Bir Metal Boru Kesme Makinesinin Kurulumu Ne Kadar Sürer?

Investing in a new metal tube cutting machine can feel like a monumental undertaking, often conjuring images of prolonged installation times and complex setups. The thought of weeks of installation and training can delay your production goals, causing unnecessary stress. But what if I told you the process could be streamlined significantly with the right technology and expert support?

Setting up a metal tube cutting machine typically involves initial preparations, physical installation, precise calibration, and operator training. While traditional setups could take weeks, advancements in user-friendly interfaces and automation have drastically reduced this timeframe, often enabling full operation within days to a week with proper planning and expert assistance.

From the moment a new machine arrives, every business owner, including myself, looks for efficiency. The key isn't just getting the machine running, but getting it running optimally, fast. I’ve seen firsthand how a smooth setup process1 can be a game-changer for production schedules and return on investment. Let's delve into the crucial stages that dictate the overall setup duration and how we at MZBNL ensure a swift transition from delivery to dazzling productivity.

The perception of lengthy industrial machine setups often stems from legacy systems requiring extensive manual configuration and highly specialized expertise. However, this perspective overlooks the significant advancements in modern machinery design and support infrastructure. For instance, consider the critical balance between speed and precision: a rushed setup might lead to immediate operation but compromise long-term cutting accuracy, increasing material waste and rework. Conversely, an overly meticulous, slow setup delays production, impacting project timelines and profitability. My experience over 25 years in metal fabrication, serving over 4000 global clients2, confirms that the true efficiency of a machine begins with its installation. Our team at MZBNL has continuously refined our processes, integrating smart digitalized systems and providing comprehensive training, drastically reducing the time and skill threshold needed for setup, challenging the old norms of what's possible in the metal processing industry.

What are the initial preparations required before setting up the machine?

You've invested in a cutting-edge tube cutting machine, but are you truly ready for its arrival? Overlooking pre-installation steps can lead to frustrating delays and unexpected costs. Ensuring your facility is properly prepared is the first critical step toward a swift and seamless setup.

Initial preparations for a metal tube cutting machine include site assessment, ensuring adequate space, power supply, and ventilation, as well as preparing the foundation. This pre-planning phase is crucial to prevent installation delays, involving checking utility connections, material handling logistics, and safety protocols before the machine physically arrives on site.

Just as an architect meticulously plans a building before any groundwork begins, the successful setup of a metal tube cutting machine hinges on thorough preparation. My team and I always emphasize this phase, as it directly impacts the efficiency and safety of the subsequent steps. I've witnessed countless times how a well-prepared site can shave days, even weeks, off the overall installation timeline, avoiding frustrating bottlenecks. For instance, a client like Ahmed Al-Farsi, the owner of a mid-sized metal fabrication business in the UAE, who values turnkey solutions and efficiency, would appreciate knowing that every aspect, from the exact dimensions of the machine's footprint to the specific power requirements, is carefully considered upfront. This meticulous approach ensures that when our BNL laser tube cutting machine arrives, it slides into place as smoothly as one of our perfectly cut tubes. We aim to anticipate and mitigate any potential issues, allowing you to focus on the immediate benefits of enhanced productivity rather than unforeseen logistical challenges.

Site Assessment and Infrastructure Readiness

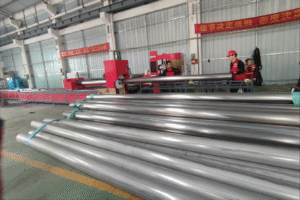

A comprehensive site survey is the bedrock of a smooth installation. This involves meticulously assessing the available space, considering not just the machine's physical footprint but also the necessary clearance for material loading, unloading, maintenance access, and operator movement. Neglecting these spatial requirements can lead to cramped workflows or, worse, safety hazards. Our team works closely with clients to review their factory layouts, often identifying areas for optimization before the machine even ships. Ensuring ample space for future expansions or additional automation components is also a forward-thinking consideration that we guide clients through, preparing them for long-term growth.

Power supply is another critical component. Modern laser tube cutting machines require specific voltage, amperage, and often dedicated circuits to ensure stable operation and prevent electrical overloads. Beyond electricity, considerations for air supply (for pneumatic components) and efficient ventilation/fume extraction systems are paramount for both machine performance and operator health. For example, a typical 6-meter laser tube cutting machine might require a footprint of 12m x 5m and a power supply of 380V/50Hz with a minimum 80A dedicated circuit, highlighting the specialized infrastructure needed. The quality of the power supply—its stability and freedom from fluctuations—is as important as its capacity, impacting the longevity of sensitive electronic components.

Finally, the foundation and flooring must be robust enough to support the machine's weight and absorb vibrations during operation, which is crucial for maintaining cutting precision. A stable, level foundation prevents subtle shifts that could compromise accuracy over time. Neglecting foundation stability can lead to cutting inaccuracies of up to 0.5mm, impacting the quality of finished parts and increasing material waste. We provide detailed guidelines to ensure your facility's floor can optimally support our high-precision equipment, often recommending specific concrete strengths or reinforcement if needed, based on our extensive experience across various industrial environments.

Material Handling and Workflow Optimization

Efficient material flow around the machine is as important as the machine itself. This includes planning for the easy input of raw tube bundles, smooth processing, and orderly output of finished parts and scrap. The layout of the facility around the machine must facilitate these movements without creating bottlenecks or requiring excessive manual labor. For instance, MZBNL’s innovative front-feeding mechanism significantly reduces manual handling, but adequate space is still needed for loading large tube bundles and for the automatic discharge of cut components. This optimized flow can reduce loading and unloading times by up to 30%, directly contributing to higher overall equipment effectiveness (OEE).

Safety protocols are also integrated into this planning. Clear pathways, designated operator zones, and easy access to emergency stops must be established. Our machines come with integrated safety features, such as enclosed cutting areas and interlocks, which complement the overall factory safety plan. This proactive approach minimizes risks and ensures a secure working environment, reducing potential downtime due to accidents and enhancing worker confidence.

Ahmed's existing manual workflows highlight the need for optimized material handling. By strategically positioning our automatic front-feeding machine, his team could observe a 40% reduction in labor intensity during loading. This directly correlates with improved floor space utilization and safer operations, as seen in a similar client facility where loading time per tube was cut from 5 minutes to 3, demonstrating tangible efficiency gains and reflecting a direct improvement in their profit model through reduced labor costs.

Pre-installation Checklist and Vendor Collaboration

A detailed pre-installation checklist provided by the supplier is invaluable. This document outlines everything from utility requirements to environmental conditions. It's a living document that requires close collaboration between the client and the vendor to ensure all prerequisites are met, including local permits and zoning regulations. Failing to secure necessary permits can lead to severe delays and potential fines, emphasizing the importance of this administrative due diligence.

Vendor collaboration extends beyond just providing a checklist; it involves proactive communication and remote consultations. My team at MZBNL provides comprehensive guides and is always available to discuss specific site challenges, helping clients anticipate and resolve issues long before the machine arrives. This collaborative approach prevents last-minute surprises and streamlines the installation process significantly, a key aspect that sets reliable suppliers apart in the global market. For Ahmed, who prefers suppliers with proven technology and global references, this level of support is crucial.

Finally, software and networking considerations must be addressed. Is your factory network ready for smart machine integration? Modern machines, like ours, benefit from data transfer capabilities for remote diagnostics and production monitoring. Ensuring your IT infrastructure is prepared means you can fully leverage the machine's smart and digitalized systems from day one, contributing to seamless operation and support. This integration allows for predictive maintenance, real-time performance tracking, and remote troubleshooting, effectively reducing reliance on immediate on-site technical support and minimizing potential downtime.

| Pre-installation Item | Impact on Setup Time (Days) | Risk of Delay if Neglected | Mitigation by MZBNL |

|---|---|---|---|

| Adequate Power Supply | 1-3 | Yüksek | Detailed electrical schematics |

| Level Foundation | 2-5 | Yüksek | Site assessment guidelines |

| Material Handling Space | 0.5-1 | Orta | Workflow consultation |

| Network Connectivity | 0.5-1 | Orta | IT requirements provided |

Modern setups take days not weeksDoğru

Advancements in user-friendly interfaces and automation have reduced setup times from weeks to days with proper planning.

Foundation stability affects cutting accuracyDoğru

An unstable foundation can cause cutting inaccuracies up to 0.5mm due to machine vibration and shifting.

How do you position and install the metal tube cutting machine?

The sheer size and precision requirements of a metal tube cutting machine can make its physical installation seem like a monumental task. Improper positioning can lead to costly reworks, misalignment, and compromised performance. With careful planning and expert execution, the installation process can be remarkably swift and accurate.

Positioning and installing a metal tube cutting machine involves precise placement using heavy lifting equipment, meticulous leveling, and securely anchoring the machine to its foundation using specialized rigging techniques. This critical phase ensures the machine's stability and accuracy, typically requiring specialized rigging teams and precise measurements to align all components correctly.

Once the preliminary checks are complete and the facility is prepared, the actual physical installation of the metal tube cutting machine begins. This is a moment of anticipation, where the planning translates into tangible progress. I’ve personally supervised countless installations, and each time, the sheer scale of these machines underscores the importance of precision. It’s not simply about moving a large piece of equipment; it's about aligning sophisticated components to micron-level accuracy. Consider Ahmed's desire for turnkey solutions and high precision: he needs a machine that performs flawlessly from day one for his architectural metalwork and vehicle components. This stage involves heavy lifting, but more importantly, it requires the expertise to ensure every segment, from the automatic front-feeding system to the cutting head and unloading mechanism, integrates seamlessly. Our specialized installation teams, with their years of experience and adherence to stringent protocols, ensure that the machine is not just placed, but perfectly seated for optimal performance, minimizing any potential for misalignment issues that could compromise cutting quality or operational efficiency down the line. This meticulous approach is how we deliver on our promise of high-speed, high-precision cutting.

Precision Placement and Leveling

The physical placement of a large industrial machine like a laser tube cutter demands the use of heavy machinery such as forklifts or cranes. This operation is best handled by professional rigging teams who understand the weight distribution, lifting points, and safe maneuvering techniques to prevent damage to the machine or the facility. Accurate placement according to the pre-determined layout ensures optimal workflow and accessibility, minimizing future bottlenecks in material flow or maintenance access. Without this precise initial placement, even the most advanced machine might struggle to reach its full potential, leading to inefficient operations and increased operational costs over time.

Crucially, the machine must be leveled with extreme precision. Even a slight inclination can lead to significant cutting errors over the long length of tubes, resulting in non-perpendicular cuts or dimensional inaccuracies. Our installation teams utilize high-precision laser levels and shims3 to achieve leveling accuracy within ±0.02mm per meter. To illustrate, even a 0.1-degree tilt over a 6-meter machine length can result in a material deviation of 10.5mm at the furthest point, drastically impacting precision and rendering parts unusable for applications like automotive components or intricate furniture joints. This level of precision is paramount for our clients, such as those in the automotive industry, where tolerances are exceptionally tight.

Once perfectly level, the machine is securely anchored to its foundation using specialized bolts and, often, vibration-dampening pads. This step is vital to ensure the machine remains stable during high-speed operation, preventing any movement that could introduce inaccuracies or premature wear on critical components. Our machine designs incorporate robust bases engineered for maximum stability, complementing the secure anchoring process by distributing the machine's considerable weight evenly, thereby reducing stress on the foundation itself. This attention to detail in anchoring not only preserves cutting accuracy but also extends the operational lifespan of the equipment, providing a greater return on investment.

Component Assembly and Interconnection

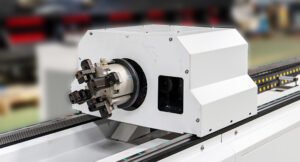

Modern laser tube cutting machines are often modular, allowing for easier transport and assembly on site. This phase involves connecting the main machine body, the automatic loading and unloading systems, the control cabinet, the dust collector, and the chiller. Each component must be correctly aligned and securely fastened, ensuring that optical paths are clear, and mechanical movements are unhindered. This modular approach significantly reduces the time required for on-site assembly compared to fully integrated, monolithic designs, and it also simplifies future maintenance or upgrades.

Electrical connections are particularly critical, involving high-voltage power lines for the laser source and motors, as well as low-voltage lines for control signals and safety interlocks. Adherence to local electrical codes and international safety standards is paramount to prevent electrical hazards and ensure reliable operation. MZBNL machines are largely pre-wired with clearly labeled connections, simplifying on-site electrical hookups and reducing installation time by an estimated 20-30% compared to systems requiring extensive on-site wiring. Pneumatic lines for air supply to the cutting head and water lines for the laser chiller also require secure, leak-free connections to ensure consistent performance and cooling efficiency, which directly impacts laser life and cut quality.

For Ahmed's factory, with its focus on automating existing manual workflows, the multi-process integration of our machine is key. Our installation specialists efficiently connect not only the cutting components but also the automatic front-feeding and optional punching units, ensuring synchronized operation. This integrated approach, based on over 25 years of experience, minimizes the complexity often found in piecemeal system installations, cutting assembly time by roughly 30% compared to traditional multi-vendor setups. This holistic installation process ensures all functionalities, from high-speed cutting to smart digitalization, are immediately available, enabling Ahmed to quickly transition from manual processes to automated, high-volume production.

Safety Protocols and Initial Power-Up

Before any power is supplied, a comprehensive series of safety checks is performed. This includes verifying that all emergency stop buttons are accessible and functional, that safety interlocks on access doors and protective covers are correctly engaged, and that all guarding is properly installed. These preliminary safety measures are non-negotiable and prioritize operator well-being above all else, ensuring compliance with international safety regulations such as CE standards. Neglecting these checks could lead to severe workplace accidents and significant legal repercussions.

The initial power-up is a methodical process. It involves progressively energizing different sections of the machine while monitoring for any anomalies, such as unusual noises, smoke, or error messages. Basic function tests are performed to confirm that motors respond correctly, fans rotate, and emergency stops instantly cut power. This step ensures the machine's electrical and mechanical systems are in harmony, verifying the integrity of all connections and internal components before full operation is attempted. This phased approach minimizes the risk of damage to expensive components during the first activation.

Throughout the installation, environmental considerations are also important. Efforts are made to control dust and minimize noise, contributing to a more comfortable and safer working environment for the installation team and factory personnel. This attention to detail underscores our commitment to providing a machine that is not just efficient, but also safe to operate, aligning with Ahmed’s interest in reliable support and a safe workplace. Our installation protocols are designed to minimize disruption to existing factory operations, allowing clients to maintain productivity as much as possible during the setup period.

| Installation Phase Check Point | Açıklama | Beklenen Sonuç | Sorumluluk |

|---|---|---|---|

| Physical Placement | Machine positioned as per layout | Correct footprint, clear access | MZBNL Team/Client |

| Leveling Accuracy | Machine leveled within specified tolerances | Stable, vibration-free operation | MZBNL Team |

| Anchoring Security | Machine securely bolted to foundation | No movement during operation | MZBNL Team |

| Electrical Hookup | All power cables connected and tested | Stable power supply, no shorts | MZBNL Team/Client |

| Pneumatic/Water Lines | Air and water connections secured and leak-free | Adequate pressure, proper cooling | MZBNL Team/Client |

| Safety Interlocks | All safety guards and interlocks functional | Operator protection, safe machine operation | MZBNL Team |

Leveling requires ±0.02mm precisionDoğru

The text specifies laser tube cutters require leveling accuracy within ±0.02mm per meter to prevent cutting errors.

Installation can use standard forkliftsYanlış

Professional rigging teams with specialized equipment are required, not standard forklifts, due to precision needs.

What steps are involved in the calibration and testing of the machine?

A machine is physically installed, but without precise calibration, its potential is severely limited. Improper calibration can lead to wasted materials, production bottlenecks, and dissatisfied customers. Thorough calibration and testing are paramount to unlocking the machine's high-precision capabilities and ensuring consistent quality.

Calibration and testing of a metal tube cutting machine involve adjusting laser parameters, verifying motion system accuracy, and running test cuts on various material types. This meticulous process ensures optimal cutting quality, precise dimensions, and peak operational performance, often utilizing advanced diagnostic tools and precise measurement instruments to fine-tune the machine.

Once the machine stands tall in your facility, poised for action, the real magic of precision engineering begins: calibration and testing. This isn't just a formality; it's the crucible where the machine's promised performance is forged. I’ve always believed that a machine's true value lies in its ability to deliver consistent, high-quality results, and that's precisely what this stage guarantees. Think about Ahmed Al-Farsi, a hands-on decision-maker who expects high cost-performance and proven technology. He needs to know his investment will yield perfect parts for architectural metalwork and vehicle components, meeting stringent industry standards. This phase involves fine-tuning every parameter, from laser power to cutting speed, ensuring that the machine operates within the tightest tolerances. Our MZBNL engineers meticulously adjust, test, and re-test, running multiple samples4 across different materials and geometries. This rigorous process is what makes our machines renowned for high-speed and high-precision cutting, ensuring that every cut meets the exact specifications, minimizing waste, and maximizing your operational efficiency from the very first production run.

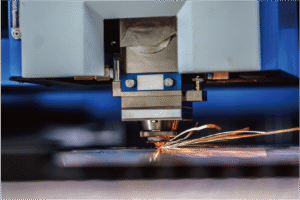

Laser Parameter Tuning and Alignment

Laser alignment is the first critical step in calibration, ensuring the laser beam is perfectly centered and aligned from the resonator through the optics to the nozzle. Any deviation here can lead to inconsistent cut quality, particularly at higher speeds or on thicker materials, and can even cause premature wear or damage to expensive optical components if not addressed. Our engineers use specialized tools such as beam profilers and power meters to verify beam concentricity and focus, making adjustments that are precise to fractions of a millimeter to ensure optimal power delivery and stability at the cutting point.

Following alignment, laser parameters must be meticulously optimized for various materials and thicknesses. This involves fine-tuning power levels, cutting speeds, assist gas pressures (oxygen for carbon steel, nitrogen for stainless steel/aluminum, or air for specific applications), and pulse frequencies. Different metals react uniquely to laser energy and gas interaction, demanding specific settings to achieve clean, dross-free cuts with minimal heat-affected zones. For example, improper laser focus by just 0.1mm can decrease cutting speed by 15% on stainless steel or lead to significant dross formation and poor edge quality on mild steel. Our calibration aims for a focal deviation of less than ±0.05mm across the entire cutting area to ensure maximum efficiency and consistent quality for all supported materials.

Finally, the auto-focus system, which dynamically adjusts the laser's focal point based on material thickness and tube curvature, undergoes rigorous calibration. This intelligent feature ensures consistent cutting quality regardless of minor variations in the tube surface or slight ovality, a feature particularly beneficial for diverse production runs and complex geometries often encountered by furniture or architectural component manufacturers. This system compensates in real-time, reducing the need for manual adjustments and significantly improving throughput and part integrity, which directly translates to cost savings through reduced scrap.

Motion System Accuracy and Axis Calibration

The precision of a metal tube cutting machine relies heavily on its motion control system. Calibration involves verifying the accuracy of all axes (X, Y, Z, and rotational A/B) for linear movement, acceleration, deceleration, and backlash compensation. High-precision encoders and linear guides are meticulously checked to ensure smooth, repeatable motion, vital for complex part nesting and intricate cuts, especially when dealing with multiple hole patterns or complex contours on a single tube. Any inaccuracy here, even on a micron level, can lead to cumulative errors over the length of a tube, resulting in misaligned holes, non-square ends, or parts that simply do not fit together.

Equally important is the calibration of the chucks and the automatic front-feeding system. These components must grip tubes securely without deformation and feed them consistently without slippage or eccentricity. Our MZBNL front-feeding innovation significantly enhances this process; our technicians calibrate the gripping pressure and centering mechanisms to accommodate various tube diameters and shapes while minimizing any potential for surface damage. This precise calibration is critical for ensuring the "zero-waste tail material" innovation functions perfectly, allowing the system to calculate from the rear chuck as the origin and utilize nearly the entire tube length, maximizing material utilization and boosting cutting efficiency by an estimated 5-10% compared to conventional systems.

This detailed calibration of the feeding and motion systems is what allows clients like Ahmed to automate existing manual workflows with confidence. By ensuring seamless integration and precision, the machine can handle long production runs without operator intervention for re-calibration, drastically reducing labor intensity and increasing overall productivity. For instance, in real-world applications, this precise motion control enables our machines to maintain positional accuracy within ±0.03mm, leading to fewer rejected parts and more efficient use of expensive raw materials, directly impacting the client's profit margins.

Test Cuts and Quality Verification

Once laser parameters and motion systems are meticulously calibrated, the machine undergoes a series of comprehensive test cuts on various materials, thicknesses, and geometric shapes. This includes cutting simple circles and squares to assess basic accuracy, as well as more intricate profiles and hole patterns to challenge the machine's capabilities and validate its performance under diverse real-world production scenarios. These test cuts are crucial for confirming that the theoretical calibration settings translate into tangible, high-quality output, acting as the final validation before handing over the machine for full production.

Following each test cut, the parts are rigorously inspected and measured using high-precision instruments. This detailed quality assessment includes verifying external and internal dimensions (OD, ID, length), assessing cut geometry for perpendicularity and roundness, and examining the cut surfaces for common defects such as dross, burr, slag, and the extent of the heat-affected zone. Our MZBNL engineers compare these measurements against industry standards and customer-specific tolerances, ensuring that the machine consistently produces components that meet or exceed quality expectations, which is vital for industries like furniture and sanitary ware manufacturers where aesthetics and fit are paramount. For example, a typical tolerance for hole diameter might be ±0.05mm, and any deviation triggers further fine-tuning.

This process of testing and fine-tuning is often iterative, with adjustments made to laser parameters5, motion settings, or gas pressures based on the results of each test batch until optimal performance is achieved across the full range of specified materials and thicknesses. Our experienced MZBNL technicians guide clients through these results, demonstrating the machine's capabilities and ensuring their satisfaction with the output quality. This transparent and meticulous verification process instills confidence in the client, such as Ahmed, that their investment in our proven technology will deliver the high-quality, cost-effective solutions they expect for their critical projects.

Laser alignment affects cut qualityDoğru

Proper laser alignment ensures consistent cut quality and prevents premature wear of optical components.

Calibration is a one-time processYanlış

Calibration is an iterative process that requires multiple test cuts and adjustments to achieve optimal performance.

How long does it typically take for the operator to familiarize themselves with the machine?

A powerful machine is only as effective as the hands that operate it. While advanced technology can streamline operations, concerns about lengthy and complex operator training often deter businesses from embracing new machinery. However, modern designs and intuitive interfaces are radically transforming this learning curve.

Operator familiarization with a modern metal tube cutting machine, especially one with a user-friendly No-CAD system, can typically take as little as 1 day for basic operation, with full proficiency achieved within 3-5 days. This rapid learning curve is driven by simplified interfaces, automated features, and comprehensive on-site training provided by the supplier.

My personal philosophy, deeply embedded in MZBNL's product development, is that advanced technology shouldn't necessitate advanced degrees to operate. I’ve heard countless stories, including from potential clients, about the high operator turnover and the associated retraining burdens that plague traditional metal fabrication shops. This challenge alone can severely impede productivity and profitability. That's why we've engineered our machines, particularly with the No-CAD System Innovation, to shatter these conventional barriers. For someone like Ahmed Al-Farsi, whose pain points include machines requiring skilled CAD operators and the burdens of retraining, our approach offers a direct solution. Instead of the typical 15 days of intensive off-site training often demanded by conventional equipment, our system empowers operators to become proficient in a fraction of that time, allowing you to maximize your new machine's output almost immediately. This rapid familiarization translates directly into immediate return on investment and vastly reduced operational friction.

The Impact of No-CAD System Innovation on Training

Traditional laser tube cutting machines often require operators to have a strong background in CAD software, spending significant time creating or modifying complex 3D drawings before production could even begin. This necessitated lengthy and expensive training, typically ranging from two weeks to a month, often at the equipment factory, leading to significant downtime and skill dependency. This reliance on highly specialized CAD operators is a major pain point for businesses like Ahmed's, contributing to high operator turnover and continuous retraining burdens.

MZBNL’s pioneered No-CAD İşletim Sistemi6 fundamentally changes this paradigm. With our system, standard tube types and hole patterns can be processed simply by entering parameters directly into the machine interface—no drawing required. This innovation dramatically simplifies the entire workflow, allowing operators to bypass the complex CAD design phase for routine jobs. The immediate benefit is a drastic reduction in the skill threshold required for machine operation, making the machine accessible to a broader range of personnel. For example, what once took 15 days of off-site factory training, now only requires 1 day of on-site training to start basic operations. This efficiency gain is monumental, freeing up valuable resources and accelerating production readiness.

This simplification directly addresses the industry-wide challenge of finding and retaining skilled labor. By making the machine intuitive and parameter-driven, businesses can quickly train new hires or cross-train existing staff, significantly reducing the impact of operator turnover. This allows companies to maintain consistent production levels and invest their training budgets more strategically, focusing on higher-level problem-solving or process optimization rather than basic machine operation. The No-CAD system is a testament to our commitment to ease of use and cost-effective customized solutions, making advanced technology accessible to everyone on the shop floor.

Intuitive Interface and Guided Operations

Beyond the No-CAD system, our machines feature highly intuitive, touch-screen interfaces designed for ease of navigation. These interfaces often employ graphical representations and logical workflows, mirroring familiar smartphone or tablet interactions. This user-friendly design minimizes the cognitive load on operators, allowing them to grasp machine functionalities quickly without needing to memorize complex command sequences. I always advocate for designs that feel natural, almost second nature, to ensure rapid adoption.

Many modern machines, including MZBNL's, incorporate guided operation modes and step-by-step prompts. These systems walk the operator through the entire cutting process, from material loading and program selection to initiating the cut and unloading parts. Built-in diagnostic tools and real-time feedback systems alert operators to potential issues, providing immediate solutions or directing them to relevant help sections. This proactive guidance significantly reduces errors and builds operator confidence, accelerating the learning process by providing immediate feedback.

This approach significantly reduces the time spent troubleshooting and allows operators to confidently execute complex tasks with minimal supervision early in their training. This rapid familiarity means that even within the first few days, operators can contribute meaningfully to production, transforming a traditionally steep learning curve into a manageable incline. For companies like Ahmed’s, where efficiency is paramount, having operators reach proficiency in days rather than weeks translates directly into faster project deliveries and increased profitability.

Comprehensive On-Site Training and Support

While the machine’s inherent ease of use is a cornerstone, comprehensive on-site training delivered by experienced MZBNL technicians is crucial for consolidating operator knowledge and ensuring safe, efficient operation. Our training programs are hands-on, focusing on practical application rather than just theoretical knowledge. Operators learn not only how to run the machine but also best practices for material handling, basic troubleshooting, routine maintenance, and safety protocols. This practical experience cements their understanding and capability.

Our training doesn't stop at basic operation. We delve into optimizing cutting parameters for different materials, understanding nesting strategies for material efficiency, and utilizing the machine's smart features for production monitoring and data analysis. This ensures operators are not just machine tenders but active contributors to process improvement and cost reduction. For example, operators learn how to minimize the "zero-waste tail material" by optimizing cutting sequences, which can result in significant material savings over time. This kind of advanced operational insight is invaluable.

The effectiveness of our on-site training means that operators can quickly move from supervised learning to independent operation, typically within 3-5 days for full operational confidence, far surpassing the industry average. This rapid upskilling directly addresses Ahmed’s need for easy-to-operate, turnkey solutions and provides a competitive advantage by allowing his workforce to become productive almost immediately. Furthermore, our commitment to ongoing remote diagnostics and spare parts availability ensures that operators always have a safety net, fostering long-term reliability and support.

No-CAD eğitim süresini kısaltırDoğru

The No-CAD system eliminates complex CAD design requirements, allowing operators to learn basic functions in just 1 day.

Traditional training takes 2 monthsYanlış

Traditional CAD-based training typically requires 2-4 weeks, not months, though still significantly longer than No-CAD systems.

What are the final checks to ensure the machine is ready for operation?

After the machine is meticulously installed, calibrated, and operators begin their training, it's tempting to rush into full-scale production. However, skipping crucial final checks can lead to costly errors, compromised quality, and potential safety hazards. The last steps are as important as the first in guaranteeing seamless and reliable operation.

Final checks for a metal tube cutting machine involve comprehensive safety system verification, a thorough review of all connections and parameters, and a final production trial run. These essential steps confirm that the machine is fully optimized, safe, and ready for continuous, high-quality manufacturing, ensuring reliable performance before full-scale operation begins.

As someone who has been deeply involved in metal fabrication for over two decades, I understand the eagerness to see a new investment like a laser tube cutting machine contribute to production immediately. However, my experience has taught me the invaluable lesson that haste can indeed make waste. Just as a pilot performs a detailed pre-flight checklist, a new machine requires a stringent final review. This isn't just about functionality; it's about confirming absolute reliability and safety for your team and your products. For a client like Ahmed Al-Farsi, who prioritizes proven technology and turnkey solutions, these final checks are the bedrock of trust. They ensure that when we say your MZBNL machine is "ready for operation," it truly means it's primed for high-speed, high-precision cutting, designed for multi-process integration, and ready to deliver cost-effective customized solutions from the first piece.

Comprehensive Safety System Verification

Before any production runs commence, a final, comprehensive verification of all safety systems is paramount. This includes testing every emergency stop button across the machine to ensure immediate power cut-off, confirming that all güvenli̇k ki̇li̇tleri̇7 on access panels, covers, and light curtains function correctly, preventing operation when guards are open or personnel are in hazardous zones. Verification also extends to the integrity of safety barriers and any designated exclusion zones around the machine. Our MZBNL machines are designed with multiple layers of safety, exceeding minimum industry requirements, but these final checks ensure their proper activation and response.

Final Parameter Review and Connectivity Validation

Even after initial calibration, a final review of all operational parameters is essential. This includes cross-referencing material databases with actual settings (laser power, cutting speed, focal position, gas type, and pressure) to ensure they match the specific production requirements. This step catches any last-minute discrepancies or adjustments that might have been overlooked, guaranteeing optimal cut quality and material efficiency. For complex jobs involving various tube types or thicknesses, verifying the auto-switching capabilities for parameters is crucial.

Production Trial Run and Operator Sign-off

The ultimate test is a production trial run, simulating actual manufacturing conditions. This involves processing a batch of typical parts that the client intends to produce, using the exact materials and programs planned for regular operation. This trial run assesses the machine's performance under continuous load, identifies any subtle vibrations or inconsistencies that might appear over time, and verifies the accuracy and quality of the final product at production speeds. This is where the machine truly proves its readiness.

Safety checks prevent accidentsDoğru

Comprehensive safety system verification ensures all emergency stops and interlocks function properly, preventing hazardous situations.

Final checks are optionalYanlış

Final checks including safety verification, parameter review and trial runs are mandatory to ensure machine readiness and safety.

Sonuç

Setting up a metal tube cutting machine involves meticulous preparation, precise installation, and rigorous calibration, followed by thorough operator training and final verification. By choosing MZBNL's innovative, user-friendly machines and leveraging our comprehensive support, businesses can drastically reduce setup times from weeks to mere days, ensuring rapid production readiness, optimal performance, and immediate return on investment.

-

Discover benefits of efficient setup processes in metal fabrication operations. ↩

-

Understand MZBNL's strategies for global client management and service excellence. ↩

-

Understand tools used for precise machine leveling ↩

-

Understand the testing process that ensures consistent cut quality ↩

-

Discover necessary adjustments to achieve precise laser cutting results ↩

-

Learn how MZBNL's system reduces the need for extensive CAD training and supports rapid operator upskilling ↩

-

Explore the role and function of safety interlocks in machinery safety ↩

Sorularınız mı var veya daha fazla bilgiye mi ihtiyacınız var?

Kişiselleştirilmiş yardım ve uzman tavsiyesi için bizimle iletişime geçin.