Tüp Lazer Kesim Makinesi Satın Almadan Önce Sorulması Gereken 5 Soru

Considering a tube laser cutting machine can feel overwhelming, but making the right choice is crucial for your business's future. Skip the pitfalls of an ill-suited investment and discover the precise questions that will guide you towards a solution that truly elevates your operations.

Before investing in a tube laser cutting machine, it's essential to ask about key features, production efficiency improvements, system compatibility, after-sales support, and the overall cost implications and return on investment. These questions ensure a strategic purchase that aligns with your operational goals and financial expectations.

As a professional in this field, I’ve seen firsthand how asking the right questions transforms a complex purchasing decision into a clear, strategic investment. Join me as we explore the critical inquiries that will empower you to select a machine that not only meets your current needs but also propels your business forward.

Navigating the landscape of industrial machinery requires more than just understanding specifications; it demands a deep dive into how a piece of equipment integrates with your existing workflows, addresses your operational pain points, and contributes to your long-term profitability. For businesses like Ahmed Al-Farsi’s mid-sized metal fabrication company in the UAE, the decision to invest in a laser tube cutting machine isn't just about acquiring new technology; it’s about strategically upgrading production efficiency, reducing skilled labor dependencies, and expanding service capabilities. My experience working with clients globally, including those focused on architectural metalwork and vehicle parts, has shown me that the true value lies in the machine's ability to deliver consistent, high-quality output while optimizing resource utilization. This critical thinking approach ensures that your investment provides a competitive edge, allowing you to not just keep pace with industry demands but to lead the way.

What are the essential features to look for in a tube laser cutting machine?

Are you struggling to identify which features truly matter amidst a sea of specifications? Ignoring critical functionalities can lead to operational bottlenecks and higher long-term costs. Focus on the core innovations that directly impact your efficiency and ease of use, ensuring your investment pays off.

Essential features to look for in a tube laser cutting machine include automation capabilities, an intuitive operating system that reduces skill dependency, integrated multi-process functions, and smart material utilization technologies. These elements are vital for maximizing productivity, simplifying operations, and achieving significant cost savings in metal fabrication.

When my clients, like Ahmed, approach me, they often detail a desire for seamless integration and reduced reliance on highly specialized operators. It’s not just about what a machine olabilir do, but how easily and efficiently it does it. Understanding these core features isn't just about ticking boxes on a spec sheet; it's about envisioning how the machine will transform your daily operations and contribute to your bottom line. Let's delve into the crucial aspects that set leading machines apart and make a real difference in a busy fabrication environment.

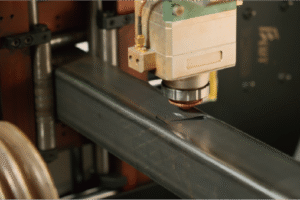

1. Revolutionary Ease of Operation: The No-CAD System

In an industry often constrained by the need for highly skilled CAD operators, the emergence of a No-CAD işletim sistemi1 represents a monumental leap forward. Traditional workflows demand that operators return to the design office for every complex 3D drawing modification, creating significant delays and increasing labor costs. For a business owner like Ahmed, who manages a team of 100+ staff and is looking to automate existing manual workflows, reducing reliance on specialized skills is a game-changer. My company, MZBNL, pioneered and perfected this No-CAD Operating System for our laser tube cutting machines, allowing standard tube types and hole patterns to be processed simply by entering parameters—no drawing required.

This innovation dramatically improves ease of use, shortens setup time, and significantly lowers the skill threshold for machine operation. Imagine the impact on a busy shop floor where every minute counts. Instead of spending 15 days on training at the equipment factory, operators now only need a single day of on-site training to become proficient. This 93% reduction in training time directly translates to quicker machine deployment and reduced overheads. For Ahmed, whose pain points include "previous machines required skilled CAD operators" and "high operator turnover caused retraining burdens," this feature directly addresses his most pressing operational challenges, ensuring continuity and reducing the costs associated with skill shortages.

2. Enhanced Automation and Efficiency: Front-Feeding & Multi-Process Integration

The pursuit of automation is central to upgrading production efficiency in modern metal fabrication. While many traditional machines still rely on manual side or rear loading, which is labor-intensive and time-consuming, advancements in feeding mechanisms have revolutionized this aspect. MZBNL's optimized front-feeding mechanism, for instance, automatically pulls the tube in from the front of the machine. This intelligent design immediately boosts feeding efficiency by approximately 40% and simultaneously reduces operator labor intensity by around 40%. For a company focused on high-volume contract-based fabrication services, as Ahmed's is, this increase in efficiency directly translates to higher throughput and reduced operational fatigue.

Beyond feeding, the integration of multiple processes2 within a single machine is another essential feature. Our Automatic Punching & Cutting Integrated Machine, for example, combines laser cutting with punching capabilities. This multi-process integration eliminates the need for separate machines and multiple setups, drastically shortening production cycles and improving overall workflow. Consider a scenario where a part requires both precise cuts and specific punching patterns; instead of moving the material between different stations, it can be completed on one machine. This streamlining is crucial for businesses handling diverse projects, from furniture components to automotive parts, allowing for greater flexibility and faster delivery times.

| Feature Type | Traditional Machine Workflow | MZBNL Laser Tube Machine Workflow | Efficiency Gain (Approx.) |

|---|---|---|---|

| CAD Gereksinimi | Complex 3D drawing per part | Parameter input for standard types | Reduced setup time by days |

| Feeding Method | Manuel yan/arka yükleme | Automatic front-feeding | 40% faster feeding |

| Process Steps | Separate cutting & punching stations | Integrated cutting & punching | Reduced material handling |

| Operatör Eğitimi | 15 days off-site | 1 gün yerinde | 93% faster training |

3. Material Optimization & Cost Savings: Zero-Waste Tail Material

Material utilization is a hidden yet significant factor in the profitability of metal fabrication. Conventional laser cutting systems typically start from the tube head, inevitably generating unusable tail material at the end of the process. This waste accumulates over time, adding up to considerable material loss and reduced profit margins, especially for high-volume operations. My company, MZBNL, recognized this inefficiency and redesigned the cutting logic to address it head-on.

Our innovative zero-tail design3 calculates from the rear chuck as the origin, allowing the system to eliminate leftover tail material as long as the remaining section is smaller than the product length. This seemingly small adjustment has a profound impact: it maximizes material utilization and boosts cutting efficiency by ensuring that nearly every inch of the tube is transformed into a sellable product. For Ahmed, whose profit model relies on delivering finished parts to builders, decorators, and OEMs, minimizing waste directly enhances his contract profitability. Beyond the direct cost savings on materials, this innovation also reduces waste disposal costs and contributes to a more sustainable manufacturing process. It’s a testament to how intelligent engineering can solve common industry pain points, ensuring that every cut contributes value.

CAD'siz sistemler eğitim süresini kısaltırDoğru

No-CAD operating systems allow operators to process standard tube types by entering parameters, reducing training time from 15 days to just 1 day.

Önden besleme verimliliği azaltırYanlış

Front-feeding mechanisms actually increase feeding efficiency by approximately 40% compared to manual side or rear loading methods.

How does a tube laser cutting machine improve production efficiency?

Is your current production bottleneck holding you back from growth? Relying on outdated methods can lead to slower output and missed opportunities. Embrace the power of advanced technology to revolutionize your workflow and achieve unprecedented levels of efficiency.

A tube laser cutting machine significantly improves production efficiency through its high-speed and high-precision cutting capabilities, integrated multi-process functionality, and automated material handling. These advancements reduce cycle times, minimize rework, and optimize labor, directly leading to increased throughput and overall operational effectiveness.

From my vantage point at MZBNL, we've witnessed firsthand how a well-chosen tube laser cutting machine can transform a business. My client Ahmed, for instance, specifically seeks automated solutions to upgrade his production efficiency, knowing it's key to expanding his business in architectural metalwork and vehicle parts supply. The true magic lies not just in cutting speed, but in how these machines streamline the entire fabrication process. Let's explore the multifaceted ways these machines deliver substantial efficiency gains, moving beyond simple speed to a holistic enhancement of your entire production line.

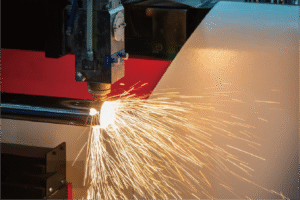

1. Speed and Precision as Core Efficiency Drivers

At the heart of any modern fabrication operation, speed and precision are paramount. Traditional cutting methods, such as sawing or manual punching, are inherently slower and prone to human error, leading to higher material waste and increased post-processing requirements. A high-speed, high-precision tube laser cutting machine drastically alters this paradigm. Our MZBNL machines, for instance, are engineered to deliver cuts at speeds previously unimaginable, maintaining micron-level accuracy throughout. This combination means that complex geometries, intricate designs, and multiple cuts can be executed in a fraction of the time it would take with conventional methods, with virtually no need for secondary finishing.

For a business like Ahmed's, which delivers finished parts to demanding clients, the ability to rapidly produce accurate components is a direct competitive advantage. Projects that once took days can now be completed in hours, allowing him to take on more contracts and meet tighter deadlines. The reduced error rate also means less material waste and fewer rejected parts, optimizing resource utilization. In a 2022 industry report4, companies investing in high-precision laser cutting technology reported an average reduction in rework by 25-30%, directly impacting profitability and project turnaround times. This shift from labor-intensive, error-prone processes to automated, precise operations is fundamental to modern production efficiency.

2. Workflow Streamlining Through Multi-Process Integration

True production efficiency isn't just about faster individual processes; it's about optimizing the entire workflow. Manual material handling, multiple setups, and transferring parts between different machines create bottlenecks and increase cycle times. This is where the multi-process integration feature of advanced tube laser cutting machines5 shines. Instead of needing a separate machine for cutting and another for punching, integrated solutions, like our Automatic Punching & Cutting Integrated Machine, allow both operations to be performed on the same platform without re-fixturing. This eliminates downtime associated with moving parts, re-aligning, and re-setting up.

Consider Ahmed's business, which manufactures items like railings, shelving, and auto parts—each often requiring both intricate cuts and precise holes. Previously, this might have involved cutting on one machine, then transporting parts to a punching press. With an integrated machine, the tube is loaded once, and the machine completes all required operations sequentially. This dramatically reduces human intervention, minimizes the risk of errors during transfer, and shortens the overall production cycle. Industry analyses show that integrated systems can reduce overall production time by 30-50% for multi-step processes, freeing up labor for more complex tasks and enabling a higher volume of finished goods to be produced per shift.

3. Operational Efficiency and Reduced Skill Dependencies

Beyond raw speed and integrated processes, the operational efficiency of a machine significantly impacts overall production. This includes aspects like ease of programming, maintenance requirements, and the skill level needed for operation. Here, the MZBNL No-CAD system stands out. Ahmed’s pain point regarding skilled CAD operators and retraining burdens is common. Traditional machines demand operators with specialized CAD software knowledge, making recruitment and training a significant hurdle. Our No-CAD system, which allows parameter-based processing of standard tube types and hole patterns, drastically simplifies operation.

This simplicity means that an operator can become proficient after just one day of on-site training, as opposed to the typical 15 days at an equipment factory. This not only reduces training costs but also minimizes the impact of operator turnover on production schedules. Furthermore, the Front-Feeding innovation reduces operator labor intensity by 40%, preventing fatigue and increasing sustained productivity over longer shifts. When combined with smart, digitalized systems that offer intuitive interfaces and diagnostic tools, the overall operational burden is significantly reduced. This translates to more consistent output, fewer errors caused by human fatigue, and a more resilient production line that is less dependent on a handful of highly specialized—and often difficult to retain—individuals.

Laser cutting reduces rework by 25-30%Doğru

High-precision laser cutting minimizes errors, leading to fewer rejected parts and less material waste.

Integrated machines cut production time by 50%Yanlış

While significant, integrated systems typically reduce production time by 30-50%, not a flat 50%.

What should you consider about the machine's compatibility with existing systems?

Are you concerned a new machine might disrupt your current setup? An isolated technological investment can create more problems than it solves, leading to inefficiencies and data silos. Prioritize compatibility to ensure seamless integration and a truly smart factory ecosystem.

Machine compatibility involves assessing how well a new tube laser cutting machine integrates with existing software (ERP/MES), processes various materials, and fits into your physical workshop infrastructure. Evaluating these aspects is crucial for a smooth operational transition, maintaining data flow, and maximizing the utility of your investment within your established production environment.

As Eric from MZBNL, I often advise clients like Ahmed, who is actively expanding his architectural metalwork and vehicle parts supply, that the true value of new machinery lies in its symbiotic relationship with existing operations. It’s not just about cutting tubes; it’s about how that cutting impacts your entire supply chain and information flow. Understanding compatibility is the bedrock of a truly intelligent manufacturing upgrade. Let's delve into the key areas where seamless integration can make or break your investment, ensuring your new machine enhances, rather than complicates, your production ecosystem.

1. Software and Data Integration Capabilities

In today's digital manufacturing landscape, a machine’s ability to communicate with existing software systems is as crucial as its cutting precision. Many fabrication businesses operate with Enterprise Resource Planning (ERP) or Manufacturing Execution Systems (MES)6 to manage orders, inventory, and production schedules. A new tube laser cutting machine, especially one that aims to elevate efficiency, must be able to seamlessly exchange data with these platforms. This means supporting standard communication protocols and offering robust APIs for integration. For Ahmed, who manages a stable, long-term business with complex contract-based fabrication services, data flow from design to production to inventory is vital for accurate costings, progress tracking, and timely delivery.

Consider a scenario where production orders are generated in an ERP system. A compatible laser cutting machine should be able to receive these job details directly, reducing manual data entry errors and setup times. Conversely, it should be able to report back on job completion, material consumption, and machine status, feeding critical data back into the ERP for real-time visibility and analytics. Without this integration, you create data silos, requiring manual data transfer that introduces delays and inaccuracies. This can directly impact project delivery times and profitability, particularly when dealing with the intricate demands of OEMs and large construction projects.

| Integration Aspect | Benefits of Compatibility | Risks of Incompatibility |

|---|---|---|

| Data Flow | Real-time production monitoring, accurate costing | Manual data entry, delays, error propagation |

| Workflow | Streamlined scheduling, reduced bottlenecks | Disjointed operations, increased manual steps |

| Ölçeklenebilirlik | Easier expansion, adaptable to new demands | Limited growth potential, system isolation |

| Support | Unified troubleshooting, remote diagnostics | Fragmented support, extended downtime |

2. Material Versatility and Processing Scope

The "tube" in tube laser cutting machine isn't a singular, monolithic entity. Different industries and applications require processing a diverse range of tube types, sizes, and materials. A critical compatibility consideration is whether the machine can effectively handle the specific materials your business works with and the variations your future projects might demand. Ahmed, for instance, expands his business in architectural metalwork and vehicle parts supply, which involves a variety of metal alloys and cross-sectional shapes for railings, shelving, and auto components. His ideal machine needs to cut round, square, rectangular, and even custom-shaped tubes, across various wall thicknesses and materials like mild steel, stainless steel, aluminum, and brass7.

A machine with limited material versatility will constrain your project capabilities and force you to either outsource specialized work or invest in additional, dedicated equipment. Conversely, a highly versatile machine allows you to take on a broader range of contracts, enhancing your market competitiveness and revenue streams. Our MZBNL machines are designed for multi-process integration and are compatible with a wide array of tube types and materials, a feature crucial for clients like Ahmed who value a turnkey solution8 that can adapt to evolving market demands. This adaptability ensures that your investment remains relevant and profitable as your business grows and diversifies its offerings.

3. Physical Footprint and Utility Requirements

While often overlooked, the physical compatibility of a new machine with your existing workshop infrastructure is paramount. A state-of-the-art laser cutting machine is a substantial piece of equipment, and its successful integration depends on practical considerations such as available floor space, power supply, ventilation, and material handling pathways. Before purchasing, it’s essential to conduct a thorough site assessment. Will the machine fit comfortably without disrupting existing workflows or creating safety hazards? Are the electrical supply and air compression systems sufficient to meet its operational demands?

For an established business like Ahmed's, which already has a functional production layout, bringing in a new large machine requires careful planning. Issues like insufficient power, inadequate cooling, or a cramped layout can lead to inefficient operation, higher utility bills, or even safety risks. A reputable supplier should offer guidance on site preparation and installation requirements. MZBNL, for example, emphasizes providing cost-effective customized solutions, which includes assessing client site conditions and offering installation support. Ensuring these physical aspects are compatible not only guarantees a smooth installation process but also ensures the machine can operate at its peak performance without placing undue strain on your existing infrastructure.

ERP integration prevents data silosDoğru

Seamless ERP/MES integration allows real-time data flow, eliminating manual transfers that create information gaps.

All tube lasers handle all materialsYanlış

Material versatility varies by machine; some cannot process specialized alloys or thick-walled tubes common in auto/construction industries.

How significant is after-sales support and warranty for tube laser cutting machines?

Are you dreading machine downtime and costly repairs? Neglecting robust after-sales support can turn a promising investment into a long-term liability. Prioritize comprehensive service and warranties to ensure continuous operation and peace of mind.

After-sales support and warranty are critically significant for tube laser cutting machines, as they directly impact uptime, operational longevity, and overall return on investment. Robust support includes comprehensive training, readily available spare parts, prompt technical assistance, and a global service network to minimize downtime and ensure sustained high performance.

From my perspective at MZBNL, I've seen countless times how the quality of after-sales support can be the deciding factor in a client's long-term success. Ahmed, my typical client, explicitly values "after-sales service and training support" and "spare parts availability and remote diagnostics," as his prior experiences sometimes lacked local service support. It’s not just about the machine itself, but the ecosystem of support that surrounds it. Let's explore why a strong post-purchase partnership is as vital as the machine's capabilities, ensuring your operations remain uninterrupted and your investment protected.

1. Comprehensive Training and Skill Transfer

The most advanced laser cutting machine is only as good as the operators who run it. Therefore, comprehensive training is not just an add-on; it's a fundamental pillar of effective after-sales support. For a business like Ahmed's, facing potential operator turnover and retraining burdens, effective training minimizes the learning curve and ensures quick proficiency. My company, MZBNL, focuses on providing user-friendly systems like our No-CAD İşletim Sistemi9, which allows operators to become proficient with just one day of on-site training, as opposed to the traditional 15 days at an equipment factory.

This drastically reduced training period translates directly into immediate productivity gains. Effective training should cover not just basic operation but also routine maintenance, safety protocols, and troubleshooting common issues. It empowers your team, fostering confidence and reducing reliance on external technicians for minor adjustments. Beyond initial setup, reputable suppliers offer ongoing training refreshers or advanced courses to help operators fully leverage new features or optimize performance. This investment in human capital ensures that your machine is utilized to its full potential, directly contributing to your bottom line by maximizing uptime and output.

2. Proactive Maintenance and Spare Parts Availability

Even the most robust machinery requires regular maintenance and, occasionally, part replacements. The significance of readily available spare parts and a proactive maintenance program cannot be overstated. A machine sitting idle due to a missing component represents lost revenue and missed deadlines. For Ahmed, who experienced "long machine lead times affected project delivery," this is a critical pain point. A reliable supplier should have a well-stocked inventory of genuine spare parts and a clear, efficient logistics chain to deliver them quickly, especially for international clients.

Furthermore, proactive maintenance agreements, which often include scheduled inspections and preventive servicing, are crucial. These agreements help identify potential issues before they escalate into major breakdowns, extending the machine's lifespan and ensuring consistent performance. Many modern machines also incorporate uzaktan tanılama yetenekleri10, allowing technicians to assess issues remotely, often resolving them without an on-site visit or guiding your team through the fix. This blend of readily available parts, preventive care, and remote support significantly minimizes downtime, ensuring your laser cutting machine remains a productive asset rather than a source of frustration.

3. Responsive Technical Support and Global Network

When an issue does arise, rapid and effective technical support is paramount. This includes access to knowledgeable technicians, clear communication channels, and a commitment to resolving problems efficiently. For international buyers like Ahmed, who sources from China, Germany, and Turkey, and prioritizes local service support, a global distributor network11 is a key differentiator. MZBNL's global distributor networks ensure that our clients, regardless of their location, have access to timely assistance.

This means having local agents or distributors who can provide on-site service, understand regional nuances, and communicate effectively in the local language. It also means having multi-channel support—phone, email, and potentially online portals for ticketing and knowledge bases. The quality of this support reflects the supplier's commitment to your long-term success. A supplier with a strong, responsive global network demonstrates their capability to minimize "equipment from some suppliers lacked local service support" pain points, ensuring that your investment in a high-tech machine is backed by equally high-quality service, protecting your operational continuity and return on investment.

Training reduces operator learning curveDoğru

Effective training programs can cut training time from 15 days to just 1 day, as mentioned with the No-CAD Operating System example.

Spare parts availability is unimportantYanlış

The text explicitly states that readily available spare parts are critical to avoid costly downtime, especially for international clients.

What are the cost implications and return on investment for tube laser cutting machines?

Are you hesitating due to the significant upfront investment? Overlooking the long-term cost benefits and potential for high returns can lead to missing out on transformative opportunities. Understand the full financial picture to make a truly informed decision.

The cost implications of a tube laser cutting machine extend beyond the purchase price to include operational, maintenance, and material costs, while its return on investment (ROI) is driven by significant efficiency gains, material savings, and enhanced production capabilities. A thorough analysis of these factors is essential to ensure a cost-effective and profitable acquisition.

As Eric from MZBNL, I recognize that for business owners like Ahmed, who values a high cost-performance ratio over low price, the decision isn't merely about the initial tag. It’s about a strategic investment that generates sustained value. My goal is to help you see beyond the sticker price to the true economic impact. Let's delve into a comprehensive financial analysis, exploring how a strategic investment in a tube laser cutting machine can deliver substantial long-term returns and secure a competitive edge for your business.

1. Understanding Toplam Sahip Olma Maliyeti (TCO)12

The initial purchase price of a tube laser cutting machine, while substantial, represents only a fraction of its total cost of ownership (TCO) over its operational lifespan. A truly informed decision requires accounting for all expenditures, including installation, training, power consumption, consumables (laser gas, nozzles, lenses), routine maintenance, spare parts, and potential software upgrades. Cheaper machines might have a lower upfront cost but could quickly accumulate higher TCO due to inefficient operation, frequent breakdowns, higher power demands, or expensive consumables. For Ahmed, whose primary purchase is a laser tube cutting machine with automatic feeding and punching capabilities, considering the TCO is crucial for his long-term profitability.

For instance, our MZBNL machines, while embodying advanced technology, are designed for cost-effectiveness. Features like the Zero-Waste Tail Material innovation directly reduce material costs, while the Front-Feeding mechanism cuts down on labor intensity, translating to lower operational expenses. Furthermore, the ease of operation with our No-CAD system significantly reduces training time and associated costs. A 2023 industry survey indicated that focusing on TCO rather than just purchase price could lead to 15-20% overall savings over a machine's 5-7 year lifespan13, making a higher quality, more efficient machine a far more economical choice in the long run.

| Maliyet Kategorisi | İlk Satın Alma | Operational Costs (Ongoing) | Maintenance & Support (Ongoing) |

|---|---|---|---|

| Machine Price | Yüksek | Low (Efficient design) | Moderate (Preventive care) |

| Installation | Orta düzeyde | N/A | N/A |

| Training | Low (1 day) | N/A | N/A |

| Energy Consumption | N/A | Orta düzeyde | N/A |

| Consumables | N/A | Low (Efficient use) | N/A |

| Labor | N/A | Low (Automation, No-CAD) | N/A |

| Spare Parts | N/A | N/A | Moderate (Global availability) |

2. Calculating Return on Investment (ROI) Through Efficiency Gains

The return on investment (ROI) from a tube laser cutting machine is primarily driven by its ability to significantly enhance production efficiency and reduce waste. For businesses like Ahmed's, which thrive on contract-based fabrication services, every improvement in speed, accuracy, and material utilization directly impacts the bottom line. The ROI isn't just about saving money; it's about making more money by increasing output and taking on more lucrative projects.

Consider the direct impact of MZBNL’s innovations:

- No-CAD System: Reduces setup time and operator training from 15 days to 1 day, saving labor costs and accelerating machine deployment.

- Önden Beslemeli İnovasyon: Increases feeding efficiency by 40% and reduces operator labor intensity by 40%, directly boosting throughput and allowing existing staff to handle more volume or focus on value-added tasks.

- Zero-Waste Tail Material: Maximizes material utilization, eliminating costly waste and significantly reducing raw material expenses. For a company processing tons of metal tubing annually, even a small percentage reduction in waste translates into substantial savings.

If a typical client, operating 8 hours a day, 5 days a week, can increase their output by just 20% due to these efficiencies, that translates to approximately 160 extra hours of production time per month, or roughly 2 extra weeks of output. For Ahmed, who earns by delivering finished parts, this could mean delivering more projects per month, directly increasing his profit margin and justifying the investment rapidly.

3. Value-Added Benefits and Long-Term Strategic Advantages

Beyond the quantifiable ROI derived from direct efficiency gains and cost savings, investing in a high-quality tube laser cutting machine offers several strategic, value-added benefits that cement long-term competitive advantages. For Ahmed, who seeks to expand his business in architectural metalwork and vehicle parts, and is even considering becoming a regional distributor, these benefits are particularly compelling.

Firstly, enhanced capabilities allow you to take on more complex and higher-value projects. The precision and versatility of a laser cutting machine enable intricate designs and specialized components that might be impossible or cost-prohibitive with traditional methods. This diversifies your service offerings and attracts premium clients. Secondly, the adoption of advanced, digitalized systems elevates your brand image as a cutting-edge, reliable fabrication partner, which is crucial for securing contracts with OEMs and large developers. Thirdly, features like MZBNL's No-CAD system and automated feeding reduce reliance on scarce skilled labor, future-proofing your operations against labor market fluctuations. Finally, for an entrepreneur like Ahmed, the potential for co-branding or exclusive distribution rights in a region like the Gulf, if the machine performs exceptionally, represents a significant growth opportunity. These strategic benefits, while harder to quantify directly, contribute immensely to market positioning, sustained growth, and long-term profitability.

TCO operasyonel maliyetleri içerirDoğru

Total Cost of Ownership accounts for installation, maintenance, and consumables beyond just purchase price.

Cheaper machines save moneyYanlış

Lower-priced machines often have higher long-term costs due to inefficiency and frequent breakdowns.

Sonuç

Making an informed decision when buying a tube laser cutting machine requires asking about essential features, efficiency improvements, system compatibility, robust after-sales support, and a clear understanding of TCO and ROI. Focusing on these five critical questions ensures your investment aligns with your business goals, delivering optimal performance and long-term profitability.

-

Understand how No-CAD systems simplify operations and reduce skill dependency in manufacturing. ↩

-

Discover how combining multiple processes on one machine enhances efficiency and reduces production time. ↩

-

Learn how intelligent cutting logic minimizes waste and boosts profitability in metal fabrication. ↩

-

Verify data and statistics on rework reduction from laser cutting investments. ↩

-

Discover how integrating multiple processes enhances overall laser cutting efficiency and workflow. ↩

-

Learn how ERP and MES systems streamline manufacturing processes and data management. ↩

-

Explore properties and applications of common metal alloys for laser cutting machines. ↩

-

Understand what a turnkey solution means and its benefits for manufacturing businesses. ↩

-

Discover how No-CAD systems simplify operation and reduce training time for laser cutting machines. ↩

-

Learn how remote diagnostics enable faster troubleshooting and reduce downtime for industrial equipment. ↩

-

Understand how a global distributor network ensures timely local support and service for international clients. ↩

-

Understand how to comprehensively calculate all costs associated with industrial machinery ownership over its lifespan. ↩

-

Explore the significant long-term financial advantages and cost reductions achievable with advanced manufacturing equipment. ↩

Sorularınız mı var veya daha fazla bilgiye mi ihtiyacınız var?

Kişiselleştirilmiş yardım ve uzman tavsiyesi için bizimle iletişime geçin.