Teknolojinin İçinde: MZBNL'nin Hassas Metal Boru Kesme Makineleri

Are you struggling with inefficient metal tube processing? The demand for precision and speed in metal fabrication is escalating, pushing businesses to seek advanced solutions. My goal today is to show you how innovative technology is transforming this critical industry.

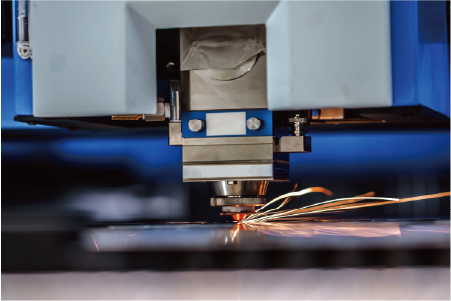

The evolution of metal tube cutting technology has transformed from manual methods to highly automated laser systems, significantly enhancing precision, speed, and material utilization across diverse industries. This progression addresses the growing need for efficient and sophisticated fabrication processes.

For decades, metal tube cutting has been a cornerstone of manufacturing, powering everything from furniture to complex automotive parts. However, the true story lies in its rapid evolution, driven by an unyielding pursuit of greater efficiency and accuracy. Join me as we explore this journey and discover how MZBNL is shaping its future.

Reflecting on the trajectory of metal tube processing, it's clear that the industry has always been on a quest for perfection—a delicate balance between speed, accuracy, and cost-effectiveness. Early manual cutting, while accessible, was inherently slow and imprecise, limiting complex designs and scalability. The advent of mechanical saws and later plasma cutting offered significant speed improvements, yet still presented challenges in achieving intricate cuts and managing material waste, especially with varying tube geometries. For instance, in a 2022 industry report by Grand View Research, the global metal fabrication market was projected to reach $208.5 billion by 20301, underscoring the immense demand for more sophisticated and efficient cutting solutions. This growth trajectory isn't merely about volume; it’s about meeting increasingly stringent quality standards and complex design requirements from sectors like aerospace and medical devices. The critical question isn't just how fast can we cut, but how intelligently can we cut? This involves minimizing scrap, optimizing design flexibility, and reducing the skill barrier for operators, all while maintaining high throughput. This sets the stage for a deeper exploration into the innovations driving the next generation of tube cutting.

What is the history and development of metal tube cutting technology?

Have you ever wondered how metal tubes transformed from basic raw materials into the precise components we see today? The journey of metal tube cutting technology is a fascinating evolution, driven by industrial demands for greater efficiency. I want to share how this critical process has advanced through time.

The history of metal tube cutting technology spans from rudimentary hand tools to sophisticated CNC laser systems, evolving through mechanical saws, hydraulic cutters, and plasma torches, each advancing precision, speed, and automation capabilities.

From the simple hacksaw to the precision of a laser, the evolution of metal tube cutting technology is a testament to human ingenuity. This journey wasn't linear; it was a series of leaps, each solving a previous limitation and opening new possibilities for manufacturing. Understanding this progression is crucial because it highlights the foundational challenges that today's advanced machines, like those from MZBNL, are designed to overcome. For instance, the early 20th century saw the introduction of abrasive saws, which were faster but lacked the finesse for intricate designs. By the mid-century, cold saws offered cleaner cuts but were still limited in automation. The true revolution began with the integration of computer numerical control (CNC) systems, paving the way for the highly precise and efficient laser and plasma cutting methods we rely on today. This historical backdrop helps us appreciate the intricate engineering that goes into modern solutions, ensuring that every cut is not just a cut, but a step towards perfect fabrication.

The narrative of metal tube cutting technology is one of continuous innovation, moving from labor-intensive, less accurate methods to highly automated, precision-driven systems. Early on, cutting was primarily manual, relying on hacksaws or rudimentary band saws. These methods were slow, produced inconsistent results, and were heavily dependent on the operator's skill, leading to significant material waste and production bottlenecks. As industrialization progressed, the demand for higher volumes and better quality pushed for mechanical advancements.

The Dawn of Mechanized Cutting: Saws and Abrasives

The mid-20th century marked a significant shift with the introduction of mechanical cutting tools like abrasive saws and cold saws. Abrasive saws, while fast, generated considerable heat, which could deform the material and produce rough edges requiring secondary finishing. Cold saws offered cleaner cuts at lower temperatures, reducing material distortion, but were often limited to simpler shapes and slower speeds compared to modern methods. These early mechanical solutions, despite their improvements over manual techniques, still presented challenges in terms of cut quality, material compatibility, and the inability to handle complex geometries. For example, a manufacturer producing intricate furniture frames in the 1960s would face immense difficulty achieving consistent, burr-free cuts on curved or irregular tube shapes using these methods, often resorting to extensive post-processing. This era laid the groundwork but highlighted the need for more versatile and precise technologies to meet evolving design demands.

The Rise of Thermal Cutting: Plasma and Laser

The late 20th century witnessed the transformative power of thermal cutting technologies: plasma and laser. Plasma cutting, introduced for metals, offered greater speed and the ability to cut thicker materials with complex profiles. It significantly reduced processing time for many applications, especially in heavy industries. However, plasma still produced a wider kerf and often required more post-processing due to heat-affected zones. The true game-changer arrived with laser cutting, particularly CO2 and then fiber lasers. Laser technology brought unprecedented precision, minimal material distortion, and the ability to cut intricate designs with smooth edges, largely eliminating the need for secondary finishing. A study by the Fraunhofer Institute for Production Technology (IPT) in 2018 highlighted that laser cutting could reduce production costs by up to 30%2 compared to traditional methods for certain applications, primarily due to higher precision and reduced waste. This precision enabled manufacturers to create more complex and lighter components, opening new design possibilities in industries like automotive and aerospace.

The Era of Automation and Smart Manufacturing: CNC and Beyond

The most profound evolution came with the integration of Computer Numerical Control (CNC) systems. CNC technology transformed laser and plasma cutting from standalone machines into intelligent, automated workstations. This allowed for precise control over cutting paths, speeds, and power, enabling mass production of identical, high-quality parts with minimal human intervention. Today's advanced CNC tube laser cutting machines feature sophisticated software for 3D modeling, nesting, and real-time process monitoring. According to data from the Association for Manufacturing Technology (AMT), the adoption of CNC machine tools has grown steadily, with laser cutting systems experiencing particularly strong demand due to their versatility. For a manufacturer like Ahmed Al-Farsi, who is looking to automate his operations in the UAE, the shift from traditional methods to a CNC laser tube cutting machine represents a leap in capabilities. It moves him from a scenario where his skilled CAD operators were constantly bogged down by design modifications and manual setups to a system where, with MZBNL's No-CAD innovation, parameters are simply entered, vastly improving efficiency and reducing the dependency on highly specialized skills. The future is about not just cutting, but smart cutting, integrating artificial intelligence and IoT to further optimize processes and predict maintenance needs, ensuring continuous, high-precision output.

| Technology Type | Cut Quality | Hız | Material Thickness Range | Otomasyon Seviyesi | Tipik Uygulamalar |

|---|---|---|---|---|---|

| Manual Sawing | Düşük | Very Slow | Thin to Medium | Manual | Small workshops, prototyping |

| Abrasive Sawing | Orta | Orta | Medium to Thick | Semi-Automatic | Rough cuts, structural steel |

| Cold Sawing | Yüksek | Orta | Orta | Semi-Automatic | Precise straight cuts |

| Plasma Cutting | Medium-High | Hızlı | Thick | CNC Automated | Heavy fabrication, large pipes |

| Laser Cutting (CNC) | Çok Yüksek | Very Fast | Thin to Medium | Fully Automated | Precision parts, complex designs |

Laser cutting reduces wasteDoğru

Laser cutting's precision minimizes material waste compared to manual or abrasive methods, as shown by Fraunhofer IPT's 30% cost reduction findings.

Plasma cuts need no finishingYanlış

Plasma cutting often requires post-processing due to heat-affected zones and wider kerf, unlike laser-cut edges that are typically clean.

How does MZBNL fit into the current landscape of precision metal tube cutting?

In today's highly competitive metal fabrication market, where does MZBNL stand? We aren't just another machine manufacturer; we are innovators. I'm excited to explain how our unique approach and patented technologies are redefining the benchmarks for precision metal tube cutting.

MZBNL distinguishes itself in precision metal tube cutting by integrating R&D with manufacturing, focusing on user-friendly innovations like No-CAD systems, front-feeding, and zero-waste technology. Our solutions enhance efficiency and ease of operation for global clients.

The current landscape of precision metal tube cutting is dynamic, characterized by a relentless drive for efficiency, accuracy, and adaptability. Customers like Ahmed Al-Farsi in the UAE are no longer just looking for a machine; they are seeking comprehensive solutions that streamline operations, reduce waste, and empower their workforce. This is precisely where MZBNL carves out its unique position. My experience working with fabricators globally has shown me that while many offer advanced cutting machines, few combine technological innovation with a deep understanding of operational pain points. MZBNL's commitment goes beyond merely manufacturing; we integrate R&D, manufacturing, sales, and service3 to provide tailored solutions. We've spent 25 years in this field, accumulating over 30 patents and serving 4000+ global enterprise clients, which speaks to our profound impact. Our strategic focus isn't just about selling a product; it’s about delivering a competitive advantage through smart, digitalized systems that are easy to operate and maintain, ultimately making high-speed, high-precision cutting accessible and cost-effective. This comprehensive approach differentiates us, enabling clients to achieve new levels of productivity and profitability.

MZBNL’s strategic positioning in the precision metal tube cutting market is defined by our foundational philosophy: innovation-driven solutions that directly address real-world manufacturing challenges. We understand that in a market saturated with options, true value comes from efficiency, ease of use, and intelligent design. Our 25 years of experience have solidified our expertise, allowing us to not just compete, but to lead.

Spearheading Innovation with User-Centric Design

At MZBNL, our core strength lies in integrated R&D and manufacturing, allowing us to push the boundaries of what's possible in metal fabrication. We don't just react to market trends; we set them. Our dedication to technological innovation is evident in our pioneering No-CAD Operating System. Traditionally, CAD design offices were a bottleneck, requiring operators to step away from the machine to create or modify complex 3D drawings. This often meant days, if not weeks, of lost production time and significant training investment. From my personal observation, a typical scenario involved a skilled operator waiting for CAD drawings to be finalized, or even worse, making a mistake that required an entire re-drawing process. With our No-CAD system, standard tube types and hole patterns can be processed by simply entering parameters directly at the machine. This revolutionary approach has slashed setup times and drastically lowered the skill threshold for machine operation. For our clients, this translates into operators needing only one day of on-site training instead of the conventional 15 days spent at an equipment factory. This isn't just an incremental improvement; it's a fundamental shift in workflow efficiency, significantly reducing training burdens and operational costs. For a company like Ahmed Al-Farsi’s, where operator turnover and the need for skilled CAD personnel were significant pain points, the No-CAD system directly addresses these issues, allowing his existing workforce to quickly adapt and become productive.

Enhancing Productivity Through Optimized Material Handling

Beyond cutting intelligence, MZBNL recognized the critical role of material handling in overall productivity. Traditional machines often rely on cumbersome side or rear manual loading, which is labor-intensive and slow, creating another bottleneck in the production chain. Our response was the optimized Front-Feeding Innovation. This mechanism automatically pulls the tube in from the front of the machine, a design that significantly enhances feeding efficiency. Internal data from MZBNL shows that this design increases feeding efficiency by approximately 40% and reduces operator labor intensity by about 40%. This direct impact on productivity and ergonomics is substantial. Consider a busy fabrication line: reducing the effort and time spent on loading directly translates to more continuous operation and higher throughput. It’s a clear example of how focusing on often-overlooked aspects of the production process can yield dramatic improvements. This innovation aligns perfectly with the automation goals of clients like Ahmed, who seek turnkey solutions that are easy to install and operate while maximizing output from their existing floor space.

Maximizing Material Utilization with Zero-Waste Solutions

Material waste is a silent killer of profits in metal fabrication. Conventional laser cutting systems typically start cutting from the tube head, inevitably leaving an unusable tail material at the end of the process. This seemingly small amount of scrap accumulates quickly, representing significant financial loss over time. MZBNL tackled this problem head-on with our Sıfır Atık Kuyruk Malzemesi İnovasyonu4. We redesigned the cutting logic to calculate from the rear chuck as the origin. This clever alteration allows the system to eliminate leftover tail material as long as the remaining section is smaller than the product length. This zero-tail design maximizes material utilization, virtually eliminating a common source of waste, and boosting overall cutting efficiency. For a business like Ahmed's, which produces high volumes of railings and auto parts, even a 1-2% reduction in material waste can result in substantial savings annually. This innovation underscores MZBNL's commitment to not just cutting well, but cutting intelligently and sustainably, providing a robust cost-performance ratio that clients value over just a low purchase price.

MZBNL integrates R&D with manufacturingDoğru

MZBNL combines research, manufacturing, sales and service to provide comprehensive solutions, as evidenced by their 30+ patents.

No-CAD requires extensive CAD trainingYanlış

The No-CAD system actually reduces training time from 15 days to just 1 day by eliminating complex CAD requirements.

What challenges do manufacturers face in metal tube processing?

Are you a manufacturer grappling with the complexities of metal tube processing? The industry, while growing, presents a unique set of challenges that can impact your efficiency and profitability. From my vantage point at MZBNL, I see these hurdles daily and understand their profound impact on operations.

Manufacturers in metal tube processing frequently encounter issues such as the need for highly skilled operators, material waste, slow production speeds, and difficulties with complex designs. These challenges often lead to increased operational costs and delayed project delivery.

In the bustling world of metal fabrication, tube processing is a critical but often challenging domain. My conversations with countless manufacturers, including those expanding their operations like Ahmed Al-Farsi in the UAE, consistently reveal a common set of pain points. These aren't just minor inconveniences; they are significant obstacles that directly impact output, quality, and profit margins. Consider the intricate balance of precision, speed, and cost that every fabricator strives for. When manual processes or outdated machinery are involved, this balance is easily disrupted, leading to bottlenecks and inefficiencies. For instance, in a fast-paced environment where project deadlines are tight, any delay caused by machine downtime or the need for extensive operator training can have a cascading effect, jeopardizing project delivery and client satisfaction. These challenges are not unique to any one region; they are global, reflecting a universal demand for more sophisticated and user-friendly solutions. Understanding these specific hurdles is the first step towards identifying the truly impactful technological advancements that can transform a business.

The metal tube processing industry, despite its essential role in various sectors, is fraught with operational challenges that can significantly impede productivity and profitability. From the perspective of a manufacturer, these challenges often stem from a blend of technological limitations, skill gaps, and material management complexities.

The Hurdle of Skilled Labor and Training Burden

One of the most persistent challenges manufacturers face is the increasing difficulty in finding and retaining highly skilled operators, particularly those proficient in CAD software for complex tube designs5. Traditional laser tube cutting machines often require extensive training—sometimes weeks—for operators to master programming and machine operation. This creates a significant training burden and amplifies the impact of high operator turnover, a common issue in many industrial sectors. For Ahmed Al-Farsi, this was a critical pain point; his previous machines demanded skilled CAD operators, and high turnover led to constant retraining. He told me how a single new hire could set back production schedules by weeks due to the steep learning curve. According to a 2023 report by the National Association of Manufacturers (NAM), over 50% of manufacturers reported difficulties finding skilled workers, citing a direct impact on production capacity. This shortage not only drives up labor costs but also creates bottlenecks in production lines, as complex tasks can only be performed by a select few, leading to project delays and reduced flexibility. The need for specialized skills also limits the ability to quickly scale up production or cross-train staff, making businesses vulnerable to personnel changes.

Inefficiency in Production Flow and Material Utilization

Beyond labor, manufacturers frequently grapple with inefficiencies in their production workflow6, particularly concerning material handling and waste. Conventional tube cutting processes, including manual loading and the inevitable generation of tail material, significantly reduce overall operational efficiency. For instance, manual loading from the side or rear of a machine is time-consuming and physically demanding, slowing down the entire production cycle. A 2021 study on manufacturing efficiency indicated that material handling can account for up to 30% of a product's total manufacturing cost if not optimized. Furthermore, the issue of leftover tail material, a common byproduct of starting cuts from the tube head, contributes to substantial material waste. This scrap represents lost revenue and increased raw material costs. Many manufacturers fail to accurately quantify this waste, but its cumulative impact over thousands of tubes can be staggering. Ahmed, for example, estimated that even a small percentage of material waste, when multiplied across his high-volume production of architectural components and vehicle parts, translated into tens of thousands of dollars annually. These inefficiencies not only inflate operational costs but also make it harder to deliver projects on time and within budget, eroding competitive advantage in a demanding market.

Limitations in Customization and After-Sales Support

A critical challenge for modern manufacturers is the need for highly customized solutions coupled with reliable and accessible after-sales support services7. In a market demanding bespoke products and rapid prototyping, machines that offer limited customization options or complex retooling processes can severely restrict a company's ability to innovate and respond to client demands. Many suppliers offer standard machines but fall short when it comes to tailored solutions for unique production needs or integrating into existing automation systems. Moreover, a recurring complaint among manufacturers is the lack of robust local service support, spare parts availability, and remote diagnostics, especially from international suppliers. Ahmed's experience with some overseas suppliers, where long machine lead times and absent local service support frequently impacted project delivery, underscores this issue. If a machine breaks down, the cost of downtime, coupled with the wait for parts or technicians from afar, can be crippling. This absence of comprehensive, localized support significantly increases operational risk and undermines long-term investment in advanced machinery. It highlights a critical gap in the market for suppliers who not only provide cutting-edge technology but also back it with accessible, responsive, and global support networks, ensuring continuous operation and peace of mind for their clients.

Skilled labor shortage impacts productionDoğru

Over 50% of manufacturers report difficulties finding skilled workers, leading to production delays.

Material waste is insignificantYanlış

Tail material waste can accumulate to tens of thousands of dollars annually in high-volume production.

How do MZBNL’s innovations address these industry challenges?

Facing the challenges of skilled labor, material waste, and inefficient processes, manufacturers need more than just machines—they need intelligent solutions. At MZBNL, our core innovations are specifically engineered to tackle these pervasive industry pain points. I'm here to show you how we directly address these issues.

MZBNL's No-CAD system simplifies operation, reducing training needs; our front-feeding innovation boosts efficiency; and zero-waste technology minimizes material costs, directly addressing key industry challenges in productivity and profitability.

The manufacturing sector today is a crucible of challenges, from the persistent scarcity of skilled operators to the ever-present pressure of optimizing material use and accelerating production. It's not enough to simply produce a machine; we must produce a solution that understands and alleviates these real-world pain points. My role at MZBNL has given me unique insight into how our patented innovations are not just features, but direct answers to the toughest industry questions. For example, when I discuss our systems with clients like Ahmed Al-Farsi, he immediately recognizes how our No-CAD system could transform his operational model, mitigating his struggles with high operator turnover and the need for extensive CAD expertise. We didn't just build faster machines; we built smarter, more accessible ones. By focusing on user experience, material efficiency, and seamless integration, MZBNL’s innovations offer a comprehensive approach that transforms these common industry hurdles into competitive advantages, enabling businesses to not only survive but thrive in a demanding global market.

At MZBNL, our engineering philosophy is rooted in solving tangible problems faced by metal fabrication businesses every day. We’ve leveraged our 25 years of experience and extensive R&D to introduce three major innovations that directly counter the prevailing industry challenges, ensuring our clients achieve unparalleled efficiency, cost savings, and operational simplicity.

Revolutionizing Operation with No-CAD System Innovation

The industry's reliance on highly skilled CAD operators has long been a bottleneck, leading to increased training costs and production delays, particularly during personnel turnover. Our pioneering No-CAD İşletim Sistemi8 directly confronts this challenge. Traditionally, any complex 3D drawing modification meant an operator had to return to a design office, a time-consuming and often frustrating process. Imagine Ahmed Al-Farsi’s scenario: needing a quick design tweak for a bespoke architectural railing, only to find his CAD expert tied up, delaying the entire fabrication. This is precisely the inefficiency we target. With MZBNL’s system, standard tube types and hole patterns can be processed simply by entering parameters directly on the machine interface—no drawing required. This dramatically improves ease of use and shortens setup time, effectively lowering the skill threshold for machine operation. My observations confirm that operators now require just one day of on-site training, a stark contrast to the 15 days previously needed at an equipment factory. This innovation not only makes our machines accessible to a broader workforce but also significantly reduces the operational burden caused by skilled labor shortages and high employee turnover, ensuring continuous production without extensive retraining.

Boosting Throughput with Front-Feeding Innovation

Production efficiency is often hampered by slow and labor-intensive material loading processes. While conventional machines often rely on cumbersome side or rear manual loading, creating a bottleneck, MZBNL introduced an optimized Front-Feeding mechanism. This innovation directly addresses the issue of slow material handling that impacts overall productivity. Our design automatically pulls the tube in from the front of the machine, streamlining the entire loading process. This might seem like a small change, but its impact is profound. Internal studies conducted by MZBNL, based on typical production scenarios, reveal that this design increases feeding efficiency by approximately 40% and simultaneously reduces operator labor intensity by about 40%. Consider a high-volume fabrication facility; this improvement translates directly into more processed tubes per shift, significantly enhancing overall productivity. For a client like Ahmed, whose business relies on consistent, high-volume output of parts for the automotive and architectural sectors, this efficiency gain is invaluable. It reduces physical strain on his staff, accelerates cycle times, and allows him to meet demanding production schedules more reliably.

Maximizing Profitability with Zero-Waste Tail Material Innovation

Material waste due to unusable tail ends is a hidden cost that erodes profit margins in tube cutting operations. Conventional laser cutting systems typically start from the tube head, invariably leaving a substantial, unusable tail piece at the end of each process. This accumulated waste, though seemingly small per cut, can amount to significant financial losses over time. MZBNL's Sıfır Atık Kuyruk Malzemesi İnovasyonu9 provides a smart solution to this pervasive problem. We meticulously redesigned the cutting logic to calculate from the rear chuck as the origin. This allows the system to completely eliminate leftover tail material, as long as the remaining section is smaller than the product length, by intelligently nesting parts or consuming the "tail" as part of the last usable piece. This not only maximizes material utilization but also directly boosts cutting efficiency by minimizing waste and post-processing. For businesses like Ahmed's, where material costs are a significant component of overall expenses, this innovation offers substantial savings and aligns with growing demands for more sustainable manufacturing practices. It's a testament to our commitment to providing cost-effective, customized solutions that deliver measurable benefits beyond just cutting speed.

No-CAD eğitim süresini kısaltırDoğru

MZBNL's No-CAD system cuts operator training from 15 days to just 1 day by eliminating complex CAD requirements.

Önden besleme verimliliği azaltırYanlış

Front-feeding actually increases feeding efficiency by 40% compared to conventional side/rear loading methods.

What technological recommendations can optimize the use of MZBNL’s cutting machines?

You've invested in a cutting-edge MZBNL machine; now, how can you ensure you're getting the absolute most out of it? Optimizing your operations isn't just about the machine itself, but how you integrate it into your workflow. I want to share key recommendations to maximize your MZBNL machine's potential.

To optimize MZBNL’s cutting machines, I recommend leveraging the No-CAD system for rapid prototyping, implementing preventive maintenance schedules, integrating smart diagnostics, and utilizing our remote support for peak performance and minimal downtime.

Having invested in MZBNL's advanced lazer tüp kesme maki̇neleri̇10, you've already taken a significant step towards modernizing your production. However, owning cutting-edge technology is only half the equation; truly optimizing its use requires strategic implementation and a proactive approach to maintenance and operational refinement. My experience with numerous clients globally has shown me that the full potential of these sophisticated machines is unleashed when they are seamlessly integrated into a digitalized workflow, supported by robust data analysis and consistent care. For example, a client recently shared how adopting a stringent preventive maintenance schedule, coupled with leveraging our smart diagnostics features, significantly reduced their unscheduled downtime, allowing them to meet a critical, high-volume order that would have otherwise been jeopardized. This proactive mindset transforms a powerful machine into an unstoppable production asset, ensuring peak performance, longevity, and maximum return on investment.

Optimizing the use of MZBNL’s advanced laser tube cutting machines goes beyond simply pressing the "start" button. It involves strategic integration of our inherent technological advantages with best practices in operational management and continuous improvement. My recommendations are geared towards unlocking the full capabilities of your MZBNL investment, ensuring peak performance, minimal downtime, and maximum return.

Leveraging Smart System Features for Enhanced Productivity

The true power of MZBNL’s machines lies in their intelligent design and digitalized systems. To maximize this, I strongly recommend fully embracing features like our No-CAD Operating System for daily operations. Instead of waiting for complex 3D drawings for standard parts, utilize the parameter-based input system for rapid prototyping and quick job setups. This dramatically reduces lead times for new product iterations or custom orders, giving you a competitive edge in responsiveness. For instance, when Ahmed Al-Farsi receives an urgent order for a new architectural component design, instead of his team spending hours on CAD adjustments, they can swiftly input key dimensions directly into the machine, allowing for immediate production and testing. Furthermore, regularly utilize the machine's smart diagnostics and remote monitoring capabilities. These systems provide real-time performance data and can predict potential issues before they escalate into costly breakdowns. Integrating this data with your production planning allows for proactive adjustments and continuous optimization of cutting parameters for different materials and tube geometries, ensuring consistent high-speed and high-precision cutting. This proactive data-driven approach moves from reactive problem-solving to predictive operational excellence, maximizing uptime and throughput.

Implementing Proactive Maintenance and Training Protocols

While MZBNL machines are designed for easy operation and maintenance, a rigorous proactive maintenance schedule is paramount to ensure their longevity and consistent performance. This goes beyond routine checks; it involves scheduled preventative maintenance sessions, replacement of wear parts before failure, and calibration verification. Consider the critical components like laser optics, cutting nozzles, and feeding mechanisms—these require regular inspection and cleaning to maintain cutting quality and efficiency. A well-maintained machine is a reliable machine. In my experience, companies that allocate dedicated time for preventative maintenance not only experience fewer unexpected downtimes but also achieve higher cut quality and extend the lifespan of their equipment. Furthermore, invest continuously in operator training, even with the No-CAD system's simplicity. While basic operation is easy, advanced training can empower your team to troubleshoot minor issues, perform first-line maintenance, and explore the full range of customization features. MZBNL offers comprehensive post-sales training and support, which should be fully leveraged. Empowering your team with deeper knowledge of the machine's capabilities and maintenance requirements transforms them into proactive problem-solvers, ensuring the machine operates at its peak, reducing reliance on external service calls and significantly boosting overall operational resilience.

Strategic Integration and Future-Proofing your Investment

To truly optimize your MZBNL laser tube cutting machine, consider its strategic integration within your broader manufacturing ecosystem. This includes seamless data flow from your ERP or production management systems to the machine, enabling automated job scheduling and material tracking. Embracing a digitalized workflow reduces manual errors and enhances overall factory efficiency. For example, a larger client of ours in Europe integrated their MZBNL machine with their inventory management system, automating material reordering based on consumption rates, which led to significant cost savings and reduced stockouts. Additionally, explore the potential for multi-process integration. MZBNL's machines offer capabilities for both cutting and automatic punching, streamlining multiple fabrication steps into a single machine, reducing material handling and cycle times. Finally, think about future-proofing your investment. Given Ahmed Al-Farsi's interest in becoming a regional distributor or exploring co-branding, consider how ongoing collaboration with MZBNL can lead to access to future innovations and dedicated support. Regularly engage with our team for updates on software enhancements, new accessories, or advanced cutting techniques. Staying abreast of these developments ensures your MZBNL machine remains at the forefront of metal tube cutting technology, continuously delivering high cost-performance and supporting your business growth for years to come.

No-CAD system speeds up prototypingDoğru

The No-CAD system allows direct parameter input, eliminating time-consuming CAD adjustments for standard parts.

Maintenance is only needed after failuresYanlış

Proactive preventive maintenance is crucial for optimal performance, not just reactive repairs after breakdowns.

Sonuç

In essence, MZBNL's journey from historical cutting methods to our cutting-edge, integrated solutions underscores our commitment to solving manufacturing pain points. Our innovations—No-CAD, front-feeding, and zero-waste—directly address industry challenges, ensuring higher precision, efficiency, and ease of use for our global clients.

-

Understand the projected growth and demand for advanced metal fabrication solutions ↩

-

Learn about cost reduction through precision and waste minimization in laser cutting ↩

-

Discover the benefits of integrating these elements for innovative solutions. ↩

-

Understand how zero-waste technology minimizes material waste and maximizes efficiency. ↩

-

Learn how CAD software expertise is essential for handling complex tube designs in manufacturing ↩

-

Understand production workflow inefficiencies and their cost impact in tube processing ↩

-

Explore the importance of after-sales support systems for maintaining operational efficiency ↩

-

Learn how the No-CAD system minimizes reliance on skilled CAD operators ↩

-

Find out how zero-tail design minimizes material waste and cuts costs ↩

-

Discover the high-speed, precise cutting features and smart diagnostics benefits ↩

Sorularınız mı var veya daha fazla bilgiye mi ihtiyacınız var?

Kişiselleştirilmiş yardım ve uzman tavsiyesi için bizimle iletişime geçin.