Tüp Lazer Kesim Makineleri Nedir ve Nasıl Çalışır?

Struggling with slow, inaccurate, and labor-intensive traditional tube cutting methods? These outdated processes often lead to material waste and limit design complexity, hindering your productivity. Imagine a solution that offers unparalleled precision, speed, and versatility, transforming your metal fabrication workflow.

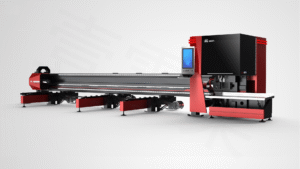

A tube laser cutting machine is a specialized piece of equipment that uses a focused, high-power laser beam to cut intricate shapes and patterns into metal tubes and pipes. It operates under computer numerical control (CNC) for high precision, speed, and repeatability in various industrial applications.

If you're looking to elevate your manufacturing capabilities, understanding the intricacies of tube laser cutting is crucial. This technology can significantly reduce production time, minimize waste, and open doors to more complex designs. Let's explore how these machines operate and the benefits they bring to modern fabrication.

The journey from manual saws and drills to fully automated laser systems has been a game-changer in metal fabrication. I recall visiting a client, Ahmed Al-Farsi in the UAE, who was grappling with the limitations of his older equipment. His team spent hours on setup, and the finish quality often required secondary operations. The demand for more intricate architectural metalwork and precise automotive parts was pushing his conventional methods to their limits. This isn't an isolated story; it's a common challenge across the industry. The advent of tube laser cutting addresses these very pain points, offering a leap in efficiency and quality that businesses like Ahmed's need to stay competitive and meet evolving market demands for sophisticated components. It’s not just about cutting metal; it’s about enabling innovation and streamlining production.

What is a tube laser cutting machine?

Are you unclear about what sets a tube laser cutting machine apart from other cutting tools? This lack of clarity can prevent you from leveraging its full potential for complex designs and efficient production. Discover the defining features and capabilities of this advanced manufacturing technology.

A tube laser cutting machine is an automated system that employs a high-intensity laser beam, directed by computer numerical control (CNC), to precisely cut, perforate, or engrave metal tubes and profiles. It enables complex geometries and high-speed processing without physical contact tooling.

Understanding what a tube laser cutting machine truly is goes beyond a simple definition. It's about recognizing a paradigm shift in how we approach tubular component manufacturing. For years, fabricators like myself relied on multiple machines and processes – sawing, drilling, milling, punching – each step adding time, potential for error, and labor cost. The integration of these capabilities into a single, automated platform is what makes these machines revolutionary. We'll delve into the core technology, its diverse applications, and the continuous advancements, such as the No-CAD systems we've pioneered at MZBNL, that are making these machines more accessible and powerful than ever. This exploration will give you a comprehensive understanding of why this technology is becoming indispensable in modern manufacturing.

A tube laser cutting machine represents a significant leap in manufacturing technology, designed specifically for the precise and efficient processing of metal tubes and pipes. Unlike general-purpose laser cutters, these machines are optimized with specialized handling systems, such as chucks and supports, to securely hold and accurately rotate cylindrical or profiled workpieces during the cutting process. The core of the machine is a high-power laser resonator (like fiber or CO2)1 that generates an intense beam of light. This beam is then guided by a series of mirrors or a fiber optic cable to a cutting head, which focuses the laser onto a very small spot on the tube's surface. The intense heat melts and vaporizes the material, while an assist gas (like oxygen, nitrogen, or air) expels the molten material and dross, creating a clean, precise cut. The entire operation is orchestrated by a Computer Numerical Control (CNC) system, which interprets a digital design file (often a CAD model) and translates it into precise movements of the cutting head and the tube itself, allowing for the creation of complex shapes, holes, slots, and end-profiles with exceptional accuracy and repeatability. This integration of laser technology, material handling, and sophisticated control systems defines the modern tube laser cutting machine.

Defining the Core Technology: Beyond a Simple Cutter

At its heart, a tube laser cutting machine is far more than just a device that cuts metal. It's an integrated system combining advanced optics, high-power laser generation, precision mechanics, and intelligent software. The laser source itself, typically a fiber laser in modern machines due to its efficiency and low maintenance, generates a highly concentrated beam of light. This beam isn't just "hot"; it's a precisely controlled energy source capable of melting and vaporizing metal with pinpoint accuracy. The quality of the cut—its narrow kerf, minimal heat-affected zone (HAZ)2, and smooth edge—is a direct result of the laser beam's properties and how it's manipulated. For instance, data from industry studies often shows that laser-cut edges can reduce the need for secondary finishing processes by up to 70% compared to traditional sawing or milling, directly impacting production time and cost.

The "cutting" aspect is facilitated by a sophisticated cutting head. This component not only focuses the laser beam to the required spot size but also incorporates a nozzle that delivers an assist gas coaxial to the beam. The choice of assist gas (e.g., oxygen for mild steel to promote an exothermic reaction for faster cutting, or nitrogen for stainless steel and aluminum to achieve an oxide-free edge) is crucial and depends on the material and desired cut quality. The cutting head often includes sensors for maintaining a constant distance from the workpiece surface (capacitive height sensing), ensuring consistent cut quality even if the tube has slight imperfections or warpage. This level of process control is what distinguishes a laser cutter from cruder thermal cutting methods.

Furthermore, the mechanical system that manipulates the tube and the cutting head is engineered for high speed and precision. Rotary chucks grip and rotate the tube, while linear axes move the cutting head along the tube's length and radially. The synchronization of these movements, managed by the CNC controller, allows for 3D cutting operations, such as bevels, copes, and complex intersections, that would be incredibly challenging or impossible with conventional 2D cutting systems or manual methods. It's this synergy of advanced technologies that elevates a tube laser cutting machine from a simple cutter to a versatile fabrication center. I remember when we first introduced our MZBNL machines; clients were astounded that operations previously requiring three or four separate manual setups could now be done in a single, automated pass.

Key Capabilities and Applications

The capabilities of tube laser cutting machines are extensive, making them suitable for a vast array of applications across numerous industries. One of the primary capabilities is the ability to cut virtually any shape or feature into a tube. This includes simple round or square holes, slots, and end cuts, but also extends to complex contours, miters, fish-mouth cuts for joining tubes, and intricate patterns. The non-contact nature of laser cutting means there's no tool wear, unlike traditional punching or sawing, ensuring consistent quality over long production runs. This capability is invaluable in industries like furniture manufacturing, where aesthetic joints and unique designs are key. For example, a designer can create a complex interlocking frame for a chair that is both strong and visually appealing, all cut precisely by the laser.

Another key capability is the high processing speed and accuracy. Modern fiber laser tube cutters can achieve cutting speeds several times faster than older CO2 lasers or mechanical methods, especially on thinner materials. Accuracies are typically within ±0.1mm or better, which is critical for industries like automotive parts production or medical equipment manufacturing. Ahmed, my client in the UAE, needed to produce components for vehicle chassis and exhaust systems. The precise fit-up required for robotic welding in his downstream processes was only achievable consistently with laser-cut tubes. His previous methods often led to parts needing manual adjustment, a bottleneck he eliminated with his new laser tube cutter.

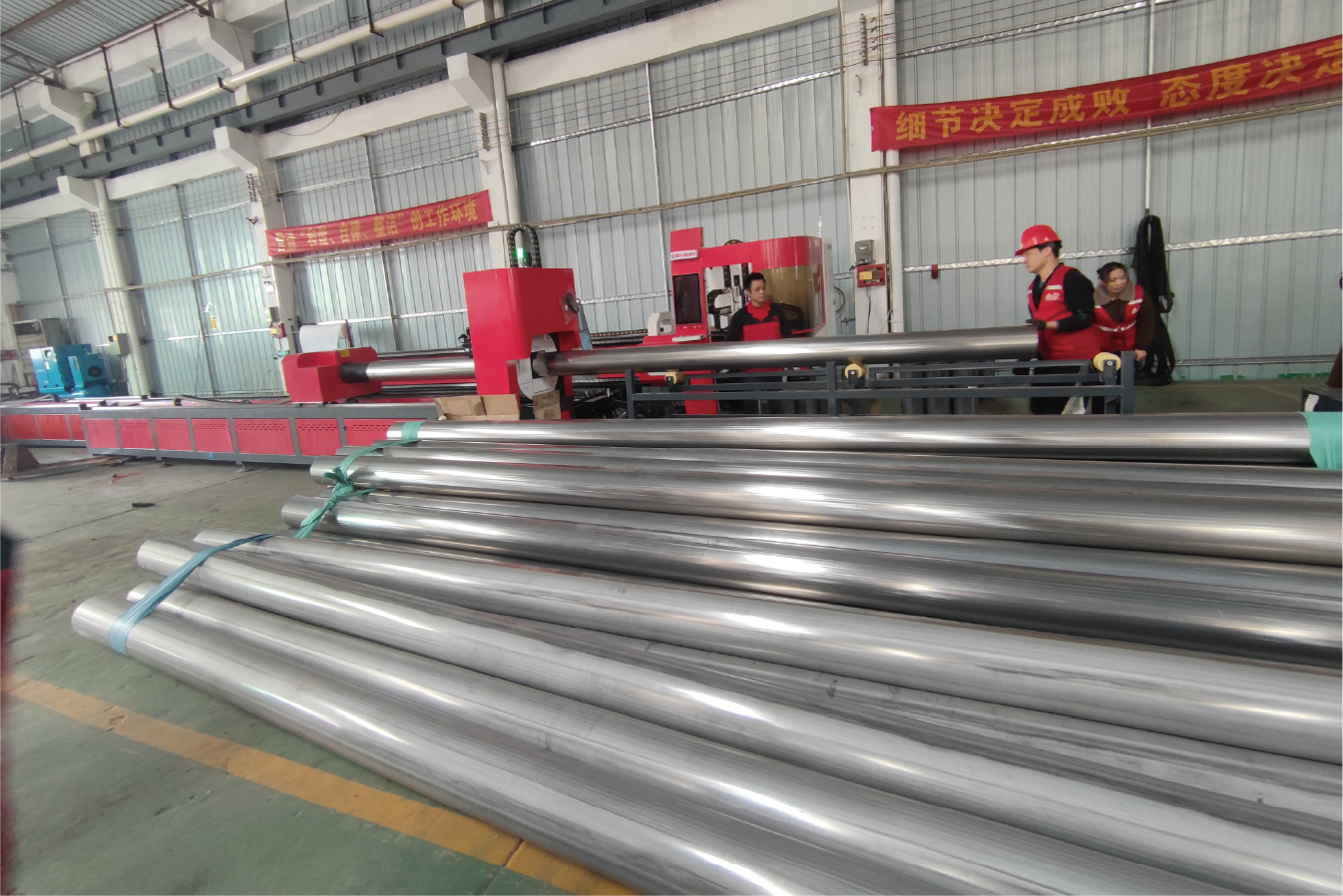

The versatility extends to material types and thicknesses. Tube laser cutters can process mild steel, stainless steel, aluminum, copper, brass, and other alloys. While maximum thickness depends on laser power and material, machines can typically handle a significant range, for instance, up to 20mm for mild steel with higher power sources. This makes them adaptable for everything from lightweight display racks (thin-walled aluminum) to heavy-duty structural components in construction (thick-walled steel). The ability to process various tube profiles – round, square, rectangular, oval, and even open profiles like C-channels or angle iron – further enhances their utility. For example, in architectural decoration, complex facades often use custom-profiled tubes with intricate laser-cut patterns, a task perfectly suited for these machines.

Evolution and Modern Advancements

The evolution of tube laser cutting technology has been remarkable. Early machines were often retrofitted flat-sheet lasers or relatively basic systems with limited automation and slower CO2 laser sources. Programming was complex, and setup times could be lengthy. However, driven by industry demand for greater efficiency and capability, significant advancements have emerged. One of the most impactful has been the widespread adoption of fiber laser sources. Fiber lasers offer higher energy efficiency (converting more electrical power into laser light), faster cutting speeds (especially in thin to medium thickness materials), and significantly lower maintenance requirements compared to CO2 lasers, as they don't have mirrors that need frequent alignment or consumables like laser gas. This shift alone has boosted productivity in many fabrication shops by 30-50% for relevant applications.

Automation has also seen huge strides. Modern machines often feature automatic bundle loaders, which can take a whole pack of raw tubes and feed them into the machine one by one without manual intervention. Sophisticated seam detection systems can identify the weld seam on a tube and orient it appropriately for cutting, crucial for applications where the seam's location matters. Automatic unloading and sorting of finished parts further reduce manual labor and streamline workflow. At MZBNL, we’ve focused heavily on such practical innovations. For instance, our Front-Feeding Innovation, which automatically pulls the tube from the front, has increased feeding efficiency by about 40% for our clients.

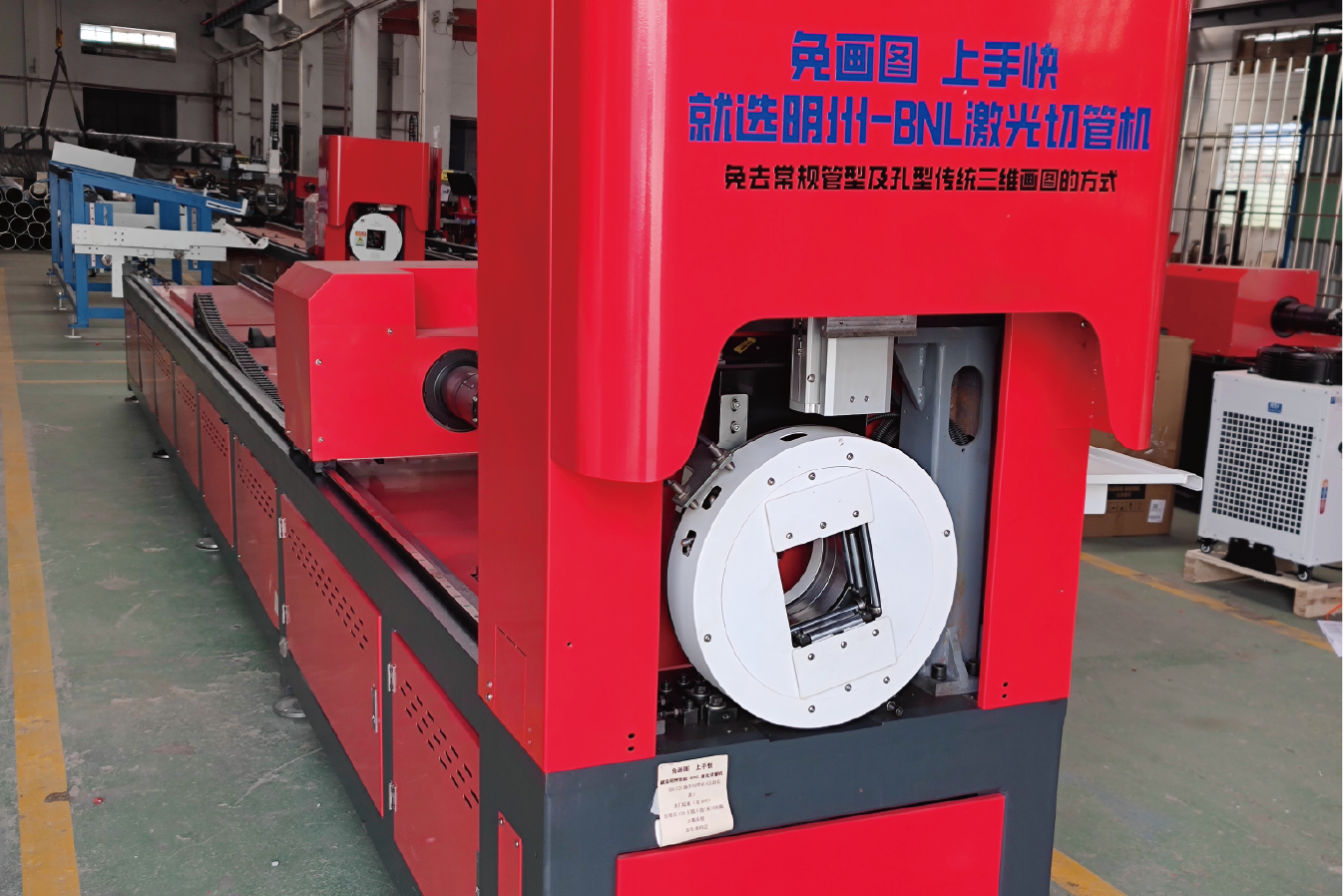

Perhaps one of the most user-centric advancements is in software and control systems. Historically, operating a tube laser cutter required skilled programmers familiar with complex CAD/CAM software. Recognizing this barrier, we at MZBNL pioneered the No-CAD Operating System. This allows operators to process standard tube types and hole patterns simply by entering parameters directly at the machine interface, without needing to go back to an office to create or modify 3D drawings. This has dramatically reduced the skill threshold and shortened setup times. Ahmed mentioned that retraining operators on his old CAD-dependent machine was a constant burden due to staff turnover. With a system like ours, new operators can be trained on-site in just a day, compared to the typical 15 days at an equipment factory for traditional systems. This ease of use, combined with other innovations like our Zero-Waste Tail Material system which maximizes material utilization, represents the cutting edge of tube laser technology, making it more powerful, efficient, and accessible than ever before.

Tube lasers use CNC controlDoğru

Tube laser cutting machines operate under computer numerical control (CNC) for precise, automated cutting operations.

Laser cutting requires physical contactYanlış

Laser cutting is a non-contact process that uses a focused beam of light to vaporize material without tool wear.

How do tube laser cutting machines differ from traditional cutting methods?

Wondering if investing in a tube laser cutter is truly superior to your existing traditional methods like sawing or drilling? Sticking with outdated techniques can mean slower production, higher labor costs, and an inability to produce complex designs. Understanding the distinct advantages is key.

Tube laser cutting machines offer superior speed, precision, and design flexibility compared to traditional methods like sawing, drilling, or milling. They enable complex cuts in a single setup, reduce material waste, and minimize the need for secondary finishing operations, enhancing overall efficiency.

The contrast between modern tube laser cutting and traditional methods is stark, and recognizing these differences is vital for any manufacturing business looking to optimize its operations. Traditional processes often involve multiple setups, manual handling, and inherent limitations in terms of precision and the complexity of shapes that can be produced. Think about the typical workshop flow: cut to length on a saw, then move to a drill press for holes, perhaps a milling machine for slots or copes. Each step introduces potential for error and consumes valuable time. We will explore how laser technology revolutionizes this by consolidating operations, dramatically improving speed and accuracy, enabling intricate designs previously unachievable, and significantly reducing material waste and the need for manual labor. For instance, a client like Ahmed who produces automotive parts found his production time per component slashed by over 60% after adopting laser cutting, simply by eliminating multiple handling and setup stages.

Tube laser cutting machines represent a paradigm shift from traditional methods such as sawing, drilling, milling, and manual torch cutting. The differences are profound, touching every aspect of the fabrication process from speed and precision to design complexity and operational efficiency. Traditional methods are often characterized by mechanical contact – a saw blade physically shearing the metal, a drill bit removing material to create a hole. These processes inherently involve tool wear, require significant clamping forces that can deform thin-walled tubes, and are often limited to simpler, predominantly 2D geometries or require multiple machine setups and manual repositioning for more complex features. For instance, creating a precise fish-mouth cut on a tube for a T-joint using traditional methods might involve a specialized (and often slow) notching machine or complex setup on a milling machine. Each step adds time, labor, and potential for cumulative error. The noise, swarf, and sometimes lubricants associated with these mechanical processes also contribute to a less clean working environment. In contrast, laser cutting is a non-contact, thermal process, offering a cleaner, faster, and far more versatile approach to tube fabrication.

Speed and Precision: A Quantum Leap

One of the most significant differentiators is the sheer speed and precision offered by tube laser cutting machines. Traditional methods, like sawing a tube to length and then drilling holes, are inherently sequential and often involve manual or semi-automatic processes that are time-consuming. A band saw might cut relatively quickly, but the subsequent drilling or milling operations add considerable time. Laser cutters, on the other hand, can perform multiple operations – cutting to length, creating holes, slots, and complex profiles – in a single, continuous automated process. Cutting speeds with modern fiber lasers can be exceptionally high, especially on thin to medium gauge materials. For example, cutting 2mm thick mild steel tube can occur at several meters per minute, a rate far exceeding what's possible with sequential mechanical operations for complex patterns.

The precision aspect is equally transformative. Mechanical cutting methods are subject to tool wear, vibration, and the inherent play in machine components, which can lead to dimensional inaccuracies. Achieving tolerances tighter than ±0.5mm consistently can be challenging. Tube laser cutters, guided by sophisticated CNC systems and utilizing a focused laser beam often as small as 0.1mm in diameter, routinely achieve accuracies of ±0.1mm to ±0.2mm or even better. This level of precision is crucial for applications requiring tight fit-up, such as robotic welding or assembly of intricate frameworks. I remember a project involving display racks for a retail client; the traditional methods we used initially led to alignment issues during assembly, causing delays. Switching to laser-cut components, where every slot and tab was perfectly placed, made assembly a breeze and dramatically improved the final product quality. This precision also minimizes the heat-affected zone (HAZ)3 compared to plasma or flame cutting, reducing material distortion and often eliminating the need for post-cutting finishing processes.

Furthermore, the repeatability of laser cutting is exceptional. Once a program is created and validated, the machine can produce hundreds or thousands of identical parts with minimal deviation. Traditional methods, especially those involving manual setups or operator judgment, are far more prone to variation. This consistency is vital for mass production and for ensuring interchangeability of parts. For businesses like Ahmed's, supplying automotive components where quality control standards are stringent, this level of repeatable precision isn't just a benefit, it's a necessity to remain a trusted supplier. The ability to deliver identical, high-quality parts, order after order, is a hallmark of laser processing.

Material Versatility and Waste Reduction

Tube laser cutting machines offer greater versatility in terms of the materials they can process and significantly contribute to material waste reduction compared to many traditional methods. While saws and drills can handle a range of metals, the tooling (blades, drill bits) often needs to be specific to the material type (e.g., different blade TPI for steel vs. aluminum) and can wear out quickly, especially with harder materials. Lasers, being a non-contact process, don't suffer from tool wear in the same way. They can effectively cut a wide array of metals, including mild steel, stainless steel, aluminum, brass, and copper, often with just adjustments to cutting parameters (laser power, speed, assist gas type, and pressure) rather than physical tool changes. This flexibility allows manufacturers to switch between different materials and jobs more quickly.

Material waste reduction is a key economic and environmental advantage. Traditional methods, particularly sawing, generate swarf or chips, which represent lost material. More significantly, the nesting of parts on a length of tube is often less efficient. For instance, when cutting multiple short parts from a long tube, the way traditional machines grip and process the material can lead to larger unusable remnants at the end of each stock length. Our MZBNL Zero-Waste Tail Material Innovation directly addresses this. Conventional systems start from the tube head and invariably leave a tail piece. By redesigning the cutting logic to calculate from the rear chuck as the origin, our system can effectively eliminate leftover tail material as long as the remaining section is smaller than the product length. This intelligent approach maximizes material utilization, which can lead to substantial cost savings, especially when working with expensive alloys. Industry data suggests that efficient nesting and tail material reduction through laser cutting can improve material yield by 5-15% or even more4 in some cases compared to less optimized traditional processes.

Consider also the creation of complex joints or features. Traditionally, achieving a precise cope or miter might involve cutting a larger section and then milling it down to the final shape, creating more waste. A laser can cut the net shape directly. Furthermore, the ability to cut intricate patterns allows for "tab and slot" designs. These designs not only aid in self-jigging during assembly, reducing the need for complex fixtures, but they also ensure parts are oriented correctly, minimizing assembly errors and potentially reducing the amount of weld material needed. This holistic approach to part design and fabrication, enabled by the laser's capabilities, inherently leads to more efficient use of raw materials.

Automation and Operational Efficiency

The level of automation and the resulting operational efficiency are perhaps the most compelling differentiators for tube laser cutting machines. Traditional tube fabrication often involves significant manual labor: loading individual tubes into a saw, transferring them to a drill press, then to a milling machine, and manually deburring each part. Each transfer and setup takes time and introduces opportunities for error or injury. In contrast, modern tube laser cutting systems are designed for high levels of automation. Features like automatic bundle loaders can handle tons of raw material, feeding tubes into the machine sequentially without operator intervention for extended periods. This allows for "lights-out" or minimally attended operation, drastically increasing machine utilization and freeing up skilled labor for other tasks.

At MZBNL, our Front-Feeding Innovation is a prime example of enhancing operational efficiency. Traditional machines often rely on side or rear manual loading, which can be awkward and slow. Our optimized front-feeding mechanism automatically pulls the tube in from the front, which we've seen increase feeding efficiency by about 40% and reduce operator labor intensity by a similar margin. This not only speeds up the process but also improves ergonomics and safety for the operator. Ahmed Al-Farsi, my client in the UAE, specifically sought automated solutions to upgrade his production. His pain point of high operator turnover and the associated retraining burdens for complex machinery made automation a key requirement. Laser systems, especially those with user-friendly interfaces like our No-CAD system, reduce the dependency on highly skilled, specialized operators for every task.

Furthermore, the consolidation of multiple operations into a single machine dramatically improves workflow and reduces work-in-progress (WIP). Instead of parts queuing at different workstations, a tube goes in one end and a finished, complex part comes out the other. This reduces material handling, factory floor space requirements, and overall lead times. The software integration also plays a crucial role. Advanced CAM software can automatically nest parts for optimal material usage, simulate the cutting process to detect potential collisions, and integrate with MRP/ERP systems5 for production planning and tracking. This holistic approach to automation goes far beyond just the cutting process itself, transforming the entire operational landscape of a fabrication shop.

Here's a comparative overview:

| Özellik | Traditional Methods (Sawing, Drilling, Milling) | Tube Laser Cutting Machine |

|---|---|---|

| Hız | Slower, multiple setups | High-speed, consolidated operations |

| Hassasiyet | Moderate, dependent on tool wear & setup | Very high (e.g., ±0.1mm), consistent |

| Karmaşıklık | Limited, often requires multiple machines | High, complex 3D cuts in one setup |

| Malzeme Atıkları | Higher (swarf, larger remnants, less nesting) | Lower (minimal kerf, advanced nesting, tail material optimization) |

| Tool Wear | Significant (blades, bits) | Minimal (non-contact process) |

| Otomasyon | Limited, often manual | High (auto loading/unloading, integrated software) |

| İşgücü Yoğunluğu | High, skilled operators for each process | Lower, reduced need for manual intervention |

| Kurulum Süresi | Longer, multiple machine setups | Shorter, quick program changes |

| Heat Affected Zone | Can be larger with some methods | Minimal, especially with fiber lasers |

| Esneklik | Tool changes often needed for material/shape | Parameter changes, high material versatility |

This table clearly illustrates the substantial advantages that tube laser cutting brings to modern manufacturing, aligning perfectly with the needs of businesses like Ahmed's that are looking to enhance productivity, quality, and automation.

Laser cutting is non-contactDoğru

Unlike sawing or drilling, laser cutting uses a focused beam of light to cut materials without physical contact, reducing tool wear and material deformation.

Geleneksel yöntemler daha hızlıdırYanlış

Laser cutting is significantly faster as it consolidates multiple operations (cutting, drilling, etc.) into one automated process, unlike sequential traditional methods.

What are the main components of a tube laser cutting machine?

Unsure about the inner workings of a tube laser cutting machine? This knowledge gap can make it difficult to choose the right equipment or troubleshoot effectively. Understanding its core components is essential for maximizing its performance and longevity.

The main components include the laser source (resonator), beam delivery system (optics/fiber), cutting head, machine bed with chucks for tube handling, a CNC controller, and assist gas delivery system. These elements work synergistically to achieve precise cuts.

To truly appreciate the capabilities of a tube laser cutting machine, it's important to understand its constituent parts and how they interact. It’s not just a single entity but a sophisticated amalgamation of high-tech systems. We'll break down the anatomy of these machines, from the laser source that generates the powerful beam to the intricate cutting head that delivers it, the robust mechanical structures that handle the tubes, and the intelligent CNC controller that orchestrates every movement. Knowing these components will not only demystify the technology but also help you in evaluating different machines and understanding maintenance requirements. For instance, when I discuss options with clients like Ahmed, explaining how a fiber laser source differs from a CO2 laser, or the importance of a robust chucking system for their specific tube sizes and weights, helps them make informed decisions.

A tube laser cutting machine is a complex assembly of several critical systems working in concert to deliver precise and efficient cutting of tubular materials. Each component plays a vital role in the overall performance, accuracy, and reliability of the machine. Understanding these components is key to appreciating the technology's capabilities and making informed decisions when selecting or operating such equipment. The primary systems can be broadly categorized into the laser generation and delivery system, the material handling and mechanical structure, and the control and software system. These components are intricately designed and integrated to ensure that a tube can be loaded, securely held, precisely moved and rotated, and cut according to a digital design with minimal operator intervention and maximum efficiency. The quality of each component, from the laser resonator to the smallest sensor in the cutting head, contributes to the final quality of the cut part.

The Laser Source and Cutting Head: The Heart of Precision

The laser source, or resonator, is where the high-intensity light beam is generated. In modern tube laser cutting machines, fiber lasers have become the dominant technology, largely supplanting older CO2 lasers6, especially for metal cutting. Fiber lasers are renowned for their high energy efficiency, excellent beam quality (which translates to finer, more precise cuts), and significantly lower maintenance requirements as they don't rely on complex mirror systems or consumable laser gases like CO2 lasers do. The power of the laser source (measured in kilowatts, e.g., 1kW to 6kW or even higher for tube applications) directly influences the cutting speed and the maximum thickness of material that can be processed. For example, a 1kW fiber laser might be suitable for thinner tubes up to 4-6mm steel, while a 3kW or 4kW source could efficiently cut steel up to 15-20mm thick. The choice of laser power is a critical consideration based on the typical range of materials and thicknesses a workshop like Ahmed's might process.

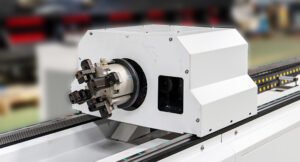

The laser beam generated by the source is then transported to the cutting head via a fiber optic cable (in fiber lasers) or a series of mirrors (in CO2 lasers). The cutting head is a highly sophisticated component responsible for focusing the laser beam to a tiny spot (often around 0.1mm to 0.2mm in diameter) on the surface of the tube. It also incorporates a nozzle through which an assist gas (such as oxygen, nitrogen, or compressed air)7 is directed coaxially with the laser beam. This gas serves multiple purposes: it protects the focusing lens from spatter, helps eject molten material from the cut kerf, and, in the case of oxygen with mild steel, can contribute to the cutting process through an exothermic reaction. Modern cutting heads often feature auto-focus capabilities to adjust for variations in material thickness and capacitive height sensing to maintain a precise distance between the nozzle and the tube surface, ensuring consistent cut quality even if the tube is not perfectly straight or round. The integrity and precision of the cutting head are paramount for achieving high-quality, dross-free cuts.

Many advanced cutting heads also offer bevel cutting capabilities, allowing them to tilt and create angled edges on the tube. This is essential for creating weld preparations or complex joints without requiring secondary operations. The design of the cutting head, including its cooling systems and internal optics, must be robust to withstand the harsh industrial environment and the high laser powers involved. The selection of the right nozzle diameter and type, along with precise control of assist gas pressure, are critical process parameters that operators adjust to optimize cut quality for different materials and thicknesses.

The Machine Bed, Chucks, and Feeding System: Ensuring Stability and Flow

The machine bed provides the foundational stability for the entire cutting operation. It must be rigid and well-damped to absorb vibrations and ensure that the precise movements of the cutting head and tube are not compromised. The overall length of the machine bed will determine the maximum length of raw tube that can be loaded and processed. For instance, standard machines might accommodate 6-meter tubes, while larger systems can handle 9-meter or even 12-meter lengths, which can be an important factor for businesses processing long structural members.

A critical element of the material handling system is the chucking mechanism. Tube laser cutters typically use at least two chucks: a rear chuck that grips and feeds the tube through the machine, and a front chuck (or a similar supporting mechanism) located near the cutting zone to provide stability and prevent whipping or sagging of the tube during rotation and cutting. These chucks must be able to securely grip various tube profiles (round, square, rectangular, oval, etc.) without distorting them, especially important for thin-walled tubes. Pneumatic or hydraulic clamping is common, and sophisticated chucks offer features like self-centering and automatic adjustment for different tube sizes. The precision of the chucks' rotation and their synchronization with the linear movements of the cutting head are essential for accurate 3D cutting. Our MZBNL machines, for example, feature robust chuck designs that have been refined over 25 years to handle a wide variety of profiles and ensure consistent gripping force.

The feeding system is responsible for loading raw tubes into the machine and positioning them for cutting. This can range from manual loading for low-volume applications to fully automatic bundle loaders for high-production environments. An automatic bundle loader can store several tons of tubes and feed them one by one into the machine, significantly reducing manual labor and allowing for extended periods of unattended operation. Our Front-Feeding Innovation at MZBNL, which automatically pulls the tube in from the front, enhances efficiency by about 40% and reduces operator strain. Efficient unloading systems for finished parts and scrap are also key components, which may include conveyor belts or automated part sorting solutions to separate good parts from remnants.

The Control System (CNC) and Software: The Brains of the Operation

Bu Computer Numerical Control (CNC) system8 is the brain of the tube laser cutting machine. It interprets the cutting program (generated by CAM software from a CAD design) and translates it into precise, coordinated movements of the laser cutting head and the tube chucks. The CNC controller manages axis movements (X, Y, Z for the cutting head, and rotational axes for the chucks), laser power modulation, assist gas control, and various sensor inputs. Modern CNC controllers offer high processing speeds and sophisticated algorithms for look-ahead control (to optimize cutting speed and acceleration around corners and complex contours) and maintaining cut quality. The user interface of the CNC system is also crucial for ease of operation, allowing operators to load programs, monitor the cutting process, make adjustments, and perform diagnostics.

Software plays an equally vital role. CAD (Computer-Aided Design) software is used to create the 2D or 3D models of the parts to be cut. CAM (Computer-Aided Manufacturing) software then takes these CAD models and generates the machine-specific G-code or M-code that the CNC controller understands. Advanced tube CAM software offers features like automatic nesting (arranging multiple parts on a stock tube length to maximize material utilization), simulation of the cutting path to detect potential collisions or errors, and optimization of cutting parameters for different materials and thicknesses. It can also automatically generate features like lead-ins, lead-outs, and micro-joints. Recognizing the bottleneck that complex CAD/CAM operations can present, especially for workshops with varying operator skill levels, we at MZBNL developed our No-CAD Operating System. This allows standard tube types and hole patterns to be processed simply by inputting parameters directly at the machine. This innovation drastically improves ease of use, shortens setup time from days to just one day of on-site training, and lowers the skill threshold, a point Ahmed particularly appreciated given his challenges with operator turnover.

The integration of the CNC and software with other factory systems, such as ERP (Enterprise Resource Planning) or MES (Manufacturing Execution Systems), is also becoming increasingly common, enabling seamless data flow for production planning, scheduling, and monitoring. This connectivity is part of the broader Industry 4.0 trend, making the tube laser cutter not just a standalone machine but an intelligent node in a connected manufacturing ecosystem. The reliability and user-friendliness of both the CNC hardware and the operating/programming software are critical for maximizing the productivity and uptime of the machine.

Fiber lazerler boru kesimine hükmediyorDoğru

Modern tube laser cutting machines primarily use fiber lasers due to their superior energy efficiency and beam quality compared to CO2 lasers.

Assist gas only removes molten metalYanlış

Assist gas serves multiple functions including protecting the lens, ejecting molten material, and contributing to exothermic reactions in some cases.

How does the tube laser cutting process work step-by-step?

Are you curious about what actually happens from the moment a design is conceived to when a perfectly cut tube emerges from the machine? Not understanding the workflow can make it hard to optimize or troubleshoot. Let's demystify the journey of a tube through the laser cutting process.

The tube laser cutting process involves: 1. Design input (CAD/CAM programming). 2. Tube loading and secure clamping. 3. Laser head positioning and parameter setting. 4. Laser cutting with synchronized tube rotation/movement. 5. Part unloading and scrap removal.

The journey of a metal tube from raw stock to a precisely fabricated component via laser cutting is a fascinating, highly orchestrated sequence of events. It's not just about pointing a laser and cutting; it's a multi-stage process that combines digital design, sophisticated material handling, and precision motion control. We'll walk through each critical step, from the initial design creation or parameter input to the final unloading of the finished part. Understanding this workflow is essential for anyone involved in operating, managing, or purchasing such equipment. For instance, when I train new operators or discuss process optimization with clients like Ahmed, breaking down the process step-by-step helps clarify how each stage impacts overall efficiency, quality, and material utilization. This knowledge empowers users to get the most out of their investment.

The tube laser cutting process, while highly automated, follows a logical sequence of steps to transform a raw tube into a precisely finished part. Each step is critical for achieving the desired quality, accuracy, and efficiency. The process begins with the digital design and programming phase, moves through material preparation and loading, then to the core cutting operation, and finally concludes with part unloading and scrap management. Modern machines integrate these steps seamlessly, often with minimal human intervention, especially in highly automated setups. For an operator or a production manager, understanding this flow helps in optimizing job scheduling, material flow, and troubleshooting any issues that may arise during production. It’s a blend of digital precision and mechanical execution, all orchestrated by sophisticated control systems.

Design Input and Programming: From Concept to Machine Code

The very first step in any tube laser cutting job is the creation or input of the part design. This typically starts with a 2D or, more commonly for complex tube parts, a 3D CAD (Computer-Aided Design) model. Engineers and designers create these models specifying all the cuts, holes, slots, copes, and other features required for the final component. For instance, an architectural firm designing a custom railing system would model each tubular component with its precise end cuts and mounting holes in a CAD program. Once the CAD model is complete, it's imported into specialized CAM (Computer-Aided Manufacturing) software, often tailored for tube cutting. The CAM software is where the "manufacturing intelligence" is applied. It "unrolls" or "unwraps" the 3D tube design onto a 2D plane for path planning if necessary, though modern 5-axis CAM can work directly in 3D. It then allows the programmer to define the cutting paths, assign laser parameters (power, speed, assist gas type and pressure)9, specify lead-ins and lead-outs (small introductory and exit cuts to ensure a clean start and finish to each feature), and plan the cutting sequence.

A crucial function of the CAM software is nesting10. If multiple identical or different parts are to be cut from standard stock lengths of tube (e.g., 6 meters), the software will arrange these parts along the tube in a way that maximizes material utilization and minimizes waste. It considers factors like common line cutting (where adjacent parts share a cut line) and the gripping requirements of the chucks. After all these parameters are set, the CAM software generates the machine-specific program, typically in G-code or M-code format. This code contains all the instructions that the machine's CNC (Computer Numerical Control) controller needs to execute the job: movement commands for all axes, laser on/off signals, gas control, etc. For simpler, standardized parts, systems like our MZBNL No-CAD system bypass the need for extensive CAD/CAM work in an office. Operators can directly input parameters for common shapes (e.g., round hole, square hole, slot at a specific angle and position) into the machine's interface, and the machine's software generates the cutting program on the fly. This is a significant time-saver for job shops or manufacturers producing standard components, as Ahmed found when he needed to quickly produce batches of shelving supports with predefined hole patterns.

The generated program is then transferred to the CNC controller of the tube laser cutting machine, usually via a network connection, USB drive, or direct input. Before starting a new job, the operator will load this program into the controller. Many systems also offer a simulation feature, either in the CAM software or on the machine controller itself, allowing the operator to virtually run through the cutting process. This helps to detect any potential collisions between the cutting head and the tube or chucks, verify the cutting path, and estimate the cycle time. This simulation step is invaluable for preventing costly errors and optimizing the program before committing actual material.

Material Loading and Clamping: Securing the Workpiece

Once the program is ready, the next step is to load the raw material – the metal tube or pipe – into the machine. The method of loading depends heavily on the level of automation of the machine. In basic setups, the operator might manually lift and place a single tube onto support rollers and guide it into the machine's rear chuck. However, for higher productivity and efficiency, most modern tube laser cutters are equipped with automatic or semi-automatic loading systems. A common solution is a bundle loader, which can hold a large quantity (often several tons) of tubes in a magazine or cassette. The loader automatically selects one tube at a time from the bundle and feeds it into the machine's processing area. These systems can often handle various tube profiles (round, square, rectangular) and sizes within a certain range, automatically adjusting to the dimensions specified in the job setup. Our MZBNL Front-Feeding innovation, which pulls the tube from the front, streamlines this process, making it faster and reducing physical strain on operators compared to traditional rear or side loading.

After the tube is fed into the machine, it must be securely and accurately clamped by the chucks. Typically, a rear chuck grips the end of the tube and is responsible for both pushing/pulling the tube longitudinally (X-axis) and rotating it (A-axis or C-axis). A front chuck or a steady rest is often positioned closer to the cutting zone to support the tube and prevent deflection or vibration during cutting, especially for long or thin-walled tubes. These chucks are usually pneumatic or hydraulic and are designed to grip the tube firmly without deforming it. Modern chucks often have self-centering capabilities and can automatically adjust their jaws to accommodate different tube sizes and profiles based on the program settings. Some machines also incorporate sensors to detect the position of the tube's weld seam. If the seam location is critical for the application (e.g., to avoid cutting through it or to place it in a specific orientation), the system can automatically rotate the tube to position the seam as required before cutting begins. This precise and stable clamping is absolutely essential for achieving the high accuracy that laser cutting is known for.

The material loading sequence also includes identifying the start of the tube. The machine's sensors detect the leading edge, and this becomes the zero point for longitudinal measurements for the cutting operations. The system ensures that the tube is advanced to the correct starting position relative to the cutting head. For machines with advanced tail material optimization, like MZBNL's Zero-Waste Tail Material system, the initial positioning and measurement are critical for calculating how to maximize the use of the entire tube length, including minimizing or eliminating the final unusable remnant.

The Cutting Process and Part Unloading: Execution and Completion

With the tube loaded, clamped, and the program initiated, the actual cutting process begins. The CNC controller takes over, orchestrating a precise ballet of movements. The cutting head, containing the focusing lens and assist gas nozzle, moves along the tube's length (Y-axis, sometimes Z-axis for height control) while the chucks rotate the tube (A or C-axis) and feed it longitudinally (X-axis). These movements are perfectly synchronized to follow the programmed cutting paths. For example, to cut a round hole, the cutting head might remain stationary or move slightly while the tube rotates beneath it. For a longitudinal slot, the head moves along the tube while the rotation is locked. For complex 3D cuts like copes or bevels, all axes (including potentially B-axis for cutting head tilt) move simultaneously. The laser beam is switched on and off precisely as needed, and the assist gas flows through the nozzle to clear the molten material11 from the cut kerf.

During the cutting process, various sensors monitor operations. Capacitive height sensing in the cutting head maintains a constant distance between the nozzle and the tube surface, compensating for any slight ovality or waviness in the tube to ensure consistent focus and cut quality. Laser power, cutting speed, and assist gas pressure are all controlled according to the parameters defined in the program for the specific material and thickness being processed. The operator can typically monitor the process through a safety window or a video feed, intervening only if an issue arises. The efficiency of this stage is paramount; any unnecessary slowdowns or interruptions can impact throughput and cost. This is where the high speeds of fiber lasers and the intelligence of the CNC controller truly shine, enabling rapid processing of complex parts.

Once a part is completely cut from the stock tube, it needs to be unloaded. Unloading strategies vary. Some machines allow the cut part to simply drop onto a collection bin or conveyor belt beneath the cutting area. More sophisticated systems might have an unloading arm or mechanism that carefully picks up the finished part and places it in a designated area, potentially sorting different parts into different bins. This is particularly important for preventing damage to delicate parts and for streamlining downstream processes. As the cutting continues along the length of the stock tube, the rear chuck advances the remaining material forward for the next part. When the stock tube is nearly consumed, the machine manages the final cuts to maximize yield, ideally using systems like MZBNL's Zero-Waste Tail Material innovation to ensure as little material as possible is left as an unusable remnant. Scrap material, such as slugs from holes or the small skeletons between nested parts, is also collected, often falling onto a separate conveyor for disposal. The cycle then repeats with the next tube from the loader, allowing for continuous, automated production.

CAD models precede CAM programmingDoğru

The process always starts with CAD design before moving to CAM software for manufacturing instructions.

Operators manually load all tubesYanlış

Modern systems use automatic bundle loaders, though manual loading exists in basic setups.

What are the advantages of using tube laser cutting machines in manufacturing?

Are high production costs, limited design capabilities, and inconsistent quality holding your manufacturing business back? Sticking with less advanced methods can mean falling behind competitors. Discover how tube laser cutters can revolutionize your output and bottom line.

Advantages include significantly increased production speed, superior cutting precision leading to better fit-up, enhanced design freedom for complex geometries, reduced material waste, lower labor costs through automation, and improved overall product quality and consistency in manufacturing.

The adoption of tube laser cutting technology brings a multitude of compelling advantages to any manufacturing operation involved in processing metal tubes and profiles. These benefits span across various aspects, from tangible improvements in speed and cost to more strategic gains like enhanced design flexibility and market responsiveness. For businesses like Ahmed's in the UAE, which aims to upgrade production efficiency and expand into new markets requiring higher precision and more complex parts, the advantages are not just incremental improvements but transformative changes. We'll delve into how these machines boost productivity, elevate product quality, enable intricate designs, reduce operational costs, and ultimately provide a significant competitive edge in today's demanding manufacturing landscape. Understanding these benefits is crucial for justifying the investment and for leveraging the technology to its fullest potential.

Tube laser cutting machines offer a compelling suite of advantages that have made them indispensable in modern metal fabrication. These benefits address many of the chronic challenges faced with traditional tube processing methods, such as low productivity, high labor costs, material wastage, and limitations in design complexity. By leveraging the unique capabilities of laser technology and advanced automation, manufacturers can achieve significant improvements in their operational efficiency, product quality, and overall competitiveness. For a business owner like Ahmed Al-Farsi, who is focused on automating manual workflows and expanding into markets that demand high precision and intricate designs (like architectural metalwork and automotive parts), these advantages directly translate into achieving his strategic goals. The impact is felt across the entire production chain, from initial design to final assembly.

Enhanced Productivity and Throughput

One of the most immediate and impactful advantages of tube laser cutting machines is the dramatic enhancement in productivity and throughput. Traditional methods often require multiple machines and setups to perform different operations on a tube – sawing to length, then drilling holes, then milling slots or copes. Each transfer between machines and each new setup consumes valuable time and labor. A tube laser cutter consolidates many of these operations into a single, automated process. A raw tube is loaded, and a fully processed part with all necessary features (cuts, holes, slots, bevels, etchings) emerges, often in a fraction of the time it would take using conventional techniques. For example, a complex part that might take 30 minutes or more to produce through multiple traditional steps could be completed in 5 minutes or less on a tube laser cutter.

This speed is further amplified by the high cutting rates of modern fiber lasers12, especially on thin to medium-gauge materials. Coupled with rapid acceleration and deceleration of the machine axes, complex cutting paths can be executed very quickly. Furthermore, automation features like automatic bundle loaders allow machines to run for extended periods, even "lights-out" during off-shifts, with minimal operator intervention. Our MZBNL Front-Feeding Innovation, for instance, increases feeding efficiency by approximately 40%, directly contributing to higher machine uptime and output. This continuous operation significantly boosts overall throughput. Industry benchmarks often show that replacing several conventional machines with a single tube laser cutter can lead to productivity gains of 50-300% or even more, depending on the complexity of the parts and the previous methods used. This means more parts per shift, shorter lead times for customers, and an increased capacity to take on more work without proportionally increasing labor or factory space.

The reduction in setup time also plays a critical role. Switching between different jobs on traditional machinery can be a lengthy process involving tool changes, jig adjustments, and test runs. On a tube laser cutter, changing to a new job often involves simply loading a new CNC program and, if necessary, making quick adjustments to chucks or supports, which can often be automated as well. Our No-CAD system at MZBNL further speeds this up for standard profiles by allowing parameter-based programming directly at the machine, reducing the reliance on offline CAM programming for common tasks and enabling faster responses to urgent or small-batch orders.

Improved Product Quality and Design Complexity

Tube laser cutting machines deliver a superior level of product quality and consistency that is difficult to achieve with traditional methods. The non-contact nature of laser cutting eliminates tool wear, meaning the first part cut is virtually identical to the last, even in long production runs. The precision of CNC-controlled laser cutting, typically achieving tolerances of ±0.1mm to ±0.2mm, ensures that parts are made exactly to specification. This high accuracy leads to better fit-up in subsequent assembly and welding processes, reducing the need for manual rework or adjustments. For Ahmed's business, supplying parts for automotive applications where precise assembly is critical for robotic welding lines, this level of consistent quality is non-negotiable. The minimal heat-affected zone (HAZ)13 produced by fiber lasers, especially when using nitrogen assist gas for stainless steel or aluminum, results in clean, smooth cut edges with little to no dross or thermal distortion. This often eliminates the need for secondary deburring or finishing operations, saving time and labor.

Beyond just quality, tube laser cutters unlock unprecedented design freedom. Designers are no longer constrained by the limitations of traditional tools. Lasers can cut virtually any contour, create intricate patterns, produce complex intersections like fish-mouths or copes with extreme precision, and even perform bevel cuts for weld preparation, all in a single setup. This capability allows engineers and architects to design more sophisticated, aesthetically pleasing, and functionally optimized components. For example, tab-and-slot designs can be easily incorporated, which simplify assembly by creating self-locating joints, reducing the need for complex jigs and fixtures, and ensuring correct orientation of parts. I've seen clients in the furniture and architectural sectors completely rethink their product designs once they understood the capabilities of laser tube cutting, leading to more innovative and competitive products. The ability to create unique, complex geometries that were previously too expensive or impossible to manufacture opens up new market opportunities.

This design flexibility also extends to prototyping and customization. New designs or modifications can be quickly programmed and tested without the need to create expensive custom tooling. This agility is crucial in today's market where product life cycles are shortening and demand for customized solutions is increasing. Whether it's a unique piece of fitness equipment or a bespoke architectural feature, the tube laser cutter can produce it efficiently, even in small batches.

Cost Reduction and Market Competitiveness

While the initial investment in a tube laser cutting machine can be significant, the long-term cost reductions and enhanced market competitiveness it offers are substantial. Labor costs are often one of the largest components of manufacturing expenses. By automating multiple processes and reducing the need for manual handling and multiple machine setups, tube laser cutters significantly reduce the labor content per part. A single operator can often oversee a highly automated laser cutting cell, whereas several operators might be needed to achieve similar output using traditional methods. This was a key factor for Ahmed, who faced challenges with high operator turnover and the associated retraining costs; the ease of use of systems like MZBNL's No-CAD, requiring only one day of on-site training, directly addresses this pain point.

Material cost savings are another significant benefit. The precision of laser cutting results in a very narrow kerf (the width of material removed by the laser), which inherently saves material compared to wider saw cuts. More importantly, advanced nesting software14, coupled with innovations like MZBNL's Zero-Waste Tail Material system, maximizes material utilization from each stock length of tube. Reducing scrap by even a few percentage points can lead to substantial savings over time, especially when working with expensive materials like stainless steel or aluminum. Furthermore, the elimination or reduction of secondary operations like deburring, grinding, or manual fitting also contributes to lower overall production costs.

These operational efficiencies – faster production, lower labor input, reduced material waste, and improved quality – collectively lead to a lower cost per part. This allows manufacturers to price their products and services more competitively in the market. Moreover, the ability to produce higher quality, more complex, and customized parts can open up new, higher-margin market segments. For businesses like Ahmed's, aiming to expand into architectural metalwork and sophisticated vehicle parts, the tube laser cutter is not just a cost-saving tool but an enabling technology that allows them to meet the stringent demands of these markets. The improved lead times and reliability also enhance customer satisfaction and can lead to increased business. Ultimately, investing in tube laser cutting technology is an investment in future competitiveness and growth.

Laser cutting increases productivityDoğru

Tube laser cutters consolidate multiple operations into one automated process, significantly reducing production time compared to traditional methods.

Laser cutting requires more laborYanlış

Tube laser cutting actually reduces labor needs through automation, allowing one operator to oversee what previously required multiple workers.

Sonuç

Tube laser cutting machines revolutionize fabrication by offering unmatched speed, precision, and design flexibility. They significantly reduce waste, cut labor costs through automation, and enhance overall product quality, empowering manufacturers like us at MZBNL to deliver superior, innovative solutions worldwide.

-

Compare fiber and CO2 laser technologies for metal tube cutting performance and efficiency. ↩

-

Learn why a minimal HAZ is crucial for maintaining material integrity in laser cutting. ↩

-

Learn about HAZ, its effects on material properties, and why minimizing it is beneficial. ↩

-

See evidence of how laser cutting improves material yield by 5-15% or more. ↩

-

Discover how integrating laser cutters with MRP/ERP enhances production planning and efficiency. ↩

-

Learn key differences and benefits of fiber lasers versus CO2 lasers for metal cutting applications. ↩

-

Understand how assist gases (oxygen, nitrogen, air) impact laser cutting quality and material suitability. ↩

-

Explore CNC technology fundamentals and its crucial role in automating precision manufacturing machinery. ↩

-

Learn how adjusting laser power, speed, and assist gas impacts cut quality and efficiency in tube processing. ↩

-

Discover how nesting software optimizes material use and reduces waste in tube laser cutting operations. ↩

-

Understand the crucial role of assist gases in achieving clean cuts and their types for metal tube laser cutting. ↩

-

Learn about fiber laser technology and its benefits for high-speed, efficient metal cutting. ↩

-

Understand HAZ and how minimizing it improves cut quality and material integrity. ↩

-

Discover how nesting software maximizes material use and reduces scrap in fabrication. ↩

Sorularınız mı var veya daha fazla bilgiye mi ihtiyacınız var?

Kişiselleştirilmiş yardım ve uzman tavsiyesi için bizimle iletişime geçin.