What Is a Metal Tube Cutting Machine? A Beginner’s Guide

Are you curious about the backbone of modern metal fabrication? Metal tube cutting machines are essential tools, transforming raw tubes into precision components. Understanding their operation is key to unlocking efficiency and innovation in countless industries.

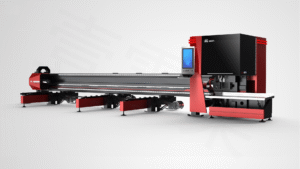

A metal tube cutting machine is a specialized industrial tool designed to precisely cut and shape metal tubes and pipes using various technologies like laser, plasma, or saw. Its primary function is to transform raw material into finished parts for diverse applications, ensuring high accuracy and efficiency in fabrication processes.

In my two decades in the metal fabrication industry, I’ve witnessed firsthand the revolutionary impact these machines have had. From small workshops to large-scale production lines, understanding their fundamental principles is crucial. Let's delve deeper into what makes these machines indispensable and how they contribute to manufacturing excellence.

When I first started MZBNL 25 years ago, the idea of automating complex tube processing seemed a distant dream. Today, we stand as a high-tech enterprise with over 30 patents, serving 4000+ global clients. The journey from manual cutting to advanced laser tube cutting machines1 highlights a profound shift in industrial philosophy, moving from labor-intensive processes to highly automated, precision-driven operations. This evolution isn't merely about technological advancement; it reflects a critical need within the industry to boost productivity, reduce waste, and improve product quality. For instance, in the early 2000s, a metal fabrication business like Ahmed Al-Farsi's in the UAE would grapple with slow, inconsistent manual cuts, leading to significant material waste and rework. Now, with integrated R&D and tailored solutions, modern machines offer unparalleled speed and accuracy, fundamentally reshaping the economic landscape of metal processing worldwide.

What is the primary function of a metal tube cutting machine?

Ever wondered how intricate metal parts for furniture or automotive components are made from simple tubes? The primary function of a metal tube cutting machine is to precisely shape raw metal tubes into specific designs, enhancing production efficiency.

The primary function of a metal tube cutting machine is to accurately and efficiently cut various metal tubes into desired lengths and shapes, including complex contours and holes. These machines are crucial for fabricating components across industries like automotive, construction, and furniture, ensuring high precision and optimizing material use.

For someone like Ahmed Al-Farsi, who runs a mid-sized metal fabrication business in the UAE, the functionality of a tube cutting machine goes beyond mere cutting; it’s about transforming raw materials into high-value finished products. He relies on these machines to deliver contract-based fabrication services for railings, shelving, and auto parts, where precision and efficiency directly impact his profit model. From my experience, a machine's true value lies in its ability to consistently meet diverse client specifications while minimizing operational costs and maximizing throughput. It’s not just about making a cut; it’s about making the right cut, every time, across a wide range of materials and complex designs.

Precision Cutting and Versatility for Diverse Applications

The core purpose of a metal tube cutting machine is to deliver precise, repeatable cuts on various types of metal tubing, allowing for complex geometries and applications. This encompasses not just straight cuts, but also intricate patterns, bevels, and holes, which are crucial for complex assemblies found in modern manufacturing. For instance, in furniture manufacturing, a single tube might require multiple cuts and punched holes for joints that must align perfectly, while in the automotive sector, exhaust pipes or chassis components demand extremely high precision for critical fitment, structural integrity, and safety. The ability to perform these diverse operations with minimal human intervention and maximum speed is what defines the utility and indispensable nature of these machines in today's demanding production environments.

The versatility extends to the types of materials and tube profiles they can handle. Modern machines can process round, square, rectangular, and even custom-shaped tubes made from steel, stainless steel, aluminum, and other alloys. This wide material compatibility ensures that manufacturers like Ahmed Al-Farsi, who deals with architectural metalwork and vehicle parts, are not limited by their machinery but empowered to take on a broader range of projects. The machine's programming flexibility, often powered by advanced CNC systems2, allows for rapid changeovers between different product designs, significantly boosting overall production agility.

This adaptability directly impacts a business's capacity to innovate and compete. For example, if a client requests a new, unusually shaped component for a display rack, a versatile tube cutting machine can quickly prototype and mass-produce it without requiring extensive retooling or manual labor, which would typically be a major bottleneck. A recent industry report indicated that manufacturers utilizing highly versatile tube cutting solutions saw a 15-20% increase in new product introduction rates compared to those relying on more specialized, less flexible equipment, underscoring the strategic advantage these machines provide.

Multi-Process Integration and Efficiency Enhancement

One of the most significant advancements in the primary function of these machines is the integration of multi-process capabilities. Earlier, separate machines were needed for cutting, punching, and notching, creating a fragmented workflow with numerous material handling points. Today, integrated machines, like MZBNL’s Automatic Punching & Cutting Integrated Machine3, can perform multiple operations in one go, from initial cut to final hole punching or slotting, all within a single setup. This consolidation of processes directly addresses pain points for customers like Ahmed, who seeks automated solutions to upgrade his production efficiency and reduce reliance on multiple, potentially less accurate, manual workflows.

By consolidating processes, businesses can drastically reduce handling time, minimize potential errors from material transfer between stations, and free up valuable factory floor space. This not only streamlines production but also contributes to higher overall product quality by minimizing opportunities for human error or material damage during transit. For example, a study by the Metal Fabrication Institute found that integrating punching and cutting operations can lead to a 30-45% reduction in overall processing time for components requiring both functionalities, significantly boosting output per shift and reducing labor costs per unit. This translates directly into a higher cost-performance ratio, a key buying preference for Ahmed.

Furthermore, this integration allows for more sophisticated part designs that would be prohibitively complex or costly with traditional, segmented manufacturing methods. For instance, a single machine can now create intricate interlocking joints or integrated fastening points on tubes, reducing the need for welding or additional assembly steps. This capability enhances design freedom for engineers and allows for the creation of lighter, stronger, and more aesthetically pleasing components, opening up new market opportunities for fabricators in sectors like architectural decoration and furniture.

Material Optimization and Waste Reduction

Beyond just cutting, modern machines offer unparalleled material utilization, which has a direct and substantial impact on operational costs and environmental footprint. My team at MZBNL pioneered the Sıfır Atık Kuyruk Malzemesi İnovasyonu4, directly addressing a critical inefficiency in conventional laser cutting systems. These traditional systems start from the tube head and typically generate unusable tail material at the end of the process, leading to significant scrap and lost revenue.

Our redesigned cutting logic, however, calculates from the rear chuck as the origin. This allows the system to virtually eliminate leftover tail material, as long as the remaining section is smaller than the product length, it can still be used. This innovative approach means that if a customer like Ahmed is cutting dozens of identical components from a long tube, the machine will optimize the cuts to minimize or entirely eliminate the scrap at the very end, ensuring every possible inch of material is converted into a valuable product. This maximizes material utilization and significantly boosts cutting efficiency, directly impacting a company's bottom line.

For a business like Ahmed's, where material costs are a significant overhead, this innovation translates directly into higher profitability and a stronger competitive edge. Industry data indicates that even a 5% reduction in material waste can lead to thousands, if not tens of thousands, of dollars in annual savings for a mid-sized fabricator, depending on their production volume and material value. This demonstrates how a machine's primary function extends beyond mere cutting to encompass economic optimization, sustainable manufacturing practices, and a reduction in the overall environmental impact of production, aligning with broader industry trends towards efficiency and resource conservation.

Modern tube cutters optimize material useDoğru

Advanced machines like MZBNL's use rear-chuck cutting logic to virtually eliminate tail material waste, maximizing utilization.

Tube cutters only make straight cutsYanlış

Modern machines create complex geometries including bevels, holes, and interlocking joints for diverse applications.

How do you prepare a metal tube cutting machine for operation?

Preparing a metal tube cutting machine for operation is crucial for both efficiency and safety. Proper setup ensures optimal performance and prevents costly errors. Let’s explore the essential steps.

Preparing a metal tube cutting machine involves several critical steps: ensuring the machine is clean and calibrated, loading the material correctly, setting up the cutting parameters in the control system, and conducting a final safety check. These preparatory actions ensure precise cuts, safe operation, and efficient production, minimizing errors and maximizing throughput.

From my years in this industry, I’ve seen that the initial setup of any machinery is as vital as the cutting process itself. It’s where precision begins and potential problems are averted. For a hands-on decision-maker like Ahmed Al-Farsi, ease of operation and quick setup are paramount. He previously faced issues with machines requiring skilled CAD operators, leading to retraining burdens due to high operator turnover. This highlights why streamlining the preparation process is so critical. My team at MZBNL recognized this challenge early on, which led us to develop innovations specifically designed to simplify and accelerate machine readiness, allowing businesses to maximize their uptime and productivity without the need for extensive specialized training.

Initial Machine and Workspace Readiness

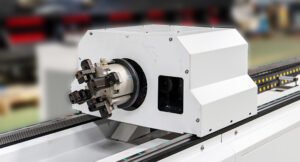

The preparation of a metal tube cutting machine begins long before the first cut is made, starting with a meticulous focus on the machine itself and its immediate surroundings. This involves a systematic approach to ensure that the machine is clean, calibrated, and free from any residual debris from previous operations. Daily or pre-shift cleaning is fundamental: removing metal chips, dust, and slag from the machine bed, chucks, and sensitive components5 like the cutting head and optical lenses (for laser systems). A clean environment is not just about aesthetics; it directly prevents contamination that can degrade cut quality, accelerate wear on sensitive parts, and even lead to system malfunctions or inaccurate sensor readings.

Beyond cleanliness, initial calibration checks are equally essential. Ensuring that the chucks are properly aligned to securely grip the tube and that the cutting head is at the correct focal length contributes directly to the precision and quality of the cut. Any misalignment, even minor, can result in distorted cuts, increased material waste, and premature wear on machine components. These checks are often guided by the machine's control system, which can prompt the operator through a series of automated or semi-automated calibration routines. Investing a few minutes in these initial readiness checks can save hours of troubleshooting and rework down the line, proving to be a critical step in maintaining high-speed and high-precision cutting capabilities.

For a mid-sized business owner like Ahmed Al-Farsi, minimizing unproductive time is crucial for profitability. While these checks might seem minor, their cumulative impact on uptime and product quality is significant. A well-maintained and properly prepared machine reduces the need for constant supervision and manual adjustments, freeing up operators for other tasks and ensuring that production targets are met consistently. This proactive approach to readiness aligns perfectly with the desire for cost-effective, customized solutions that contribute to a seamless production workflow.

Streamlining Programming with No-CAD System Innovation

A revolutionary aspect of machine preparation, particularly relevant for our clients and a key differentiator for MZBNL, is the simplification of the programming setup. Traditionally, the process of preparing cutting paths involved operators returning to the design office to create or modify complex 3D CAD (Computer-Aided Design) drawings before production could start. This was an inherently inefficient, time-consuming, and skill-intensive process, requiring specialized CAD expertise and creating a bottleneck in the workflow. This pain point was frequently articulated by customers like Ahmed, who faced challenges with skilled CAD operator requirements and high operator turnover.

At MZBNL, we pioneered and perfected a No-CAD Operating System for our laser tube cutting machines. With this groundbreaking system, standard tube types and hole patterns can now be processed simply by entering parameters directly into the machine interface; no complex 3D drawing is required. This innovation dramatically improves ease of use, significantly shortens setup time, and lowers the skill threshold for machine operation. For example, while conventional machines6 might require 15 days of intensive training at the equipment factory for an operator to become proficient in programming and setup, our user-friendly No-CAD system means operators now only need one day of on-site training.

This technological leap directly addresses Ahmed's preference for turnkey solutions that are easy to install and operate, and it alleviates the retraining burdens caused by operator turnover. By simplifying the programming step, businesses can achieve faster project turnaround times, reduce labor costs associated with highly skilled CAD designers, and empower a broader range of personnel to operate the machinery effectively. This not only enhances overall productivity by getting jobs started quicker but also democratizes access to advanced manufacturing capabilities, making high-precision cutting more accessible to a wider range of businesses.

Optimized Material Loading and Pre-Production Validation

The final critical stage of preparation involves proper material handling, loading, and a conclusive pre-production validation. While traditional machines relied on cumbersome side or rear manual loading, which was labor-intensive and often inefficient, my team at MZBNL introduced an optimized front-feeding mechanism. This innovative design automatically pulls the tube in from the front of the machine, increasing feeding efficiency by approximately 40% and reducing operator labor intensity by about 40%. This not only speeds up the loading process but also ensures the material is accurately positioned within the machine's chucks and supports, reducing the chances of miscuts, material jams, or damage during the initial feed.

Once the material is loaded, a crucial step involves verifying the correct material type, dimensions, and quantity against the programmed job order. This seemingly simple check prevents costly errors that could arise from using the wrong material or an incorrect tube size. Modern machines often integrate sensors that can confirm material presence and even some basic dimensional parameters, adding an extra layer of assurance. This aligns with Ahmed's need for high accuracy, as incorrect material loading can lead to parts that don't meet specifications, resulting in expensive rework or scrap.

A thorough final check, often involving a dry run or a small test cut, completes the preparation process. This includes verifying power connections, ensuring sufficient assist gas pressure (for laser cutting), checking coolant levels, and confirming that all safety interlocks are engaged7. This comprehensive pre-production validation ensures that the machine is truly ready for safe, efficient, and precise production. It minimizes the risk of unexpected interruptions or quality issues once mass production begins, solidifying the machine’s role as a reliable and cost-effective asset for any metal fabrication business.

Cleanliness affects cut qualityDoğru

Debris on machine components can distort cuts and damage sensitive parts like optical lenses.

CAD skills are essential for MZBNL machinesYanlış

MZBNL's No-CAD system allows parameter entry without 3D drawings, reducing skill requirements.

What are the key safety measures to follow when using a metal tube cutting machine?

Operating powerful industrial machinery demands strict adherence to safety protocols. When using a metal tube cutting machine, prioritizing safety is non-negotiable to protect operators and ensure a hazard-free work environment.

Key safety measures for metal tube cutting machines include wearing appropriate personal protective equipment (PPE), understanding and utilizing machine safety interlocks, ensuring proper ventilation, and maintaining a clear work area. Regular training and adherence to manufacturer guidelines are also crucial for preventing accidents and ensuring operator safety during all operations.

When I first started in metal fabrication, safety was often an afterthought for some, but I quickly learned it must be ingrained in every step. For clients like Ahmed Al-Farsi, safety isn't just about compliance; it's about protecting his 100+ staff and ensuring smooth, uninterrupted operations. High operator turnover and retraining burdens were among his pain points, emphasizing the need for machines that are not only efficient but also inherently safe and easy to train on. At MZBNL, we believe that robust safety features and comprehensive training are as important as cutting precision. It's about empowering operators to work confidently and securely, fostering a culture where well-being is paramount, and production doesn't come at the cost of human safety.

Mandatory Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) is the absolute first line of defense and a non-negotiable requirement when operating any metal tube cutting machine. This critical gear includes specific items designed to shield operators from the inherent hazards of the cutting process. Safety glasses or, more specifically, laser-rated eyewear are paramount for laser cutting machines, providing protection against the intense light and stray reflections at specific wavelengths. Without proper eye protection, operators face severe risks, including permanent vision damage from sparks, metal debris, or direct exposure to the laser beam8. Similarly, hearing protection, such as earplugs or earmuffs, is vital to mitigate the high noise levels generated by cutting operations, which can lead to long-term hearing impairment if not addressed.

Gloves and sturdy work boots are equally essential components of PPE. The handling of metal tubes, especially after cutting, often presents sharp edges, burrs, and potential pinch points, necessitating robust gloves to protect hands from cuts, abrasions, and crushing injuries. Steel-toed boots provide crucial protection against falling objects, such as heavy metal tubes, and prevent foot injuries from accidental impacts or punctures. Consistent enforcement of PPE usage is not just a regulatory compliance matter; it is a foundational aspect of a robust workplace safety culture. Regular checks to ensure all operators are wearing the correct and properly fitted PPE should be part of the daily operational routine, reinforcing the message that safety is a shared responsibility and a top priority.

For a business like Ahmed Al-Farsi’s, which has over 100 staff, strict adherence to PPE protocols directly translates into fewer workplace injuries, reduced absenteeism, and lower workers' compensation claims. A safe workforce is a productive workforce, and minimizing incidents related to inadequate protection helps maintain operational continuity and morale. My experience has shown that when employees feel truly protected, they work more confidently and efficiently, enhancing overall productivity and contributing positively to the company's reputation for employee care.

Integrated Machine Safeguards and Emergency Protocols

Modern metal tube cutting machines are engineered with sophisticated safety safeguards and emergency procedures built directly into their design, providing multiple layers of protection. Enclosed cutting areas, often with interlocked doors or light curtains, are standard features that prevent the machine from operating if a guard is open or if an operator accidentally enters a hazardous zone during operation. For instance, MZBNL machines are equipped with comprehensive safety interlocks9 that immediately halt all machine movement and cutting processes if any protective barrier is breached or if an unauthorized entry into the cutting envelope is detected. This automatic shutdown capability minimizes accidental exposure to the high-power laser beam or moving components.

Strategically placed emergency stop buttons are another critical safety feature, providing operators with an immediate and accessible means to shut down the entire equipment in case of any unforeseen hazard, malfunction, or critical error. These "E-stop" buttons are highly visible and designed for quick activation, ensuring a rapid response to any dangerous situation. Regular testing of these safety features, often as part of a daily or weekly pre-operation checklist, is crucial to ensure their reliability and functionality when needed most. This proactive validation confirms that the machine’s safety systems are always in optimal working order, providing confidence to operators and management alike.

Furthermore, clear lockout/tagout procedures are indispensable during maintenance, cleaning, or repair activities. These procedures ensure that the machine is completely de-energized and cannot be accidentally restarted while personnel are working on it, preventing serious injuries or fatalities. Training on these protocols should be thorough and mandatory for all maintenance staff and operators involved in setup or troubleshooting, ensuring a disciplined approach to machine safety beyond just regular operation.

| Safety Measure | Amaç | Implementation Example (MZBNL) | Impact on Operator/Business |

|---|---|---|---|

| PPE Enforcement | Protects operators from immediate hazards. | Mandatory laser goggles, ear protection, safety gloves. | Reduces injury rates, ensures workforce health. |

| Machine Interlocks | Prevents operation under unsafe conditions. | Enclosed cutting area with door sensors; emergency stops. | Minimizes accidental exposure to cutting zone. |

| Ventilation Systems | Removes fumes, smoke, and fine particles. | Integrated fume extraction connected to filtration unit. | Improves air quality, protects respiratory health. |

| Operatör Eğitimi | Ensures proper understanding of machine and safety. | 1-day on-site training for No-CAD system, detailed manuals. | Reduces errors, boosts confidence, lowers retraining burden. |

Cultivating a Safe Work Environment and Continuous Training

Beyond physical safeguards, maintaining a consistently safe working environment and providing continuous, effective training are crucial for long-term safety and operational excellence. The area around the metal tube cutting machine should be kept meticulously clean, well-lit, and free of clutter to prevent slips, trips, and falls, which are common industrial accidents. Clear pathways for material handling and emergency egress must always be maintained, ensuring operators can move freely and safely, especially during busy production periods. Proper ventilation systems are also necessary to extract fumes, dust, and particulate matter generated during the cutting process. These airborne contaminants, if inhaled over prolonged periods, can lead to serious respiratory issues. High-quality fume extraction systems, often integrated directly into the machine, are essential for protecting operators from these health hazards and complying with air quality regulations.

Continuous operator training is perhaps the most dynamic and crucial safety measure. Even with the most advanced, user-friendly machines, regular refreshers on operating procedures, safety protocols, and emergency responses are vital. For companies like MZBNL, which offer advanced systems like the No-CAD Operating System, comprehensive training is integrated into the product offering. Instead of requiring 15 days of intensive training at the equipment factory to master complex CAD interfaces, our user-friendly design means operators only need 1 day of focused on-site training. This directly addresses Ahmed Al-Farsi’s pain point regarding high operator turnover and retraining burdens, ensuring that new staff can quickly and safely become proficient, thereby significantly reducing the likelihood of accidents related to inexperience or improper machine handling.

Furthermore, fostering a culture of safety where employees are encouraged to report near misses, suggest safety improvements, and actively participate in safety discussions empowers them to be proactive guardians of their own and their colleagues' well-being. This collective responsibility, coupled with robust technical support and readily available spare parts, ensures that any potential safety issues or machine malfunctions can be addressed swiftly and effectively, keeping the production line moving safely and efficiently.

PPE prevents laser eye damageDoğru

Laser-rated eyewear is essential to protect operators from permanent vision damage caused by direct beam exposure or reflections.

Machine interlocks are optionalYanlış

Safety interlocks are mandatory built-in features that automatically halt operation when protective barriers are breached.

How does the cutting process work in a metal tube cutting machine?

At the heart of a metal tube cutting machine lies a sophisticated process that transforms raw material into precision parts. Understanding this cutting process reveals the intricate dance of technology and engineering.

The cutting process in a metal tube cutting machine typically involves loading the tube into a chuck system, followed by precise laser beam or cutting tool delivery guided by CNC programming. The machine then moves along the tube's axis, accurately slicing and shaping the material according to digital designs, often integrating advanced features for speed and material optimization.

For a fabrication business owner like Ahmed Al-Farsi, the efficiency and precision of the cutting process are not just technical specifications; they are direct drivers of his profit model. He delivers finished parts to builders, decorators, and OEMs, meaning the quality and speed of his output are paramount. When I discuss our machines, I always emphasize how the cutting process itself has evolved. It’s no longer just about making a cut, but about optimizing every nanosecond of operation, from the moment the material is loaded to the final part being ejected. My team at MZBNL has spent 25 years perfecting this, ensuring our machines offer high-speed, high-precision, and multi-process integration. This dedication translates into tangible benefits for our clients, ensuring they can meet tight deadlines and maintain competitive pricing in demanding markets like the UAE.

CNC-Driven Laser Beam Mechanics

The actual cutting process in a modern metal tube cutting machine, particularly a laser tube cutting machine, is a highly orchestrated sequence of events primarily driven by sophisticated Computer Numerical Control (CNC) systems. Once the metal tube is securely loaded into the machine’s chucks—often leveraging MZBNL's optimized front-feeding mechanism, which increases feeding efficiency by about 40%—the CNC program takes over. This program, which for our machines can be generated simply by entering parameters thanks to our No-CAD system, translates the digital design into incredibly precise machine movements. The process begins with the generation of a high-power laser beam from a resonator, typically a fiber laser for modern tube cutters due to its efficiency and beam quality.

This powerful beam is then meticulously directed through a series of mirrors and lenses, focusing it to an incredibly small spot, sometimes as fine as a human hair, at the surface of the metal tube. The intense energy density at this focal point rapidly melts, vaporizes, or burns through the material, creating a very narrow and precise cut kerf. To enhance cut quality and remove molten material, an assist gas—such as oxygen for ferrous metals (which promotes an exothermic reaction for faster cutting) or high-purity nitrogen for stainless steel and aluminum (to prevent oxidation and ensure a clean, dross-free edge)—is simultaneously delivered coaxially with the laser beam. This gas blows away the molten material and also serves to protect the sensitive focusing lens from debris and spatter, ensuring consistent beam quality throughout the cutting operation.

The efficiency of this process is truly remarkable. Modern fiber laser tube cutting machines can achieve cutting speeds that are several times faster than traditional methods, with power levels reaching up to 12kW or more for thicker materials. This high speed, combined with the non-contact nature of laser cutting, minimizes material distortion and heat-affected zones, resulting in parts that require less post-processing. For a busy fabricator like Ahmed Al-Farsi, this means faster production cycles, higher throughput, and ultimately, greater profitability per project.

Advanced Motion Control for Complex Geometries

The precision and versatility of modern metal tube cutting machines stem from their advanced motion control systems. Sophisticated servo motors and high-precision linear guides enable the cutting head and the tube rotation to move simultaneously and with extreme accuracy along multiple axes. This synchronized multi-axis movement is what allows the machine to cut not only straight lines but also intricate contours, precise holes, slots, and even complex 3D shapes on the tube surface. For example, when creating parts for automotive frames, bicycle components, or complex display racks, consistent hole alignment, precise miter cuts, and accurate angle cuts are absolutely critical for subsequent welding, assembly, and structural integrity.

The CNC system continuously monitors and adjusts various cutting parameters in real-time, such as laser power, cutting speed, and focal position, to adapt to variations in material thickness, type, or even slight imperfections in the tube's straightness. This dynamic adjustment ensures consistent cut quality and accuracy throughout the entire length of the tube, even for very long workpieces. The ability to perform complex cuts without manual intervention reduces the potential for human error and ensures repeatable results, which is a major advantage for mass production and for maintaining high standards in industries like medical equipment and fitness equipment manufacturing, where precision is paramount.

This level of motion control also enables features like automatic edge detection and compensation, where the machine can detect the exact position and orientation of the tube and adjust the cutting path accordingly. This minimizes setup time and further enhances material utilization by ensuring cuts are made precisely where intended, even on slightly irregular tubes. For Ahmed’s business, where projects often involve a variety of tube shapes and sizes, this advanced capability ensures that his team can deliver high-quality finished parts to demanding clients like builders and OEMs, enhancing his reputation and securing long-term contracts.

Zero-Waste Material Optimization

A significant innovation that directly impacts profitability and sustainability in the cutting process is the optimization of material utilization, specifically addressing the issue of tail material waste. Conventional laser cutting systems typically operate by starting the cut from the tube head and often generate unusable tail material at the very end of the process, which is essentially scrap. This leftover material, though sometimes small in length, accumulates significantly over high-volume production, leading to considerable material waste and increased operational costs.

My team at MZBNL recognized this inefficiency and redesigned the cutting logic to calculate from the rear chuck as the origin. This groundbreaking Zero-Waste Tail Material Innovation allows the system to eliminate leftover tail material, as long as the remaining section is smaller than the required product length, it can be fully utilized. This means that instead of discarding a short remnant, the machine intelligently incorporates it into the production plan, maximizing material utilization and boosting cutting efficiency. This optimization is not just theoretical; it translates into tangible savings, as material costs are a major component of manufacturing expenses.

This advanced approach means that if Ahmed is cutting dozens of identical components from a long tube, the machine will optimize the cuts to minimize or entirely eliminate the scrap at the very end, offering substantial cost savings over time. Industry analysis indicates that implementing such zero-waste strategies can reduce material consumption by up to 10-15% compared to traditional methods, directly enhancing the cost-performance ratio that Ahmed values. This innovation also aligns with broader industry trends towards more sustainable manufacturing practices, reducing the environmental footprint of production while simultaneously improving economic outcomes for businesses.

CNC controls laser cuttingDoğru

CNC systems precisely guide the laser beam's movement and power during tube cutting operations.

Oxygen is used for all metalsYanlış

Nitrogen is preferred for stainless steel and aluminum to prevent oxidation, while oxygen is used for ferrous metals.

What are the maintenance steps for ensuring the longevity of a metal tube cutting machine?

Just like any high-performance asset, a metal tube cutting machine thrives on consistent maintenance. Proper care isn't just about avoiding breakdowns; it's about maximizing uptime and extending its operational lifespan, ensuring peak performance.

Ensuring the longevity of a metal tube cutting machine requires routine cleaning and regular inspection of critical components, timely replacement of wear parts, and consistent software updates. Adhering to manufacturer-recommended maintenance schedules, addressing issues promptly, and lubricating moving parts are also essential for maximizing operational efficiency and lifespan.

From my vantage point, spanning over two decades in this industry, I’ve seen that even the most advanced machinery is only as good as the care it receives. For a client like Ahmed Al-Farsi, who values high cost-performance ratio and expects robust post-sales training and support, maintenance isn't merely a chore—it’s an investment. He needs his machines to be consistently reliable, with spare parts availability and remote diagnostics being key sourcing points. My commitment at MZBNL is to provide solutions that are not just easy to operate but also easy to maintain, ensuring sustained peak performance and minimizing downtime. We understand that a machine sitting idle due to neglected maintenance is a lost opportunity for profit, and we prioritize support to keep our clients' operations running smoothly.

Proactive Cleaning and Regular Visual Inspections

Routine cleaning and meticulous visual inspections form the bedrock of any effective maintenance program for metal tube cutting machines. This daily or weekly regimen is crucial for preventing the accumulation of dust, metal chips, slag, and other debris that can significantly impact machine performance and longevity. Operators must meticulously clean the machine bed, the chucks, and critically, the cutting head and any optical components (for laser cutters). A clean environment prevents contamination, which can degrade cut quality, accelerate wear on sensitive parts, and lead to inaccurate sensor readings. For laser machines, particular attention must be paid to the protective windows and focusing lenses, as even minor smudges, dust particles, or spatter can drastically reduce laser power transmission and beam focus, directly affecting cut precision and speed.

Beyond just cleaning, regular visual inspections should be diligently performed to identify any early signs of wear, such as loose bolts, frayed cables, unusual vibrations, or excessive play in moving parts. Checking for lubrication leaks or unusual noises can also indicate impending issues. Documenting these inspections, no matter how minor the findings, helps in tracking potential issues before they escalate into major problems, allowing for proactive intervention rather than reactive repairs. This systematic approach ensures that the machine is always operating within its optimal parameters, minimizing the risk of unexpected breakdowns that could halt production and incur significant costs.

For a business like Ahmed Al-Farsi’s, where continuity of operation is crucial for meeting delivery deadlines and maintaining client satisfaction, these proactive steps are invaluable. A well-maintained machine runs more reliably, consistently producing high-quality parts and reducing the need for costly unscheduled maintenance. Our philosophy at MZBNL emphasizes that prevention is always better than cure, and empowering operators with clear cleaning and inspection protocols10 directly contributes to the overall efficiency and profitability of our clients.

Strategic Component Replacement and Consumable Management

Component longevity and the timely replacement of wear parts are absolutely critical for avoiding unexpected breakdowns, maintaining consistent cut quality, and ensuring the long-term health of a metal tube cutting machine. Consumable parts like nozzles, protective lenses, and ceramic rings in a laser cutting head have a finite operational lifespan. They must be replaced not just when they fail, but according to the manufacturer’s recommendations or when early signs of degradation become evident through cut quality issues or diagnostic alerts. Failing to replace these small, relatively inexpensive parts proactively can lead to secondary, more severe damage to more expensive components, like the laser resonator itself, resulting in significantly higher repair costs and extended downtime.

The cutting chucks, which securely grip and rotate the tube during the cutting process, also experience wear over time due to friction and the repeated clamping forces. These must be regularly inspected for damage, misalignment, or excessive wear that could compromise material stability during cutting, leading to inaccurate cuts or tube slippage. Lubrication of all moving parts, including linear guides, bearings, and gears11, is another vital step that reduces friction, prevents premature wear, and ensures smooth, precise machine movements. Using the correct type and amount of lubricant, as specified by the manufacturer, is paramount, as incorrect lubrication can be as detrimental as no lubrication.

For Ahmed, who explicitly prioritizes spare parts availability and a high cost-performance ratio, having a reliable supplier like MZBNL with a robust global distributor network and readily accessible inventory ensures minimal downtime when replacements are needed. Proactive replacement of these components, rather than waiting for them to fail, prevents cascade failures and maintains the machine’s inherent precision and efficiency. It’s akin to regularly changing the oil and filters in your car; a small, consistent investment for a significant benefit in extending the vehicle’s life, optimizing fuel efficiency, and preventing costly engine repairs.

Leveraging Digital Diagnostics and Expert Support

In the era of smart manufacturing, embracing digitalized systems and leveraging expert after-sales support significantly enhances machine longevity, efficiency, and overall operational resilience. Modern metal tube cutting machines, including those from MZBNL, are increasingly equipped with advanced diagnostics and remote monitoring capabilities. These intelligent systems can continuously track machine performance data, analyze operational metrics, identify potential issues through sensor readings, and even alert operators or service technicians to impending problems before they lead to critical failures. This predictive maintenance approach allows for scheduled interventions rather than disruptive emergency repairs, minimizing production downtime and associated costs.

Regular software updates are also crucial for maintaining optimal machine performance and longevity. These updates often include performance enhancements, bug fixes, security patches, and even new features that optimize machine operation, improve cutting algorithms, or enhance user interface functionality. Ensuring the machine’s control system is running the latest software can prevent unexpected glitches and ensure compatibility with evolving manufacturing standards and design software. This ongoing digital upkeep is as important as the physical maintenance for a high-tech machine.

For customers like Ahmed, who specifically seeks strong after-sales service, training support, and remote diagnostics, MZBNL's commitment to supporting its global enterprise clients ensures that technical assistance, troubleshooting, and even remote training can be provided promptly. This global support network, combined with our 25 years of experience and 30+ patents, means that any issues are resolved swiftly, minimizing the impact of potential long machine lead times or lack of local service support that might have affected his project delivery in the past. This holistic approach to maintenance, combining diligent physical care with advanced digital foresight and responsive expert support, ensures the machine remains a high-performing and reliable asset for years to come, solidifying its return on investment.

Cleaning prevents contaminationDoğru

Regular cleaning of metal chips and debris prevents contamination that degrades cut quality and accelerates wear.

Lubrication is optionalYanlış

Proper lubrication of moving parts is essential to reduce friction and prevent premature wear, not optional.

Sonuç

A metal tube cutting machine is vital for precise fabrication, transforming raw tubes into components. Proper setup, strict safety measures, understanding the cutting process, and diligent maintenance are key to maximizing efficiency and longevity. Investing in modern, user-friendly machines like MZBNL's ensures high-quality output and sustained profitability.

-

Discover the industrial impact of modern laser tube cutting advancements ↩

-

Explore CNC systems' role in boosting manufacturing automation and flexibility ↩

-

Understand the efficiency and cost advantages of integrated metalworking machines ↩

-

Discover how zero-waste innovations significantly reduce material costs ↩

-

Ensure machine cleanliness to prevent contamination and maintain cut quality ↩

-

Understand training needs for operating traditional vs. modern machines ↩

-

Ensure safety by understanding interlocks and their importance ↩

-

Learn about the importance of protecting eyes from potential hazards in laser cutting. ↩

-

Discover how safety interlocks prevent accidents and safeguard operators in industrial settings. ↩

-

Discover how systematic protocols enhance machine efficiency and minimize unexpected downtime. ↩

-

Find out about lubrication techniques and their critical role in reducing wear and improving precision. ↩

Sorularınız mı var veya daha fazla bilgiye mi ihtiyacınız var?

Kişiselleştirilmiş yardım ve uzman tavsiyesi için bizimle iletişime geçin.