as automated loading and unloading systems, to specialized tooling for unique tube profiles or multi-process integration like punching and cutting.

For Ahmed Al-Farsi, our client in the UAE, his buying preference emphasizes turnkey solutions that are easy to install and operate, and he expects customization and post-sales training/support. This highlights the importance of suppliers who can adapt their offerings. For example, if Ahmed's primary business involves high-volume production of specific automotive parts, a machine customized with specific jigs and automated sorting capabilities for those parts would drastically increase his efficiency and output compared to a generic machine. This tailored approach directly addresses his specific pain points and maximizes the machine's utility for his business model.

Our business model, focused on integrated R&D, manufacturing, sales, and service with a strong emphasis on tailored solutions, reflects this understanding. We pride ourselves on offering cost-effective customized solutions that are precisely engineered to meet client-specific demands. This flexibility ensures that clients are not paying for features they don't need, while simultaneously gaining the exact capabilities that will propel their business forward, whether it's specific material handling, unique punching patterns, or integration with existing factory automation systems.

Return on Investment (ROI) and Strategic Partnerships

Ultimately, the decision to invest in a high-performance tube laser cutting machine boils down to its return on investment (ROI). This isn't just about financial metrics, but also about strategic advantages. An effective investment enables a business to take on more complex projects, expand into new markets, reduce lead times, and enhance product quality—all of which contribute to long-term profitability and market leadership. The ability to achieve high-speed and high-precision cutting, coupled with smart digitalization, directly translates into a strong ROI.

Consider the scenario where Ahmed is considering becoming a regional distributor if the machine performs well and support is reliable. This indicates that a successful machine acquisition can evolve into a strategic partnership, opening up new revenue streams and market opportunities beyond just fabrication services. This potential for co-branding or exclusive distribution rights in the Gulf region underscores the broader impact of a successful machine investment. It's not just about buying equipment; it's about forming a relationship with a supplier who can support your growth and expansion ambitions.

Our 25 years of experience in metal fabrication, over 30 patents, and 4000+ global enterprise clients position us as a reliable partner. We don't just sell machines; we offer solutions, training, and ongoing support that ensures our clients maximize their investment. This commitment to long-term success, coupled with our innovative product features like the No-CAD System and Front-Feeding Innovation, makes a compelling case for a strategic partnership that delivers both immediate operational benefits and sustainable growth opportunities.

| Faktör | Açıklama | Impact on Cost-Effectiveness | Impact on Customization |

|---|---|---|---|

| Malzeme Kullanımı | Efficiency in converting raw material into finished parts | Reduces material waste, lowers operational costs | Optimized nesting for specific part geometries |

| Enerji Tüketimi | Power usage during operation | Lower utility bills, reduced carbon footprint | Energy-efficient components for tailored power needs |

| Consumables Lifespan | Durability and replacement cost of cutting nozzles, lenses, etc. | Reduces recurring expenses, less frequent replacements | Choice of specific consumables for different materials |

| Otomasyon Seviyesi | Degree of automated loading, unloading, and process integration | Reduces labor costs, increases throughput | Modular automation add-ons for specific workflows |

| Service & Support Cost | Expenses for maintenance, spare parts, and technical assistance | Minimizes downtime, extends machine lifespan | Tailored service contracts, specialized training |

Material waste reduction saves costsDoğru

The "Zero-Waste Tail Material Innovation" demonstrates how advanced cutting logic can significantly reduce material waste, leading to substantial long-term savings.

Initial price determines total costYanlış

Total cost of ownership includes operational expenses, maintenance, and material efficiency - a cheaper initial machine often costs more long-term.

Sonuç

Choosing a high-performance tube laser cutting machine is a strategic investment in efficiency and growth. Focus on precision, speed, versatility, ease of use, smart system integration, and long-term cost-effectiveness, ensuring your choice directly addresses your operational needs and propels your business forward.

-

Learn how new technologies optimize processes beyond traditional metalworking methods for better efficiency. ↩

-

Understand the advantages and challenges of exporting fabrication equipment globally to expand business reach. ↩

-

Discover how precision influences production quality and efficiency in manufacturing industries. ↩

-

Discover benefits of multiple processes like punching and drilling within one machine. ↩

-

Learn about user interface innovations that simplify the operation of laser cutting machines ↩

-

Explore how intuitive touchscreens enhance machine operation and efficiency ↩

-

Understand smart diagnostics and their role in preventive maintenance ↩

-

Discover how machines communicate, analyze, and self-optimize in modern manufacturing ↩

-

Explore the benefits of energy-efficient systems in reducing operational costs ↩

Sorularınız mı var veya daha fazla bilgiye mi ihtiyacınız var?

Kişiselleştirilmiş yardım ve uzman tavsiyesi için bizimle iletişime geçin.