Metal Boru Kesme Makinesi Üretim Tesisimizin İçine Bir Göz Atın

Facing the challenge of finding cutting-edge metal tube processing solutions? Many businesses struggle with outdated machinery, leading to inefficiencies and lost opportunities. At MZBNL, we’re revolutionizing the industry by integrating unparalleled innovation and precision directly into our manufacturing process, ensuring you receive only the best.

Our metal tube cutting machine production facility, the heart of MZBNL, integrates advanced R&D, manufacturing, and stringent quality control. Leveraging over 25 years of expertise, we utilize state-of-the-art automation and proprietary innovations to craft high-speed, precise, and cost-effective solutions for our global clientele.

Stepping through the doors of our production facility, you're not just entering a factory; you're embarking on a journey through two and a half decades of unwavering dedication to excellence and technological advancement. We invite you to discover the meticulous craftsmanship and revolutionary engineering that define every MZBNL machine.

In an ever-evolving global market, the manufacturing of high-precision metal tube cutting machines is a complex dance between tradition and innovation. It demands a critical balance: upholding rigorous quality standards while pushing the boundaries of what's possible with automation and digital integration. Our facility isn't merely an assembly line; it's a dynamic ecosystem where theoretical breakthroughs meet practical application. We critically assess every stage, from raw material sourcing to final machine calibration, scrutinizing inefficiencies and embracing continuous improvement. With over 30 patents and serving more than 4,000 enterprise clients globally, our commitment extends beyond production—it's about foreseeing future industry needs and proactively developing solutions. This dedication allows us to bridge the gap between abstract engineering concepts and tangible, high-performance machinery, ensuring that every machine we produce is not just a tool, but a strategic asset designed to address the most pressing challenges faced by businesses today.

What is the historical background of our metal tube cutting machine production facility?

Have you ever wondered about the origins of groundbreaking technology? Many innovations are born from a simple need to do things better, but the journey from concept to reality is often complex. Our facility's history is a testament to this, starting from humble beginnings with a clear vision.

Our metal tube cutting machine production facility began with a clear vision over 25 years ago: to revolutionize metal fabrication through advanced automation. Initially focused on addressing fundamental industry inefficiencies, our history is marked by continuous technological adaptation, strategic growth, and a steadfast commitment to delivering superior, precision-engineered solutions.

My personal journey with MZBNL (or "our" journey if preferred for consistency), much like the evolution of our production facility, has been one of continuous learning and adaptation. When we first envisioned MZBNL, the metal fabrication industry was ripe for disruption, burdened by manual processes and limited precision. We knew that to truly make an impact, we needed more than just a workshop; we needed a hub of innovation where ideas could transform into tangible, high-performance machinery. From those early days, the core philosophy was simple yet ambitious: to build machines that not only met but exceeded the evolving demands of global manufacturers. This involved countless hours of research, prototyping, and refining, all aimed at creating a production environment that could consistently deliver excellence. The foundation we laid then, focusing on robust engineering and forward-thinking design, has been instrumental in shaping the advanced facility you see today, meticulously crafted to uphold our pioneering spirit.

The Foundational Years and Early Vision

In the late 1990s, when MZBNL first set its roots, the metal fabrication industry was predominantly reliant on conventional cutting methods—processes that were often labor-intensive, prone to human error, and severely limited in precision for complex designs. My personal experience during that era, observing the inefficiencies firsthand in various workshops, fueled a critical realization: there was a desperate need for automation1 that could not only cut faster but also achieve unprecedented levels of accuracy. Our initial vision was profoundly simple yet revolutionary: to integrate cutting-edge laser technology into tube processing, transforming what was once a laborious craft into a streamlined, high-precision operation. We began with a small team, a big idea, and a relentless dedication to R&D, focusing on building robust, reliable machines that could empower businesses to achieve higher throughput and superior product quality. This early commitment to solving core industry pain points, such as the need for skilled CAD operators or the inefficiency of manual loading, laid the groundwork for our future innovations, creating a strong ethos of problem-solving that continues to define our approach today. This foundational period, though challenging, instilled in us the resilience and foresight necessary to navigate the dynamic landscape of industrial manufacturing, setting a precedent for continuous improvement and technological leadership.

We initially observed a significant gap in the market for integrated solutions. Many available machines performed only single functions, requiring multiple setups and transfers for complex parts like those found in architectural metalwork or automotive components. This fragmentation led to increased cycle times and higher labor costs for businesses. Our early models aimed to consolidate these processes, introducing rudimentary automation to handle tasks that previously required multiple manual interventions. For instance, early prototypes explored automated clamping and simple positional adjustments, a stark contrast to the purely manual operations prevalent at the time. This strategic focus on integration was driven by early feedback from manufacturers who struggled with project delays and rising operational expenses due to fragmented workflows. Our ambition was to reduce these bottlenecks, providing a more cohesive and efficient fabrication experience from the very start.

The very first facility, while modest, was designed as a hub for both engineering and hands-on testing. We didn't just design machines; we built them, tested them, and refined them iteratively, learning from every cut and every calibration. This iterative approach was critical for refining our initial designs and understanding the real-world demands placed on industrial machinery. For example, early on, we discovered that even minor vibrations during high-speed cutting could compromise precision, leading to extensive research into machine frame stability and damping technologies. This dedication to practical application and continuous refinement, rather than just theoretical design, became a cornerstone of our development process. It allowed us to quickly identify and rectify design flaws, ensuring that each subsequent iteration of our machines was more robust, accurate, and user-friendly, directly addressing the pain points our potential clients faced.

Navigating Industry Shifts and Technological Leaps

As the 21st century dawned, the metal fabrication industry began to experience a profound shift, driven by increasing demands for mass customization, shorter lead times, and higher material efficiency. We critically examined these macro trends, realizing that our early successes in automation were just the beginning. The advent of more powerful fiber lasers, coupled with advancements in computer numerical control (CNC) technology, presented both opportunities and challenges. We had to make crucial decisions about investing heavily in these nascent technologies, which at the time were significantly more expensive and complex than traditional CO2 lasers. Our proactive investment, however, paid dividends, allowing us to dramatically improve cutting speeds and achieve accuracies previously unattainable. This strategic pivot enabled us to cater to emerging sectors, like high-volume furniture manufacturing and specialized automotive parts production, where precision and speed were paramount.

A key turning point came with the global push towards smarter manufacturing processes. Simply automating tasks was no longer enough; machines needed to "think" and adapt. This led us to integrate advanced sensor technology2 and sophisticated control algorithms into our production lines and, consequently, into our machines themselves. For example, we invested in high-resolution optical systems to monitor cutting parameters in real-time, allowing for immediate adjustments to optimize cut quality and minimize waste. This was a significant departure from older systems that relied heavily on manual oversight and post-process inspection. The move towards smart manufacturing also influenced our internal production, enabling us to implement more agile manufacturing processes that could quickly adapt to design changes or new client specifications, a critical capability in the fast-paced modern industrial landscape.

The evolution was not without its hurdles. Integrating complex software with robust hardware required significant R&D investment and a highly skilled workforce. We faced the challenge of retraining our engineers and technicians to master new programming languages and robotic systems. For instance, the transition to fully integrated multi-axis cutting, a feature now standard on our machines, demanded a deep understanding of kinematic modeling and collision avoidance algorithms. This necessitated forging partnerships with leading research institutions and attracting top talent in robotics and AI. It was a strategic imperative to ensure our production capabilities remained at the forefront of the industry, capable of delivering the innovative solutions our clients, like Ahmed, would eventually seek—solutions that promised greater efficiency and ease of use, directly addressing their pain points related to skilled operator requirements and high turnover.

Establishing a Legacy of Excellence and Global Footprint

Over the past two and a half decades, our production facility has not just grown in size but in its global impact. From our initial focus on the domestic market, we strategically expanded our reach, recognizing the immense demand for advanced metal fabrication solutions in emerging economies and established industrial hubs alike. Our commitment to rigorous quality assurance standards, including ISO certifications3 and CE compliance, became a cornerstone of our global expansion strategy. This dedication to international benchmarks ensured that an MZBNL machine delivered to Southeast Asia or North America met the same exacting standards as one serving our local market. The trust earned from this consistent quality has been instrumental in building a client base exceeding 4,000 global enterprises, reflecting our reputation for reliability and performance across diverse industrial applications.

Our journey to a global footprint was punctuated by significant milestones. A pivotal moment was securing our first major international patent for an innovative feeding mechanism, which not only validated our R&D prowess but also opened doors to new markets. This was followed by strategic participations in major international trade shows like Metal & Steel Saudi Arabia and Tube Middle East, where we showcased our evolving product lines. For instance, our participation in these events allowed us to engage directly with potential clients like Ahmed Al-Farsi, understanding their specific needs—such as the demand for easy-to-operate machines and robust after-sales support—and tailoring our offerings accordingly. These direct interactions solidified our understanding of regional demands, informing product development and service strategies.

Our manufacturing ethos has always centered on precision and durability, qualities that resonate deeply with our global clientele. We understand that our machines are significant investments for our customers, and their longevity directly impacts their profitability. For example, our decision to implement a comprehensive 7-stage quality control protocol, from raw material inspection to final performance testing, was a direct response to feedback from overseas clients seeking maximum uptime and minimal maintenance. This meticulous approach has not only reduced warranty claims but has also fostered long-term relationships, with many clients becoming repeat purchasers or even regional distributors, as Ahmed is considering. This holistic approach to production, from innovation to global support, has forged MZBNL’s legacy as a leader in the metal tube cutting machine industry, a testament to our enduring commitment to excellence.

MZBNL has 25+ years of expertiseDoğru

The text explicitly states the company leverages over 25 years of expertise in metal tube cutting machine production.

Early machines used CO2 lasersYanlış

The text mentions they later transitioned from CO2 lasers to fiber lasers, implying their earliest machines didn't use laser technology at all but rather addressed manual process inefficiencies.

How has our production facility evolved to meet industry demands?

The industrial landscape is constantly shifting, demanding greater efficiency, precision, and adaptability from manufacturers. How do facilities like ours keep pace with such rapid changes, let alone lead the way? Our evolution has been a deliberate response to these pressing industry needs.

Our production facility has undergone a profound evolution, transitioning from traditional methods to integrated smart manufacturing. Driven by industry demands for higher precision and efficiency, we've invested heavily in automation systems, IoT, and flexible production lines, ensuring we can deliver customized, high-performance metal tube cutting solutions that consistently meet future market requirements.

Witnessing the transformation of our production facility has been incredibly rewarding, a journey that mirrors the broader shifts within global manufacturing. Early on, the industry's demand was primarily for robust, functional machines. Today, the landscape is far more sophisticated, requiring intelligent, interconnected systems that can handle complex tasks with minimal human intervention. This evolution wasn't accidental; it was a strategic imperative driven by constant dialogue with our clients and a deep understanding of their pain points. We recognized that businesses, like Ahmed's metal fabrication enterprise in the UAE, needed more than just a cutting tool; they required a comprehensive solution that could seamlessly integrate into their existing workflows, optimize material usage, and reduce reliance on highly specialized labor. Our facility's transformation reflects this philosophy, moving beyond simple automation to embrace a holistic approach where every process is designed for maximum efficiency, adaptability, and ultimately, enhanced value for our customers, ensuring we stay ahead of tomorrow's demands today.

From Manual Craftsmanship to Automated Precision

The transition from predominantly manual processes to integrated automation marks a defining chapter in our facility's evolution. In the early days, skilled technicians spent considerable time on precise measuring, alignment, and manual loading of tubes—a process prone to variability and bottlenecking. As industry demand for higher throughput and tighter tolerances intensified, this manual approach became unsustainable. We critically assessed these bottlenecks, investing in advanced robotic arms for material handling and automated loading systems. For instance, the implementation of our optimized Front-Feeding mechanism4, a BNL innovation, was a direct result of this shift. This system automatically pulls the tube from the front, increasing feeding efficiency by approximately 40% and reducing operator labor intensity by about 40%. This wasn't merely about replacing human hands; it was about elevating human capability, allowing our skilled workforce to focus on quality control, programming, and strategic oversight rather than repetitive tasks.

This automation extends beyond simple material movement to the core cutting processes themselves. Where traditional methods might involve multiple machines for different operations (cutting, punching, notching), our facility now leverages integrated multi-process machines. These intelligent systems, equipped with high-speed and high-precision cutting capabilities, can perform a sequence of operations without manual intervention. For example, a single machine can now cut a tube to length, punch intricate holes, and even engrave markings in one continuous cycle. This integration drastically reduces setup times and minimizes the risk of errors associated with transferring workpieces between machines. The result is a consistent, high-quality output that meets the stringent demands of industries like furniture and sanitary ware manufacturing, where every millimeter counts.

The impact of this automation on overall production efficiency has been transformative. We've seen a significant reduction in cycle times for complex parts, enabling us to fulfill larger orders with shorter lead times—a critical advantage in a competitive market. Furthermore, the precision achieved through automated control systems ensures minimal material waste and superior finish quality, which directly translates into cost savings for our clients. Consider a client like Ahmed Al-Farsi, who is seeking to automate his existing manual workflows; the prospect of a machine that eliminates the need for manual loading and streamlines multiple processes into one integrated system directly addresses his need for greater efficiency and reduced labor costs. This strategic shift from manual craftsmanship to automated precision isn't just about what we build, but how efficiently and accurately we build it, setting new benchmarks for the industry.

The Integration of Smart Manufacturing and IoT

The true leap in our facility's evolution came with the integration of smart manufacturing principles and the Internet of Things (IoT). We recognized that while automation made processes faster, intelligence made them smarter and more adaptive. Our machines, and indeed our entire production environment, are now equipped with an array of sensors collecting real-time data5 on everything from machine performance and material consumption to ambient temperature and humidity. This rich data stream is then fed into centralized analytical systems, allowing us to gain unprecedented insights into our operations. For instance, predictive maintenance algorithms analyze machine vibrations and temperature readings to anticipate potential component failures before they occur, enabling proactive servicing and minimizing costly downtime. This proactive approach ensures our production lines run smoothly, mirroring the reliability we build into our machines for our clients.

A cornerstone of our smart manufacturing strategy is the development and implementation of our proprietary digitalized systems. This includes sophisticated Manufacturing Execution Systems (MES) that orchestrate the entire production flow, from order entry to final dispatch. These systems ensure seamless communication between different stages of production, allowing for dynamic scheduling and resource allocation. For example, if a specific component batch is delayed, the MES can automatically re-route other tasks or adjust production schedules to maintain overall efficiency, minimizing disruptions. This level of digital integration is not just about internal efficiency; it's also about providing our clients with machines that are "smart and digitalized." Our BNL No-CAD Operating System, for instance, dramatically simplifies machine operation by allowing standard tube types and hole patterns to be processed simply by entering parameters, eliminating the need for complex 3D drawings. This innovation is a direct outcome of our commitment to smart, user-friendly design, born from our own experience with complex systems.

Furthermore, IoT integration allows for real-time quality monitoring and traceability. Every product component is tracked from its origin through each stage of manufacturing, creating a comprehensive digital footprint. This means that if any quality deviation is detected, we can pinpoint its source immediately, implement corrective actions, and prevent faulty products from progressing further. For our clients, this translates into machines of unparalleled reliability and consistency. For example, if Ahmed Al-Farsi were to inquire about the manufacturing history of a specific part in his machine, our IoT system could provide a detailed breakdown of its journey through our facility. This commitment to data-driven quality control and process optimization underscores our belief that truly advanced manufacturing is not just about building machines, but about building intelligent systems that continuously learn, adapt, and improve, setting a new standard for precision and operational excellence in the industry.

Customization and Scalability in a Demanding Market

The modern industrial market is characterized by a paradox: the demand for mass production coexists with an equally strong demand for highly customized solutions. Our production facility has evolved to master this delicate balance, transforming itself into a hub capable of both large-scale, standardized manufacturing and agile, bespoke machine building. We critically analyzed the traditional trade-off between efficiency and customization, implementing modular design principles for our core machine components. This allows us to maintain the efficiency of batch production for standard modules while seamlessly integrating unique features or specifications required by individual clients. For instance, a client might require specialized clamping mechanisms for unusually shaped profiles, or a different automation interface to integrate with their existing factory software. Our modular approach enables us to adapt rapidly without overhauling the entire production line.

To facilitate this dual capacity, we have invested significantly in flexible manufacturing systems (FMS). Unlike rigid assembly lines, our FMS allows for quick reconfiguration of tools and workflows, enabling us to switch between producing different machine models or incorporating specific customized elements with minimal downtime. This flexibility is crucial for addressing the diverse needs of our client base, which spans from small metal pipe processing factories needing a compact, entry-level machine to large automotive parts producers requiring high-volume, multi-process integration. For example, when a client like Ahmed Al-Farsi, with his diverse business in architectural metalwork and vehicle parts, expresses interest in a "turnkey solution that is easy to install and operate" with "customization and post-sales training/support," our facility is uniquely positioned to deliver. We can configure a machine precisely to his needs, from specific cutting capacities to integrated punching capabilities, ensuring it fits seamlessly into his existing operational framework.

Furthermore, our ability to scale production up or down quickly is a direct outcome of this evolved facility structure. We can efficiently ramp up output during periods of high demand, leveraging optimized supply chain relationships and integrated production planning. Conversely, during periods requiring more focused R&D or custom builds, our flexible systems ensure resources are allocated optimally without significant overheads. This scalability is not just about volume; it’s about the agility to respond to market shifts and client-specific projects with speed and precision. This comprehensive approach to customization and scalability ensures that MZBNL remains a preferred supplier for businesses worldwide, providing "cost-effective customized solutions" that empower them to remain competitive and innovative, regardless of their operational scale or specific industrial demands.

Modular design enables customizationDoğru

The facility uses modular components to efficiently incorporate client-specific features.

Manual processes had higher precisionYanlış

Automation actually increased precision by reducing human variability in measurements.

What current technologies are being utilized in our production facility?

Ever wondered what powers the precision and speed behind cutting-edge industrial machinery? The answer lies in the sophisticated technologies woven into every stage of our production process. Our facility is a living testament to the relentless pursuit of technological mastery.

Our production facility harnesses state-of-the-art technologies, including advanced fiber laser cutting systems, robotic welding, and proprietary innovations like our No-CAD Operating System. We integrate sophisticated IoT sensors and digitalized quality control, ensuring every MZBNL machine achieves unparalleled precision, efficiency, and smart functionality for global industrial applications.

Stepping onto the floor of our production facility is akin to entering a technological symphony, where every machine and system plays a vital role in crafting precision metal tube cutting solutions. For me, it’s a source of immense pride to see the culmination of years of R&D and strategic investment brought to life. We don't just assemble parts; we engineer excellence, leveraging the very latest advancements in laser technology, robotics, and intelligent control systems. This isn't about adopting technology for its own sake; it’s about meticulously integrating tools that solve real-world problems and enhance the performance of every machine we send out. The core belief driving this technological integration is simple: to create machines that are not only powerful and accurate but also intuitive and reliable for our clients worldwide, enabling them to achieve unprecedented levels of productivity and material utilization, directly addressing their need for cutting-edge, user-friendly solutions.

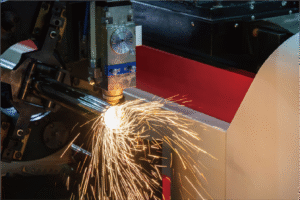

Advanced Laser Cutting and Welding Technologies

At the heart of our production facility lies an array of advanced laser cutting and welding technologies, crucial for manufacturing the intricate components of our metal tube cutting machines with unparalleled precision. We utilize high-power fiber laser systems, not just for the final product our clients receive, but extensively within our own manufacturing processes. These industrial-grade lasers are employed to precisely cut metal sheets and structural frames that form the backbone of our machines. Their ability to deliver extremely narrow kerf widths and achieve superior edge quality means less material waste and minimal post-processing for our internal components, which directly translates into tighter tolerances for the finished MZBNL machines. This internal application of advanced laser technology underscores our commitment to precision, ensuring that the very tools we use to build our machines are themselves at the forefront of technological capability.

Beyond cutting, our facility incorporates sophisticated robotic welding systems. While traditional welding can be subject to human variability, robotic welding6 ensures consistent bead penetration, uniform weld strength, and repeatability across thousands of components. This is particularly vital for structural elements like machine beds and gantry frames, where rigidity and long-term stability are paramount. For instance, our robotic welders use advanced vision systems to precisely locate weld seams and adjust parameters in real-time, adapting to minor variations in material. This level of automated precision significantly enhances the overall structural integrity and durability of our machines, ensuring they can withstand the rigorous demands of high-speed, continuous operation for years. The consistent quality achieved through robotic welding is a key factor in the long lifespan and reliable performance of every machine we produce.

The integration of these advanced laser cutting and welding technologies within our own production cycle allows us to achieve what we promise our clients: "high-speed and high-precision cutting" in their operations. By utilizing these technologies internally, we gain firsthand experience and insights into their optimal performance and limitations. This practical understanding directly informs our machine designs and operational parameters. For example, our experience with high-speed laser cutting in our own facility has enabled us to fine-tune the motion control systems and cutting head designs of our client machines, leading to faster cutting speeds and better edge finishes. This continuous feedback loop between our internal manufacturing processes and our product development ensures that every MZBNL machine is engineered not just for theoretical excellence, but for proven, real-world performance, setting a benchmark for manufacturing quality in the industry.

Proprietary Innovations: The BNL Edge

A critical differentiator for our production facility, and indeed our entire brand, lies in the integration and meticulous execution of our proprietary BNL innovations. These are not merely features; they are foundational design philosophies that are engineered and perfected within our own walls. Our No-CAD Operating System, for example, is developed and rigorously tested here. We've built specialized simulation environments and real-world testing cells to validate its intuitive interface and ensure it can process standard tube types and hole patterns by simply entering parameters, eliminating the need for complex 3D drawings. This innovation directly addresses a significant pain point for clients like Ahmed Al-Farsi, who previously struggled with the need for skilled CAD operators and high operator turnover. By simplifying the interface, we've reduced the on-site training time from a typical 15 days at an equipment factory to just 1 day of on-site training. This ease of use is a direct result of the extensive R&D and user-centric design principles applied in our facility.

The BNL Front-Feeding Innovation is another prime example of how our internal R&D translates into tangible client benefits. While traditional machines rely on side or rear manual loading, our team meticulously designed and integrated an optimized front-feeding mechanism into the physical structure of our machines. In our facility, we have dedicated sections for assembling and calibrating this precise system, ensuring that it automatically pulls the tube in from the front of the machine with maximum efficiency. This design increases feeding efficiency by about 40% and reduces operator labor intensity by approximately 40% for our clients. The seamless operation of this system, from the precision of the grippers to the speed of the indexing, is a testament to the detailed engineering and robust testing protocols we employ during the manufacturing process, ensuring consistent, high-performance feeding in real-world industrial environments.

Our Zero-Waste Tail Material Innovation is perhaps one of the most resource-efficient advancements developed and implemented in our facility. Unlike conventional systems that generate unusable tail material at the end of the cutting process, our engineers redesigned the cutting logic to calculate from the rear chuck as the origin. This sophisticated control algorithm, developed and refined in our software development labs within the facility, allows the system to eliminate leftover tail material as long as the remaining section is smaller than the product length. This zero-tail design maximizes material utilization and significantly boosts cutting efficiency for our clients. The rigorous validation of this system, including countless material utilization tests and performance benchmarks conducted right here, ensures that our machines deliver exceptional material savings.

| İnovasyon | Geleneksel Yöntem | BNL Advantage | Client Benefit |

|---|---|---|---|

| No-CAD Sistemi | Requires skilled CAD operators for complex 3D drawings. | Operators enter parameters for standard tube/hole types; no drawing needed. | Dramatically improves ease of use, shortens setup time, lowers skill threshold, reduces training from 15 days to 1 day. Addresses "skilled CAD operators" and "high operator turnover" pain points. |

| Önden Besleme | Side or rear manual loading, inefficient and labor-intensive. | Optimized front-feeding mechanism automatically pulls tube in. | Increases feeding efficiency by ~40%, reduces operator labor by ~40%. Enhances productivity and ergonomics. |

| Sıfır Atık Kuyruk Malzemesi | Generates unusable tail material at the end of the process. | Cutting logic calculates from rear chuck, eliminates leftover tail material. | Maximizes material utilization, boosts cutting efficiency, reduces material waste. |

These innovations are not just theoretical concepts; they are tangible solutions that are meticulously brought to life through precise manufacturing and rigorous testing within our facility. They embody our commitment to delivering machines that are not only technologically superior but also provide clear, measurable operational and economic benefits to our global customers.

Integrated Quality Control and Testing Systems

The pinnacle of our technological utilization is our comprehensive and integrated quality control and testing systems. We understand that precision in manufacturing demands equally precise methods of verification. Every single component, from the smallest electronic sensor to the largest steel frame, undergoes multi-stage inspection using advanced metrology equipment. For instance, our facility employs Coordinate Measuring Machines (CMMs) capable of measuring geometric characteristics with micron-level accuracy. These machines are essential for verifying the dimensional precision of critical machine parts, ensuring that all components fit together perfectly and maintain precise alignment during operation. This meticulous pre-assembly inspection reduces errors down the line and guarantees the "high-precision cutting" capability of our final machines.

Beyond individual components, our assembly lines incorporate in-line testing protocols that continuously monitor critical parameters during the construction process. As a machine takes shape, its electrical systems, mechanical movements, and optical alignments are tested in real-time. For example, during the assembly of the laser cutting head and beam delivery system, we use laser interferometers to precisely measure and verify optical path alignment, ensuring maximum power delivery and beam quality. This continuous feedback loop allows for immediate adjustments and corrections, preventing defects from accumulating and ensuring that each machine meets our exacting performance standards before it even leaves the assembly bay. This proactive quality assurance is critical for guaranteeing the "easy to operate and maintain" features of our machines, as fundamental issues are resolved long before they become problems for our clients.

The final stage of our quality control process involves comprehensive full-load performance testing in a dedicated testing laboratory within our facility. Here, every completed MZBNL machine is subjected to rigorous operational scenarios, simulating continuous use under various conditions. This includes testing cutting speed, accuracy, repeatability, and system stability across a range of material types and thicknesses. For example, we conduct long-duration cutting tests to ensure the thermal stability of the machine and the consistency of cut quality over extended periods. This final validation, often involving running the machine for dozens of hours, ensures that every product leaving our facility is not only functional but performs optimally and reliably from day one. This meticulous integrated quality control, from component verification to comprehensive operational testing, underscores our unwavering commitment to delivering machines of superior quality, reliability, and performance to our global clientele.

Fiber lasers ensure precision cuttingDoğru

High-power fiber laser systems deliver narrow kerf widths and superior edge quality, minimizing material waste and post-processing needs.

Robotic welding reduces variabilityYanlış

Robotic welding actually eliminates human variability through consistent bead penetration and uniform weld strength, ensuring structural integrity.

What challenges does our production facility face in maintaining efficiency?

Even with cutting-edge technology, manufacturing efficiency is a constant challenge. How do we navigate the complexities of global supply chains, balance customization with mass production, and ensure a highly skilled workforce? These are the daily hurdles we confront.

Our metal tube cutting machine production facility faces ongoing challenges in maintaining peak efficiency, including navigating complex global supply chains, balancing demands for customization with standardized production, and attracting/retaining skilled talent. We continuously adapt to these dynamic pressures, striving for operational excellence while delivering high-quality, innovative solutions to our global clients.

Maintaining peak operational efficiency in a high-tech manufacturing environment like ours is a continuous endeavor, far from a static state. As I've observed over the years, the complexities of the global market introduce new variables daily that can impact everything from lead times to product innovation. Consider the journey of a single component—it might originate from one part of the world, be processed in another, and finally arrive at our facility for integration. This intricate dance requires meticulous planning and swift adaptation to unforeseen disruptions. Furthermore, the very success of our customization offerings brings its own set of challenges, demanding flexible production lines that can seamlessly pivot between bespoke designs and high-volume standard models. These inherent complexities, coupled with the ever-present need for a highly skilled workforce, present a formidable set of challenges that we diligently work to overcome, ensuring that our commitment to delivering superior machinery remains unwavering despite external pressures.

Navigating Supply Chain Complexities in a Global Market

One of the most significant challenges our production facility faces in maintaining efficiency is the inherent complexity of navigating a global supply chain7. While sourcing components internationally allows us access to the best technologies and competitive pricing, it introduces a multitude of variables that can impact production schedules and costs. We rely on a vast network of suppliers from various countries, including key components from regions like Germany, for their precision engineering, and other parts from robust manufacturing hubs like China and Turkey. Each region comes with its own logistics, regulatory frameworks, and potential for disruption, from geopolitical shifts to natural disasters or even a global pandemic. These external factors can lead to unexpected delays, increased shipping costs, and, critically, longer machine lead times for our clients, directly impacting project delivery schedules, as experienced by clients like Ahmed Al-Farsi.

To mitigate these risks, we have implemented a multi-tiered supplier management strategy. This involves not only vetting suppliers for quality and reliability but also establishing strong, long-term partnerships that foster transparency and mutual support. For example, we maintain a diversified supplier base for critical components, ensuring that if one source experiences an issue, we have alternative options to minimize disruption. However, this diversification itself adds a layer of complexity in terms of managing relationships and ensuring consistent quality across different vendors. Furthermore, the fluctuating costs of raw materials and shipping can unpredictably impact our production expenses, requiring constant negotiation and strategic purchasing to maintain our "cost-effective customized solutions" for clients. This dynamic environment demands agile decision-making and continuous monitoring of global economic indicators to anticipate and respond to potential supply chain shocks.

The challenge extends beyond simply obtaining parts; it also encompasses ensuring the quality and compatibility of components from diverse origins. While our in-house quality control is rigorous, relying on external suppliers means we must meticulously inspect every incoming batch to ensure it meets our exacting standards. This process requires significant investment in inspection equipment and a highly trained team dedicated to quality assurance for incoming materials. For instance, a batch of steel tubes might pass a basic visual inspection, but require advanced metallurgical testing to ensure its structural integrity for high-precision laser cutting. Any deviation can lead to rework or scrap, undermining efficiency. This intricate balancing act—leveraging global advantages while mitigating inherent risks—is a constant operational challenge that requires sophisticated logistics, robust quality assurance, and proactive communication to sustain our production efficiency and deliver reliable machines on schedule.

Balancing Customization with Standardized Production

Another critical challenge for our production facility is striking the delicate balance between offering "cost-effective customized solutions" and maintaining the efficiency of standardized mass production. While customization is a core value proposition for MZBNL, enabling us to tailor machines to specific client needs—such as Ahmed Al-Farsi's desire for a laser tube cutting machine with automatic feeding and punching capabilities—it inherently introduces complexities into the manufacturing process. Each unique feature or specification can require different tooling, programming adjustments, and assembly steps, deviating from a streamlined, repetitive workflow. This can lead to increased complexity in production planning, higher per-unit costs for customized components, and potentially longer lead times if not managed meticulously. The allure of bespoke solutions must be weighed against the imperative of efficient, scalable manufacturing.

To address this, we have strategically implemented a modular design philosophy8 for our machines. This approach, while highly beneficial, still presents challenges. While core components are standardized, the vast array of possible configurations means our assembly lines must be highly flexible and adaptable. This requires continuous training for our assembly teams to be proficient in handling diverse machine variants and specialized installations. For example, integrating a unique material handling system for a client in the medical equipment sector might require a distinct set of skills and tools compared to assembling a standard machine for furniture manufacturing. This means our production engineers must constantly optimize workflows to minimize the impact of customization on overall efficiency, ensuring that the benefits of tailored solutions outweigh the potential for production bottlenecks.

Furthermore, managing the inventory for both standardized components and custom-ordered parts adds another layer of complexity. We must maintain sufficient stock of common modules to facilitate rapid assembly, while also precisely forecasting demand for specialized components to avoid excessive inventory holding costs or, conversely, shortages that halt production. This requires sophisticated inventory management systems and close coordination between sales, engineering, and procurement departments. The goal is to provide bespoke solutions that meet specific industry demands—such as those from automotive parts producers or architectural decoration companies—without compromising the overall efficiency and cost-effectiveness of our production. This ongoing challenge necessitates continuous process improvement and strategic resource allocation to ensure we can consistently deliver both high-volume standard machines and unique, custom-engineered solutions with minimal disruption to our production flow.

Attracting and Retaining Skilled Talent in a Specialized Industry

Perhaps one of the most persistent and crucial challenges our production facility faces is attracting and retaining highly skilled talent in the specialized field of metal fabrication machinery manufacturing. The intricate nature of designing, building, and programming advanced laser tube cutting machines requires a unique blend of engineering expertise, technical proficiency, and practical experience. Our reliance on "smart and digitalized systems," multi-process integration, and proprietary innovations like the No-CAD Operating System means we need engineers, technicians, and even assembly line operators who are not only adept with traditional manufacturing techniques but also proficient in robotics, automation software, and data analytics. The demand for such highly specialized skills often outstrips supply, leading to intense competition for talent in the labor market.

This challenge is exacerbated by the phenomenon of operator turnover, a pain point even our clients like Ahmed Al-Farsi experience. While our No-CAD system significantly lowers the skill threshold for machine operation for our clients, our internal manufacturing processes and R&D still require deeply knowledgeable personnel. Training new employees to the rigorous standards required for precision manufacturing is a time-consuming and resource-intensive process. A single misstep in assembly or calibration can impact the "high-speed and high-precision cutting" capability of a final machine. Therefore, retaining experienced staff who embody the institutional knowledge and craftsmanship passed down through our 25 years of experience is paramount. High turnover can lead to a dip in efficiency, increased training costs, and potential inconsistencies in product quality, directly impacting our ability to maintain a consistent output of high-quality machines.

To counter this, we invest heavily in continuous professional development and fostering a culture of innovation and learning within our facility. We provide ongoing training programs, often in partnership with academic institutions, to ensure our team stays abreast of the latest technological advancements in laser mechanics, automation, and software engineering. We also implement mentorship programs and career progression paths to encourage long-term commitment. However, despite these efforts, the global demand for skilled manufacturing talent remains high, making recruitment and retention a perpetual challenge. This ongoing need to secure and cultivate a top-tier workforce underscores the human element in maintaining our production efficiency, recognizing that even with the most advanced automation, the expertise and dedication of our people remain indispensable to MZBNL's success.

Global supply chains increase production complexityDoğru

International sourcing introduces variables like logistics, regulations, and geopolitical risks that require sophisticated management strategies.

Customization improves production efficiencyYanlış

While customization meets client needs, it disrupts standardized workflows and requires additional resources, reducing overall efficiency.

What strategic solutions have we implemented to overcome these production challenges?

Facing complex production challenges requires more than just identifying problems; it demands strategic, forward-thinking solutions. How do we transform obstacles into opportunities for growth and efficiency? Our approach involves a multi-faceted strategy focused on innovation and collaboration.

To overcome production challenges, our facility has strategically implemented lean manufacturing principles, continuous R&D investment, and robust global partnerships. These solutions optimize workflows, foster innovation, ensure a highly skilled workforce, and strengthen our supply chain, ultimately enhancing efficiency, reliability, and our ability to deliver advanced metal tube cutting machines worldwide.

Overcoming the inherent complexities of high-tech manufacturing isn't a passive process; it requires proactive strategic solutions and a commitment to continuous improvement. From my vantage point, it has been inspiring to witness how our team, over two and a half decades, has consistently transformed every challenge into an opportunity for refinement and growth. We recognized early on that relying solely on intuition wasn't enough; we needed data-driven strategies, agile methodologies, and a deeply ingrained culture of problem-solving. This approach has allowed us to not only mitigate immediate production hurdles but also to build a resilient and adaptable manufacturing framework. Our solutions are designed not just for today's demands but also with an eye towards future innovation9, ensuring that MZBNL remains at the forefront of the industry, delivering the superior quality and efficiency our global clients have come to expect.

Lean Manufacturing Principles and Continuous Improvement

One of the cornerstone strategic solutions we've implemented to overcome production challenges is the rigorous adoption of Lean Manufacturing principles and a commitment to continuous improvement. Lean methodologies focus on systematically identifying and eliminating waste in all its forms—overproduction, waiting, unnecessary transport, over-processing, excess inventory, unnecessary motion, and defects. For instance, we've optimized our production line layout using value stream mapping, significantly reducing the distance materials and components travel between workstations. This physical re-organization has, on average, cut internal transport time by 15%, contributing directly to faster assembly and reduced operational costs. This systematic approach allows us to pinpoint inefficiencies that might otherwise go unnoticed, such as excessive setup times for machine components or redundant quality checks.

Furthermore, we've instilled a culture of Kaizen, or continuous improvement, throughout our facility. This means empowering every employee, from the assembly line technician to the senior engineer, to identify potential areas for improvement and propose solutions. Regular cross-functional team meetings are held to review production data, analyze bottlenecks, and brainstorm innovative ways to streamline processes. For example, our team successfully reduced the final machine calibration time by 10% through a series of small, incremental adjustments to the testing sequence and software interface, building on feedback from multiple shifts. This bottom-up approach to problem-solving not only fosters a sense of ownership among our employees but also ensures that improvements are practical and impactful, directly addressing the daily challenges encountered on the factory floor.

The application of Lean principles has been particularly effective in managing the complexities introduced by our "cost-effective customized solutions." By focusing on flexibility and waste reduction, we can reconfigure our production lines more efficiently for custom orders, minimizing the disruption to standard machine production. For instance, by standardizing our jig and fixture designs with quick-change mechanisms, we've reduced machine model changeover times by 20%, allowing for seamless transitions between different customer specifications. This strategic agility ensures that while we cater to unique client needs—such as Ahmed's desire for specific automatic feeding and punching capabilities—our overall production efficiency remains high. This systematic pursuit of operational excellence, driven by Lean methodologies, ensures that our facility operates at peak performance, consistently delivering high-quality metal tube cutting machines with optimized lead times.

Investment in R&D and Employee Training

A foundational strategic solution for overcoming our production challenges, particularly in maintaining technological leadership and addressing talent gaps, is our unwavering investment in research and development (R&D) coupled with robust employee training programs. Our R&D department is not merely focused on developing new products; it's intricately linked to our production facility, constantly innovating processes and refining existing technologies to enhance efficiency and quality. For example, the development of our BNL No-CAD Operating System10 was a significant R&D undertaking that directly addressed the pain point of needing highly skilled CAD operators, experienced by clients like Ahmed. By making machine operation more intuitive, we not only simplify the learning curve for our customers but also streamline our own internal testing and setup processes, improving overall production flow. This continuous cycle of innovation ensures that our machines are not just current but future-proof.

Parallel to R&D, we place immense importance on continuous employee training. In a rapidly evolving industry driven by "smart and digitalized systems" and "multi-process integration," the skills of our workforce must constantly adapt. We conduct regular, comprehensive training sessions for our engineers, technicians, and assembly staff, covering new software updates, advanced manufacturing techniques, and the latest safety protocols. For example, when we introduced more advanced robotic welding systems, every relevant staff member underwent intensive certification training, ensuring they could operate and troubleshoot the new equipment effectively. This proactive investment in human capital directly counters the challenge of "high operator turnover" by building a highly skilled, adaptable workforce that is proficient with our complex technologies.

Furthermore, our training initiatives extend beyond technical skills to foster a deeper understanding of our company's innovations and customer needs. We educate our production teams on the specific benefits of features like the BNL Front-Feeding Innovation (which increases feeding efficiency by ~40% and reduces operator labor by ~40%) and the Zero-Waste Tail Material Innovation (which maximizes material utilization). This comprehensive understanding empowers our employees to contribute more effectively to quality control and process improvement, as they grasp the tangible impact of their work on our clients' operations. By ensuring our team is not only highly skilled but also deeply knowledgeable about our unique product features and customer benefits, we fortify our ability to consistently produce machines that are "easy to operate and maintain," reinforcing MZBNL’s reputation for both technological prowess and user-centric design.

Robust Supplier Partnerships and Global Service Network Expansion

To effectively navigate the complexities of global supply chains and ensure consistent product delivery, a critical strategic solution has been the cultivation of robust, long-term supplier partnerships. We view our suppliers not merely as vendors, but as extensions of our own manufacturing ecosystem. This involves more than just transactional relationships; it entails collaborative planning, shared quality standards, and mutual investment in R&D. For example, we work closely with key component suppliers in Germany for high-precision laser optics and control systems, engaging in joint design reviews to ensure components are perfectly optimized for our machine architecture. This deep integration allows us to mitigate risks associated with fluctuating material costs and unexpected lead times, ensuring a stable and reliable flow of high-quality parts that underpins our "high-speed and high-precision cutting" machine capabilities.

Beyond our direct manufacturing inputs, another crucial solution addresses the client-facing pain points related to after-sales support and spare parts availability, which clients like Ahmed Al-Farsi value highly. We have strategically invested in expanding our global service network, building a comprehensive system of local agents and distributors across our main export countries, including Southeast Asia, the Middle East, Europe, and North America. This localized presence ensures that our clients receive prompt technical assistance, hands-on training, and readily available spare parts, directly countering the "lack of local service support" and "long machine lead times" that Ahmed experienced with previous suppliers. For example, if a client in the UAE requires a specific part, our local distributor can quickly supply it, minimizing downtime and ensuring uninterrupted operations.

This dual strategy of strong supplier partnerships and an expansive global service network creates a resilient framework for our operations. The reliable supply chain ensures our production facility maintains efficiency, while the widespread service network ensures our clients receive world-class support post-purchase. Furthermore, this network enables us to gather invaluable real-world feedback from diverse markets, informing future product development and ensuring our machines continue to meet evolving industry demands. For instance, insights from our Middle East clients regarding specific environmental operating conditions can lead to design modifications that enhance machine durability in hot climates. This comprehensive, two-pronged approach ensures that MZBNL not only produces superior machinery but also provides the end-to-end support that builds lasting client relationships, even fostering opportunities for clients like Ahmed to consider becoming regional distributors.

Lean manufacturing reduces wasteDoğru

The text explicitly states that lean principles focus on eliminating various forms of waste like overproduction and unnecessary transport.

R&D only focuses on new productsYanlış

The text clarifies that R&D also innovates processes and refines existing technologies, not just developing new products.

Sonuç

At MZBNL, our production facility embodies 25 years of innovation, seamlessly blending advanced technology with a client-centric approach. We overcome manufacturing complexities by embracing smart automation, pioneering unique innovations, and cultivating strong global partnerships, ensuring every machine delivers unparalleled precision, efficiency, and reliability for our diverse clientele worldwide.

-

Discover how automation enhances speed and accuracy in metal fabrication ↩

-

Explore the role of sensor tech in optimizing manufacturing and reducing waste ↩

-

Learn about ISO certification's role in ensuring quality and safety in manufacturing ↩

-

Discover how Front-Feeding increases efficiency and reduces labor ↩

-

Understand IoT's impact on manufacturing productivity and reliability ↩

-

Learn how robotic welding ensures uniform weld quality and structural integrity ↩

-

Learn about the complexities and benefits of operating within global supply chains. ↩

-

Understand how modular design can enhance manufacturing flexibility and efficiency. ↩

-

Sürekli iyileştirmenin inovasyonu nasıl teşvik ettiğini ve gelecekteki taleplere nasıl uyum sağladığını keşfedin ↩

-

No-CAD sistemlerinin operasyonları basitleştirmedeki avantajlarını anlamak ↩

Sorularınız mı var veya daha fazla bilgiye mi ihtiyacınız var?

Kişiselleştirilmiş yardım ve uzman tavsiyesi için bizimle iletişime geçin.