Top Applications for a Tube Laser Cutting Machine in the Furniture Industry

Your furniture designs are getting more complex, but traditional methods can't keep up. This bottleneck slows production and inflates costs, putting you behind competitors who have already upgraded their technology.

The top applications are creating intricate frames for chairs and tables, custom shelving units, and decorative metalwork. A tube laser cutter enables complex joints and high-precision components, which are essential for modern, minimalist, and bespoke furniture designs that consumers increasingly demand.

I've spent years on factory floors, and I've seen firsthand how the right technology can transform a business. The shift from manual processing to automated laser cutting isn't just an upgrade; it's a fundamental change in how you think about design, production, and profitability. In this article, I'll walk you through exactly how tube laser cutting is reshaping the furniture industry and what it means for your operation. Let's dive in.

What Is the Role of Tube Laser Cutting in the Furniture Industry?

Making metal furniture used to be a slow, multi-step process. Cutting, drilling, and punching were separate, labor-intensive jobs that often resulted in costly errors and inconsistencies.

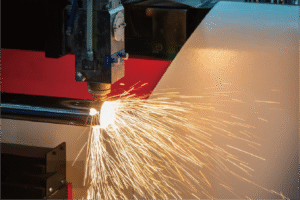

A tube laser cutter uses a focused laser beam to precisely cut, perforate, and engrave metal tubes. In furniture, it automates the creation of complex frames, joints, and components, replacing multiple traditional processes with a single, highly accurate operation.

When I talk to factory owners, I often ask them to count the number of steps it takes to get a single metal tube ready for assembly. The answer is usually three or four: sawing to length, moving it to a drill press for holes, then to another station for notching. Each step introduces a risk of human error, material damage, and production delays. A tüp lazer kesim makinesi changes this entire workflow. It consolidates all these processes into one seamless, automated operation. The machine takes a raw tube and, based on a digital design, performs all the necessary cuts, holes, and complex profiles in a single pass. This leap in technology is not just about doing the same work faster; it's about enabling a level of precision and design complexity that was previously impractical or impossible. It allows for perfect, repeatable results every time, ensuring that every chair leg, table frame, or shelf support is identical. This consistency is the foundation of high-quality furniture manufacturing.

What Are the Current Trends in Furniture Design and Manufacturing?

Today's consumers want unique, custom furniture, not generic, mass-produced items. This demand for personalization creates a huge challenge for manufacturers who are still relying on outdated, inflexible production lines.

Key trends include minimalist designs with clean lines, demand for personalized pieces, and the use of mixed materials like metal and wood. Sustainability and efficient production are also major drivers, pushing manufacturers toward more advanced, less wasteful technologies.

I travel to markets across Southeast Asia, Europe, and North America, and the message from consumers is clear: they want furniture that tells a story. This has led to several dominant trends that directly impact how we need to manufacture.

The Rise of Minimalism and Complex Geometries

Modern aesthetics favor clean lines, sleek profiles, and intricate patterns. Designers are creating chairs, tables, and lighting fixtures that look simple but are built on complex geometric foundations. These designs often require precise angles, seamless joints, and unique cutouts that are nearly impossible to achieve consistently with manual tools.

Personalization is the New Standard

From office furniture to home decor, customers expect options. They want to choose the size, color, and even the structural design of their products. This trend, known as toplu özelleşti̇rme[^1], requires a manufacturing process that is agile and can switch between different designs without long setup times.

Sustainability in Manufacturing

Both consumers and regulators are putting pressure on manufacturers to be more environmentally friendly. This means reducing material waste, lowering energy consumption, and creating durable products. Inefficient processes that generate piles of scrap metal are no longer just costly; they are a liability to a brand's reputation.

What Challenges Do Furniture Makers Face with Traditional Cutting Methods?

Relying on old cutting methods is like trying to win a race on foot. These processes are slow, inaccurate, and incredibly wasteful, leading to high operational costs and crippling production bottlenecks.

Traditional methods like sawing, drilling, and punching are labor-intensive, slow, and prone to error. They struggle with complex designs, produce significant material waste, and require multiple machines, which increases lead times and operational costs.

I've seen the frustration in the eyes of production managers who are constantly battling the limitations of their equipment. The problems are consistent across the board. First, there's the issue of accuracy. A manual saw cut followed by a drill press operation will never have the same precision as a single, computer-controlled laser cut. This leads to parts that don't fit together perfectly, requiring extra time for grinding, welding, and finishing. Second, material waste is a huge cost driver. Traditional methods often leave unusable tail material on every single tube, which adds up to significant losses over a year. Third, the process is incredibly slow. Moving tubes from one station to another, setting up each machine, and performing manual checks create a workflow that is riddled with non-productive time. This makes it impossible to respond quickly to urgent or custom orders. The table below breaks it down clearly:

| Metrik | Geleneksel Yöntemler | Tüp Lazer Kesim |

|---|---|---|

| Hız | Yavaş, çok adımlı süreç | Fast, single-pass operation |

| Accuracy | Low, operator-dependent | High, digitally controlled |

| Malzeme Atıkları | High (tail material, errors) | Minimal to zero |

| Labor | High, requires skilled operators | Low, easy to operate |

| Esneklik | Low, long setup for changes | High, instant design changes |

How Do Tube Laser Cutting Machine Provide Innovative Solutions?

Furniture manufacturers are desperately looking for a competitive edge. Falling behind on technology isn't just a risk; it means actively losing business to more agile and efficient competitors every day.

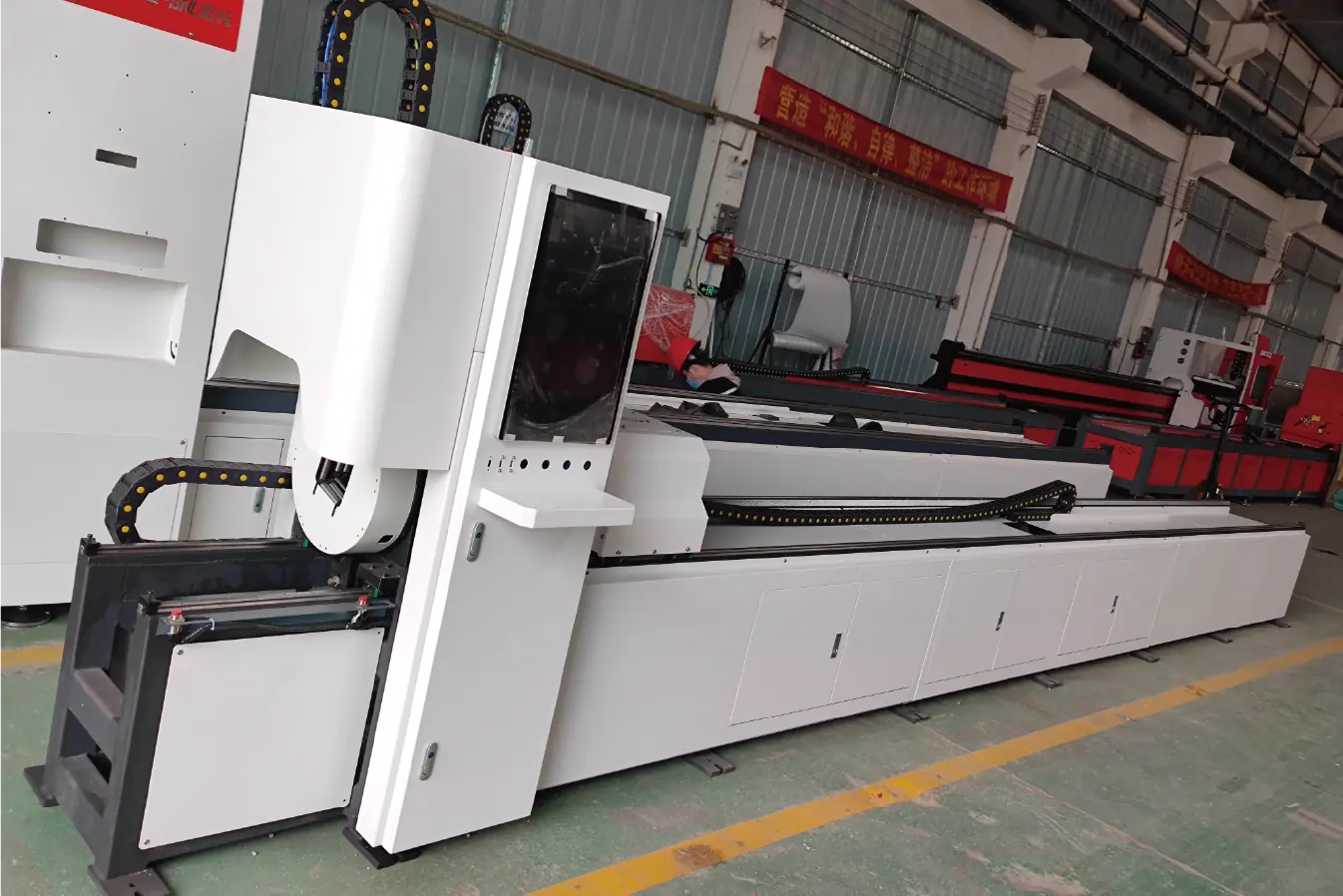

Tube laser cutters offer solutions by consolidating steps into one automated process. Our innovations, like the No-CAD system for fast setup, a front-feeding mechanism for efficiency, and zero-waste cutting, directly address costs, speed, and material utilization.

At MZBNL, we didn't just build another laser cutter. We listened to the challenges faced by over 4,000 clients and engineered solutions to their biggest problems. Our goal was to make this powerful technology accessible, efficient, and profitable for everyone, not just large corporations.

The No-CAD Revolution: From 15 Days to 1

The biggest barrier to adopting new technology is often the training required. That's why we developed our pioneering No-CAD sistemi. Instead of needing a skilled engineer to create complex 3D drawings for every standard tube, an operator can simply input parameters like length, hole diameter, and position directly into the machine. This innovation reduces on-site training from 15 days to just one day. It empowers companies to respond to market demands for custom furniture almost instantly.

Front-Feeding: Boosting Efficiency by 40%

I've watched operators struggle with heavy tubes, using side or rear-loading systems that are slow and physically demanding. Our Önden Beslemeli mekanizma automates this process, increasing feeding efficiency by approximately 40% and reducing operator labor by a similar margin. It’s safer, faster, and keeps the machine running with minimal downtime.

Zero-Waste Cutting: Maximizing Profitability

Material cost is one of the biggest expenses in furniture manufacturing. We tackled this head-on with our Sıfır Atık Kuyruk Malzemesi teknolojisi. By redesigning the cutting logic, our machine's rear chuck can move forward through the front chuck, allowing the laser to cut the entire length of the tube. This simple but brilliant change completely eliminates tail material waste, directly boosting your material utilization and profitability.

What Are the Future Prospects for Furniture Manufacturing Technology?

The manufacturing landscape is always evolving at a rapid pace. The question is no longer if you should upgrade, but what technology you need to be prepared for what's coming next.

The future lies in intelligent, automated, and eco-friendly manufacturing. We'll see deeper software integration (Industry 4.0), robotics for handling, and advanced laser technologies that allow for even greater design freedom and material efficiency.

Looking ahead, I see the tube laser cutter becoming the central hub of an intelligent furniture production line. The next wave of innovation will focus on total integration. Imagine a system where a customer's online order for a custom table is sent directly to the laser cutter, which then communicates with robotic arms to load the correct tubes, execute the cuts, and place the finished parts on a conveyor for automated welding and assembly. This is the promise of Industry 4.0, and it's closer than you think. At MZBNL, we are already developing smarter systems that can self-diagnose issues, optimize cutting paths with AI to save energy, and provide real-time production data directly to a manager's phone. The goal is a "lights-out" manufacturing environment that is not only hyper-efficient but also environmentally sustainable. This continuous technological advancement will further empower furniture makers to meet evolving consumer demands for quality, personalization, and sustainability.

Sonuç

A tube laser cutting machine is no longer just a tool; it is a core strategic asset for modern furniture manufacturers. It unlocks design freedom, enables mass customization, drastically cuts costs by reducing waste and labor, and secures a powerful competitive advantage in a demanding global market.

Sorularınız mı var veya daha fazla bilgiye mi ihtiyacınız var?

Kişiselleştirilmiş yardım ve uzman tavsiyesi için bizimle iletişime geçin.