Tüp Lazer Kesim Makineleri Üretim Verimliliğini Nasıl Artırır?

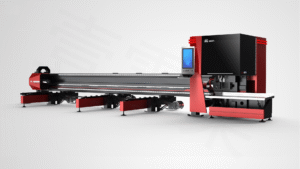

Struggling with slow, traditional tube processing methods? These outdated techniques (manual sawing/oxy-fuel cutting)1 often lead to high material waste, labor costs, and production bottlenecks, hindering your ability to compete. Modern tube laser cutting machines offer a transformative solution, revolutionizing your manufacturing efficiency and output quality.

Tube laser cutting machines enhance manufacturing efficiency by automating complex cutting tasks, increasing precision, reducing material waste, and significantly speeding up production cycles compared to traditional methods. This technology streamlines workflows and boosts overall productivity.

The leap from conventional methods to laser precision isn't just an upgrade; it's a fundamental shift in how we approach metal fabrication. As someone who has witnessed this transformation firsthand at MZBNL, I've seen businesses unlock unprecedented levels of productivity. Let's explore how these machines achieve such remarkable results and what it means for your operations.

Beyond just speed, the integration of tube laser cutters fundamentally redefines the manufacturing landscape. Consider the architectural sector, where intricate designs are paramount. Previously, achieving these designs meant multiple manual steps, each a potential point of error. Now, a single machine can execute complex profiles with unmatched accuracy. Research from industry analysts indicates that businesses adopting advanced laser cutting see, on average, a 25-30% reduction in production time2. For instance, one of our clients, Ahmed Al-Farsi from the UAE, transitioned his metal fabrication business, initially bogged down by manual processes for railing production, to our automated laser tube cutters. The result was not just faster output, but a significant improvement in consistency, allowing him to take on larger, more complex contracts. This isn't just about cutting metal; it's about cutting down inefficiencies across the entire value chain.

What are the key features of tube laser cutting machines?

Are you unsure what truly sets modern tube laser cutting machines apart? Without understanding their core capabilities, you might miss out on features crucial for optimizing your specific production needs, potentially leading to a less-than-ideal investment. Let's delve into the key features that make these machines indispensable for efficient, high-quality tube fabrication.

Key features of tube laser cutting machines include high-speed precision cutting, automated loading/unloading, advanced CNC control, the ability to process various tube shapes and materials, and often, integrated software for design and operation, like MZBNL's No-CAD system.

Understanding these features is the first step towards appreciating the sheer power and versatility of tube laser cutting technology. It’s not just about a single capability, but how these elements work in concert to deliver exceptional results. For example, at MZBNL, we’ve focused on innovations like our No-CAD system, front-feeding mechanisms, and zero-waste tail material designs, which directly address common pain points in manufacturing. These aren't just abstract concepts; they translate into tangible benefits for businesses like Ahmed's, who sought ease of use and efficiency. We’ll explore how these specific attributes contribute to a more streamlined and productive workflow.

The capabilities of modern tube laser cutting machines are extensive, driven by continuous innovation in both hardware and software. These features are designed not just to cut metal, but to transform the entire fabrication process, making it faster, more accurate, and more cost-effective. When I speak with clients like Ahmed Al-Farsi, who runs a mid-sized metal fabrication business in the UAE, his primary concerns revolve around upgrading production efficiency and finding automated solutions that are easy to install and operate. The features we build into our MZBNL machines, such as the No-CAD system and automated front-feeding, directly address these needs, turning complex tasks into manageable operations. Let's break down some of the most impactful features that define these powerful tools.

Advanced Cutting Heads and Laser Sources

The very essence of a tube laser cutting machine's performance lies in its cutting head and the laser source that powers it. Modern machines predominantly utilize fiber lasers, which have become the industry standard for several compelling reasons. Fiber lasers are celebrated for their exceptional energy efficiency, often converting a higher percentage of electrical power into laser power compared to older CO2 lasers. This efficiency translates into lower operating costs and a reduced environmental footprint. Moreover, fiber lasers require significantly less maintenance, as they lack the complex mirror systems and gas consumables associated with CO2 technology. Their beam quality is another critical advantage, particularly when processing reflective materials like aluminum, brass, and copper, which can be challenging for CO2 lasers. The precision of the cutting head itself is paramount. Many are equipped with features like auto-focus, which automatically adjusts the laser's focal point to accommodate variations in material thickness or surface imperfections, ensuring consistent cut quality without manual intervention. Collision protection systems are also common, safeguarding the delicate cutting head from accidental impacts, which could otherwise lead to costly repairs and downtime.

The power output of the laser source is a crucial determinant of the machine's capabilities. Higher laser power generally allows for faster cutting speeds, especially in thicker materials, and expands the range of materials that can be processed effectively. However, it's not merely about the raw wattage; sophisticated control over the laser output is equally important. Advanced power modulation allows the laser to pulse rapidly or vary its intensity with extreme precision. This control is vital for creating intricate patterns, achieving fine details on delicate parts, and producing clean, sharp edges with minimal heat-affected zones (HAZ)3. A smaller HAZ is particularly important in applications where the material's structural integrity or metallurgical properties must be preserved, such as in the manufacturing of medical devices or aerospace components. This level of control ensures that even complex geometries can be cut with high fidelity to the original design.

At MZBNL, we've consistently seen how the careful selection and integration of cutting-edge laser sources and intelligent cutting heads empower our clients to tackle diverse manufacturing challenges. Ahmed's company in the UAE, for example, serves both the architectural metalwork sector, requiring aesthetic precision, and the automotive parts industry, demanding robust, functional components. The ability of our machines to deliver consistently accurate cuts across a wide spectrum of tube profiles, materials, and thicknesses – a capability largely due to advanced laser control and responsive cutting head technology – was a decisive factor in his investment. Our internal research and client feedback indicate that a well-matched laser source and cutting head can enhance cutting speeds by as much as 30-40% on specific materials and applications when compared to less optimized or older generation systems, directly impacting productivity and cost-effectiveness.

Automation and Material Handling Systems

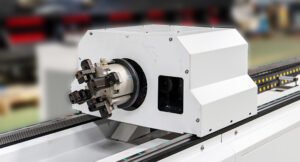

Automation is a defining characteristic of modern manufacturing excellence, and tube laser cutting machines are at the forefront of this trend. Features such as automatic bundle loaders represent a significant leap in efficiency. These systems can take a large bundle of raw tubes – often weighing several tons – and autonomously feed them into the machine one by one. The loader automatically singulates each tube, orients it correctly, and delivers it to the cutting area. This continuous, automated process drastically minimizes the need for manual labor in material loading, freeing up operators for other value-added tasks and reducing physical strain and the risk of injury associated with heavy lifting. Such systems can typically handle a variety of tube lengths, shapes (round, square, rectangular), and sizes, adapting to different production runs with minimal setup changes.

The automation doesn't stop at loading. Increasingly sophisticated automated unloading and part-sorting systems are becoming integral to high-productivity laser cutting cells. Once a tube has been processed, these systems can distinguish between finished parts and scrap material. Finished parts can then be carefully unloaded and sorted into designated bins or onto conveyors, perhaps even palletized, ready for the next stage of production or shipping. This automation in the post-cutting phase further reduces manual handling, prevents damage to freshly cut parts, improves workshop organization, and ensures a smooth, continuous flow of materials. Consider the high-volume production demands of the furniture industry or automotive component manufacturing; automated handling ensures that the laser cutter's high speed isn't bottlenecked by slow manual unloading and sorting. Our MZBNL front-feeding innovation, which automatically pulls the tube in from the front, is a prime example of optimizing this process, increasing feeding efficiency by approximately 40% and concurrently reducing operator labor intensity by a similar margin. This ergonomic and efficiency-driven design directly contributes to a more productive and safer working environment.

The cumulative impact of these automation features on overall productivity is profound. Studies from organizations like the Manufacturing Technology Centre (MTC) have demonstrated that well-implemented automation in material handling within fabrication environments can slash cycle times by up to 50% in certain scenarios. For Ahmed, whose business plan involved scaling up the production of automotive parts and architectural elements, the automated feeding and potentially automated unloading capabilities of our machines were a critical enabler. It allowed his company to confidently pursue larger order volumes and more complex projects without needing a proportional surge in manpower, a key consideration for any business focused on sustainable growth and improved operational leverage. This shift from manual to automated handling is fundamental for businesses striving for higher throughput, consistent output quality, and a competitive edge in a demanding market.

| Özellik | Manual Process Time (Est.) | Automated Process Time (Est.) | Efficiency Gain |

|---|---|---|---|

| Tube Loading (per tube) | 2-5 minutes | 30-60 seconds | 75-80% |

| Part Sorting (per batch) | 15-30 minutes | 5-10 minutes | 60-67% |

| Setup Between Jobs | 20-40 minutes | 5-15 minutes | 62-75% |

| Unloading (per part) | 15-30 seconds | 5-10 seconds (integrated) | 67-80% |

Intelligent Software and Control Systems

The \"brain\" of any tube laser cutting machine is its sophisticated software suite and Computer Numerical Control (CNC) system. These systems have evolved dramatically, now offering highly intuitive graphical user interfaces, powerful nesting algorithms that optimize material usage by intelligently arranging parts on the tube, and seamless integration with industry-standard CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software. This integration allows design data to flow directly to the machine, minimizing errors and speeding up the programming process. However, one of the most transformative developments in recent years, and an area where MZBNL has been a pioneer, is the advent of systems that reduce or even eliminate the need for traditional CAD drawings for many standard cutting operations.

At MZBNL, drawing on our 25 years of experience in metal fabrication and responding to direct customer feedback, we pioneered and perfected a No-CAD Operating System for our laser tube cutting machines. The conventional workflow often required operators or engineers to return to a design office to create or modify complex 3D CAD drawings even for relatively simple cuts or standard profiles. This back-and-forth was notoriously inefficient and time-consuming. With MZBNL’s No-CAD system, operators can now process a wide variety of standard tube types (round, square, rectangular, oval) and common hole patterns (circles, slots, rectangles) simply by entering key parameters directly into the machine's control interface – no drawing is required for these tasks. This innovation dramatically enhances ease of use, drastically shortens setup times from potentially hours or days to mere minutes, and significantly lowers the skill threshold for machine operation. Ahmed specifically highlighted his preference for a \"turnkey solution that is easy to install and operate,\" and our No-CAD system was a direct answer to this need. It meant his operators, who might not be CAD specialists, could be trained and become proficient in just 1 day of on-site training, a stark contrast to the 15 days often required for training at the equipment factory with more complex systems. This was a critical advantage for him, especially considering his concerns about high operator turnover and the associated retraining burdens.

Beyond simplifying operations and reducing training time, intelligent software also underpins other critical efficiency-boosting features. A prime example is MZBNL’s Zero-Waste Tail Material innovation. Traditional laser tube cutting systems typically start cutting from the head of the tube and, due to the mechanics of chucking and feeding, often generate an unusable section of tail material at the end of the process, regardless of how well parts are nested. We re-engineered the cutting logic. Our system intelligently calculates cutting paths starting from the rear chuck as the origin point. This allows the machine to utilize the entire length of the tube more effectively, virtually eliminating leftover tail material as long as the remaining section of the tube is smaller than the product length itself (or can be used for a final, smaller part). This zero-tail design not only maximizes material utilization, providing a direct and significant impact on cost-effectiveness (especially with expensive materials like stainless steel or aluminum), but also contributes to overall cutting efficiency by minimizing unnecessary remnant handling. Industry reports and our own client data suggest that advanced nesting software combined with features like zero-tail cutting can improve material yield by an impressive 5-15%, delivering substantial annual savings.

Fiber lasers require less maintenanceDoğru

Fiber lasers lack complex mirror systems and gas consumables, making them more reliable and easier to maintain than CO2 lasers.

Higher laser power always means better cuttingYanlış

While higher power allows faster cutting, sophisticated control over laser output is equally important for precision and material integrity.

How do tube laser cutting machines impact manufacturing processes?

Are your current manufacturing processes plagued by bottlenecks and inefficiencies? Relying on outdated tube fabrication methods often leads to extended lead times, increased labor costs, and compromised quality, impacting your overall competitiveness. Discover how tube laser cutting machines streamline operations, reduce manual intervention, and integrate seamlessly to revolutionize your entire manufacturing workflow.

Snippet paragraph: Tube laser cutting machines impact manufacturing processes by significantly reducing setup times, enabling complex cuts in a single operation, improving material utilization through precise nesting, and allowing for greater design flexibility, thereby streamlining the entire production flow.

The introduction of a tube laser cutting machine is more than just adding a new piece of equipment; it's a catalyst for re-engineering entire manufacturing workflows. From the initial design phase to the final product assembly, its effects are far-reaching. As we've seen with clients at MZBNL, like Ahmed who sought to automate his manual workflows for producing architectural metalwork and vehicle parts, the impact extends beyond just cutting speed. It touches on inventory management, labor allocation, and even the ability to take on more complex projects. Let's explore these transformative effects in detail.

The integration of tube laser cutting technology fundamentally reshapes the landscape of manufacturing processes far beyond the immediate cutting operation. It acts as an enabler for leaner, more agile, and highly responsive production systems. When I discuss these impacts with potential clients, I often refer to the experience of established customers like Ahmed Al-Farsi. His goal was to automate existing manual workflows to enhance efficiency and expand his business in architectural metalwork and vehicle parts. The tube laser cutter became the cornerstone of this transformation, not just by replacing old machines but by allowing a complete rethinking of how work flowed through his shop. This technology collapses multiple traditional steps into one, offering a paradigm shift in how products are conceived, designed, and manufactured.

Streamlining Design to Production Workflow

One of the most profound impacts of tube laser cutting machines is the dramatic simplification and acceleration of the entire workflow from initial design concept to finished part. Traditional tube fabrication methods are often characterized by a sequence of discrete, labor-intensive steps. A typical process might involve creating detailed 2D or 3D designs, then translating these into physical templates or manual layout markings on the tube. This would be followed by separate operations such as sawing to length, drilling holes, milling slots or copes, and finally, extensive deburring and cleaning. Each of these handoffs and individual processes introduces opportunities for error accumulation, variability in quality, and significant additions to the overall lead time. Tube laser cutting machines, particularly those equipped with advanced integrated CAD/CAM software or innovative direct parameter input systems like MZBNL's No-CAD solution, consolidate the vast majority of these operations into a single, highly automated process on one machine.

This powerful integration means that design iterations and modifications can be implemented with unprecedented speed and ease. If a design requires adjustment, the changes can be made directly in the software, and the machine can produce the revised part almost instantaneously, without the need for re-tooling or extensive manual re-setup. This agility is invaluable in industries characterized by short product development cycles, frequent design updates, or a high degree of customization. For example, a manufacturer of retail display racks, a sector MZBNL serves, can use our machines to quickly adapt designs to new product dimensions or branding requirements, or offer clients unique, customized fixtures without incurring prohibitive costs or extended production delays. This capability to rapidly translate digital designs into physical parts is a cornerstone of modern, responsive manufacturing.

Ahmed's experience in the UAE, where he supplies intricate architectural metalwork for railings and facades, perfectly illustrates this benefit. Previously, realizing complex, non-standard railing designs involved painstaking manual layout, cutting, and shaping by skilled craftsmen. With the MZBNL laser tube cutter, his team can now take a sophisticated digital design and directly produce components featuring complex copes, precise notches, weld preps like bevels, and intricate patterns, all in a single, continuous operation. This has not only slashed his project lead times significantly but also expanded his capacity to undertake more architecturally challenging and lucrative projects, aligning perfectly with his business expansion goals. Industry data consistently shows that such highly integrated digital manufacturing systems can reduce the critical design-to-part time by as much as 70-80% for components with moderate to high complexity, a truly transformative impact on operational speed.

Enhancing Production Flexibility and Customization

Tube laser cutting machines provide an unparalleled level of production flexibility, enabling manufacturers to efficiently process an extensive variety of tube shapes, sizes, and materials. These machines are not limited to simple round tubes; they can adeptly handle square, rectangular, oval, and even custom-extruded profiles. The range of processable materials is also broad, typically including various grades of mild steel, stainless steel, aluminum, copper, and brass. This inherent versatility allows manufacturers to diversify their product offerings and cater to a wider range of customer needs without the necessity of investing in a multitude of different specialized machines for each type of job or material. This consolidation of capabilities into a single platform is a significant economic and operational advantage.

A key enabler of true manufacturing agility is the ability to switch between different cutting jobs and diverse part designs with minimal setup time. Modern tube laser cutters excel in this regard, often featuring quick-change chucking systems, automatic nozzle changers, and intuitive software interfaces that allow for rapid loading of new programs and material parameters. This capability makes it economically viable to produce small batches or even one-off custom parts with nearly the same efficiency as large, repetitive production runs. This is particularly beneficial for businesses serving niche markets or those offering highly customized products, such as manufacturers of specialized medical equipment, bespoke fitness apparatus, or custom automotive components. Our MZBNL machines, designed with features like the quick-change chucks and the streamlined No-CAD parameter input for standard jobs, empower operators to rapidly adapt to new cutting requirements, thus maximizing machine uptime and responsiveness to customer orders.

This enhanced flexibility directly translates into a company's ability to react swiftly and effectively to fluctuating market demands and evolving customer preferences. Research conducted by industry analysts like the Aberdeen Group has consistently found that best-in-class manufacturers who strategically leverage flexible automation technologies, including advanced laser cutting, achieve significantly higher rates of on-time delivery, improved customer satisfaction scores, and greater overall profitability. For Ahmed, whose business model involves supplying components to both the cyclical construction sector and the dynamic automotive parts market in the Middle East, the capacity to quickly pivot production schedules based on incoming orders or new design specifications from clients is absolutely crucial for maintaining his competitive edge and ensuring business resilience. This adaptability is no longer a luxury but a necessity in today's fast-paced global marketplace.

| Process Stage | Geleneksel Yöntem | Tube Laser Cutting Impact |

|---|---|---|

| Design Transfer | Manual drawing interpretation, template creation | Direct CAD/CAM import or parameter input (No-CAD) |

| Material Setup | Manual loading, clamping, alignment for each op | Automated bundle loading, single setup for multiple ops |

| Cutting & Shaping | Sawing, drilling, milling, notching (separate ops) | All-in-one cutting, beveling, hole-making, etching |

| Secondary Operations | Deburring, grinding, manual finishing | Significantly reduced or eliminated due to cut quality |

| Lead Time | Days/Weeks for complex parts | Hours/Days, sometimes minutes for simpler parts |

| Labor Input | High, multiple skilled operators needed | Low, single operator can manage multiple machines |

Reducing Reliance on Specialized Labor Skills

While tube laser cutting machines are undoubtedly sophisticated pieces of high-technology equipment, significant advancements in software, control systems, and machine design have made them considerably easier to operate and maintain than their predecessors or many traditional fabrication machines. Conventional tube processing often demanded a team of highly skilled tradespeople – welders with specific certifications, machinists adept at setting up and running mills and lathes, and fitters precise in assembly. As Ahmed Al-Farsi noted from his experience in the UAE, finding, training, and retaining such specialized labor can be a major operational challenge, often exacerbated by high operator turnover rates and the subsequent, costly burden of continuous retraining.

The intuitive, often graphical, user interfaces of modern laser cutters, coupled with extensive libraries of pre-programmed cutting parameters for common materials and tube profiles, significantly lower the skill threshold required for proficient operation. Simplified maintenance routines also contribute to this accessibility. MZBNL’s proprietary No-CAD system stands as a prime example of this trend. By empowering operators to execute a wide range of standard cutting jobs simply by inputting dimensional parameters, rather than requiring them to possess expert-level CAD modeling skills, we have dramatically reduced the necessary training period. As I mentioned, this has condensed typical factory training durations of 15 days or more down to just a single day of effective on-site training. This not only makes it faster and more cost-effective to onboard new staff but also allows businesses to deploy their existing highly skilled workforce to more complex, value-added tasks such as advanced programming, quality control, or product development, rather than tying them to repetitive cutting operations.

Furthermore, the inherent automation designed into these machines reduces the physical demands placed on operators. Features like automated bundle loaders and MZBNL's innovative front-feeding mechanism, which we estimate reduces operator labor intensity by around 40%, contribute to improved workplace ergonomics and can lead to a reduction in musculoskeletal injuries often associated with manual material handling. While a good technical understanding is, of course, still beneficial for routine maintenance and advanced troubleshooting, the day-to-day operation of the machine becomes much more accessible to a broader range of employees. This operational ease allows businesses like Ahmed's to maintain high levels of productivity and quality consistency even if they face challenges in sourcing or retaining a large pool of highly specialized fabrication experts. This democratization of advanced manufacturing technology was a key selling point for Ahmed, who was keen to reduce his operational dependency on a small number of highly skilled, and often scarce and expensive, CAD operators and traditional machinists.

Laser cutters reduce setup timesDoğru

Tube laser cutting machines consolidate multiple operations into one, eliminating the need for re-tooling between different cutting jobs.

Laser cutters require CAD expertiseYanlış

Modern systems like MZBNL's No-CAD allow operators to input dimensional parameters without needing advanced CAD modeling skills.

What are the measurable benefits of using tube laser cutting machines?

Are you looking for concrete evidence of how tube laser cutters can boost your bottom line? Without quantifiable benefits, investing in new technology can feel like a leap of faith, making it hard to justify the expenditure. Let’s explore the measurable advantages—from material savings to increased throughput—that clearly demonstrate the ROI of tube laser cutting machines.

Snippet paragraph: Measurable benefits include significantly reduced material waste (up to 15% with features like MZBNL's zero-tail design), increased production speed (2-5x faster), lower labor costs per part, and improved accuracy leading to fewer reworks and assembly issues.

The decision to invest in advanced manufacturing technology like a tube laser cutting machine often hinges on its quantifiable impact on the business. It's not enough for it to be 'better'; it needs to deliver tangible returns. At MZBNL, we've seen clients achieve remarkable improvements in key performance indicators. For example, Ahmed's pursuit of automated solutions was driven by a desire to upgrade production efficiency in his UAE-based metal fabrication business. These machines deliver on that promise through several key metrics that we will now examine closely.

When businesses evaluate new capital equipment, the numbers must speak for themselves. Tube laser cutting machines offer a compelling suite of measurable benefits that directly impact profitability, efficiency, and competitiveness. As an integrated R&D, manufacturing, and sales organization with over 4000 global enterprise clients, we at MZBNL have amassed extensive data and witnessed countless success stories. Clients like Ahmed Al-Farsi, who prioritize a high cost-performance ratio, are looking for clear evidence of how such an investment will pay off. Let's delve into the specific, quantifiable advantages that make these machines a smart choice for modern manufacturers.

Significant Material Cost Reduction

One of the most immediate and financially impactful benefits of adopting tube laser cutting technology is the substantial reduction in material waste. Traditional tube processing methods, such as abrasive sawing or band sawing, inherently create a wider kerf – the width of material removed during the cut. While a single kerf might seem small, aggregated over thousands of cuts, this can amount to a significant volume of wasted material. Furthermore, conventional cutting approaches often struggle to optimize the use of each raw tube, frequently resulting in an unusable remnant or "tail piece" at the end of each stock length due to chucking limitations. This tail material, which can sometimes be quite long, goes directly to the scrap bin, representing a direct loss of valuable raw material.

Tube laser cutting machines address material waste on multiple fronts. Firstly, the laser beam itself creates an extremely narrow kerf, typically much smaller than mechanical cutting tools, instantly saving material on every cut. More significantly, the advanced CNC software that controls these machines usually incorporates sophisticated nesting algorithms4. These algorithms intelligently analyze the parts to be cut and arrange their layout along the length of the tube in the most compact way possible, minimizing the space between parts and maximizing the number of components that can be yielded from each stock tube. MZBNL’s proprietary Zero-Waste Tail Material innovation offers an even greater advantage. By fundamentally redesigning the cutting logic to calculate all operations from the rear chuck as the origin point, our system can often continue cutting useful parts until virtually the entire tube is consumed, effectively eliminating the traditional tail material scrap as long as the remaining section is smaller than the product's length or can be used for a final small part. This single feature can improve material utilization by several crucial percentage points. For businesses processing high volumes or expensive materials like stainless steel, titanium, or specialized alloys, these savings translate directly and substantially to the bottom line.

For a business like Ahmed Al-Farsi's in the UAE, which fabricates a considerable volume of metal tubing for architectural projects and automotive components, even a conservative 5-10% reduction in raw material waste can lead to tens of thousands of dollars in annual savings. Industry reports and case studies frequently cite overall material savings in the range of 5% to as high as 15%5 following the adoption of modern laser cutting technology coupled with optimized nesting strategies and features like zero-tail cutting. To put this in perspective, if a company has an annual expenditure of $500,000 on raw tube material, a 10% saving equates to an additional $50,000 in profit or cost reduction, significantly accelerating the return on investment for the laser cutting machine.

Drastic Improvement in Production Speed and Throughput

Speed is a paramount competitive differentiator in today's fast-paced manufacturing environment. Tube laser cutting machines offer a quantum leap in production speed compared to most conventional methods, especially when dealing with complex profiles or parts requiring multiple operations. A single laser cutting machine can execute a variety of tasks – precise cutting to length, drilling holes of various shapes and sizes, creating complex notches or copes for tube intersections, beveling edges for weld preparation, and even etching part numbers or assembly marks – all in a single setup, without needing to move the tube between different workstations. Traditional methods, in contrast, would typically require separate machines and multiple manual handlings for sawing, drilling, milling, and grinding operations, each adding to the cumulative cycle time.

The inherently high cutting speeds of modern fiber lasers, particularly when processing thin to medium-gauge materials, combined with the rapid acceleration and positioning capabilities of the machine's axes, result in very short processing times per part. When these fast cutting speeds are augmented by integrated automation features, such as automatic bundle loaders for continuous material supply and automated part unloading systems, the overall throughput of the manufacturing cell can be dramatically increased. MZBNL’s innovative front-feeding mechanism, for instance, is designed to enhance feeding efficiency by approximately 40% compared to some traditional side or rear manual loading methods. This means that significantly more parts can be produced within the same timeframe, or alternatively, the same production volume can be achieved much faster. This reduction in lead times allows businesses to be more responsive to customer demands, accept urgent orders, and improve their cash flow by shortening the order-to-delivery cycle. For manufacturers producing items like display racks, shelving units, furniture components, or fitness equipment, where production volumes can be substantial and deadlines tight, this increased capacity and speed are invaluable competitive assets.

Consider a practical scenario: a moderately complex tube component requires cutting to length, drilling four holes, and notching both ends for a T-joint. Using traditional methods, this sequence might easily take 5 to 10 minutes per part, including all the necessary handling, setup, and movement between machines. A modern tube laser cutter could potentially perform all these operations, with higher precision, in under a minute, sometimes in as little as 30-40 seconds depending on the material and complexity. We have consistently observed clients like Ahmed Al-Farsi reduce their cycle times for intricate components by over 60-70%, and in some cases even more. This efficiency gain enabled him to meet the stringent deadlines imposed by his construction and automotive OEM customers and to confidently bid on larger, more time-sensitive projects. This vastly improved speed translates directly into higher revenue potential per machine hour and optimized utilization of capital assets.

| Benefit Category | Traditional Method Metric | Tube Laser Cutter Metric | Typical Improvement |

|---|---|---|---|

| Malzeme Kullanımı | 75-85% yield | 90-98% yield (with nesting & zero-tail) | 10-20% improvement |

| Cycle Time (complex part) | 5-10 minutes/part | 0.5-2 minutes/part | 60-90% reduction |

| Setup Time (new job) | 1-2 hours | 10-30 minutes | 75-87% reduction |

| Labor per Part | High (multiple handlings) | Low (automated process) | 50-80% reduction |

| Rework Rate | 3-5% | <1% | 67-80% reduction |

| Energy Consumption/Part | Higher (multiple machines) | Lower (efficient single machine) | 20-40% reduction |

Enhanced Part Quality and Consistency Leading to Reduced Rework

The precision achieved by laser cutting technology is generally far superior to that of most traditional mechanical cutting methods. Lasers produce exceptionally clean, accurate cuts with a very small heat-affected zone (HAZ)6, especially when cutting parameters are optimized. This results in parts that consistently meet very tight dimensional tolerances, often within a few thousandths of an inch. This high level of accuracy is critical because it ensures that components fit together perfectly during subsequent assembly stages, significantly reducing or even eliminating the need for time-consuming manual adjustments, grinding, or rework. This "fit-first-time" capability streamlines the entire assembly process, saving both time and labor costs downstream.

Consistency is another hallmark advantage of laser cutting. Once a cutting program is created and validated, the laser cutter will produce identical parts repeatedly, batch after batch, with minimal variation, regardless of operator skill level. This high degree of repeatability is absolutely crucial for industries such as automotive parts production, medical equipment manufacturing, and aerospace, where component interchangeability, strict quality standards, and process validation are paramount. Furthermore, the optimized laser cutting process often results in edges with minimal burring and dross (resolidified molten material). This superior edge quality frequently minimizes or entirely eliminates the need for secondary deburring operations, which are often manual, labor-intensive, and can be a source of ergonomic issues and inconsistencies.

For Ahmed Al-Farsi, whose business supplies components to demanding Original Equipment Manufacturers (OEMs) in the automotive and construction sectors, the ability to deliver parts with consistently high quality and dimensional accuracy was a non-negotiable requirement. The implementation of tube laser cutting technology directly addressed this need. Fewer rejected parts, smoother and faster assembly processes for his customers, and reduced internal scrap rates all contribute to lower overall manufacturing costs and, importantly, higher customer satisfaction and a stronger reputation for reliability. Numerous industry studies and our own client data have shown that businesses implementing advanced laser cutting technology typically see a remarkable reduction in scrap and rework rates, often by over 75-80%. This not only saves the direct costs associated with wasted material, labor, and energy but also frees up capacity, improves overall operational efficiency, and enhances the manufacturer's standing as a quality supplier.

Tube lasers reduce material wasteDoğru

Advanced nesting algorithms and zero-tail cutting can improve material utilization by 5-15% compared to traditional methods.

Laser cutting requires more reworkYanlış

Laser cutting actually reduces rework by 75-80% due to superior accuracy and consistency in part production.

What challenges might arise with tube laser cutting machines?

Considering a tube laser cutter but worried about potential hurdles? Ignoring potential challenges like initial investment, training needs, or maintenance can lead to unexpected difficulties and hinder the realization of the technology's full benefits. Let's proactively address common challenges and discuss how to navigate them effectively for a smooth integration.

Snippet paragraph: Challenges with tube laser cutting machines can include the initial high investment cost, the need for operator training (though simplified by systems like MZBNL's No-CAD), maintenance requirements, and ensuring optimal material handling and workflow integration.

While the benefits of tube laser cutting machines are compelling, it's also important to approach this technology with a clear understanding of potential challenges. Forewarned is forearmed. At MZBNL, we believe in transparency and helping our clients prepare for every aspect of adopting new equipment. Ahmed, for instance, was concerned about operator training and potential service support issues based on past experiences with other suppliers. Addressing these concerns head-on is crucial for a successful implementation and long-term satisfaction.

Embracing any advanced manufacturing technology, including tube laser cutting machines, comes with a learning curve and potential obstacles. As a company with 25 years of experience and a commitment to technological innovation and tailored solutions, we at MZBNL understand the importance of a realistic perspective. My typical customer, Ahmed Al-Farsi, with his strong engineering background, is a hands-on decision-maker who actively seeks automated solutions but also wisely considers potential pain points. His past experiences with equipment lacking local service support or requiring highly skilled CAD operators made him cautious. Addressing these potential challenges proactively is key to a successful and rewarding adoption of this powerful technology.

Initial Investment and ROI Calculation

Undoubtedly, the most significant initial challenge for many businesses considering a tube laser cutting machine is the substantial upfront capital investment. These are highly sophisticated pieces of precision engineering, incorporating advanced laser sources, robust mechanics, intelligent CNC controls, and often complex automation systems. Consequently, their price can range from tens of thousands of dollars for smaller, more basic models to several hundred thousand dollars, or even more, for high-power, large-format machines with extensive automation features like bundle loaders and automated part sorting. This initial outlay requires careful financial planning, thorough justification, and a clear understanding of the long-term financial benefits. It's not a decision to be taken lightly, especially for small to medium-sized enterprises (SMEs).

To effectively navigate this financial hurdle, conducting a comprehensive and realistic Return on Investment (ROI) calculation7 is absolutely essential. This analysis must go far beyond simply comparing the machine's purchase price to an arbitrary payback period. A robust ROI model should meticulously quantify all potential cost savings, including reduced material waste (thanks to better nesting and features like MZBNL's Zero-Waste Tail Material innovation), lower direct and indirect labor costs per part (due to automation and consolidated operations), decreased energy consumption compared to multiple older machines, and a significant reduction in rework and scrap. Simultaneously, the calculation must project potential revenue increases stemming from higher throughput, the ability to take on more complex and higher-margin jobs, faster lead times attracting new customers, and improved overall competitiveness. Financial aspects such as available financing options, equipment leasing agreements, and potential government grants or tax incentives for investments in advanced manufacturing technology should also be thoroughly explored, as these can significantly impact the net investment and cash flow. Ahmed, for example, specifically stated that he "values high cost-performance ratio over low price," indicating his willingness to invest if the long-term benefits clearly justify the initial expenditure.

We at MZBNL make it a priority to work closely with our prospective clients to help them develop a clear and compelling financial justification for investing in our laser tube cutting solutions. By providing detailed, conservative estimates on efficiency gains, tangible material savings (often showcasing the specific impact of our No-CAD system on setup time or the Zero-Waste feature on yield), and demonstrable reductions in labor requirements per part, we assist them in building a strong, data-driven business case. For instance, if a machine investment is $200,000, but credible projections show annual operational cost savings of $70,000 (from materials, labor, energy) and the capacity to generate an additional $30,000 in profit from new or expanded business, the simple payback period is just two years. More sophisticated ROI analyses considering the time value of money, like Net Present Value (NPV) or Internal Rate of Return (IRR), would further solidify the financial attractiveness of such an investment, making it a strategically sound decision rather than just an expense.

Operator Training and Skill Requirements

While modern tube laser cutting machines are intentionally designed to be more user-friendly and intuitive than ever before, operating and maintaining this advanced technology still necessitates a certain baseline level of skill and dedicated training. Operators need to acquire a solid understanding of the machine's various functions, learn how to safely load and unload materials, navigate the control software to select programs or input parameters (even with systems like No-CAD), perform routine daily and weekly maintenance checks, and adhere strictly to all safety protocols associated with Class IV laser systems8. Ahmed Al-Farsi’s previous concerns regarding high operator turnover and the subsequent, recurring burden of retraining underscore this area as a critical consideration for any business adopting new CNC technology. The challenge isn't just the initial training, but ensuring knowledge retention and ongoing skill development.

The primary challenge in this domain often lies in either finding existing personnel with the requisite aptitude and technical inclination or developing these skills within the current workforce. Furthermore, operators must become proficient not just with generic laser cutting principles but with the specific machine model and its unique software interface and capabilities. This is precisely where MZBNL’s innovations, such as our pioneering No-CAD Operating System, provide a significant advantage. By drastically simplifying the operational requirements for a wide range of standard cutting tasks – allowing parameter input instead of demanding intricate CAD expertise – we have substantially reduced the traditional training barrier. As I've mentioned, this innovation has condensed the typical 15-day intensive factory training period common with more complex systems down to an highly effective 1-day on-site training program. This not only lowers the initial training cost and time investment but also makes it easier to cross-train multiple employees, thereby increasing operational flexibility and reducing dependence on a single "expert" operator.

Moreover, the availability of continuous, accessible, and high-quality training resources and responsive technical support from the equipment supplier is absolutely vital for long-term success. This support ecosystem should ideally include comprehensive, clearly written operational and maintenance manuals (in the user's language), online tutorials or video resources, and a readily available helpdesk for troubleshooting. At MZBNL, we also place strong emphasis on preventative maintenance training, empowering our clients' operators to proactively care for their machines and handle many minor issues independently, thus reducing reliance on external service technicians and minimizing potential downtime. A well-trained, confident operator is not merely a button-pusher; they become a key asset in maximizing the machine's uptime, optimizing its performance, and ensuring consistent output quality. Investing in thorough and ongoing operator training should therefore be viewed not as an operational expense, but as a crucial investment in sustained productivity and manufacturing excellence.

| Challenge Area | Traditional Approach Concern | MZBNL Solution / Mitigation Strategy |

|---|---|---|

| Initial Cost | High capital expenditure, difficult justification | Detailed ROI analysis, financing partner referrals, cost-effective solutions with high value |

| Operator Skill | Need for CAD experts, long & costly training | No-CAD system (1-day training), intuitive interface, simplified operation |

| Maintenance | Unexpected downtime, specialized technicians needed | Preventative maintenance training, remote diagnostics, readily available spare parts |

| Integration | Disrupting existing workflow, shop floor layout | Phased implementation support, workflow consultation, compact machine footprints |

| Technical Support | Slow response times, lack of local presence | Global distributor network, responsive after-sales service, remote support |

| Material Versatility | Difficulty with certain materials or profiles | Advanced laser sources, optimized cutting parameters, application support |

Maintenance, Consumables, and Technical Support

Like any sophisticated piece of industrial machinery, tube laser cutting machines demand regular, diligent maintenance to ensure they operate at peak performance, maintain their accuracy, and achieve their expected operational lifespan. This proactive upkeep involves a range of tasks, including the routine cleaning of sensitive optical components (lenses, protective windows), periodic checks and adjustments of beam alignment, timely replacement of consumable parts such as nozzles and ceramic insulators, and scheduled servicing of critical subsystems like the laser source, chiller unit, and motion system components. Neglecting these essential maintenance routines can swiftly lead to a degradation in cut quality, an increase in unexpected machine downtime, reduced processing speeds, and potentially necessitate more extensive and costly repairs down the line.

The ongoing operational budget must also account for the cost of consumables and essential spare parts. Consumables, by their nature, wear out or are expended during the cutting process and include items like cutting nozzles (which vary by material type and thickness), focusing lenses, and protective windows for the optics. The frequency of replacement will depend on usage intensity and the types of materials being processed. Choosing a supplier, such as MZBNL, that ensures the ready availability of high-quality, reasonably priced spare parts is a crucial consideration during the machine selection process. Ahmed Al-Farsi, in his purchasing preferences, specifically prioritized suppliers with "proven technology and global references," and stressed the importance of "after-sales service and training support," including "spare parts availability and remote diagnostics." This reflects a common concern among experienced buyers who understand that the total cost of ownership9 extends far beyond the initial purchase price. MZBNL addresses this by maintaining a robust global distributor network and stocking critical spare parts strategically to minimize delivery times.

Access to reliable, responsive, and knowledgeable technical support is another absolutely critical factor for ensuring the long-term success and productivity of a tube laser cutting machine. In the unfortunate event that a machine experiences a fault or goes down unexpectedly, a swift and effective resolution is paramount to minimize production losses and maintain delivery schedules. This is where a supplier's established local presence, or their capability to provide robust remote diagnostic and support services, becomes invaluable. MZBNL's commitment extends beyond just selling a machine; we provide comprehensive post-sales training and ongoing support, including advanced remote diagnostic capabilities that allow our technicians to often identify and resolve issues without needing an immediate site visit. This ensures that our clients, whether they are based in our home market of China, or in our key export regions like Southeast Asia, the Middle East (like Ahmed), Europe, or North America, receive the timely and effective assistance they need. We firmly believe that the machine itself is only one component of the overall solution; unwavering, long-term support is equally important for our clients to maximize their return on investment and achieve sustained operational excellence.

Tube laser cutters require operator trainingDoğru

Even with simplified systems like No-CAD, operators need training on safety protocols and machine functions.

Maintenance can be skipped without consequencesYanlış

Regular maintenance is crucial to prevent quality degradation and costly repairs.

What recommendations can optimize the use of tube laser cutting machines?

Want to ensure you're getting the absolute most out of your tube laser cutting investment? Simply acquiring the machine isn't enough; without optimizing its use through proper training, workflow integration, and maintenance, you might not achieve its full efficiency potential. Let's explore key recommendations to maximize your machine's performance, longevity, and overall contribution to your manufacturing success.

Snippet paragraph: To optimize tube laser cutting machines, invest in comprehensive operator training, implement preventative maintenance schedules, utilize advanced nesting software for material efficiency, and continuously evaluate and refine your workflow integration for maximum productivity.

Owning a state-of-the-art tube laser cutting machine is a significant step, but truly unlocking its potential requires a strategic approach to its operation and integration. It’s about creating an ecosystem around the machine that supports peak performance. From my experience at MZBNL, working with clients like Ahmed who are keen on maximizing automation and efficiency, I’ve seen that a few key practices can make a world of difference. These aren't just technical tips but holistic strategies that encompass people, processes, and technology.

Acquiring a technologically advanced tube laser cutting machine is a major stride towards enhanced manufacturing capabilities, but the journey to peak operational efficiency doesn't end there. To truly maximize the return on this significant investment and harness its full potential, a proactive and strategic approach to its utilization is essential. As a representative of MZBNL, a company built on technological innovation and providing tailored solutions, I've seen firsthand how dedicated optimization efforts can transform a good investment into a game-changing asset. Our typical client, Ahmed Al-Farsi, who actively pursues automated solutions to upgrade production efficiency, would be keenly interested in practical strategies to get the most out of his laser tube cutting machine. These recommendations encompass operator proficiency, machine care, intelligent software use, and seamless workflow integration.

Comprehensive Operator Training and Skill Development

Even with the increasing sophistication and user-friendliness of modern tube laser cutting machines, including intuitive interfaces like MZBNL's No-CAD system, the importance of comprehensive and ongoing operator training cannot be overstated. Effective training should extend far beyond just learning the basic "on/off" and program loading procedures. Operators should develop a thorough understanding of the machine's capabilities and limitations, the nuances of cutting various materials (steel, stainless steel, aluminum, etc.) and different tube profiles, and the impact of adjusting key cutting parameters (such as laser power, cutting speed, assist gas type, and pressure) on cut quality and efficiency. Furthermore, equipping operators with basic troubleshooting skills can empower them to resolve minor issues quickly, minimizing reliance on external technicians and reducing costly downtime. Investing robustly in initial training is crucial, but equally important is fostering a culture of continuous learning and skill development to keep pace with software updates, new features, or evolving best practices in laser cutting.

Training programs should ideally not be limited to just one or two primary operators. Cross-training multiple staff members on the laser cutting machine creates operational redundancy and flexibility. This ensures that production can continue smoothly even if a key operator is absent due to illness, vacation, or attrition. For businesses like Ahmed's, which had previously experienced challenges with high operator turnover, establishing a robust internal training program, consistently supplemented by resources and updates from the equipment supplier, can help build a more resilient, skilled, and adaptable workforce. A critical component of any operator training regimen must be an exhaustive coverage of safety protocols. Lasers, even when fully enclosed as per Class 1 safety standards10 during operation, are powerful tools, and operators must be thoroughly versed in all safety procedures, proper use of personal protective equipment (PPE) if required during maintenance, and emergency protocols to ensure a safe working environment for everyone in the vicinity of the machine.

At MZBNL, we recognize the pivotal role of operator proficiency. That's why we provide thorough on-site training, which, for our No-CAD system, can effectively equip operators in just a single day. We also encourage our clients to identify and develop "super-users" or internal champions within their teams. These individuals can then act as mentors and trainers for new or less experienced operators, cascading knowledge throughout the organization. Alongside hands-on training, we supply detailed operational and maintenance manuals, and ensure our clients have access to our technical support teams for ongoing queries and guidance. The ultimate goal is to instill confidence and high-level proficiency in the operators, enabling them to leverage the machine's full capabilities safely, efficiently, and effectively. A well-trained and engaged operator is often the first line of defense in preventative maintenance, capable of spotting subtle changes in machine performance or cut quality that might indicate a developing issue before it escalates into a major problem.

Implementing a Proactive Maintenance Schedule

Adopting a reactive approach to maintenance – essentially waiting for something to break before fixing it – is an inefficient and often very costly strategy when dealing with sophisticated equipment like tube laser cutting machines. Unexpected downtime disrupts production schedules, can lead to missed delivery deadlines, and emergency repairs are typically more expensive than planned maintenance. Therefore, implementing a proactive, preventative maintenance (PM) schedule11 is absolutely essential for keeping the machine in peak operational condition, ensuring consistent cut quality, and significantly extending its productive lifespan. This PM program should involve a series of regular checks, scheduled cleaning of critical components (especially optics like lenses and protective windows, as well as nozzles), lubrication of moving parts as per manufacturer specifications, and the timely replacement of known wear parts (like filters or certain seals) before they reach a point of failure.

The machine manufacturer, such as MZBNL, will typically provide a detailed recommended PM schedule, outlining daily, weekly, monthly, and annual maintenance tasks. Strictly adhering to this schedule, and just as importantly, keeping meticulous logs of all maintenance activities performed, can significantly reduce the incidence of unexpected breakdowns and ensure the machine continues to perform to its original specifications. Training machine operators to perform many of the daily and weekly checks themselves can be a very effective strategy, as they are closest to the machine and most likely to notice any subtle changes in its operation or output. For a business owner like Ahmed Al-Farsi, who explicitly valued equipment reliability and sought suppliers offering strong after-sales service and support, understanding and committing to a diligent PM schedule would be a fundamental part of his operational strategy to maximize uptime and protect his investment.

Furthermore, leveraging advanced features like remote diagnostics, if offered by the supplier (as MZBNL does), can significantly aid in proactive maintenance. These systems can allow technicians to remotely monitor machine status, analyze error codes, and sometimes identify potential issues or drifts in performance before they become critical, enabling planned interventions rather than emergency responses. MZBNL consistently emphasizes the critical importance of preventative maintenance and provides clear, actionable guidelines and support to our clients. The relatively small investment in time and resources required for a robust PM program pays off handsomely in the form of reduced unscheduled downtime (industry data suggests effective PM can cut this by up to 50%), consistently high cut quality, lower long-term repair costs, and a longer, more productive life for the laser cutting machine.

| Optimization Area | Key Action | Beklenen Sonuç | MZBNL Support Example |

|---|---|---|---|

| Operator Skills | Invest in initial & ongoing training, cross-train | Higher efficiency, better quality, reduced errors, flexibility | 1-day No-CAD training, detailed manuals, super-user development |

| Maintenance | Implement rigorous Preventative Maintenance schedule | Increased uptime, longer machine life, consistent output | PM schedules, remote diagnostics, service support |

| Material Usage | Utilize advanced nesting software, zero-tail features | Reduced waste, lower material costs, improved profitability | Zero-Waste Tail Material innovation, nesting tips |

| Workflow Integration | Analyze & optimize material flow, job scheduling | Reduced bottlenecks, higher overall plant productivity | Consultation on process integration, automation advice |

| Software Utilization | Master all software features (CAD/CAM, No-CAD) | Faster programming, optimized cutting paths, new capabilities | No-CAD system training, CAD/CAM integration support, parameter libraries |

| Continuous Improvement | Regularly review performance, seek operator feedback | Ongoing efficiency gains, problem prevention | User forums, feedback channels, application notes |

Continuous Workflow Optimization and Software Utilization

A tube laser cutting machine, no matter how advanced, should not operate as an isolated "island of automation" within a manufacturing facility. To truly maximize its profound benefits, it must be seamlessly and intelligently integrated into the broader production workflow. This holistic approach involves optimizing the flow of raw materials to the machine and the movement of finished parts away from it, developing efficient job scheduling systems that minimize changeover times and maximize machine utilization, and critically, ensuring that downstream processes (such as bending, welding, or assembly) have the capacity to keep pace with the laser's significantly increased output. Regularly reviewing, analyzing, and refining these surrounding workflows is a key ongoing activity for sustained efficiency gains. Bottlenecks shifted from the cutting stage to a later stage still impede overall productivity.

Fully leveraging the diverse capabilities embedded within the machine's control software is another crucial aspect of optimization. This extends beyond basic program loading and execution. It includes mastering advanced nesting features to squeeze the maximum number of parts from every tube, thereby minimizing material waste. It involves understanding how to fine-tune cutting parameters (power, speed, gas pressure, focal point) for different materials, thicknesses, and desired edge qualities. Operators and programmers should also become proficient in utilizing any built-in diagnostic tools, performance monitoring features, or advanced cutting techniques (like fly-cutting for certain patterns) that the software offers. For users of MZBNL machines, this means not only fully understanding the power and simplicity of the No-CAD system for rapid setup of standard parts but also effectively integrating the machine with more comprehensive CAD/CAM systems for highly complex or unique 3D designs. Ahmed Al-Farsi’s expressed interest in "turnkey solutions that are easy to install and operate" underscores the importance of establishing an efficient, well-understood workflow from the very first day of operation.

Consider adopting principles of lean manufacturing12 around the laser cutting cell to further enhance efficiency. This might involve strategies such as minimizing Work-In-Progress (WIP) inventory around the machine, meticulously organizing tooling, consumables, and raw materials for quick and easy access (e.g., using 5S methodologies), and empowering machine operators to actively participate in identifying and suggesting process improvements. The goal should always be one of continuous improvement (Kaizen). As a high-tech enterprise with over 25 years of deep experience in metal fabrication and having served over 4,000 global enterprise clients, MZBNL often shares best practices and provides consultative advice to our clients on optimal workflow integration, drawing from a vast repository of successful implementations across diverse industries. Ultimately, it is the optimization of the entire system – encompassing the machine, the software, the people, and the processes – that truly drives transformative and sustainable efficiency gains in manufacturing.

Operator training reduces downtimeDoğru

Comprehensive training enables operators to troubleshoot minor issues quickly, minimizing reliance on external technicians.

Maintenance is only needed when issues ariseYanlış

Proactive preventative maintenance schedules are essential to prevent breakdowns and maintain peak performance.

Sonuç

Tube laser cutting machines profoundly enhance manufacturing efficiency by increasing speed, precision, and material utilization while reducing labor and operational complexities. Adopting this technology, supported by strategic optimization from partners like MZBNL, empowers businesses like yours to achieve superior productivity and a stronger competitive edge.

-

"Understand inefficiencies and limitations of traditional tube processing methods." ↩

-

"Explore studies showing how laser cutting boosts production speed and overall efficiency." ↩

-

"Learn about Heat-Affected Zone (HAZ) and why minimizing it is crucial for material integrity." ↩

-

Learn how nesting software intelligently arranges parts to maximize material yield and reduce waste. ↩

-

See industry data on material waste reduction (5-15%) using laser tube cutting technology. ↩

-

Discover how minimizing the HAZ with lasers maintains material integrity and part quality. ↩

-

Learn to evaluate financial viability of new manufacturing technology investments. ↩

-

Understand critical safety measures and regulations for operating high-power laser equipment. ↩

-

Discover factors beyond purchase price that influence long-term machinery costs. ↩

-

"Understand laser safety classifications and operator protection measures for industrial equipment." ↩

-

"Discover typical PM tasks and benefits for laser cutter longevity and consistent performance." ↩

-

"Explore core lean principles to enhance production efficiency and minimize operational waste." ↩

Sorularınız mı var veya daha fazla bilgiye mi ihtiyacınız var?

Kişiselleştirilmiş yardım ve uzman tavsiyesi için bizimle iletişime geçin.