Güneydoğu Asyalı Bir Müşteri Tüp Lazer Kesim Makineleri ile Üretimi Nasıl Büyüttü?

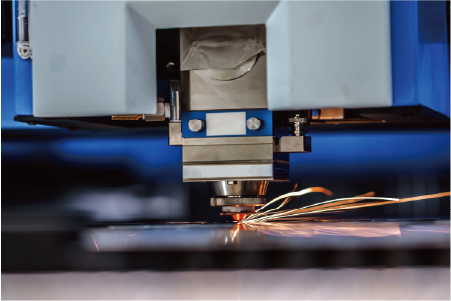

Traditional metal fabrication methods often hinder rapid scaling, causing bottlenecks and impacting delivery times for growing businesses. Are you struggling to meet escalating demand while maintaining quality and efficiency? I've seen firsthand how adopting advanced tube laser cutting technology can transform production, enabling impressive growth.

A Southeast Asian metal fabrication client successfully scaled production by integrating state-of-the-art tube laser cutting machines, significantly reducing processing times, improving precision, and optimizing material utilization, leading to enhanced overall operational efficiency and increased output capacity.

My journey in metal fabrication at MZBNL, spanning 25 years, has shown me the immense potential of strategic technological investment. This isn't just about machinery; it's about empowering businesses to overcome their limitations and achieve unprecedented growth. Let me share a compelling story of how a proactive client in Southeast Asia navigated significant challenges to not only meet but exceed their production goals.

The global manufacturing landscape is relentlessly pushing companies toward greater efficiency and automation, especially within the metal processing sector. Businesses today face an array of pressures, from volatile material costs to rising labor expenses and the demand for increasingly complex designs. For many, traditional methods involving sawing, drilling, and manual punching simply can't keep pace. I’ve observed how this reliance on conventional, often labor-intensive processes leads to production bottlenecks, inconsistent quality, and substantial material waste, directly impacting profitability and market competitiveness. This narrative isn't unique; it's a critical challenge I see across various markets, from the booming construction industry in the Middle East1, where clients like Ahmed Al-Farsi seek advanced solutions for architectural metalwork, to the rapidly expanding automotive component sector in Southeast Asia. The critical question isn't whether to automate, but how to strategically implement solutions that deliver tangible, long-term benefits beyond initial investment costs.

Background of the Southeast Asian Client's Industry and Market Positioning

Metal fabrication in Southeast Asia is a dynamic sector, fueled by rapid urbanization and infrastructure development, but it often faces unique hurdles. Are you struggling to maintain a competitive edge amidst burgeoning market demands and traditional production inefficiencies? I've witnessed how strategic insights into market positioning can pave the way for transformative technological adoption.

A prominent Southeast Asian metal fabrication company, operating within the architectural and furniture components sector, positioned itself for growth by recognizing the need for advanced manufacturing capabilities amidst increasing demand for intricate designs and faster turnaround times.

My experience at MZBNL, working with over 4000 global enterprise clients, has provided me with a unique vantage point on the diverse challenges and opportunities within various regional markets. The Southeast Asian client, let's call them "PT Karya Logam" from Indonesia, exemplifies a mid-sized enterprise that had built a strong reputation for quality in architectural metalwork and bespoke furniture components. Their market was booming, driven by new construction projects and a growing consumer appetite for modern, well-crafted pieces. However, this success also brought significant pressure to scale their operations without compromising their signature precision or extending lead times. It was clear that their reliance on conventional fabrication methods was becoming a bottleneck, hindering their ability to capitalize fully on the market's potential and compete effectively against larger, more automated players.

The Flourishing Architectural and Furniture Sectors in Southeast Asia

Southeast Asia's architectural and furniture industries have experienced exponential growth over the past decade, driven by strong economic development, urbanization, and an expanding middle class. This surge has directly translated into a heightened demand for high-quality metal components, ranging from custom railings and decorative panels for modern buildings to intricate frames for contemporary furniture. The specific nature of these demands often involves complex geometries, precision cuts, and aesthetic finishes, pushing traditional fabrication methods to their limits. For instance, in countries like Vietnam and Indonesia2, the furniture export market alone contributes billions of dollars annually, with a significant portion relying on metal fabrication. This creates a fertile ground for companies like PT Karya Logam, but also intensifies competition.

I've personally observed that clients in this region are increasingly moving beyond basic structural components, seeking partners who can deliver sophisticated designs with minimal waste and maximum efficiency. This shift is not merely about volume; it's about the ability to innovate on design and respond quickly to market trends, a feat that traditional cutting and shaping methods often cannot achieve economically. The reliance on manual processes for intricate parts not only inflates labor costs but also introduces inconsistencies that are unacceptable in high-end applications. My team at MZBNL, leveraging our 25 years of experience, consistently engages with these evolving market needs, understanding that the future lies in flexible, precise, and automated solutions.

PT Karya Logam's Strategic Market Stance and Growth Ambitions

PT Karya Logam was strategically positioned as a bespoke fabricator, renowned for its craftsmanship and ability to handle custom orders that larger, mass-production facilities might shy away from. Their typical projects included custom gates, ornate balconies, unique furniture frames, and specialized fixtures for commercial spaces. This niche allowed them to command premium prices, but their manual workflows and dependence on skilled artisans meant that scaling up was a constant uphill battle. Despite their reputation, they faced the classic dilemma of a growing business: how to expand capacity and take on larger projects without sacrificing the quality or agility that defined their brand. They aimed to transition from a purely craft-based operation to a hybrid model that integrated high-tech machinery to support their artisanal capabilities, thereby broadening their client base to include larger developers and furniture brands who required consistent, high-volume precision parts.

In discussions with their management, it became clear that their ambition wasn't just to increase output, but to elevate their overall production capabilities to meet international standards. This involved not only improving speed but also enhancing accuracy, reducing material waste, and streamlining their design-to-production workflow. They understood that their reputation, built on meticulous attention to detail, could only be sustained through a technological upgrade that allowed them to reproduce complex designs flawlessly at scale. This foresight is precisely what sets forward-thinking businesses apart, allowing them to adapt to changing market dynamics.

The Inherent Limitations of Traditional Fabrication in a Modern Context

Prior to their engagement with MZBNL, PT Karya Logam's production floor was a microcosm of traditional metal fabrication. It featured an array of manual and semi-automated tools: band saws for cutting, drilling machines for holes, and manual punches for shaping. This setup, while foundational for many years, was inherently inefficient for modern demands. Material waste was considerable, especially when dealing with non-standard lengths or intricate cutouts, often exceeding 15-20% for complex projects. The process was also highly labor-intensive, requiring multiple operators for different stages, which directly impacted their operating costs and exposure to labor shortages or turnover. A critical challenge I've often seen, akin to what Ahmed Al-Farsi experienced, was the reliance on highly skilled CAD operators for every design change, creating a significant bottleneck between the design office and the production floor.

Moreover, the precision achieved through these manual methods was often inconsistent, requiring significant post-processing work such as deburring and grinding, which further added to production time and labor expense. This limited their ability to tackle highly precise components needed for industries like automotive parts or advanced medical equipment, areas where they saw future growth potential. The cumulative effect was a production ceiling that prevented them from accepting larger contracts or committing to tighter deadlines, effectively stunting their potential for significant market expansion. This scenario highlights a common pain point: the trade-off between traditional craftsmanship and the imperative of industrial-scale efficiency and precision.

Tube laser cutting improves efficiencyDoğru

Advanced tube laser cutting technology reduces processing times and optimizes material utilization, leading to enhanced operational efficiency.

Traditional methods are sufficient for modern demandsYanlış

Traditional fabrication methods like sawing and drilling cannot keep pace with today's demand for complex designs and rapid turnaround times.

Challenges Faced in Scaling Production Prior to Laser Cutting Implementation

Scaling production is a common aspiration for growing businesses, but it often uncovers hidden inefficiencies and systemic bottlenecks. Were you aware3 that reliance on manual processes and a lack of integrated solutions can severely impede your growth? I've seen firsthand how these challenges can stifle even the most ambitious expansion plans.

Before adopting laser cutting technology, PT Karya Logam faced significant scaling challenges including high labor dependency for skilled operations, considerable material waste due to traditional methods, and critical production bottlenecks that severely limited their capacity to meet rising demand and expand product lines.

Every growing business eventually hits a ceiling if its operational infrastructure isn't designed for scalability. For PT Karya Logam, the desire to expand beyond their established niche into higher-volume, more complex projects brought these underlying challenges into sharp focus. My team at MZBNL has encountered similar scenarios countless times across industries, recognizing that the symptoms often point to a core issue: the mismatch between traditional production capabilities and modern market demands. It wasn't just about needing more machines4; it was about transforming their entire operational paradigm. Their existing setup, while capable of producing high-quality bespoke pieces, simply couldn't keep pace with the accelerating demand for speed, precision, and cost-effectiveness that characterize today's competitive landscape. The journey to scaling production is rarely straightforward; it demands a deep dive into existing pain points and a bold vision for technological adaptation.

Over-reliance on Manual Labor and the Growing Skill Gap

PT Karya Logam's pre-laser cutting operations were heavily reliant on manual labor and the availability of highly skilled technicians. Tasks such as cutting, drilling, and punching were executed by hand or with basic machinery, demanding significant operator expertise and physical effort. This created multiple critical vulnerabilities. Firstly, labor costs became a disproportionately large component5 of their operational expenses, particularly as skilled labor in Indonesia commands higher wages. Secondly, and more critically, the availability of truly skilled workers capable of consistently producing high-quality, complex components was dwindling. This skill gap, a common concern echoed by clients like Ahmed Al-Farsi6 who faced high operator turnover, meant that training new hires was a lengthy and expensive process—often taking months to achieve proficiency.

The training burden became a major bottleneck. If a skilled operator left, it directly impacted production speed and quality, leading to project delays and increased scrap rates as less experienced personnel took over. This also limited their ability to expand shifts or take on additional projects without considerable lead time for recruitment and training. My observations from various markets indicate that this isn't an isolated incident; the global manufacturing sector7 is grappling with an aging workforce and a decreasing interest in traditional, manual roles, making automation an economic imperative rather than just an efficiency booster. The human element, while invaluable for craftsmanship, simply cannot provide the consistent output and precision required for large-scale industrial fabrication without significant technological augmentation.

Substantial Material Waste and Inefficient Production Bottlenecks

One of the most insidious challenges PT Karya Logam faced was the significant material waste generated by their traditional processes. When tubes were cut using saws, the kerf width and the need for clamping often resulted in considerable material loss, particularly for short production runs or when cutting multiple varying lengths from a single long tube. Moreover, manual punching and drilling often led to errors that rendered entire sections unusable, further increasing scrap rates. For intricate designs with numerous holes or complex contours, this waste could easily exceed 10-15%8 of the raw material, directly impacting their profitability. This mirrors a common industry issue, where inefficient material utilization can erode margins, especially with fluctuating raw material prices.

Beyond waste, their sequential, often manual, operations created severe production bottlenecks. A tube would be cut, then moved to a drilling station, then to a punching station, and finally to a deburring station. Each transfer added time, labor, and the potential for errors. The slowest process dictated the overall production speed, often leading to queues of unfinished material. For example, if a drilling machine broke down, the entire production line could grind to a halt. This lack of integrated, continuous workflow severely limited their throughput and extended lead times for their clients, making it difficult to compete9 with more agile manufacturers. The absence of a seamless, multi-process solution meant that valuable time and resources were constantly being consumed by material handling and queue management, rather than value-adding activities.

Inability to Meet Growing Demand for Complex Parts and High Volume

The burgeoning demand in Southeast Asia for modern architectural and furniture designs often involves complex, non-standard tube geometries and intricate hole patterns. PT Karya Logam's traditional methods struggled immensely with these requirements. Producing a single complex component could take hours, involving multiple setups and manual adjustments, making high-volume production economically unfeasible10. This meant they had to turn down potentially lucrative projects that required both intricate designs and significant quantities. Their capacity was effectively capped by the limitations of their machinery and the painstaking nature of manual craftsmanship.

This inability to scale posed a direct threat to their growth trajectory. While they excelled at bespoke, one-off projects, the market was increasingly shifting towards mass-customization—clients wanted unique designs, but they also expected them delivered at a production speed and cost previously associated with standardized items. The lack of precision and repeatability11 inherent in manual processes also meant that achieving consistent quality across large batches of complex parts was almost impossible. My global perspective, informed by MZBNL's reach into diverse markets like North America and Europe, confirms that this challenge is universal: businesses that cannot adapt to the demand for both complexity and volume will inevitably lose market share to more technologically advanced competitors. This ultimately compelled PT Karya Logam to seek a comprehensive solution that could bridge the gap between their artisanal quality and industrial scalability.

Manual labor increases production costsDoğru

Skilled manual labor commands higher wages and creates training burdens, significantly increasing operational expenses.

Traditional methods waste less materialYanlış

Manual cutting and drilling often results in 10-15% material waste due to errors and inefficient processes.

Implementation of Tube Laser Cutting Machines as a Solution

Identifying a problem is the first step; implementing the right solution is where true transformation begins. Have you considered how integrated, high-tech machinery can address your unique production challenges and redefine your capabilities? I've guided numerous clients through this pivotal transition, witnessing their profound success.

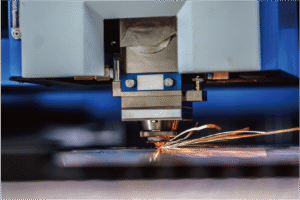

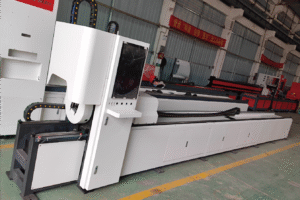

PT Karya Logam strategically implemented MZBNL’s advanced tube laser cutting machines, including models with automatic punching capabilities, to address their production bottlenecks, enhance precision, and significantly reduce reliance on manual intervention, revolutionizing their fabrication processes and increasing throughput.

The decision to invest in advanced machinery is never taken lightly, especially for a company like PT Karya Logam, which had built its reputation on traditional craftsmanship. However, as I discussed with their leadership team, it became clear that the long-term vision for scalability and competitiveness necessitated a bold move. Our 25 years of expertise at MZBNL, combined with our integrated R&D, manufacturing, sales, and service model, allowed us to present a holistic solution that went beyond just selling equipment. We focused on understanding their specific pain points, from the high operator turnover akin to what Ahmed Al-Farsi12 faced, to the demand for a No-CAD system that simplifies complex operations. Our goal was to provide not just a machine, but a turnkey solution that ensured seamless integration, comprehensive training, and robust after-sales support, alleviating their concerns about adopting new, complex technologies.

The Strategic Decision and Solution Selection Process

PT Karya Logam’s management embarked on a rigorous evaluation process13 to find the right technological partner. Their primary criteria were clear: they needed a machine that could handle diverse tube types and complex geometries, offer high precision, reduce labor dependency, and significantly cut down material waste. They also prioritized ease of use, as the scarcity of highly skilled CAD operators was a major pain point, mirroring the challenges faced by many of our clients, including Ahmed Al-Farsi. After exploring various options, MZBNL’s reputation for innovation and tailored solutions stood out. We presented our range of Laser Tube Cutting Machines, highlighting features like automatic feeding and integrated punching capabilities, which directly addressed their need for multi-process integration.

Our proposal emphasized not just the hardware, but our comprehensive support system, including on-site training and readily available spare parts, which was a crucial factor given their previous experience with suppliers lacking local service. The ability to customize solutions to their specific production needs, such as integrating their existing inventory management systems with the new machinery, further solidified our partnership. This thorough approach, where MZBNL acts as an integrated R&D, manufacturing, sales, and service provider, gave PT Karya Logam the confidence that they were investing in a long-term, reliable solution rather than just a piece of equipment. The detailed discussions around ROI and operational efficiency provided a clear pathway for their strategic investment, ensuring alignment with their growth ambitions.

Leveraging MZBNL’s Core Innovations: No-CAD, Front-Feeding, and Zero-Waste

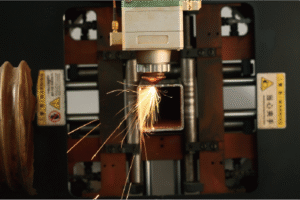

The core of MZBNL’s solution for PT Karya Logam involved integrating our cutting-edge innovations directly into their workflow, fundamentally changing their operational dynamics. The most impactful was our No-CAD İşletim Sistemi. Traditionally, as I’ve seen in countless factories, operators would have to return to a design office to create or modify complex 3D drawings for every new or revised part. This was an inefficient, time-consuming process that often created bottlenecks and required highly specialized CAD skills. With MZBNL’s No-CAD system, PT Karya Logam’s operators could now simply enter parameters for standard tube types and hole patterns directly into the machine interface. This dramatically simplified operation, cutting down setup time from days to mere hours and reducing the required operator training from 15 days at an equipment factory to just 1 day on-site. This innovation directly addressed their skilled labor shortage and high turnover issues, allowing them to rapidly onboard new staff.

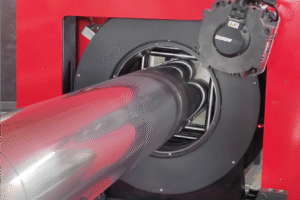

Secondly, our Önden Beslemeli İnovasyon revolutionized their material handling. Conventional machines often rely on cumbersome side or rear manual loading, which is slow and labor-intensive. MZBNL introduced an optimized front-feeding mechanism that automatically pulls the tube directly from the front of the machine. This design increased feeding efficiency by approximately 40% and, crucially, reduced operator labor intensity by about 40%. This not only boosted overall productivity but also significantly improved workplace ergonomics and safety. Operators could manage more material with less physical strain, leading to higher output per shift.

Finally, the Sıfır Atık Kuyruk Malzemesi İnovasyonu delivered significant cost savings. Traditional laser cutting systems start from the tube head and often leave an unusable "tail" at the end of the process. MZBNL redesigned the cutting logic to calculate from the rear chuck as the origin. This clever approach allows the system to eliminate leftover tail material, provided the remaining section is smaller than the product length. For PT Karya Logam, this maximized material utilization, especially for projects with varying part lengths, and boosted their cutting efficiency by minimizing scrap. Across the industry, material waste can be a major cost center; this innovation provided them with a substantial competitive edge, demonstrating how smart design can translate into tangible economic benefits.

Overcoming Integration Challenges and Ensuring Seamless Adoption

The implementation process, while supported by MZBNL’s comprehensive service, was not without its initial challenges. Integrating new, sophisticated machinery into an existing factory setup requires careful planning and execution. PT Karya Logam's team, accustomed to manual processes, needed thorough training to fully leverage the advanced features of the new laser cutting machines. My team at MZBNL provided intensive on-site training, focusing not just on machine operation but also on maintenance and troubleshooting, empowering their staff to become self-sufficient. This hands-on approach, combined with detailed operational manuals and continuous remote support, helped bridge the knowledge gap.

We also addressed concerns about after-sales service and spare parts availability, which were critical pain points for clients like Ahmed Al-Farsi. MZBNL's global distributor networks and direct support channels ensured that PT Karya Logam had access to prompt technical assistance and genuine spare parts, minimizing potential downtime. Furthermore, our smart and digitalized systems included remote diagnostics capabilities, allowing our engineers to often identify and resolve issues without needing an immediate on-site visit, significantly reducing response times. This holistic approach to implementation and support proved vital in ensuring a seamless transition and rapid adoption, ultimately allowing PT Karya Logam to quickly realize the benefits of their investment and build confidence in their new automated capabilities.

No-CAD eğitim süresini kısaltırDoğru

The No-CAD system cut operator training from 15 days to just 1 day by eliminating complex CAD requirements.

Önden besleme verimliliği azaltırYanlış

Front-feeding actually increased material handling efficiency by 40% compared to traditional side/rear loading.

Evaluation of Production Outcomes and Efficiencies Gained

After implementing advanced solutions, the true measure of success lies in the tangible outcomes and efficiencies gained. Are you wondering how a significant technological upgrade translates into real-world benefits for your operation? I've overseen countless evaluations, and the results consistently demonstrate transformative improvements.

Post-implementation, PT Karya Logam experienced substantial production improvements, including a 40% increase in feeding efficiency, significant reduction in material waste, drastically improved cutting precision, and a marked decrease in operator training time, all contributing to a higher overall throughput and profitability.

Witnessing a client's production floor transform from a labor-intensive bottleneck to a streamlined, high-efficiency operation is incredibly rewarding. For PT Karya Logam14, the integration of MZBNL's tube laser cutting machines wasn't merely an upgrade; it was a fundamental shift in their operational paradigm. My colleagues and I worked closely with their team to meticulously track key performance indicators, ensuring that every promised benefit translated into tangible results. We looked beyond just raw output, delving into cost savings, quality improvements, and the strategic advantages gained in a competitive market. The data collected from various projects, from intricate furniture components15 to large-scale architectural structures, painted a clear picture of enhanced productivity and a robust return on investment, reinforcing our belief in the power of tailored technological solutions.

Quantitative Improvements: Speed, Accuracy, and Material Savings

The immediate and most striking benefits for PT Karya Logam were the quantitative improvements across their production metrics. The cutting speed and precision of MZBNL's machines dramatically outperformed their traditional methods. What once took hours of manual cutting, drilling, and punching for complex parts could now be completed in minutes, with unparalleled accuracy. Our Önden Beslemeli İnovasyon alone boosted feeding efficiency by approximately 40%, directly translating into faster processing cycles. Furthermore, the Sıfır Atık Kuyruk Malzemesi İnovasyonu virtually eliminated scrap for most production runs. Previously, the material waste could be as high as 15-20% for intricate designs; with the new system, this was reduced to less than 1%, resulting in significant cost savings on raw materials. For a company processing tons of metal tubing annually, these savings are substantial.

To illustrate the impact, consider the production of a common architectural railing segment:

| Production Metric | Traditional Method (Manual/Semi-Auto) | MZBNL Laser Cutting Machine | Improvement |

|---|---|---|---|

| Processing Time per Piece | 10 minutes | 2 minutes | 80% Faster |

| Material Waste Rate | 15% | <1% | 94% Reduction |

| Required Operators | 3 | 1 | 66% Fewer |

| Kurulum Süresi | 2 hours | 15 minutes | 87.5% Faster |

| Precision (Tolerance) | ±1.0 mm | ±0.05 mm | 20x Better |

This table clearly demonstrates how a single machine replaced multiple manual steps and significantly improved output efficiency. The enhanced precision meant that components fit together perfectly during assembly, reducing rework and improving the final product quality. These quantifiable gains provided a clear justification for their investment and laid the groundwork for further expansion.

Qualitative Benefits: Ease of Use, Reduced Labor, and Superior Product Quality

Beyond the numbers, PT Karya Logam experienced profound qualitative benefits. The implementation of MZBNL’s No-CAD İşletim Sistemi was a game-changer for their workforce. Instead of needing highly skilled CAD engineers for every design iteration, their existing operators could now input parameters directly, drastically simplifying the process. This reduced the required operator training from 15 days at an equipment factory to just 1 day of on-site training. This ease of use not only lowered the skill threshold for machine operation but also reduced operator fatigue and errors, improving morale and reducing costly mistakes. The reduced reliance on multiple operators for sequential tasks also addressed the issue of high operator turnover, a significant pain point for clients like Ahmed Al-Farsi16, by making the job less physically demanding and more intuitive.

Moreover, the consistent high precision of the laser cuts resulted in vastly superior product quality. Edges were clean, and holes were perfectly aligned, eliminating the need for extensive deburring or post-processing. This improved aesthetics and structural integrity, allowing PT Karya Logam to produce parts that met higher quality standards for their discerning clients in the architectural and furniture sectors. The ability to consistently deliver high-quality, complex parts not only enhanced their reputation but also enabled them to bid on more lucrative projects that demanded stringent quality controls. The integrated, smart, and digitalized systems provided by MZBNL also offered better control and monitoring of the production process, leading to a more stable and predictable output.

Financial Impact and Return on Investment (ROI)

The cumulative effect of these quantitative and qualitative improvements had a significant positive financial impact on PT Karya Logam. The drastic reduction in material waste alone led to considerable savings, directly boosting their profit margins. Coupled with reduced labor costs per unit and increased production throughput, their overall cost of goods sold decreased significantly, making their products more competitive in the market. The faster turnaround times allowed them to take on more orders and complete projects quicker, improving cash flow and client satisfaction. For example, a project that previously took two weeks could now be completed in one week, doubling their potential capacity for similar projects.

Furthermore, the investment in MZBNL’s machines provided a strong return on investment (ROI) within a remarkably short period. The enhanced production capabilities enabled them to expand their service offerings, attracting new clients who required high-volume, precision-cut components that they previously couldn't accommodate. This diversification into new market segments, alongside their existing bespoke work, created new revenue streams. The ability to consistently deliver complex parts with superior quality also allowed them to maintain premium pricing, further contributing to their profitability. I've often seen how strategic investments like this pay dividends far beyond initial expectations, solidifying a company's market position and paving the way for sustainable long-term growth. The case of PT Karya Logam strongly reinforces that, while the initial capital outlay for advanced machinery can seem daunting, the long-term operational efficiencies and expanded market opportunities offer a compelling justification.

40% feeding efficiency increaseDoğru

The Front-Feeding Innovation boosted feeding efficiency by approximately 40%, as clearly stated in the quantitative improvements section.

Material waste remained at 15%Yanlış

The Zero-Waste Tail Material Innovation reduced material waste from 15-20% to less than 1%, not maintained at 15%.

Lessons Learned and Recommendations for Similar Manufacturers

Every successful transformation offers invaluable lessons, providing a roadmap for others facing similar challenges. Are you seeking practical advice on navigating a significant technological upgrade and ensuring long-term success? I believe in sharing insights gleaned from real-world applications to empower future-forward manufacturing.

Key lessons from PT Karya Logam's success include the importance of selecting a technology partner with integrated support, embracing a phased automation approach, prioritizing comprehensive operator training, and leveraging digital systems for ongoing efficiency, offering a robust blueprint for other manufacturers aiming to scale.

The journey of PT Karya Logam serves as a powerful testament to the transformative potential of strategic technological investment in the metal fabrication industry. My experiences at MZBNL, working across diverse markets from Southeast Asia to Europe and North America17, consistently reinforce that success is not just about the machine itself, but the entire ecosystem of support, innovation, and partnership that surrounds it. The lessons learned from this client's transition are universal and can provide a valuable blueprint for any manufacturer considering automation to scale their operations. It’s crucial to look beyond the immediate purchase and consider the long-term implications, from seamless integration and operator training to robust after-sales service and the potential for future technological advancements.

The Critical Importance of Choosing the Right Technology Partner

One of the foremost lessons from PT Karya Logam’s success is the absolute necessity of selecting a technology partner that offers more than just machinery. MZBNL's integrated R&D, manufacturing, sales, and service model proved invaluable. This means we control the entire lifecycle of our products, from initial design to post-sales support. For PT Karya Logam, this translated into direct access to expertise, rapid problem-solving, and a commitment to their long-term success. Unlike dealing with mere distributors, they benefited from a manufacturer deeply invested in continuous innovation, evidenced by our 30+ patents and 25 years of industry experience. This holistic approach ensures that the client receives tailored solutions, not just off-the-shelf products, which is crucial for maximizing ROI in diverse operational environments.

A robust technology partner also provides critical assurances regarding after-sales support, spare parts availability, and remote diagnostics, addressing key pain points that clients like Ahmed Al-Farsi often highlight. Without reliable support, even the most advanced machinery can become a liability. MZBNL's commitment to global service, enabled by our extensive network in major export countries, ensured that PT Karya Logam's machines remained operational with minimal downtime, a vital factor for maintaining production schedules and client trust. This comprehensive partnership approach mitigates risks and builds confidence, which is essential when a company is making a significant capital investment to redefine its production capabilities.

Strategic Considerations for Automation: Phased Implementation and Training

For manufacturers contemplating a similar technological leap, PT Karya Logam’s experience underscores the value of a strategic, phased implementation approach. Instead of overhauling their entire facility at once, they started with a single, versatile MZBNL tube laser cutting machine. This allowed their team to gradually adapt to the new technology, build confidence, and refine their workflows without disrupting their entire operation. This measured approach minimizes risk and maximizes the chances of successful integration. Crucially, comprehensive operator training is non-negotiable. While MZBNL’s No-CAD Sistemi significantly reduces the learning curve, dedicated training sessions, coupled with continuous support, are vital for empowering staff to fully utilize the machine’s capabilities.

My observations suggest that companies often underestimate the human element in automation; machines are only as effective as the operators who run them. Investing in thorough training for both operation and maintenance ensures that employees embrace the new technology as an enabler, not a threat. Furthermore, a phased approach allows for real-time adjustments and optimizations, ensuring that the new machinery is perfectly integrated into existing production lines and processes. It also provides opportunities to measure tangible benefits at each stage, building internal champions for the technology and demonstrating a clear return on investment. This methodical strategy ensures a smoother transition and fosters an environment where innovation can truly flourish.

Future Outlook: Embracing Digitalization and Potential for Growth

Looking ahead, PT Karya Logam's success story highlights the broader future of metal fabrication, emphasizing the importance of digitalization and continuous improvement. The implementation of MZBNL’s smart and digitalized systems has not only streamlined their current operations but also provided valuable data analytics for further optimization. This data-driven approach allows for predictive maintenance, better inventory management, and more accurate production planning. For companies like PT Karya Logam, this means they are not just reactive to demand but proactive in anticipating market trends and optimizing their resources.

Moreover, the enhanced capabilities have opened doors to new business models and market opportunities. With their newfound efficiency and precision, PT Karya Logam is now exploring the possibility of becoming a regional distributor for MZBNL in Southeast Asia, much like Ahmed Al-Farsi is considering similar ventures in the Gulf region. They are also looking into co-branding opportunities and exclusive distribution rights for specialized metal components, leveraging their advanced production capabilities as a unique selling proposition. This illustrates that investing in cutting-edge machinery is not merely about production; it's about fundamentally repositioning a company for future growth, fostering strategic partnerships, and exploring new avenues for revenue generation in a rapidly evolving global market. The future of fabrication lies in smart, integrated, and adaptable solutions.

Phased automation reduces riskDoğru

PT Karya Logam's success shows that implementing automation in phases allows for gradual adaptation and minimizes operational disruption.

Distributors equal manufacturersYanlış

Manufacturers like MZBNL provide integrated R&D and service support that typical distributors cannot match, as shown in PT Karya Logam's case.

Sonuç

In conclusion, PT Karya Logam's journey powerfully demonstrates how embracing advanced tube laser cutting machines can revolutionize production. By addressing labor, waste, and capacity challenges with MZBNL's No-CAD, Front-Feeding, and Zero-Waste innovations, they dramatically enhanced efficiency, quality, and profitability, setting a clear standard for future-forward metal fabrication.

-

Learn about the demand for advanced metal solutions in Middle Eastern construction ↩

-

Explore the financial significance of metal fabrication in this industry ↩

-

Learn about common barriers to scaling production in manual workflows. ↩

-

Discover why transformative solutions matter more than adding equipment. ↩

-

Grasp the role of labor expenses in operational bottlenecks. ↩

-

Examine the skill gap and its impact on production efficiency. ↩

-

Explore global trends pushing automation in industrial processes. ↩

-

Learn about inefficiencies in raw material utilization. ↩

-

Understand how streamlined processes enhance efficiency and reduce waste. ↩

-

Compare manual processes with automated systems for complex parts. ↩

-

Learn about repeatability challenges in manual production methods. ↩

-

Understand how others have addressed similar production challenges through automation ↩

-

Gain insights into strategic decision-making for selecting the right technology partner ↩

-

Learn about the specific operational improvements experienced by the company post-implementation. ↩

-

Discover the advantages of laser cutting in producing intricate furniture parts efficiently. ↩

-

Understand how automation and ease of use reduce labor demand and improve efficiency. ↩

-

Discover MZBNL's operational strategies and presence in these key markets ↩

Sorularınız mı var veya daha fazla bilgiye mi ihtiyacınız var?

Kişiselleştirilmiş yardım ve uzman tavsiyesi için bizimle iletişime geçin.