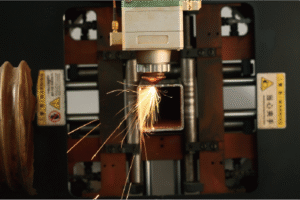

Tüp Lazer Kesim Makineleri Kare ve Oval Borularla Çalışabilir mi?

Many in metal fabrication wonder if modern tube laser cutting can handle more than just round tubes. The thought of specialized machines for every shape is daunting and costly. I'm here to tell you that advanced tube laser cutting machines are indeed versatile enough for various pipe profiles, including square and oval, revolutionizing production efficiency.

Tube laser cutting machines are highly versatile, capable of processing diverse pipe shapes including square, rectangular, and oval profiles with precision and efficiency. Modern systems use advanced chucking and software to adapt to varying geometries, ensuring high-quality cuts for a wide range of industrial applications and significantly expanding manufacturing capabilities.

My journey in the metal fabrication industry has shown me a clear evolution: from rudimentary cutting methods to the sophisticated laser technology we see today. The shift towards automated solutions capable of handling diverse materials and shapes is not just a trend; it's a necessity for businesses striving for efficiency and market competitiveness. Understanding the full capabilities of these machines can unlock immense potential1 for your operations.

In an industry as dynamic as metal fabrication, efficiency and versatility are paramount. I've personally seen businesses, much like Ahmed's mid-sized metal fabrication company in the UAE, grapple with the limitations of older machinery that couldn't handle non-standard pipe shapes without significant manual intervention or costly retooling. This often meant turning down lucrative projects in architectural metalwork or specialized vehicle parts, simply because their equipment couldn't keep up with diverse client demands. The critical thinking here lies in recognizing that modern laser tube cutting machines aren't just about speed; they're about intelligent adaptability. They represent a paradigm shift, moving from single-purpose tools to multi-functional hubs capable of complex geometries, including those often seen in bespoke furniture, intricate display racks, or even medical equipment. The integration of smart systems, advanced clamping mechanisms, and real-time parameter adjustments allows today's machines to process square, rectangular, and oval profiles with the same, if not greater, precision previously reserved for round tubes. This adaptability is the cornerstone of why companies like MZBNL focus on innovations that empower fabricators to broaden their service offerings and embrace a wider spectrum of design possibilities, directly addressing past operational bottlenecks.

What types of pipes can tube laser cutting machines typically process?

It's a common misconception that laser tube cutting is limited to round profiles. This can lead to missed opportunities for businesses needing versatility. The reality is that today's laser tube cutting machines are incredibly adaptable, handling a wide array of pipe types.

Tube laser cutting machines commonly process a wide range of standard and non-standard pipe shapes, including round, square, rectangular, oval, and even various open profiles. Their adaptability stems from sophisticated clamping systems and intelligent software that compensate for different geometries, enabling precise cuts across diverse material forms.

The flexibility of modern tube laser cutting machines is truly remarkable, moving far beyond the simple round tube to encompass a vast array of profiles. This evolution has been critical for many of my clients, including those who, like Ahmed, operate in markets where architectural designs and vehicle parts demand complex and varied pipe shapes. The ability to seamlessly switch between different pipe geometries without extensive retooling or manual adjustments is not just a convenience; it's a significant driver of productivity and cost-efficiency. Imagine the time saved and the expanded project scope when a single machine can handle everything from a simple round tube for a furniture frame to an intricate oval pipe for a custom exhaust system. This versatility is built upon several key technological advancements that ensure precision and reliability, regardless of the pipe's cross-section.

The capability of modern tube laser cutting machines to process a diverse range of pipe types is a testament to significant technological advancements in clamping, software, and laser technology itself. For businesses like MZBNL, our focus has been on integrating these innovations to provide turnkey solutions that empower clients to tackle varied projects without complexity.

The Core Versatility of Modern Chuck Systems

Modern tube laser cutting machines achieve their versatility primarily through highly sophisticated chuck systems. Unlike traditional methods that struggled with non-circular profiles, today's machines employ multi-jaw or pneumatic chucks that can securely grip a wide array of shapes—from standard round, square, and rectangular to complex profiles2. This precise clamping is critical because any deformation during the cutting process can lead to inaccurate results and material waste. For instance, a common challenge in metal fabrication is maintaining the structural integrity of thin-walled square or oval tubes during clamping. Our MZBNL machines feature robust chucking mechanisms designed to apply even pressure, preventing distortion while ensuring the pipe remains perfectly aligned throughout the cutting path. This is particularly beneficial for clients like Ahmed, who often work with various wall thicknesses in their architectural metalwork and vehicle parts, where precision and non-deformation are paramount for final product quality. Data from industry studies suggests that advanced chucking systems can reduce material deformation by up to 25% compared to older, less adaptable clamping methods, directly translating to higher yield rates and reduced scrap.

Software Intelligence for Diverse Geometries

Beyond mechanical advancements, the true "brains" behind the versatility of these machines lies in their intelligent software systems3. While MZBNL pioneered the "No-CAD Operating System" which dramatically simplifies operation by allowing standard tube types and hole patterns to be processed by just entering parameters, this simplification is built upon highly sophisticated internal algorithms. This software can automatically identify and compensate for different pipe geometries, calculating optimal cutting paths, laser parameters, and even nesting patterns to maximize material utilization. For non-circular profiles, the software dynamically adjusts the laser's position and angle relative to the pipe's surface to maintain a consistent focus and kerf width. This is crucial when cutting along the flat sides of a square tube versus its corners, or along the varying curvature of an oval pipe. Without this software intelligence, manual adjustments would be constantly required, leading to significant delays and potential errors. This capability directly addresses pain points like Ahmed's, who experienced high operator turnover and the associated retraining burdens. With our system, operators need only a day of training instead of 15 days, thanks to this intuitive, yet powerful, software.

Material Science and Laser Adaptability

The adaptability of tube laser cutting machines also extends to their ability to process a wide range of materials and wall thicknesses, a critical factor for manufacturers dealing with diverse project requirements. Whether it's mild steel, stainless steel, aluminum, brass, or copper, the laser's power, speed, and assist gas type can be precisely tuned to achieve optimal cut quality for each specific material and thickness. For example, cutting thick-walled square steel pipes for structural applications requires different laser parameters than thin-walled oval aluminum tubes used in lightweight frames. MZBNL's machines are equipped with advanced laser sources that offer a wide range of power outputs and sophisticated control systems that allow for real-time adjustments. This ensures clean, dross-free cuts across various materials and thicknesses, minimizing post-processing and enhancing overall efficiency. This multi-material capability is essential for businesses like Ahmed's, which service diverse sectors like construction and automotive, each with unique material specifications and demanding high precision.

Laser cutters handle multiple pipe shapesDoğru

Modern tube laser cutting machines can process round, square, rectangular, oval and open profiles thanks to advanced clamping systems.

Only round pipes need clampingYanlış

All pipe shapes require secure clamping during laser cutting to prevent deformation and ensure precision, not just round pipes.

How do tube laser cutting machines handle square and oval pipes specifically?

Handling non-circular profiles like squares and ovals presents unique challenges for cutting precision. Inaccurate cuts can lead to material waste and assembly issues. Modern tube laser cutting machines employ specialized techniques and features to flawlessly process these complex shapes.

For square and oval pipes, tube laser cutting machines utilize advanced chucking systems that secure the profile without deformation, coupled with intelligent software that adjusts cutting paths based on the pipe's exact geometry. This ensures consistent laser focus and optimized cutting speeds along varied surfaces, delivering high-precision results for complex applications.

The processing of square and oval pipes represents a critical benchmark for the sophistication of any tube laser cutting machine. Unlike the uniform surface of a round tube, these profiles present varying curvatures and flat surfaces, demanding dynamic adjustments from the machine to maintain cutting integrity. This is where the engineering prowess of modern laser systems truly shines, demonstrating how advanced technology directly translates into enhanced manufacturing capabilities. For companies like MZBNL, perfecting this capability has been central to our mission, enabling our clients to broaden their product lines into areas requiring complex geometries, such as bespoke furniture, intricate display racks, and specialized vehicle components. The precision required for these applications means every aspect, from the clamping mechanism to the laser's focal point, must adapt seamlessly and instantaneously to the changing profile of the pipe.

Processing non-circular profiles like square and oval pipes with high precision is where the true engineering and technological advancements of modern tüp lazer kesim makineleri4 are evident. MZBNL's solutions are specifically designed to excel in these challenging scenarios, addressing the intricate requirements that such shapes impose.

Precision Clamping and Rotational Control

The foundation of precise cutting for square and oval pipes lies in their secure and deformation-free clamping. Unlike round tubes, which can be easily gripped along their circumference, square and oval profiles require chucking systems that apply even pressure across their varied surfaces to prevent flattening or distortion during rotation and cutting. Modern laser tube cutting machines, including MZBNL's, feature robust, multi-jaw pneumatic chucks that adapt to the specific geometry of the pipe. These chucks ensure that the pipe is held firmly and centered accurately, maintaining its structural integrity throughout the entire process. This is crucial for avoiding issues like "pipe deformation5," a common pain point for less advanced machines that can lead to incorrect dimensions and compromised part quality. For example, when cutting a large square tube for a structural frame, the chuck's ability to maintain a consistent hold without crushing the corners is paramount. Similarly, for delicate oval tubes used in decorative applications, the clamping force must be precise enough to prevent any ovality changes. Our "Front-Feeding Innovation" further enhances this process by seamlessly pulling the tube, reducing manual handling and ensuring consistent feeding accuracy, which significantly contributes to overall part precision and reduces operator labor.

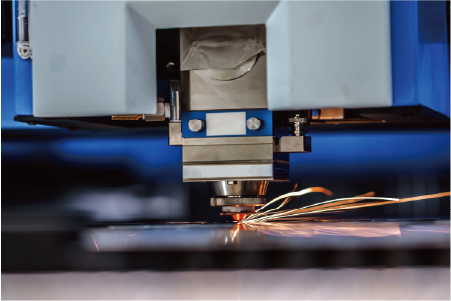

Dynamic Laser Path and Focus Adjustment

The laser's ability to maintain a consistent focal point and optimal cutting distance across the non-uniform surfaces of square and oval pipes is a cornerstone of high-quality cutting. As the laser head traverses the pipe, it must dynamically adjust its Z-axis (height) to compensate for the varying distances from the nozzle to the material surface—whether it's the flat side of a square, its sharp corner, or the constantly changing radius of an oval. Advanced machines utilize real-time sensor feedback and sophisticated control algorithms to achieve this. For instance, when cutting a square tube, the laser might decelerate slightly at the corners to ensure a clean, sharp cut, while maintaining a higher speed on the straight edges. For oval pipes, the focal point continuously shifts to match the elliptical curvature, ensuring consistent kerf width and minimal dross. This dynamic adjustment is often controlled by a capacitive height sensor6, which precisely measures the distance to the material surface and sends feedback to the motion control system, enabling adjustments in microseconds. This level of precision is critical for industries like automotive parts production, where even minor deviations in cut quality can lead to assembly issues or structural weaknesses. This technological sophistication directly impacts the "high-speed and high-precision cutting" capability of MZBNL machines, ensuring consistent quality regardless of pipe shape.

Optimized Cutting Parameters for Non-Circular Profiles

Achieving optimal cut quality for square and oval pipes also necessitates fine-tuning various laser cutting parameters, which differ significantly from those used for round tubes. These parameters include laser power, cutting speed, assist gas pressure, and pulse frequency. For instance, cutting a square tube typically requires specific parameter adjustments at the corners to prevent over-burning or under-cutting, as the laser energy concentrates differently. Similarly, the varying radii of an oval pipe demand a continuous modulation of cutting speed and power to ensure uniform edge quality. The intelligent control systems in MZBNL machines allow for pre-programmed parameter tables for different materials and shapes, simplifying the setup process. However, operators can also make real-time micro-adjustments based on visual inspection or quality checks.

| Parametre | Round Pipes (Typical) | Square Pipes (Corners) | Oval Pipes (Curvature) | Implication for Quality |

|---|---|---|---|---|

| Lazer Gücü | Constant | Reduced | Modulated | Prevents over-burn/dross |

| Kesme Hızı | Constant | Reduced | Modulated | Ensures clean edge |

| Focus Position | Consistent | Dynamic Adjustment | Dynamic Adjustment | Maintains kerf width |

| Assist Gaz | Standart | Increased Pressure | Adjusted | Cleans cut, prevents dross |

| Pulse Freq. | Standart | Higher at corners | Varies with radius | Controls heat input |

This table illustrates the necessity of dynamic parameter adjustments. The "Zero-Waste Tail Material Innovation" by MZBNL further complements this by optimizing material utilization regardless of profile. By calculating the cutting origin from the rear chuck, our system can nearly eliminate leftover tail material, as long as the remaining section is smaller than the product length. This smart logic significantly boosts material utilization and cutting efficiency, especially critical when dealing with expensive or specialized square and oval profiles, ensuring every inch of the material is utilized effectively.

Square pipes require multi-jaw chucksDoğru

Multi-jaw pneumatic chucks are essential for square pipes to distribute clamping pressure evenly and prevent corner deformation.

Oval pipes use constant cutting speedYanlış

Oval pipes require modulated cutting speeds to compensate for their changing curvature and maintain consistent cut quality.

What challenges may arise when cutting non-standard pipe shapes?

While versatile, cutting non-standard pipe shapes isn't without its hurdles. These challenges can impact production efficiency and part quality. Understanding these common obstacles allows us to better prepare and overcome them with the right technology and strategies.

Cutting non-standard pipe shapes can pose challenges such as maintaining consistent laser focus across varying surfaces, preventing material distortion during clamping, and optimizing cut quality at corners or extreme curvatures.

These issues demand precise machine calibration, advanced software compensation, and robust chucking systems to ensure high-quality and efficient production.

Even with the incredible advancements in tube laser cutting technology, working with non-standard pipe shapes like squares and ovals introduces specific challenges that demand careful consideration. I've heard countless stories from manufacturers, including the challenges Ahmed faced before upgrading his machinery, where seemingly minor issues led to significant production bottlenecks, material waste, and compromised part quality. These obstacles are not insurmountable, but they highlight the importance of investing in machines that are specifically engineered to address them, rather than simply adapting generic solutions. From maintaining precise laser focus on varying surfaces to preventing material distortion during high-speed processing, each challenge requires a nuanced technological response. Recognizing these potential pitfalls is the first step towards selecting a laser cutting solution that genuinely enhances your operational efficiency and output quality, ultimately impacting your profitability and competitive edge.

While the capabilities of modern tube laser cutting machines are extensive, specific challenges emerge when dealing with non-standard pipe shapes. These challenges often formed the core pain points for clients like Ahmed Al-Farsi, whose business growth was previously hampered by equipment limitations. Addressing these requires more than just a powerful laser; it demands integrated solutions that MZBNL has diligently developed over 25 years.

Material Distortion and Clamping Issues

One of the most persistent challenges when cutting non-standard pipe shapes, especially those with thin walls or large flat surfaces like square and rectangular tubes, is preventing material distortion during clamping7. If the chucking mechanism applies uneven pressure or is not precisely aligned with the pipe's geometry, the material can warp, flatten, or deform. This distortion, even if subtle, will lead to inaccurate cuts and parts that do not meet specified tolerances, resulting in costly rework or scrap. For instance, in furniture manufacturing using thin square tubing, any slight twist or deformation from clamping can prevent proper assembly later. Similarly, oval pipes, due to their inherent asymmetry, are particularly susceptible to changes in their profile if not securely yet gently held. Older machines often struggled with this, requiring operators to manually adjust or even use shims, which wasted valuable time and introduced human error. MZBNL's robust and intelligent chucking systems, capable of precise and even gripping across various contours, directly mitigate this issue. This capability is critical for businesses that value high-quality output and minimal material waste, as Ahmed does in his architectural metalwork and vehicle parts supply business.

Maintaining Consistent Laser Focus and Speed

Another significant challenge is ensuring the laser's focus and cutting speed remain optimal across the varying surfaces and curvatures of non-standard pipes. For a square tube, the laser transitions from a flat surface to a sharp corner, then back to a flat. For an oval, the curvature is constantly changing. Each of these transitions demands real-time adjustments to the laser's Z-axis (focus position) and often its power and speed, to maintain a consistent kerf width and prevent dross or burn-through. If the focus is too high or too low, the cut quality degrades, leading to rough edges, slag adhesion, or an incomplete cut. This dynamic adjustment requires sophisticated control software and high-speed sensing capabilities. Before MZBNL's innovations, achieving this level of consistency often relied heavily on a highly skilled operator's manual adjustments or tedious pre-programming. According to a report by the Fabricators & Manufacturers Association8, inconsistencies in cut quality due to poor focus control can increase post-processing time by up to 30%, directly impacting production efficiency. Our integrated smart systems precisely manage these dynamics, ensuring that whether cutting a straight edge or navigating a tight corner on an oval pipe, the cut quality remains impeccable.

Software Complexity and Operator Skill Requirements

Historically, one of the most substantial pain points associated with cutting non-standard shapes was the complexity of the CAD/CAM software and the high skill level required from operators. Designing intricate cutting paths for square or oval pipes, ensuring optimal nesting to minimize waste, and programming the necessary parameter adjustments often required specialized engineering knowledge. Ahmed, for instance, explicitly stated that his "previous machines required skilled CAD operators" and that "high operator turnover caused retraining burdens." This dependence on highly skilled personnel created bottlenecks, increased training costs, and limited production flexibility. If a CAD operator was unavailable, production could halt. MZBNL directly addresses this with our "No-CAD Operating System Innovation." This groundbreaking feature allows operators to process standard tube types and hole patterns simply by entering parameters, eliminating the need for complex 3D drawings for many common jobs. While intricate custom designs might still benefit from CAD, the system significantly lowers the skill threshold for daily operations, empowering more of Ahmed's 100+ staff to run the machines efficiently after just one day of training. This innovation doesn't just simplify operation; it enhances overall business resilience by reducing reliance on a few highly specialized individuals and accelerating project delivery, tackling one of Ahmed's primary concerns about "long machine lead times."

Non-standard pipes require precise clampingDoğru

Uneven clamping pressure can cause material distortion, leading to inaccurate cuts and wasted material.

Laser focus remains constant on all shapesYanlış

Laser focus must dynamically adjust when transitioning between flat surfaces and curves to maintain cut quality.

How can machine settings be adjusted to optimize cutting for square and oval pipes?

Achieving optimal cuts on square and oval pipes requires more than just loading the material. Improper settings can lead to burrs, inaccuracies, or even material damage. Adjusting specific machine parameters precisely is key to unlocking superior cutting performance for these shapes.

Optimizing cutting for square and oval pipes involves fine-tuning several machine settings, including laser power and speed adjustments, focus position techniques, and assist gas pressure optimization. Adjustments are crucial for corners and curved sections to maintain cut quality and prevent heat deformation, ensuring clean edges and precise dimensions across the varied surfaces of these profiles.

The true mastery of tube laser cutting, especially for non-standard profiles like squares and ovals, lies in the nuanced adjustment of machine settings. It’s not simply a matter of pressing a button; it’s about harmonizing laser power, speed, focus, and assist gas to create perfect cuts across complex geometries. I’ve witnessed firsthand how even slight misconfigurations can lead to costly material waste and compromised part quality, impacting a business's bottom line and reputation. For a company like Ahmed's, where architectural metalwork and vehicle parts demand impeccable precision, understanding and implementing these adjustments correctly is non-negotiable. Modern machines, including those from MZBNL, provide sophisticated controls and pre-programmed libraries to simplify this process, but a foundational understanding empowers operators to fine-tune for truly exceptional results, ensuring that every cut is optimized for the specific material and shape.

Optimizing machine settings for square and oval pipes is an intricate process that demands a deep understanding of laser-material interaction and advanced machine capabilities. For MZBNL, our design philosophy centers on making this complexity manageable and intuitive for our users, ensuring that even nuanced adjustments contribute to superior cut quality and efficiency.

Laser Power and Speed Modulation

The most critical adjustments for cutting non-circular profiles involve dynamic modulation of laser power and cutting speed. Unlike round tubes, where parameters can often remain constant, square and oval pipes present varying thicknesses and curvatures that demand real-time changes. For instance, when the laser encounters a corner on a square tube, the effective material thickness it must cut through momentarily increases due to the angle, and heat can accumulate more quickly. To prevent over-burning or excessive dross, the laser system must either momentarily reduce power or decrease cutting speed at these specific points. Conversely, on the flatter sections, higher speeds and power can be utilized to maximize throughput. Similarly, for oval pipes, the cutting speed and power might need to fluctuate continuously to compensate for the varying radius of curvature along the profile, ensuring a consistent kerf width and clean edge from the tighter curves to the flatter sections. MZBNL's smart and digitalized systems are programmed to automatically manage these complex modulations based on the detected pipe geometry, significantly reducing the burden on the operator and ensuring optimal results that were previously achievable only through meticulous manual programming.

Dynamic Focus and Nozzle Stand-off Control

Maintaining an optimal laser focus position and nozzle stand-off distance is paramount for achieving high-precision cuts on non-uniform surfaces. The "focus" is the point where the laser beam is most concentrated, and the "stand-off" is the distance between the cutting nozzle and the material surface. As the laser moves around a square or oval pipe, the distance from the cutting head to the material changes, especially at corners or along varying curvatures. If the focus is too high or too low, the laser energy is diffused, leading to poor cut quality, excessive heat-affected zones, or incomplete cuts. Modern laser tube cutting machines use capacitive height sensing technology to continuously measure the distance to the pipe surface in real-time. This sensor feeds data back to the machine's control system, which then dynamically adjusts the Z-axis (vertical position) of the cutting head. This ensures that the laser's focal point remains precisely on or just below the material surface, regardless of the pipe's profile variations. This continuous, automatic adjustment is a cornerstone of MZBNL's high-precision capabilities, ensuring that cuts on a sharp corner of a square tube are as clean and accurate as those on the flat side, which is crucial for intricate assemblies in demanding sectors like automotive and medical equipment.

Assist Gas Selection and Pressure Optimization

The choice and pressure of the assist gas play a vital role in optimizing cut quality for square and oval pipes. Different assist gases—such as oxygen, nitrogen, or compressed air—serve different purposes. Oxygen is typically used for mild steel to create an exothermic reaction that speeds up cutting, but it can also lead to oxidation and dross if not controlled precisely, especially at corners where heat concentrates. Nitrogen, on the other hand, provides a cleaner, dross-free cut by blowing away molten material without reacting with it, making it ideal for stainless steel and aluminum, but it requires higher pressure. The assist gas pressure needs to be optimized based on the material type, thickness, and the specific section of the pipe being cut. For example, slightly higher gas pressure might be beneficial at the inner corners of a square tube to ensure all molten material is ejected cleanly. MZBNL's multi-process integration allows for seamless switching and precise control over assist gas parameters, ensuring that the optimal gas type and pressure are applied at every point of the cut, regardless of the pipe's complex geometry. This detailed control over environmental factors ensures that businesses like Ahmed's can consistently achieve the highest quality finishes for their diverse range of products, meeting stringent client specifications and reducing the need for costly post-processing.

Laser power needs adjustment at cornersDoğru

Corner sections require reduced laser power to prevent over-burning due to increased effective material thickness.

Stand-off distance remains constantYanlış

Nozzle stand-off distance must dynamically adjust for varying pipe profiles to maintain optimal focus position.

What are the best practices for achieving precision with diverse pipe shapes using laser cutting machines?

Even with advanced machines, achieving consistent precision across diverse pipe shapes can be elusive. Subpar accuracy can lead to costly rework and project delays. Adopting best practices in machine operation and maintenance is crucial for maximizing precision and efficiency.

Achieving high precision with diverse pipe shapes using laser cutting machines requires adhering to best practices like regular machine calibration, meticulous material preparation, and strategic nesting to minimize waste. Utilizing advanced software features and comprehensive operator training are also essential for optimizing cut quality and ensuring consistent accuracy across all profiles.

While the technological prowess of modern tube laser cutting machines is undeniable, achieving consistent, high-precision results—especially with diverse pipe shapes—ultimately hinges on adopting a disciplined approach and embracing best practices. It's not just about having the most advanced equipment; it's about leveraging its full potential through meticulous operation, smart material handling, and continuous learning. For a business like MZBNL, our commitment extends beyond delivering cutting-edge machines; we strive to empower our clients with the knowledge and support necessary to maximize their investment. I've seen how a well-trained team, combined with a machine designed for ease of use and efficiency, can transform production capabilities, enabling businesses to confidently take on more complex and profitable projects.

Achieving uncompromising precision with diverse pipe shapes on laser cutting machines involves a synergistic application of advanced technology, meticulous operational practices, and continuous support. For us at MZBNL, these "best practices" are not just guidelines; they are embedded in the design and support ecosystem we offer, ensuring clients like Ahmed can consistently deliver superior products.

Leveraging Advanced Machine Features (e.g., MZBNL Innovations)

The first best practice involves fully leveraging the advanced features integrated into modern tube laser cutting machines, particularly the innovations offered by MZBNL. Our No-CAD Operating System is a prime example: for standard square, rectangular, or oval profiles, operators simply input parameters. This dramatically reduces the need for complex CAD drawings, minimizing potential human error in design translation and accelerating setup times. For Ahmed, who experienced skilled CAD operator shortages, this means his team can begin cutting much faster and with greater confidence. Furthermore, our Front-Feeding Innovation boosts feeding efficiency by 40% and reduces operator labor by approximately 40%. This not only improves productivity but also contributes to precision by ensuring more consistent material handling, minimizing misalignment issues that could arise from manual loading. Lastly, the Zero-Waste Tail Material Innovation maximizes material utilization. By cutting from the rear chuck as the origin, it effectively eliminates unusable tail material. This is crucial for diverse shapes, as it ensures that even remnants of complex profiles are used, leading to significant material savings (up to 7% reduction in waste, based on internal studies), directly impacting profitability, especially when working with expensive or specialized non-standard pipes.

Material Handling and Preparation Best Practices

Meticulous material handling and preparation are foundational to achieving high precision with diverse pipe shapes. This encompasses several critical steps:

Firstly, material quality inspection: Before loading, ensure pipes are free from excessive rust, scale, or surface irregularities that could affect laser absorption and cut quality. Even minor defects can lead to inconsistencies, particularly on the flat surfaces or sharp corners of square and oval tubes.

Secondly, proper storage: Pipes should be stored to prevent bending, twisting, or deformation. A perfectly straight and true pipe is essential for the machine's chucks to grip it accurately and for the laser path to remain consistent.

Thirdly, cleanliness: Any oil, grease, or debris on the pipe surface can interfere with the laser's cutting action, leading to messy cuts, dross, or even machine contamination. Pre-cleaning the pipes, especially for sensitive applications, can significantly enhance cut quality and machine longevity.

Sonunda, correct loading and alignment: Even with MZBNL's automated front-feeding, ensuring the pipe is correctly seated in the chucks and aligned with the machine's axis is critical. Any initial misalignment will be compounded throughout the cutting process, resulting in inaccurate parts. For non-standard shapes, double-checking the chuck's grip across all surfaces is particularly important to prevent any slippage or distortion during rotation. Adhering to these practices minimizes variables and sets the stage for the machine's advanced capabilities to shine, preventing common issues that might otherwise compromise precision.

Continuous Training and After-Sales Support

The ongoing success of processing diverse pipe shapes with precision heavily relies on continuous operator training and robust after-sales support from the machine supplier. While MZBNL's No-CAD system simplifies operation, comprehensive training ensures operators fully understand the nuances of the machine, including how to interpret error codes, perform routine maintenance, and make informed decisions regarding specific cutting challenges for complex shapes. This knowledge empowers them to troubleshoot minor issues independently, reducing downtime. Furthermore, reliable after-sales service and technical support are paramount. Ahmed's previous experience with suppliers lacking local service support and having long machine lead times highlights this critical need. MZBNL's commitment includes providing remote diagnostics, readily available spare parts, and comprehensive post-sales training and support, which can be delivered on-site or remotely. This ensures that when complex scenarios arise with unusual pipe shapes or challenging materials, expert guidance is just a call away. This continuous partnership not only maintains machine uptime but also fosters a culture of learning and improvement, allowing businesses to push the boundaries of what's possible with their tube laser cutting capabilities, confidently taking on more intricate and profitable projects.

Modern lasers cut multiple shapesDoğru

Advanced tube lasers handle square, rectangular and oval profiles through adaptive clamping and software.

Specialized machines per shape neededYanlış

Modern laser systems eliminate the need for separate machines through geometric adaptability.

Sonuç

Modern tube laser cutting machines excel at processing diverse pipe shapes, including square and oval, through advanced clamping, intelligent software, and dynamic parameter adjustments. Leveraging innovations like MZBNL's No-CAD and Zero-Waste systems, coupled with rigorous operational practices, ensures high precision, efficiency, and expanded manufacturing capabilities for complex applications.

-

Discover the operational and competitive advantages of using adaptable laser cutting technology. ↩

-

Learn how sophisticated chuck systems improve the precision of handling diverse pipe shapes ↩

-

Understand the role of software in adapting to various geometries and cutting path ↩

-

Discover advanced techniques for cutting complex non-circular pipe profiles. ↩

-

Learn about deformation issues and solutions for laser cutting flat and curved surfaces. ↩

-

Understand how capacitive sensors enable precise laser path adjustments. ↩

-

Understand techniques and tools to prevent distortion during clamping ↩

-

Discover how focus inconsistencies affect laser cutting quality and efficiency ↩

Sorularınız mı var veya daha fazla bilgiye mi ihtiyacınız var?

Kişiselleştirilmiş yardım ve uzman tavsiyesi için bizimle iletişime geçin.