Tüp Lazer Kesim Makinelerinin İnşaat Alanındaki Gerçek Dünya Kullanım Örnekleri

Are you grappling with the limitations of traditional metal fabrication in your construction projects, facing slow progress and design constraints? This often leads to project delays, inflated costs, and a frustrating inability to bring complex architectural visions to life. Fortunately, tube laser cutting machines offer a transformative solution, empowering precision, speed, and innovation in construction.

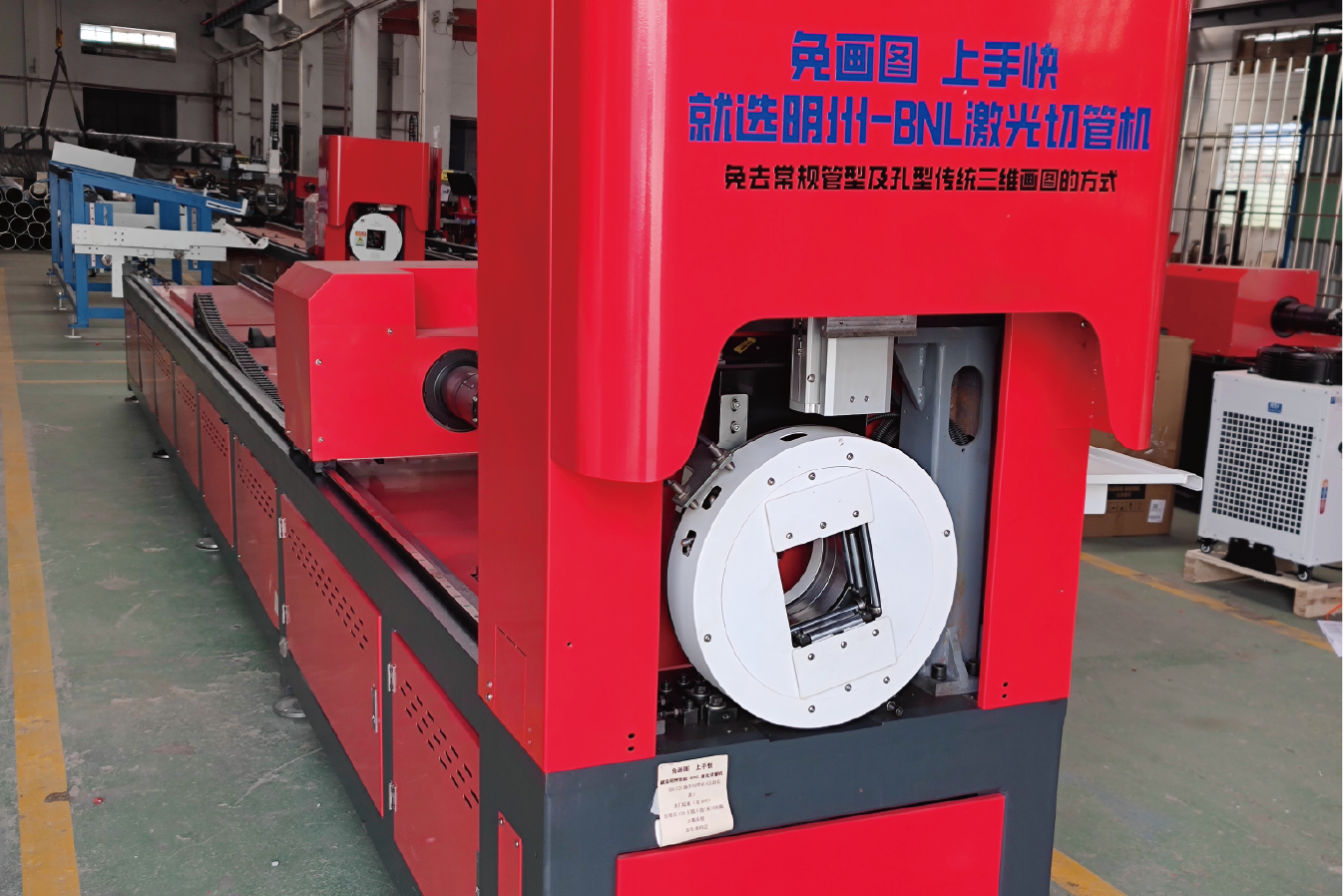

Tube laser cutting machines automate the precise cutting, notching, and shaping of metal tubes and profiles used in building projects. This technology facilitates intricate designs, enhances material efficiency, and significantly accelerates the fabrication of both structural and architectural components, profoundly impacting modern construction methodologies.

The construction industry is constantly pressed to deliver more intricate designs faster and more economically. As someone who's been in the metal fabrication machinery business for years with MZBNL, I've seen this pressure mount. It’s fascinating to witness how technologies like advanced tube laser cutting are stepping up, not just as an aid, but as a fundamental driver of change. Let's delve into how these machines are reshaping the way we build.

The journey towards adopting advanced manufacturing in construction, an industry sometimes seen as traditional, is now accelerating. The demand for enhanced efficiency, sustainable practices, and greater architectural freedom is compelling. Tube laser cutting machines, like the ones we develop at MZBNL, are central to this shift. While the initial investment might seem significant, the ROI becomes clear when you consider the dramatic improvements in speed, precision, waste reduction, and optimized labor. For instance, industry analyses, such as those from the Fabricators & Manufacturers Association (FMA)1, indicate that automated cutting can slash fabrication times by as much as 70% over manual techniques. This isn't merely about cutting metal faster; it's about enabling a paradigm shift in construction methodology, allowing architects to design with fewer constraints and contractors to execute complex projects predictably and profitably. Think about the soaring space frames in modern airports or the intricate facades of new commercial buildings – these are increasingly reliant on the precision of laser-cut components.

What role do tube laser cutting machines play in modern construction projects?

Are you struggling to execute complex metal designs within tight construction schedules using conventional methods? This often results in compromised precision, increased labor, and an inability to meet the sophisticated demands of modern architecture. Tube laser cutting machines provide a definitive answer, enabling intricate fabrication with unmatched accuracy and speed.

Tube laser cutting machines are pivotal in modern construction, enabling the automated, high-precision fabrication of complex structural and architectural metal components. They support intricate designs, optimize material use, minimize manual labor, and significantly shorten project timelines, thereby fostering greater efficiency and innovation in building.

Understanding the precise functions of these machines truly highlights their indispensability in today's construction landscape. It’s far more than just cutting pipes; it’s about unlocking new possibilities in structural engineering and architectural expression. I recall a client, Ahmed Al-Farsi from the UAE, who runs a mid-sized metal fabrication business. He was looking to upgrade his facility and was particularly impressed by how our MZBNL machines could effortlessly handle the complex joinery needed for the architectural metalwork he specializes in—a task that was a constant bottleneck with his manual processes. This technological leap is vital for contractors who aim to deliver top-tier, complex structures with greater efficiency and reliability. Let's explore the multifaceted contributions these machines make.

Tube laser cutting machines have become indispensable tools in modern construction, fundamentally altering how metal components are designed, fabricated, and integrated into building projects. Their role extends far beyond simple cutting, impacting everything from architectural freedom to structural integrity and project timelines. At MZBNL, we've seen firsthand how businesses like Ahmed's, which serve diverse sectors from architectural decoration to automotive parts, can leverage this technology to gain a competitive edge.

Enabling Complex Geometries and Architectural Freedom

One of the most significant roles of tube laser cutting machines is their ability to produce highly complex cuts and features on tubes and profiles with exceptional precision. This includes bevels, copes, notches, slots, and intricate hole patterns that would be incredibly time-consuming, difficult, or even impossible to achieve with traditional manual methods like sawing, drilling, and grinding. This capability directly translates into greater architectural freedom. Architects are no longer as constrained by fabrication limitations and can design more aesthetically ambitious and structurally innovative buildings. Parametric designs%20Parametric%20design%20is%20a%20design,relationship%20between%20design%20intent%20and%20design%20response.)2, organic shapes, and non-standard connection details become far more feasible and cost-effective to realize. For instance, creating the components for a geometrically complex geodesic dome or a flowing, artistic metal facade relies heavily on the precision cutting that these machines offer.

The precision offered by tube laser cutting, often within ±0.1mm, is a game-changer for construction projects. This accuracy ensures that fabricated components fit together perfectly during on-site assembly. This minimizes the need for costly and time-consuming adjustments, re-welding, or forcing parts to fit, which can compromise structural integrity. This "first-time fit" capability is especially critical in modular construction and prefabrication3, where entire sections of buildings are assembled off-site. The tight tolerances ensure that modules connect seamlessly, speeding up the overall construction process. Industry observations suggest that such precision can reduce assembly errors in complex steel structures by a very significant margin, leading to faster project completion and higher quality builds. Ahmed's pursuit of automated solutions for architectural metalwork, such as ornate railings and custom display racks, directly benefits from this precision, allowing him to deliver intricate designs that were previously too labor-intensive or prone to error.

Consider iconic modern architectural projects like the sweeping canopies of international airports or the intricate steelwork supporting large atriums. Many of these structures rely on precisely laser-cut tubular components to achieve their aesthetic and structural goals. For example, a project might involve a unique facade made of interlocking, custom-angled steel tubes. Manually fabricating hundreds or thousands of such unique components with the required accuracy would be a monumental task. A tube laser cutter, driven by a CAD model, can produce these parts consistently and efficiently. At MZBNL, our machines are designed to handle such complexity, and with features like our "No-CAD System Innovation," even operators without extensive 3D drawing skills can produce standard tube types and hole patterns simply by entering parameters, greatly enhancing ease of use and reducing the skill threshold.

Enhancing Structural Integrity and Material Optimization

The precision of tube laser cutting also plays a crucial role in enhancing the structural integrity of buildings. By enabling complex end preparations on tubes, such as perfect bevels for welding or intricate interlocking joints, engineers can design connections that distribute loads more effectively and provide greater strength compared to simpler, manually fabricated joints. This contributes significantly to the overall safety, durability, and longevity of the constructed facility. For example, in seismic zones, the ability to create precise and robust connections in steel frames is paramount.

Material optimization is another key role. Tube laser cutting machines, particularly when coupled with advanced nesting software, can arrange parts on raw material lengths in a way that minimizes waste. This is not only a direct cost saving, especially when working with expensive materials like stainless steel or specialized alloys, but also an important environmental benefit. Our MZBNL machines incorporate a "Zero-Waste Tail Material Innovation." This redesigned cutting logic calculates from the rear chuck as the origin, allowing the system to eliminate leftover tail material as long as the remaining section is smaller than the product length. This can result in material savings of 5-10% or even more in certain applications, a significant figure when dealing with large volumes of material, directly impacting Ahmed's bottom line for his contract-based fabrication services.

Imagine a project involving a large-span roof truss for a sports arena. Using tube laser cutting, engineers can design optimized truss members where each tube is cut to the exact length with precise end preparations (e.g., copes, bevels) for seamless connection to other members or gusset plates. This precision not only ensures a strong and accurate assembly but can also lead to material savings by allowing for more efficient structural designs that use less steel without compromising strength. The reduced weight can also translate to easier transportation and erection on site. For a fabricator like Ahmed, offering components that are optimized for both material use and ease of assembly provides a strong competitive advantage when bidding for projects.

Accelerating Project Timelines through Automation and Prefabrication

Perhaps one of the most impactful roles of tube laser cutting machines is their ability to dramatically accelerate project timelines. This is achieved primarily through automation and sheer processing speed. Laser cutting is significantly faster than most manual cutting, sawing, drilling, and grinding operations. A single tube laser cutting machine can perform multiple operations that would otherwise require several separate manual steps, different machines, and considerable material handling between stations. This consolidation of processes drastically reduces the overall fabrication time for tubular components.

The high level of automation is a key factor. Modern tube laser cutting machines are typically integrated into a digital workflow (CAD/CAM). Design data is sent directly from the design office to the machine, minimizing the potential for human error in interpreting drawings and reducing setup time. Our BNL "No-CAD System Innovation" further accelerates this by allowing operators to input parameters directly for standard shapes and hole patterns, significantly reducing the dependency on skilled CAD operators. This was a major pain point for Ahmed, who faced challenges with operator turnover and the associated retraining burdens. The ability for an operator to be trained on-site in just one day, as opposed to the traditional 15 days at the equipment factory, is a huge efficiency gain. Furthermore, BNL’s front-feeding innovation increases material feeding efficiency by about 40% and reduces operator labor intensity by a similar margin, directly contributing to faster throughput.

This speed and precision make tube laser cutting ideal for prefabrication. Components can be manufactured to tight tolerances in a controlled factory environment and then transported to the construction site ready for immediate assembly. This significantly reduces on-site labor requirements, minimizes weather-related delays, and generally speeds up the overall construction schedule. For instance, the entire steel frame for a series of modular classrooms or retail units could be fabricated and pre-assembled in sections using laser-cut tubes. Reports from the modular construction sector often cite reductions in on-site construction duration by 30-40% or more when leveraging such advanced prefabrication techniques. By adopting this technology, Ahmed can confidently take on larger projects and meet the increasingly tight deadlines common in the construction industry, particularly for his clients in architectural metalwork and vehicle parts supply.

| Feature Impacted | Traditional Method Performance | Tube Laser Cutting Performance (e.g., MZBNL) | Improvement Highlight |

|---|---|---|---|

| Design Complexity Handling | Limited, labor-intensive | High, automated processing | Enables intricate architectural and structural designs |

| Fabrication Speed | Slow, multi-step process | Fast, consolidated operations | Up to 70% reduction in fabrication time possible |

| Component Precision | Lower, operator-dependent | High (e.g., ±0.1mm), consistent | Ensures perfect fit-up, reduces on-site rework |

| Malzeme Atıkları | Higher | Lower (e.g., zero-tail material innovation) | Significant material cost savings (5-10%+) |

| Labor Requirement | High, skilled for many tasks | Lower, simplified operation (e.g., No-CAD) | Reduces reliance on scarce skilled labor, lowers costs |

| CAD Dependency | High for complex parts | Reduced/eliminated for standard parts | Faster setup, lower skill barrier for operation |

Laser cutting reduces fabrication timeDoğru

Industry analyses show tube laser cutting can reduce fabrication time by up to 70% compared to manual methods.

Manual methods offer better precisionYanlış

Tube laser cutting achieves precision within ±0.1mm, far surpassing manual cutting's operator-dependent accuracy.

How have tube laser cutting machines improved construction efficiency?

Are project delays and budget overruns a constant source of stress in your construction business? Inefficient fabrication processes for metal components are often a major culprit, leading to wasted materials, inflated labor costs, and missed deadlines that can damage your profitability and reputation. Tube laser cutting machines offer a powerful solution by dramatically boosting construction efficiency through streamlined fabrication, unparalleled precision, and minimized waste.

Tube laser cutting machines enhance construction efficiency by automating intricate cutting tasks, significantly cutting down fabrication time, reducing material wastage via optimized nesting and features like zero-tail cutting, and guaranteeing high precision for smoother, faster assembly, ultimately leading to quicker project completion and reduced labor expenditure.

The pursuit of greater efficiency is a relentless driver in the construction sector. It's not merely about accelerating work, but about working smarter. Having been involved with MZBNL and seeing the evolution of metal fabrication technology, I’ve observed how embracing innovations like tube laser cutting can be a genuine game-changer. Consider the cascading benefits: quicker fabrication leads to faster assembly, which in turn means projects are completed sooner, liberating resources and capacity for new undertakings. Ahmed, my client in the UAE, was specifically seeking automated solutions to elevate his production efficiency for his growing architectural metalwork and vehicle parts supply business. He understood that investing in such technology was key to scaling his operations and improving his competitive standing. Let’s explore the specific mechanisms by which these machines deliver such substantial efficiency gains.

The impact of tube laser cutting machines on construction efficiency is multifaceted and profound. By addressing traditional bottlenecks in metal fabrication, these machines enable a leaner, faster, and more cost-effective approach to building. At MZBNL, we've designed our machines with features specifically aimed at maximizing these efficiencies, drawing on 25 years of experience in metal fabrication and insights from over 4000 global enterprise clients.

Streamlining the Fabrication Workflow

One of the primary ways tube laser cutting machines improve efficiency is by consolidating multiple traditional fabrication steps into a single, automated process. Conventionally, preparing a metal tube for a construction assembly might involve sawing it to length, then moving it to a milling machine for coping or notching, then to a drill press for holes, and finally to a deburring station. Each step requires material handling, setup time, and the potential for error accumulation. A tube laser cutter, however, can perform all these operations – cutting to length, creating complex profiles, beveling edges, and cutting holes of various shapes and sizes – in one continuous operation on a single machine. This dramatically reduces material movement, queue times between operations, and the overall footprint required for fabrication.

This streamlined workflow is further enhanced by advanced CAD/CAM integration4. Digital 3D models of the required components are directly translated into machine instructions by CAM software. This eliminates the need for manual interpretation of drawings on the shop floor, reducing the likelihood of errors and significantly cutting down on setup times. For instance, our MZBNL machines feature a \"No-CAD System Innovation,\" which is a pioneering development. For standard tube types and common hole patterns, operators can bypass the CAD office entirely. They simply enter the required parameters (length, diameter, hole size, location, etc.) directly into the machine's control interface. This dramatically improves ease of use and shortens setup time, especially for repeat jobs or simple modifications. This was a critical factor for Ahmed, who, like many fabricators, struggled with the dependency on skilled CAD operators and the training overhead associated with high staff turnover. Our system allows an operator to become proficient with just one day of on-site training.

Consider a manufacturer producing steel frames for modular housing units. Before implementing tube laser cutting, their process for preparing the tubular frame members might have involved five or six distinct workstations and manual operations. By adopting a tube laser cutter, they could potentially reduce this to a single automated station. This not only frees up valuable floor space and labor but can also cut the lead time for producing a standard frame from several days to a matter of hours. Furthermore, innovations like MZBNL's front-feeding mechanism, which automatically pulls the tube from the front of the machine, contribute to this efficiency by increasing feeding speed by approximately 40% and reducing operator labor intensity by a similar margin compared to traditional side or rear manual loading methods. This enhances overall productivity and improves workplace ergonomics.

Achieving Unprecedented Speed and Precision

The sheer speed of laser cutting is a major contributor to improved efficiency. Depending on the material type, thickness, and the complexity of the cut, tube laser cutters can process material at very high speeds – often several meters per minute for common mild steel thicknesses. This high throughput is essential for meeting the tight schedules common in construction projects and allows fabricators to take on more work without proportionally increasing their labor force or equipment fleet. The ability to cut complex shapes at these speeds means that design intricacy no longer has to be a major bottleneck in the fabrication process.

Precision is the other side of the speed coin when it comes to efficiency. Tube laser cutting machines typically offer exceptional accuracy, often within ±0.1mm. Parts cut with this level of precision fit together perfectly during assembly on the construction site. This significantly reduces, or even eliminates, the need for on-site modifications such as grinding, re-cutting, or forcing components to fit. These on-site adjustments are notoriously time-consuming, labor-intensive, and can lead to delays and additional costs. The \"first-time fit\" achieved with laser-cut parts means that assembly crews can work much faster and more efficiently. This precision also enables more sophisticated joint designs, like tab-and-slot or interlocking features, which can simplify and expedite the assembly process, almost like putting together a high-precision metal puzzle.

Let's take the example of fabricating the intricate railings and balustrades for a large commercial building or a series of balconies. Such projects often involve hundreds or even thousands of tubular components, many of which might have unique angles or connection details. Using traditional methods, ensuring consistency and accuracy across all these parts would be a significant challenge. With tube laser cutting, each component can be produced to exact specifications, repeatedly and reliably. Ahmed, whose business includes producing railings and shelving, would see a direct and substantial improvement in efficiency. His assembly teams would spend less time wrestling with ill-fitting parts, and there would be fewer rejections or rework due to manufacturing errors. This translates directly to faster project completion for his clients (architectural decoration companies, builders) and higher profitability for his business.

Minimizing Material Waste and Rework

Material waste is a significant cost factor in metal fabrication. Tube laser cutting machines, when combined with intelligent nesting software, play a crucial role in minimizing this waste. The software analyzes all the parts required for a job and arranges them on standard raw material lengths (e.g., 6-meter or 12-meter tubes) in the most efficient way possible, minimizing the amount of unusable scrap. This is particularly beneficial when working with more expensive materials like stainless steel or aluminum, where even small percentage savings can have a big impact on the overall project cost. At MZBNL, our \"Zero-Waste Tail Material Innovation\" takes this a step further. By redesigning the cutting logic to calculate from the rear chuck as the origin, our system can effectively eliminate leftover tail material, provided the remaining section is smaller than the product length. This maximizes material utilization far beyond what's typically achievable.

The reduction in errors and subsequent rework is another key efficiency gain. Manual fabrication processes are inherently prone to human error – misread dimensions, incorrect angle cuts, or misplaced holes can lead to parts being scrapped or requiring extensive and costly rework. The high degree of automation and the precision inherent in laser cutting virtually eliminate these types of manufacturing errors. When parts are cut correctly the first time, every time, it means less wasted material, less wasted labor spent on corrections, and a smoother overall production flow. This reliability allows fabricators to plan their production schedules with greater confidence.

Industry data consistently shows that automated cutting systems can lead to significant reductions in material waste5, often in the range of 10-15% compared to traditional manual methods, and even more when specialized features like zero-tail cutting are employed. For a business like Ahmed's, which processes substantial volumes of metal for clients like automotive parts producers and furniture manufacturers, these savings accumulate rapidly and directly improve the bottom line. If his business fabricates, say, 100 tons of steel tubing per month, a 10% material saving translates to 10 tons of steel saved – a considerable financial benefit. This allows him to offer more competitive pricing to his clients or to reinvest the savings into further business development, perhaps even exploring his interest in becoming a regional distributor for high-performing machinery.

| Efficiency Aspect | Traditional Fabrication Approach | Tube Laser Cutting (e.g., MZBNL) Approach | Tangible Efficiency Improvement |

|---|---|---|---|

| Workflow Complexity | Multiple, separate manual operations & machines | Consolidated, single automated process on one machine | Drastically reduced material handling, labor, lead time |

| Setup & Programming | Manual, time-consuming, prone to operator error | Digital (CAD/CAM), fast, No-CAD for standard parts | Rapid job changeovers, increased machine uptime |

| Processing Speed | Slow, operator-skill dependent | High-speed, consistent, automated cutting | Significantly increased throughput, shorter project cycles |

| Part Accuracy | Variable, lower precision, requires checking | Consistently high precision (e.g., ±0.1mm) | Minimized on-site rework, faster assembly, better quality |

| Malzeme Kullanımı | Higher scrap rates, significant tail material waste | Optimized nesting, Zero-Waste Tail Material option | Substantial material cost savings (e.g., 5-15% or more) |

| Labor Efficiency | High labor input per part, multiple skilled roles | Lower labor input, one operator for automation | Reduced labor costs, addresses skill shortages effectively |

Lazer kesim malzeme israfını azaltırDoğru

Tube laser cutting machines use intelligent nesting software to optimize material usage, significantly reducing scrap compared to manual methods.

Manual cutting is more preciseYanlış

Laser cutting achieves ±0.1mm precision, far exceeding manual methods which are prone to human error and inconsistency.

What are some specific examples of tube laser cutting in construction applications?

Finding it hard to connect the dots between the technical capabilities of tube laser cutting and its actual use in the construction field? It's common to wonder how this advanced technology translates into tangible structures and components. Without concrete examples, the impressive benefits can feel somewhat abstract, making it challenging to fully appreciate its transformative potential or to justify specifying it for your projects. Let's bridge that gap by exploring some specific, real-world applications, ranging from complex architectural statements to robust structural systems, truly showcasing its versatility.

Specific examples include crafting intricate steel trusses for expansive structures like stadiums and atriums, producing custom architectural facades and curtain wall support systems, manufacturing precise components for modular and prefabricated buildings, and creating bespoke railings, staircases, and balustrades featuring complex designs and joinery.

The true impact and versatility of tube laser cutting technology become vividly clear when we examine its diverse applications across the wide spectrum of construction. This isn't a niche technology confined to one type of project; its capabilities are being ingeniously leveraged in numerous ways, from the highly artistic to the purely functional, where precision and speed are paramount. I often find myself sharing success stories with clients like Ahmed Al-Farsi, illustrating how businesses similar to his are utilizing these machines not just to improve existing processes but to expand their service offerings significantly—for instance, transitioning from basic pipe cutting to fabricating high-value, complex architectural elements that command better margins. This is particularly relevant for Ahmed, whose interests span architectural metalwork, display racks, and automotive parts. Let's delve into some compelling real-world scenarios that highlight this technology in action.

Tube laser cutting machines have carved out a significant niche in numerous construction applications, enabling projects that were once considered too complex, time-consuming, or costly with traditional methods. At MZBNL, we've witnessed our machines being employed by diverse clients, from large architectural firms to specialized fabrication shops like Ahmed's, which supply components to furniture manufacturers, automotive parts producers, and the architectural decoration sector.

Architectural Marvels: Facades, Canopies, and Decorative Elements

One of the most visually striking applications of tube laser cutting is in the creation of complex architectural facades and building skins. The technology allows for intricate patterns, perforations, and custom-angled cuts in metal tubes that form these external layers. Architects can design unique, lightweight, and aesthetically stunning exteriors that define a building's character. For example, a facade might consist of a lattice of interconnected tubes, each cut at a precise angle to create a specific geometric or organic pattern. This would be extremely challenging to achieve with manual cutting. Similarly, decorative screens, brise-soleils (sunshades)6, and artistic metal installations often rely on the precision of laser-cut tubes to realize the designer's vision.

Elaborate canopies and entryways are another area where tube laser cutting shines. These structures frequently involve custom-angled connections, complex joinery, and varying tube profiles to create supportive frameworks that are both functionally robust and visually appealing. Tube laser cutting ensures that all components are fabricated to exact specifications, simplifying assembly and ensuring structural integrity. Consider the large, sweeping glass canopies found at modern transportation hubs or corporate headquarters; the underlying steel or aluminum support structures often feature intricately cut tubular members. Ahmed’s focus on architectural metalwork for railings and decorative features aligns perfectly here. He could leverage a tube laser cutter to produce highly customized, ornate designs for high-end residential or commercial projects, moving beyond standard offerings.

A compelling, albeit large-scale, illustration of complex metalwork is the Louvre Abu Dhabi's iconic dome, which, while involving various fabrication techniques, showcases the kind of geometric complexity in metal that advanced manufacturing enables. More directly, a company specializing in bespoke metalwork for luxury retail interiors might use tube laser cutting to create unique shelving systems, display fixtures, and intricate artistic installations. These elements often require non-standard tube shapes and precise connections, all achievable with tube laser cutting. For Ahmed, this could mean producing premium display racks for high-end retail clients or custom furniture components for boutique manufacturers, significantly enhancing the value he can offer. Our MZBNL machines, with their capability for high-speed, high-precision cutting, are ideal for such applications.

Structural Integrity: Trusses, Space Frames, and Support Systems

In structural applications, tube laser cutting is invaluable for fabricating trusses, particularly those used for long-span roofs in stadiums, exhibition halls, airports, and large industrial buildings. These trusses are often composed of numerous tubular chord and web members that must connect at precise angles. Tube laser cutting enables the accurate cutting of these members, including complex copes (profiled end cuts to fit against another round tube) and bevels for welding. This precision ensures strong, reliable connections and significantly speeds up the assembly and welding process, whether on-site or in a prefabrication shop.

Space frames, which are three-dimensional truss-like structures7 often made from interconnected tubular members and spherical nodes, are another key application. The accuracy of the laser-cut tube ends and the precise placement of bolt holes or weld preparations are critical for the geometric integrity and ease of assembly of these complex structures. Using laser-cut components reduces the need for expensive custom jigs and fixtures during assembly and minimizes the risk of cumulative errors that can plague large, complex frameworks. This method ensures that the final structure matches the engineering design, crucial for proper load distribution.

Beyond these large-superstructure applications, tube laser cutting is also used for more common structural support systems. This includes fabricating pipe racks in industrial processing plants, support frames for heavy machinery, custom-designed mezzanine floors, or even specialized, heavy-duty scaffolding systems for complex industrial maintenance. The ability to quickly and accurately fabricate custom lengths, angles, and connection details is invaluable, especially in retrofit projects where standard off-the-shelf components may not fit existing conditions. For instance, if Ahmed's clients in the automotive sector need custom jigs or support structures for their production lines, a tube laser cutter allows him to deliver these with precision and speed. The "Start Cutting Without CAD Drawings" feature on BNL machines would be particularly beneficial for rapid prototyping or producing variations of standard support elements.

Specialized Construction: Modular Buildings and Custom Fixtures

The rise of modular and prefabricated construction has created a significant demand for precisely fabricated components, and tube laser cutting is a perfect fit. This technology is extensively used to create the steel or aluminum frames for modular units such as temporary or permanent housing, classrooms, site offices, bathroom pods, and even hotel rooms. The high precision of laser-cut tubes ensures that these modules, manufactured off-site in a factory environment, will fit together perfectly and align correctly when assembled on the construction site. This accuracy is fundamental to the speed and quality advantages offered by modular construction methods.

Tube laser cutting also excels in the production of custom fixtures and fittings within buildings. This broad category includes manufacturing components for bespoke staircases (stringers, handrails, balusters), safety railings for industrial platforms, architectural balustrades with intricate designs, and custom handrail systems. Beyond these, it extends to specialized commercial and industrial fixtures like heavy-duty shelving units for warehouses, robust display racks for retail environments (a direct market for Ahmed), and even structural frames for custom-built furniture. The ability to cut precise holes for connections, create smooth bends (when combined with benders), and ensure consistent quality makes laser cutting ideal for these applications where both aesthetics and functionality are important.

Consider a company that produces custom fitness equipment, another potential client type for Ahmed. They would use tube laser cutting to create the robust frames for treadmills, weight machines, squat racks, and other exercise apparatus. The machines allow for precise hole patterns for adjustable components, complex angles for ergonomic designs, and clean, accurate end preparations for strong, aesthetically pleasing welds. This ensures the final products are safe, durable, and meet high quality standards. For Ahmed, having a tube laser cutting machine like an MZBNL model, which offers high-speed and high-precision cutting, would allow him to competitively serve such clients by producing parts that require minimal post-processing and assemble flawlessly. His interest in supplying display rack and shelf suppliers, as well as furniture and sanitary ware manufacturers, directly benefits from this capability.

| Application Area | Specific Construction Example | Key Advantage of Tube Laser Cutting | Relevance to MZBNL / Ahmed's Business |

|---|---|---|---|

| Architectural Facades/Skins | Custom geometric patterns on building exteriors | Enables intricate designs, aesthetic freedom | Ahmed can offer high-value architectural metalwork. |

| Structural Trusses/Frames | Stadium roofs, airport terminals, industrial space frames | Precise connections for strength, faster assembly | Potential for Ahmed to expand into light structural fabrication. |

| Modular Construction | Prefabricated steel frames for housing/office units | Speed, accuracy, and repeatability for modules | Growing market; Ahmed could supply frame components. |

| Staircases & Railings | Bespoke architectural staircases, ornate balustrades | Customization, complex joinery, smooth finishes | Core business area for Ahmed; enhances design capability. |

| Custom Fixtures & Furniture | Display racks, industrial shelving, furniture frames | Precision for assembly, design flexibility | Directly serves Ahmed's existing client base. |

| Automotive/Equipment Parts | Chassis components, support frames for machinery | Complex shapes, high-volume capability | Supports Ahmed's automotive parts supply. |

Tube laser cutting enables complex architectural facadesDoğru

The technology allows for intricate patterns and custom-angled cuts in metal tubes, making it ideal for creating unique building exteriors.

Tube laser cutting is only used for small-scale projectsYanlış

This technology is extensively used in large-scale applications like stadium roofs, airport terminals, and industrial space frames.

How was the project impacted by the use of tube laser cutting machines?

Are you evaluating the true, measurable differences that adopting tube laser cutting technology can make to the outcome of a construction project? It's natural to wonder beyond the technical specifications. Without a clear understanding of the direct, tangible impacts on timelines, costs, and quality, it can be challenging to see past the initial investment and fully appreciate the transformative benefits that await. The good news is that these machines profoundly and positively impact projects by significantly slashing timelines, elevating quality standards, reducing overall costs, and unlocking new avenues for innovative design.

Projects incorporating tube laser cutting machines typically achieve marked reductions in both fabrication and assembly durations, experience lower material wastage, benefit from enhanced structural accuracy and overall quality, and gain greater design flexibility. This consistently results in overall cost savings and expedited project completion.

When a new technology like advanced tube laser cutting is introduced into the construction workflow, its genuine value is ultimately measured by the concrete changes it brings to project outcomes. It's one thing to discuss the impressive features of a machine, but it’s an entirely different and more compelling story to witness how those features translate into tangible improvements on the ground. I’ve personally seen clients, much like Ahmed Al-Farsi, initially approach this technology with a degree of caution, only to become staunch advocates once they experience the profound impact on their own production floor efficiency and their ability to deliver projects more effectively. The enhancements are rarely just marginal; they are often transformative, creating a ripple effect that positively influences everything from the project budget and schedule to the final aesthetic appeal and long-term structural performance. Let's examine these wide-ranging impacts more closely.

The integration of tube laser cutting machines into construction projects yields a cascade of positive impacts, fundamentally altering traditional metrics for success. These impacts are not just theoretical; they are consistently observed by fabricators and contractors who adopt this technology. At MZBNL, our focus on innovations like the No-CAD system, front-feeding, and zero-waste tail material is specifically designed to amplify these positive outcomes for our clients, addressing key pain points like those Ahmed experienced with skilled labor shortages and the need for greater operational efficiency.

Accelerated Project Timelines and Reduced On-Site Labor

A primary impact of using tube laser cutting machines is the significant compression of overall project schedules. The speed and efficiency of fabricating tubular components off-site mean that this critical path activity is completed much faster than with traditional methods. For instance, structural steel frames, architectural metalwork, or components for modular units can be produced in a fraction of the time. This allows subsequent construction phases, such as erection, cladding, or internal fit-out, to commence sooner, leading to an earlier overall project completion date. This acceleration is vital in a time-sensitive industry where delays can incur substantial financial penalties or missed market opportunities.

This acceleration is coupled with a notable reduction in on-site labor requirements. Because components are precisely cut and prepared in a controlled factory environment, they arrive on site ready for immediate assembly. This minimizes the need for skilled on-site welders, fitters, and fabricators to perform extensive cutting, grinding, shaping, or drilling adjustments. Such on-site "hot work" is often slow, dependent on weather conditions, and can pose safety risks. Reducing it means smaller, more efficient on-site crews can achieve more in less time. This is particularly beneficial in regions experiencing shortages of skilled construction labor8 or where on-site labor costs are very high. Ahmed, for instance, identified high operator turnover and retraining burdens as pain points. While this refers to his shop floor, the principle extends to site work: easier-to-assemble parts, thanks to machine precision, reduce the reliance on highly specialized (and often scarce) on-site assembly skills.

Consider a specific example: a project involving the construction of a multi-story commercial building with a complex steel exoskeleton featuring numerous tubular elements. Using traditional fabrication methods, the detailed cutting and preparation of these tubes might have been estimated to take 10-12 weeks, followed by a lengthy on-site assembly period involving significant welding and adjustment. By employing tube laser cutting for off-site prefabrication, the fabrication time for the tubular components could be reduced to 4-5 weeks. Furthermore, the precision of the laser-cut parts would ensure a much smoother and faster on-site assembly, potentially cutting the erection time for that steel package by 30-40%. Innovations like MZBNL's front-feeding system, which increases feeding efficiency by about 40%, contribute directly to such gains in fabrication speed, thus shortening the critical path.

Enhanced Quality, Accuracy, and Structural Performance

The impact on quality and accuracy is another crucial benefit. Automated tube laser cutting produces parts with a level of consistency and precision that is virtually impossible to achieve reliably with manual methods. Each component, whether it's the first or the thousandth, is cut to the same tight tolerances (often ±0.1mm with MZBNL machines). This uniformity eliminates the variability inherent in manual processes, which can be affected by operator skill, fatigue, or interpretation of drawings. The result is a higher overall quality of the fabricated assemblies and a finished structure that more closely adheres to the design specifications.

This enhanced accuracy directly translates into improved structural performance. Precise cuts and meticulously prepared joint interfaces (e.g., perfectly beveled edges for full penetration welds, accurately coped ends for truss connections) ensure stronger, more reliable connections that meet or exceed engineering requirements. This contributes significantly to the safety, durability, and long-term performance of the structure. Fewer on-site modifications and forced fits mean that the original design intent regarding load paths and stress distribution is maintained, leading to a more robust and reliable building. This was a key consideration for Ahmed, whose engineering background made him appreciate the value of precision in ensuring the integrity of automotive parts and architectural structures.

Imagine a project constructing a pedestrian bridge with gracefully curving tubular steel arches. The success of such a design hinges on each segment of the arch being cut to exact lengths and angles to ensure a smooth, continuous curve and proper load distribution. Tube laser cutting guarantees this precision. As a result, the on-site assembly process becomes more like assembling a perfectly engineered kit of parts, rather than a challenging fabrication exercise. Industry studies often highlight that rework due to poor fit-up of steel components can account for a surprisingly high percentage of steel erection costs, sometimes as much as 10-15%9. The precision offered by tube laser cutting largely eradicates this costly and time-consuming rework.

Significant Cost Savings and Improved Material Utilization

The culmination of speed, precision, and reduced labor often results in significant overall cost savings on a project. Direct cost reductions come from several areas: fewer labor hours required for both off-site fabrication and on-site assembly; substantially less material waste due to optimized nesting software10 and innovative features like MZBNL's "Zero-Waste Tail Material Innovation"; and a dramatic reduction in errors that would otherwise lead to scrapped parts or costly rework. These direct savings can be substantial, especially on projects involving large quantities of tubular steel or expensive alloys.

Beyond these direct savings, there are also significant indirect cost benefits. Shorter project durations mean lower site overheads (e.g., site management costs, equipment rental, security). A faster construction timeline also allows the building owner or developer to achieve a quicker return on their investment, as the facility can be occupied or become operational sooner. For fabrication businesses like Ahmed's, the increased throughput enabled by tube laser cutting means they can take on more projects with the same or even fewer resources, boosting overall profitability and growth potential. Ahmed specifically mentioned that he values a high cost-performance ratio over simply a low price, indicating an understanding that true value comes from efficiency and quality, not just initial outlay.

From a financial perspective, the impact can be quantified. Various metal fabrication industry analyses suggest that integrating automated tube cutting technology can lead to overall project cost reductions in the range of 5-10% specifically on the steel package, even after amortizing the investment in the machinery. For a large construction project where the steel fabrication component might run into millions of dollars, these percentage savings translate into very substantial sums. For example, on a $1 million steel fabrication contract, a 7% saving represents $70,000. This improved cost-effectiveness directly impacts Ahmed's ability to win competitive bids for projects involving railing, shelving, and auto parts, and to improve his overall profit model. It could also provide the financial leverage he needs to consider becoming a regional distributor or exploring co-branding options, confident in the performance and cost-efficiency of the technology he represents.

| Project Impact Area | Impact Using Traditional Methods | Impact Using Tube Laser Cutting (e.g., MZBNL) | Quantifiable Benefit Example (General Industry Data) |

|---|---|---|---|

| Overall Project Timeline | Longer due to slow fabrication & extensive on-site work | Shorter due to rapid prefabrication & faster assembly | 15-30% reduction in schedule for steel package delivery |

| Fabrication Labor Costs | High, due to manual multi-step processes | Significantly lower due to automation & process consolidation | Up to 40-50% reduction in fabrication labor hours per ton |

| On-Site Assembly Costs | High, due to fitting, adjustments, rework | Lower, due to precise fit-up of components | 10-20% reduction in steel erection labor costs |

| Malzeme Kullanımı | Higher scrap rates (5-15% typical) | Maximized via nesting & zero-tail (e.g., <3% scrap) | Potential for 5-10% or more overall material cost savings |

| Component Quality/Accuracy | Variable, operator-dependent, higher defect rates | Consistently high quality, ±0.1mm accuracy, low defects | >95% reduction in part rejections or on-site rework |

| Design Innovation Scope | Limited by manual fabrication complexities | Enables highly complex, previously unfeasible designs | Opens new markets for intricate architectural metalwork |

Laser cutting reduces project timelinesDoğru

Tube laser cutting machines can compress fabrication schedules by 60-70% compared to traditional methods, accelerating overall project completion.

Manual cutting achieves better accuracyYanlış

Automated laser cutting maintains ±0.1mm tolerances consistently, while manual processes suffer from operator-dependent variability and fatigue errors.

What lessons were learned from using tube laser cutting machines in these construction projects?

Are you contemplating the integration of tube laser cutting into your operations but feeling cautious about potential unforeseen challenges or the nuances of maximizing its benefits? It's wise to be proactive. Investing in sophisticated new technology without a clear understanding of the associated learning curve, operational adjustments, and best practices can unfortunately lead to suboptimal results or avoidable frustrations. However, by carefully examining the lessons learned from real-world applications and early adopters, we can effectively anticipate these challenges and strategically position ourselves to unlock the full, transformative potential of this technology.

Key lessons from implementing tube laser cutting include the critical importance of comprehensive training for both design and machine operation, the necessity of integrating the machine into a robust digital workflow (CAD/CAM), a thorough understanding of material properties for optimal cutting results, and crucially, leveraging the technology for genuine design innovation rather than merely as a direct replacement for older, less capable methods.

Every significant technological advancement, and tube laser cutting is certainly no exception, comes with an inherent learning curve and a period of adaptation. While the advantages are undeniably compelling, fully realizing them requires more than simply purchasing and installing a state-of-the-art machine. It invariably involves a willingness to adapt existing processes, invest in upskilling personnel, and sometimes even fundamentally rethink design approaches to align with the new capabilities. Reflecting on the collective experiences of both early pioneers and seasoned users – insights I've gathered over years at MZBNL and through conversations with clients like Ahmed Al-Farsi as he navigated his own technological upgrade – can provide invaluable guidance for those looking to harness the full power of tube laser cutting effectively and efficiently. Let’s explore some of THE most critical takeaways.

The journey of integrating tube laser cutting machines into construction projects has been one of continuous learning and refinement for the industry. While the technology delivers remarkable benefits, maximizing its potential requires attention to several key areas. At MZBNL, we try to incorporate these lessons into our machine design, training, and support services to ensure our clients, including those like Ahmed with specific pain points and ambitious goals, achieve success smoothly.

The Critical Role of Design for Manufacturing (DfM)

A fundamental lesson learned is that to truly exploit the capabilities of tube laser cutting, designs must be optimized specifically for this manufacturing process – a principle known as Design for Manufacturing (DfM)11. Simply taking old drawings intended for manual fabrication (sawing, drilling, manual coping) and feeding them to a laser cutter will likely yield some benefits in speed and accuracy, but it won't unlock the technology's full potential. Designers and engineers need to develop a deep understanding of what the machine can do: the types of complex cuts it can make (bevels, slots, intricate patterns), the precision it offers for interlocking joints, and how to leverage these capabilities to simplify assembly downstream. For example, designing parts with tab-and-slot features that allow them to self-jig during assembly can drastically reduce the need for complex fixtures and cut down on welding time.

This necessitates a shift in mindset and often requires close collaboration between the design team, the engineering department, and the machine operators or fabrication managers on the shop floor. Early input from the fabrication team during the design phase can lead to significant improvements in manufacturability, cost-effectiveness, and assembly efficiency. They can provide practical feedback on how a particular connection detail might be optimized for laser cutting or how a slight design modification could improve material yield. For example, our MZBNL "No-CAD System Innovation" greatly simplifies the process for common, standardized tube types and hole patterns by allowing parameter input directly at the machine. This is a fantastic time-saver and lowers the skill threshold for many routine tasks. However, for truly complex, bespoke architectural or structural designs, a thoughtful DfM approach, where designers consciously utilize the unique strengths of laser cutting, remains paramount to achieving the best results.

I recall a client, a manufacturer of custom architectural metalwork, who initially used their new tube laser cutter primarily as a faster way to cut tubes to length and drill holes. They saw an improvement, but it wasn't transformative. After their design team underwent specialized DfM training focused on tube laser capabilities, they began incorporating features like precise miter cuts for seamless corner joints, complex fish-mouth copes for stronger truss connections, and even etched part numbers and assembly marks. This holistic approach led to a further 30% reduction in their assembly time and a noticeable improvement in the aesthetic quality of their finished products. Ahmed, with his strong engineering background and hands-on decision-making style, would quickly grasp the value of such DfM principles and could champion their adoption within his organization to maximize the ROI from his MZBNL machine.

Importance of Integrated Digital Workflows and Skilled Personnel

Another crucial lesson is the absolute necessity of a well-integrated digital workflow, typically revolving around CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software12. For a tube laser cutting machine to operate at peak efficiency, there must be a seamless and accurate flow of information from the initial 3D design model to the machine's controller. This involves robust CAD software for creating the part geometry, specialized CAM software for generating the optimal cutting paths and nesting layouts, and reliable data transfer protocols. Any bottlenecks or errors in this digital chain can lead to delays, incorrect parts, and wasted material. Investing in good quality software and ensuring proper integration and data management practices are therefore essential.

While advanced tube laser cutters like those from MZBNL are designed for ease of use and high levels of automation (reducing the need for some traditional manual fabrication skills), they do require a new set of skills from operators and technicians. Personnel need to be proficient in operating the machine's control interface, understanding basic CAM principles (even if much is automated), performing routine maintenance, and troubleshooting minor issues. Comprehensive training is therefore vital. Ahmed’s previous experiences with high operator turnover and the associated retraining burdens highlight this exact point. This is why MZBNL emphasizes user-friendly systems like our No-CAD interface and provides efficient training programs – for example, our 1-day on-site training compared to the traditional 15 days at the equipment factory. This drastically reduces the learning curve and gets the machine productive much faster.

Industry surveys, such as those occasionally published by manufacturing journals like IndustryWeek or the Fabricators & Manufacturers Association (FMA), consistently point to the availability of skilled personnel as a significant factor in successfully adopting advanced manufacturing technologies. Companies that invest not just in the initial training but also in ongoing skill development for their workforce tend to see a much higher and faster return on their technology investments. For Ahmed, ensuring his team is thoroughly trained on his new MZBNL laser tube cutting machine, including understanding its remote diagnostics capabilities and the efficient procurement of spare parts (both key sourcing points he identified), will be crucial for sustained high performance and minimizing downtime.

Strategic Material Management and Maintenance Protocols

The performance of a tube laser cutting machine is also significantly influenced by the quality and consistency of the raw material being processed, as well as the diligence with which maintenance protocols are followed. Different materials – such as mild steel, stainless steel, aluminum, or various alloys – and even different tube profiles (round, square, rectangular, oval, custom extrusions) behave differently when subjected to a high-energy laser beam. They require specific cutting parameters13, including laser power, cutting speed, assist gas type (e.g., oxygen, nitrogen), and gas pressure, to achieve optimal cut quality, speed, and dross-free edges. Developing a good understanding of these material-specific parameters, perhaps through a combination of supplier recommendations, experimentation, and building an internal knowledge base, is a key lesson for consistent results.

Equally important is adherence to a proactive and preventative maintenance schedule. Tube laser cutting machines are sophisticated pieces of equipment with precision optical components, high-speed motion systems, and complex control electronics. Regular maintenance, as outlined by the manufacturer (like the detailed guidelines provided by MZBNL for our machines), is absolutely essential to ensure long-term reliability, consistent cutting performance, and the minimization of unplanned and costly downtime. This typically includes tasks like cleaning the laser optics (lenses and mirrors), checking and replacing consumable parts (nozzles, ceramic insulators), verifying assist gas pressures and purity, and inspecting mechanical systems for wear. Neglecting maintenance can lead to deteriorating cut quality, reduced cutting speeds, increased error rates, and ultimately, premature failure of critical components.

I remember a case where a fabrication shop was experiencing intermittent issues with cut quality on their stainless steel tube projects. After a service visit and consultation (the kind of after-sales support Ahmed prioritizes), it was discovered that two factors were at play: firstly, they weren't consistently adjusting their cutting parameters to account for slight variations between different batches of stainless steel from their supplier, and secondly, their maintenance schedule for cleaning the protective lens window had become lax. By implementing a more rigorous material batch checking process and strictly adhering to the recommended daily and weekly maintenance routines for the laser head, they were able to resolve the cut quality issues completely and restore their machine to peak operational effectiveness (OEE). For Ahmed, knowing that MZBNL offers reliable after-sales service, training support, readily available spare parts, and remote diagnostic capabilities would provide significant peace of mind and contribute to the long-term success of his investment.

| Lesson Learned Category | Key Insight from Industry Experience | Actionable Advice for New Adopters (like Ahmed) | Anticipated Benefit / Problem Avoided |

|---|---|---|---|

| Design & Engineering | Design For Manufacturing (DfM) is paramount to unlock full potential. | Train designers on laser cutting capabilities; encourage early fabricator collaboration. | Optimized material use, reduced assembly time, innovative products. |

| Digital Workflow | Seamless CAD/CAM integration is critical for efficiency and accuracy. | Invest in robust software; establish clear digital processes and data management. | Minimized errors, faster programming, better production scheduling. |

| Operator & Staff Skills | New skill sets are required; training is essential for proficiency. | Provide comprehensive, machine-specific training (e.g., MZBNL's 1-day program). | Reduced operator error, higher machine uptime, improved morale. |

| Material Characteristics | Material type, quality, and consistency directly impact cut results. | Develop/use optimal cutting parameters for each material; ensure good sourcing. | Consistent high cut quality, maximized speed, reduced dross. |

| Makine Bakımı | Proactive, regular maintenance is vital for reliability and longevity. | Strictly follow manufacturer's maintenance schedule; train staff on daily checks. | Minimized unplanned downtime, sustained performance, longer machine life. |

| Strategic Implementation | Don't just replace; leverage the technology to innovate and transform. | Explore new design possibilities, target higher-value work, rethink processes. | Competitive differentiation, new market opportunities, increased profitability. |

DfM unlocks laser cutting potentialDoğru

Design for Manufacturing principles are essential to fully leverage tube laser cutting capabilities beyond simple replacement of traditional methods.

Old designs work perfectly with laserYanlış

Simply using old drawings with laser cutters yields limited benefits; designs must be optimized for the technology's unique capabilities.

Sonuç

Tube laser cutting machines are unequivocally reshaping construction by enabling intricate designs, dramatically boosting operational efficiency, and elevating structural quality. For businesses like Ahmed's in the UAE, embracing this technology with strategic planning, thorough training, and a focus on innovation leads to profound project impacts.

-

Access industry insights and resources from a leading metal fabrication association. ↩

-

Explore how parametric designs enable innovative and complex architectural forms. ↩

-

Learn how modular construction improves building efficiency and project timelines. ↩

-

Discover the role of CAD/CAM software in automating and optimizing tube laser cutting processes. ↩

-

See data supporting how automation in tube cutting significantly reduces material waste and costs. ↩

-

Learn about brise-soleils and their fabrication using precise tube laser cutting techniques. ↩

-

Discover benefits and applications of laser-cut components in complex space frame construction. ↩

-

Understand current skilled labor shortages in construction and how technology offers viable solutions to this challenge. ↩

-

Learn how precision cutting drastically reduces costly rework from poor component fit-up in steel erection projects. ↩

-

Discover how nesting software minimizes material waste and boosts overall efficiency in fabrication processes. ↩

-

Learn DfM principles to optimize designs for tube laser cutting and improve overall efficiency. ↩

-

Understand how CAD/CAM software streamlines the tube laser cutting process from design to production. ↩

-

Explore key laser cutting parameters and their impact on achieving optimal cut quality. ↩

Sorularınız mı var veya daha fazla bilgiye mi ihtiyacınız var?

Kişiselleştirilmiş yardım ve uzman tavsiyesi için bizimle iletişime geçin.