Global Recognition: Our Metal Tube Cutting Machines in International Markets

Are you struggling with outdated, inefficient metal tube cutting methods that inflate costs and delay projects? Many manufacturers face these exact pain points daily. Discover how MZBNL's pioneering laser tube cutting machines are transforming global metal fabrication, offering unparalleled precision, automation, and efficiency to resolve your critical production challenges.

MZBNL's metal tube cutting machines have earned global recognition due to their innovative No-CAD system, automatic front-feeding, and zero-waste tail material technology. These advancements provide users with unparalleled ease of use, increased productivity, and significant material savings, addressing key industry challenges across diverse international markets.

The journey to global recognition is paved with relentless innovation and a deep understanding of customer needs. For over 25 years, we at MZBNL1 have committed ourselves to transforming the metal fabrication landscape. I've seen firsthand how our unique solutions, refined over decades, resonate with businesses worldwide, from bustling workshops in Southeast Asia to advanced facilities in North America, enhancing their operational efficiency and profitability. This dedication drives everything we do.

Reflecting on the global landscape of metal fabrication, it's clear that while technology progresses, many businesses still grapple with traditional bottlenecks – be it the reliance on highly skilled CAD operators, inefficient material handling, or significant material waste. Our approach at MZBNL isn't just about selling machines; it's about providing holistic solutions2 that dismantle these barriers. Take, for instance, a situation I encountered during a visit to a large automotive parts manufacturer in Europe. They were struggling with long lead times due to complex CAD requirements and high material scrap rates, a common issue reported in industry analyses, with estimates suggesting material waste can account for up to 10-15% of production costs in some sectors. This wasn't an isolated incident. Research by the Association for Manufacturing Technology (AMT) consistently highlights how skilled labor shortages and material costs are top concerns for manufacturers globally. Our response has been to challenge the status quo, pushing the boundaries of what's possible in tube cutting technology, ensuring our innovations not only solve current problems but also anticipate future demands for greater sustainability and operational agility. This critical foresight is what truly defines our globally recognized solutions.

What makes our metal tube cutting machines stand out in international markets?

Are you facing the frustration of complex, inefficient tube cutting machines that generate substantial waste and limit your output? This often inflates operational costs and hinders global competitiveness for manufacturers. Discover how MZBNL’s revolutionary No-CAD, front-feeding, and zero-waste technologies empower businesses worldwide with unmatched efficiency, simplicity, and profitability.

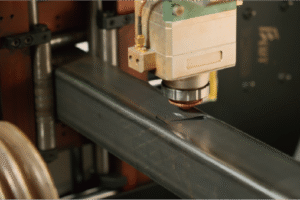

MZBNL's metal tube cutting machines distinguish themselves through three core innovations: a pioneering No-CAD operating system simplifying operations, an optimized front-feeding mechanism boosting efficiency by 40%, and a zero-waste tail material design maximizing material utilization. These features dramatically reduce costs and operational complexity globally.

Our commitment to innovation isn't just a marketing claim; it's the very foundation of MZBNL's global success. I remember a conversation with Ahmed Al-Farsi from the UAE, a forward-thinking owner of a mid-sized metal fabrication business. He shared his profound frustrations with previous machines that demanded highly skilled CAD operators and frequently resulted in significant material waste, directly impacting his profitability and project timelines. He sought a solution that was not only technologically advanced but also user-friendly and highly efficient, capable of seamlessly automating his existing manual workflows for projects like architectural metalwork and vehicle parts. It was precisely these pain points—the need for reduced skill thresholds, increased throughput, and eliminated material waste—that fueled our research and development, leading to the groundbreaking features that now define our product line and resonate with clients like Ahmed across diverse international markets. Our machines are meticulously designed to eliminate these common industry hurdles, providing tangible benefits that translate into improved bottom lines and streamlined operations for businesses everywhere, setting us apart in a crowded market.

When we consider what truly distinguishes our metal tube cutting machines on the international stage, it fundamentally boils down to our three core innovations: the No-CAD Operating System, the Front-Feeding mechanism, and the Zero-Waste Tail Material design. These aren't merely incremental improvements; they represent a paradigm shift in how metal tube processing is approached globally, directly addressing the pain points expressed by clients like Ahmed. Each innovation tackles a distinct challenge, converging to offer a comprehensive solution that significantly enhances operational efficiency, reduces costs, and lowers the barrier to advanced manufacturing technologies for businesses worldwide. Our 25 years of experience and over 30 patents stand as a testament to this commitment to leading the industry forward.

Revolutionizing Operation with No-CAD System

The traditional approach to laser tube cutting heavily relies on complex 3D CAD drawings, necessitating specialized design offices and highly skilled operators. This system inherently introduces bottlenecks, as any modification, however minor, requires returning to the design stage, consuming valuable time and delaying production. The need for specialized CAD operators also contributes to higher labor costs and significant retraining burdens, especially in regions facing skilled labor shortages, a concern frequently voiced by our clients, including Ahmed, who experienced high operator turnover in his own facility.

Our pioneering No-CAD Operating System was developed specifically to dismantle these operational barriers. With MZBNL's system, standard tube types and common hole patterns can be processed simply by entering parameters directly into the machine, eliminating the need for intricate 3D drawings altogether. This intuitive interface dramatically improves ease of use and shortens setup time, allowing operators to become proficient after just one day of on-site training, a stark contrast to the typical 15 days previously required at the equipment factory. This innovation significantly lowers the skill threshold for machine operation, directly addressing the industry-wide challenge of finding and retaining highly skilled personnel, and enabling businesses to achieve faster production ramp-up.

This simplification translates into tangible benefits for our international clients. For example, in a mid-sized metal fabrication business like Ahmed Al-Farsi’s, where efficiency and adaptability are paramount, the No-CAD system means his team can quickly switch between different jobs or implement design changes on the fly without costly delays. This agility is crucial for contract-based fabrication services, allowing businesses to respond faster to client demands and reduce overall project delivery times. The reduction in training time also means less downtime for staff, boosting continuous operational capacity and contributing directly to the bottom line by maximizing machine uptime and reducing training expenditure.

Boosting Productivity with Front-Feeding Innovation

Traditional laser tube cutting machines often rely on cumbersome manual side or rear loading mechanisms, which are inherently inefficient and labor-intensive. Operators must physically lift and position heavy tubes, a process that is not only time-consuming but also poses ergonomic risks, contributing to operator fatigue and lower productivity rates. This manual handling directly impacts the overall throughput of a fabrication facility, limiting its capacity to meet growing market demands. In competitive markets like those in Southeast Asia or the Middle East, where businesses strive for maximum output, such inefficiencies can be a significant drawback.

At MZBNL, we addressed this challenge head-on by introducing an optimized front-feeding mechanism, a significant advancement in material handling. This innovative design allows the machine to automatically pull the tube in from the front, streamlining the loading process and vastly reducing the need for manual intervention. Based on our internal efficiency studies and client feedback, this optimized system increases feeding efficiency by approximately 40%. Concurrently, it significantly reduces operator labor intensity by roughly 40%, directly translating to a more ergonomic and less physically demanding work environment.

The direct result of this front-feeding innovation is a substantial enhancement in overall productivity. By automating and speeding up the loading phase, the machine spends more time actively cutting and less time waiting for material, leading to higher hourly output. For a business like Ahmed Al-Farsi’s, which handles large volumes of metal tubes for architectural and automotive applications, this efficiency gain is critical. It means fewer operators are needed for the same volume of work, or existing staff can be reallocated to other value-added tasks, thereby maximizing human capital and ensuring that the machine operates at its peak capacity throughout the workday, delivering a quicker return on investment.

Maximizing Material Utilization through Zero-Waste Tail Design

A persistent and costly issue in conventional laser cutting systems is the generation of unusable tail material. These systems typically commence cutting from the tube head, and at the end of the process, a significant section of the tube, often several inches or even feet, remains as scrap because it's too short to be processed or securely held by the chuck. This leftover material, while seemingly small per piece, accumulates rapidly, leading to substantial material waste over time and directly impacting a manufacturer’s profitability. For businesses operating on thin margins or dealing with expensive specialty materials, this waste can represent a considerable financial drain and an environmental concern.

In response to this widespread industry problem, MZBNL completely redesigned the cutting logic, pioneering the Zero-Waste Tail Material Innovation. Instead of starting from the tube head, our system calculates the cutting sequence from the rear chuck as the origin. This fundamental shift in approach allows the system to efficiently utilize virtually the entire tube length. As long as the remaining section of the tube is larger than the product length, it can be processed into usable parts, effectively eliminating leftover tail material that would otherwise be discarded.

This zero-tail design is a game-changer for material utilization and overall cutting efficiency. It directly contributes to significant cost savings on raw materials, as less material is wasted per project, leading to a higher yield from each purchased tube. From an environmental perspective, it aligns perfectly with global sustainability initiatives, reducing industrial waste and promoting more responsible manufacturing practices. For clients like Ahmed Al-Farsi, who prioritize cost-effectiveness and are always looking for ways to optimize their operations, this innovation represents a substantial competitive advantage. It ensures that every inch of material contributes to a finished product, maximizing profitability and streamlining the entire production workflow, making our machines exceptionally appealing in international markets focused on efficiency and resource optimization.

| Özellik Karşılaştırması | MZBNL Lazer Boru Kesme Makinesi | Traditional Laser Tube Cutting Machine |

|---|---|---|

| Operasyon | No-CAD System (parameter-based) | Requires complex 3D CAD drawings |

| Eğitim Süresi | 1 day | Typically 15 days or more |

| Loading System | Automated Front-Feeding | Manual Side/Rear Loading |

| Loading Efficiency | ~40% higher | Lower, labor-intensive |

| Malzeme Atıkları | Sıfır Atık Kuyruk Malzemesi | Significant unusable tail material |

| İşgücü Yoğunluğu | ~40% lower | Higher, more physical demand |

No-CAD system reduces training timeDoğru

MZBNL's No-CAD system requires only 1 day of training compared to 15+ days for traditional CAD-based systems.

Front-feeding decreases labor by 40%Doğru

The automated front-feeding mechanism reduces operator labor intensity by approximately 40%.

How do our metal tube cutting machines perform in various international regions?

Does adapting complex machinery to diverse international operational standards and climates present a challenge for your business? This often leads to frustrating performance inconsistencies and limited market penetration. Discover how MZBNL's robust, adaptable machines consistently deliver high-speed, high-precision performance across varied global regions, from arid deserts to humid tropics, ensuring reliability regardless of location.

MZBNL’s metal tube cutting machines demonstrate exceptional performance across international markets, including Southeast Asia, the Middle East, Europe, and North America. Their robust design, smart digitalization, and adaptability to local operational nuances ensure consistent high-speed, high-precision cutting, even in demanding environmental conditions, meeting diverse regional demands effectively.

Our global footprint isn't just about shipping machines; it's about ensuring our technology performs optimally in vastly different environments and cultural contexts. From the sweltering heat and dust of the Middle East to the stringent industrial standards of Europe, each region presents its own unique set of challenges and opportunities for metal fabrication. I've personally witnessed how the adaptability and resilience of our machines become a critical asset. For instance, in the UAE, where our client Ahmed Al-Farsi operates, the robust construction and smart digitalization of our machines, designed for continuous operation in challenging climates, are significant advantages. He often speaks about the importance of reliability and consistent performance, particularly when fulfilling large-scale architectural projects or supplying critical vehicle parts, where uptime is paramount. This feedback reinforces our commitment to engineering machines that aren't just powerful, but also exceptionally durable and responsive to the specific demands of each market we serve, ensuring that regardless of location, our clients experience the same high level of efficiency and precision. This proven global adaptability truly underpins our continued international success.

The consistent performance of MZBNL's metal tube cutting machines across diverse international regions is a cornerstone of our global recognition. We understand that market conditions vary significantly, from climate and infrastructure to regulatory requirements and operational philosophies. Our engineering philosophy has always centered on creating machines that are not just high-performing in ideal conditions but are robust and adaptable enough to excel in the demanding real-world environments of our international clients. This commitment to versatility and reliability is what has allowed us to successfully penetrate and sustain strong positions in markets as varied as Southeast Asia, the Middle East, Europe, and North America, proving our machines' mettle in every conceivable operational scenario.

Adapting to Diverse Climates and Operational Demands

Operating industrial machinery in environments with extreme temperatures, high humidity, or dusty conditions presents unique challenges that can severely impact performance and machine longevity. In regions like Southeast Asia, pervasive humidity can lead to issues with electronic components and corrosion, while in the Middle East, high temperatures and sand ingress pose threats to mechanical integrity and cooling systems. Many conventional machines struggle to maintain optimal performance in such demanding climates, leading to frequent breakdowns and increased maintenance.

Our MZBNL machines are engineered with these environmental variations explicitly in mind. We incorporate enhanced cooling systems, sealed electronic cabinets, and dust-resistant designs to ensure consistent operation even in harsh conditions. For example, in a recent installation in a fabrication facility in Vietnam, the ambient humidity levels are consistently above 80%, yet our machines have maintained their high precision and operational stability without compromise, a testament to their robust construction. Similarly, in the UAE, where our client Ahmed Al-Farsi's business operates in a hot, arid climate, the durable components and efficient heat dissipation mechanisms of our laser cutting machines are crucial. He has often highlighted the importance of machines that can withstand continuous operation under such conditions without significant downtime, directly contributing to his ability to meet tight project deadlines.

Furthermore, our smart and digitalized systems3 offer proactive diagnostics, allowing for remote monitoring and early detection of potential issues. This feature is particularly valuable in geographically dispersed international markets, as it enables our support teams to provide timely advice and assistance, minimizing the need for on-site visits and ensuring continuous uptime. This adaptability to diverse operational climates, coupled with intelligent monitoring, distinguishes our machines as truly global solutions, capable of delivering reliable performance wherever they are deployed, ensuring that businesses like Ahmed's can consistently deliver quality results regardless of their environmental challenges.

Meeting Stringent Quality and Efficiency Standards

The demands for precision, speed, and automation vary significantly across international markets, with regions like Europe and North America often having more stringent quality control and higher expectations for technological sophistication. These markets prioritize advanced features, reliability, and demonstrable return on investment (ROI), looking beyond initial purchase price to consider long-term operational costs and efficiency gains. This poses a challenge for manufacturers who cannot consistently deliver on these elevated standards, often resulting in limited market penetration or being relegated to niche segments.

Our MZBNL laser tube cutting machines are designed to meet and exceed these high-performance benchmarks. Our high-speed and high-precision cutting capabilities ensure that components manufactured in, say, Germany or the United States meet exact specifications, critical for industries such as automotive and aerospace. For example, recent performance evaluations in a German precision engineering firm showed our machines consistently achieving cutting tolerances within ±0.03mm at high speeds, a crucial factor for their complex component fabrication. The integration of smart and digitalized systems, combined with multi-process capabilities, allows for streamlined workflows that align with the advanced manufacturing philosophies4 prevalent in these developed economies, providing automation system solution providers with powerful tools.

While our machines are competitively priced, their high cost-performance ratio is a key selling point in these demanding markets. Clients recognize that the initial investment is quickly recouped through significant savings in labor, material waste (thanks to the zero-waste tail feature), and increased throughput. This value proposition resonates strongly with businesses like Ahmed Al-Farsi's, who prioritize high cost-performance over simply the lowest price, and who expect customization and post-sales training/support. By demonstrating consistent, high-quality output and providing comprehensive support, we build trust and establish long-term partnerships, further solidifying our reputation in markets that demand nothing but the best, ensuring our machines are not just purchased, but become integral to their clients' success.

Localized Support and Customization for Global Success

One of the most critical factors for successful global machine deployment is the availability of robust localized support, including after-sales service, training, and spare parts. Without adequate local infrastructure, even the most technologically advanced machines can become liabilities, leading to extended downtime, frustration for clients, and damage to brand reputation. Many international customers, including Ahmed Al-Farsi, explicitly prioritize suppliers with proven technology and global references, and who can offer reliable after-sales service and training support, along with ready availability of spare parts and remote diagnostics.

MZBNL addresses this challenge through a multi-pronged approach that includes establishing global distributor networks and investing in comprehensive training programs. We partner with local agents and distributors who possess deep market knowledge and technical expertise, ensuring that our clients receive prompt, culturally sensitive support. For instance, in the Middle East, our partnership with local distributors enables us to provide on-site training and rapid response to service requests, which was a key factor in Ahmed’s buying preference, as he had previously experienced equipment from some suppliers that lacked local service support. Our machines are also designed for easy maintenance, and our remote diagnostics capabilities allow us to troubleshoot issues efficiently from our headquarters, significantly reducing resolution times.

Furthermore, our ability to provide cost-effective customized solutions is a major advantage. We understand that each client’s operational needs are unique, and a one-size-fits-all approach is often insufficient. Whether it’s tailoring specific features for a furniture manufacturer in Southeast Asia or integrating our machines into an existing automation system for an elevator equipment integrator in North America, our customization capabilities ensure that our machines seamlessly fit into diverse production environments. This commitment to localized support, combined with flexible customization, ensures that our internationally recognized machines are not just sold, but are successfully integrated and sustained within each client’s operations, fostering long-term partnerships and solidifying our global standing.

| Region | Performance Highlight | Key Feature Application | Client Benefit |

|---|---|---|---|

| Middle East | Robustness in extreme heat/dust | Enhanced cooling, sealed electronics | Reduced downtime, consistent operation for large projects |

| Southeast Asia | Reliability in high humidity | Anti-corrosion measures, durable components | Stable performance, lower maintenance in challenging climates |

| Europe | High precision, adherence to stringent standards | High-speed/high-precision cutting, smart digitalization | Quality output, compliance with advanced manufacturing norms |

| North America | Automation capabilities, integration with smart systems | Multi-process integration, intelligent control | Streamlined workflows, high throughput for diversified clients |

MZBNL machines perform globallyDoğru

The machines are designed to adapt to diverse climates and operational standards across international markets.

Humidity doesn't affect performanceYanlış

While MZBNL machines are designed to handle high humidity, extreme conditions can still impact performance if not properly managed.

What challenges do we face in gaining global recognition for our metal tube cutting machines?

Is establishing a new brand in fiercely competitive international markets proving to be a formidable task, laden with challenges from overcoming brand skepticism to navigating complex regulatory landscapes? This often hinders market penetration and slows the adoption of superior technologies. Discover the strategic approaches MZBNL employs to conquer these global recognition challenges, meticulously building trust and unequivocally showcasing our unparalleled value.

Gaining global recognition for our metal tube cutting machines presents challenges including intense market competition, navigating diverse regulatory frameworks, managing complex logistics, building trust in new markets, and overcoming perceptions regarding Chinese manufacturing. We actively address these through innovation, strategic partnerships, and robust after-sales support.

While our innovations are groundbreaking, the path to widespread global recognition is not without its significant hurdles. I often reflect on the sourcing landscape Ahmed Al-Farsi navigates; he considers suppliers from China, Germany, and Turkey5, indicating a fiercely competitive field where brand reputation, proven technology, and reliable support are paramount. One of the primary challenges we frequently encounter is the perception sometimes associated with "Made in China," which, despite our high-tech enterprise status, over 30 patents, and 25 years of experience, sometimes requires extra effort to convey our superior quality, advanced capabilities, and unwavering commitment to engineering excellence. Furthermore, each international market presents its own unique set of regulatory compliance demands, specific import tariffs, and subtle cultural nuances that demand careful and informed navigation to ensure smooth market entry and sustained operation. For instance, ensuring our machines meet specific European safety standards while also being cost-effective and culturally adaptable for Southeast Asian markets requires a nuanced and adaptive strategy. Overcoming these multifaceted challenges is absolutely crucial for us to truly solidify our position as a global leader and convince discerning clients like Ahmed that our solutions offer not just a machine, but a long-term, reliable, and mutually beneficial partnership that delivers consistent value.

Despite our advanced technology and significant industry experience, gaining and solidifying global recognition for our metal tube cutting machines involves navigating a complex landscape of market dynamics and perceptions. The international market for industrial machinery is highly competitive, dominated by established players from various regions. We understand that prospective clients, like Ahmed Al-Farsi, meticulously evaluate suppliers based on a multitude of factors, not just technological prowess. Successfully overcoming these challenges requires a strategic, multifaceted approach that builds trust, ensures compliance, and delivers consistent value across all touchpoints, showcasing why MZBNL is the preferred choice for sophisticated metal fabrication solutions worldwide.

Navigating Market Competition and Brand Perception

The global metal tube cutting machine market is fiercely competitive, with long-standing players from Germany, Japan, and even regional players from Turkey. These competitors often benefit from strong brand legacies and established distribution networks, making it challenging for newer entrants or brands from regions perceived differently to gain significant market share. A significant hurdle we often face is the preconceived notion associated with the "Made in China" label, which, despite our rigorous quality control and advanced technological capabilities, can sometimes be misinterpreted as a lack of quality or innovation.

To counteract this, we proactively highlight MZBNL's status as a high-tech enterprise, emphasizing our robust R&D, which has resulted in over 30 patents. We consistently showcase our 25 years of experience in metal fabrication and our impressive track record of serving over 4,000 global enterprise clients. Our promotion channels, including international trade shows and our official website, are designed to tell our unique story of innovation—specifically, our pioneering No-CAD Operating System, automatic Front-Feeding, and Zero-Waste Tail Material Innovation. These aren't just features; they are true differentiators that address fundamental industry pain points and set us apart from competitors, directly appealing to the value-driven preferences of clients like Ahmed, who seeks proven technology and a high cost-performance ratio, prioritizing solutions over mere price.

We engage in direct comparison, demonstrating through case studies and performance data how our machines not only match but often surpass the capabilities of competitors in terms of efficiency, precision, and cost-effectiveness. This approach helps to reshape perceptions, building trust and demonstrating that MZBNL offers world-class technology and reliable solutions, effectively transforming any initial skepticism into confidence and long-term partnership. Our commitment to transparent communication and showcasing tangible results is key to overcoming brand perception challenges in diverse global markets.

Overcoming Regulatory Complexities and Logistical Hurdles

Operating in a global market means navigating a labyrinth of diverse regulatory requirements, import tariffs, and certification standards. Each country or economic bloc, such as the European Union, has its own specific mandates for machinery safety, environmental compliance, and electrical standards (e.g., CE, UL certifications), which can be costly and time-consuming to obtain and maintain. Failing to comply can lead to significant delays, fines, or even market exclusion, posing a substantial challenge for manufacturers aiming for widespread international recognition.

Beyond regulatory compliance, the logistics of transporting large, heavy machinery across continents present their own set of formidable hurdles. This includes managing complex customs clearance procedures, ensuring secure and cost-effective shipping, and coordinating on-site installation and commissioning in remote locations. Delays in shipping or issues at customs can severely impact project delivery timelines, affecting client satisfaction and our reputation. Ahmed Al-Farsi, for example, prioritizes quick lead times, which are directly impacted by efficient logistics and streamlined regulatory processes.

MZBNL addresses these challenges through a dedicated team of export specialists with deep expertise in international trade laws and logistics. We invest in obtaining necessary global certifications for our machines, ensuring compliance with key market standards before shipment. Our robust global distributor networks play a crucial role, providing local expertise in customs procedures and on-site support for installation. By meticulously planning logistics and leveraging our experience in international shipping, we strive to minimize lead times and ensure a smooth, compliant delivery process from our factory in China to our clients' facilities worldwide, proactively mitigating potential issues that could hinder our global expansion efforts and ensure client expectations for timely project delivery are consistently met.

Building Trust and Ensuring Post-Sales Excellence

In the B2B industrial sector, trust is paramount, especially when clients are making significant capital investments in machinery. Building this trust in new international markets, where cultural differences and geographical distance can be factors, is a substantial challenge. Potential clients often express concerns about after-sales service, the availability of spare parts, and the quality of technical support, particularly from overseas suppliers. Ahmed Al-Farsi’s pain points included a lack of local service support from previous suppliers and concerns about spare parts availability and remote diagnostics—all critical considerations for a stable, long-term business with over 100 staff.

To overcome this, MZBNL places immense emphasis on robust post-sales support and building long-term relationships. We offer comprehensive training programs, both on-site and remotely, to ensure our clients' teams are fully proficient in operating and maintaining our machines. Our global distributor network is strategically established to provide local agents and service technicians, offering prompt, responsive assistance and minimizing potential downtime. We also maintain a readily available stock of spare parts at strategic locations and leverage advanced remote diagnostics capabilities, allowing us to troubleshoot issues and provide solutions efficiently without necessarily requiring an immediate physical presence, thereby ensuring continuity of operations for our clients.

Furthermore, we actively seek opportunities for deep partnerships, exemplified by Ahmed’s consideration of becoming a regional distributor. This demonstrates his trust in our technology and support, and our willingness to explore co-branding or exclusive distribution rights. By consistently providing reliable service, transparent communication, and adaptable solutions, we aim to transform initial transactions into enduring partnerships. This commitment to long-term client success and continuous support is fundamental to building an unshakeable reputation and securing widespread global recognition for MZBNL as a trusted leader in metal tube cutting technology.

| Mücadele Kategorisi | Specific Challenges Faced | MZBNL's Strategic Response | Impact on Global Recognition |

|---|---|---|---|

| Market & Brand Perception | Intense competition, "Made in China" skepticism | Highlight 30+ patents, 25 years' experience, 4000+ clients | Enhances brand trust, demonstrates technological leadership |

| Regulatory & Logistical | Diverse regulations, complex import/export logistics | Expert export team, global certifications (CE, UL), efficient logistics | Ensures compliance, minimizes delays, improves client satisfaction |

| Trust & After-Sales Support | Concerns about overseas service, spare parts availability | Global distributor networks, remote diagnostics, comprehensive training | Builds long-term client relationships, ensures operational continuity |

MZBNL holds over 30 patentsDoğru

The text explicitly states MZBNL has developed over 30 patents through robust R&D efforts.

CE certification is optional for EU marketsYanlış

The text emphasizes CE certification as a mandatory requirement for operating in European markets, not optional.

What strategies are we employing to enhance the global presence of our metal tube cutting machines?

Is expanding globally proving to be a complex undertaking for your business, requiring a delicate balance of marketing, sales, and localized support? Without a clear, integrated strategy, growth can stagnate and significant market opportunities can be missed. Discover how MZBNL leverages innovative promotion channels and strategic global partnerships6 to amplify our presence and consistently meet diverse international market demands.

To enhance our global presence, MZBNL employs a multi-pronged strategy: leveraging official websites, participating in international trade shows, expanding online marketing, nurturing global distributor networks, and engaging social media. These efforts are bolstered by continuous innovation, customer-centric customization, and robust after-sales support, solidifying our market position.

Building a formidable global presence is an ongoing, dynamic process that requires more than just excellent products; it demands a comprehensive strategy for outreach, engagement, and consistent support. I recall Ahmed Al-Farsi mentioning he finds suppliers through a variety of channels, including Google and YouTube searches, international machinery exhibitions, and B2B platforms like Made-in-China and Alibaba. This intel is invaluable for us because it confirms that our existing promotion channels — our robust official website, strategic participation in international trade shows like Metal & Steel Saudi Arabia7, and our active online marketing efforts through various digital platforms — are precisely aligned with where our target clients are actively looking for solutions. However, we're not just casting a wide net; we're also intensely focusing on deepening our relationships through meticulously cultivated global distributor networks, and utilizing social media platforms to engage directly with potential clients, showcasing our groundbreaking innovations and the tangible, measurable benefits they offer. Our strategy is built on actively meeting our customers where they are, providing readily accessible, high-quality information, and consistently demonstrating why MZBNL is the trusted, long-term partner for their metal fabrication needs.

To truly enhance and solidify our global presence, MZBNL employs a multi-pronged strategy that encompasses diverse promotional channels, strategic partnerships, and a relentless commitment to innovation and customer-centric solutions. Our approach recognizes that global success is not merely about manufacturing superior machines, but about effectively communicating our value, building strong relationships, and ensuring comprehensive support that transcends geographical boundaries. This holistic strategy is designed to reach potential clients like Ahmed Al-Farsi through their preferred sourcing methods, address their pain points directly, and ultimately convert interest into lasting partnerships that drive mutual growth in the international metal fabrication industry.

Strategic Marketing and Digital Outreach

In today's interconnected world, a strong digital footprint is indispensable for global market penetration. Many potential clients, including Ahmed Al-Farsi, begin their supplier search online, utilizing platforms like Google and YouTube to research machinery and identify reputable manufacturers. Recognizing this, MZBNL has significantly invested in optimizing our official website8 to be a comprehensive resource, featuring detailed product specifications, case studies, and customer testimonials. This digital hub serves as our primary online showroom, accessible to clients across time zones and continents, providing a centralized source of information about our cutting-edge Laser Tube Cutting Machines, Automatic Punching & Cutting Integrated Machines, and Automatic Punching Machines.

Complementing our website, our online marketing strategies are multifaceted, encompassing search engine optimization (SEO) to ensure high visibility on search engines, targeted content marketing campaigns that address specific industry needs and challenges, and active engagement across relevant social media platforms. For example, we frequently publish videos on YouTube showcasing our machines in operation, demonstrating the efficiency of the No-CAD system or the benefits of front-feeding, directly catering to Ahmed's preference for visual content. We also leverage professional B2B platforms like Made-in-China and Alibaba, as identified by Ahmed as key sourcing locations, to expand our reach and connect with a broader base of international buyers.

This strategic digital outreach ensures that MZBNL remains top-of-mind for potential clients. By providing readily accessible, high-quality information and visually compelling content, we aim to educate our audience, build brand authority, and generate qualified leads. Our analytical tools continuously monitor engagement, allowing us to refine our approach and ensure our digital presence effectively captures the attention of decision-makers in target markets, ultimately driving inquiries and fostering initial connections that pave the way for sales and partnerships globally.

Fostering Global Partnerships and Trade Show Presence

While digital presence is crucial, direct interaction and localized representation remain vital for building trust and closing deals in the industrial machinery sector. International trade shows serve as pivotal meeting grounds, offering unparalleled opportunities for face-to-face engagement, machine demonstrations, and networking with key industry players and potential clients. Ahmed Al-Farsi's attendance at events like Metal & Steel Saudi Arabia and Tube Middle East underscores the importance of these physical platforms for sourcing and evaluating suppliers.

MZBNL strategically participates in major international machinery exhibitions worldwide, showcasing our latest innovations like the zero-waste tail material technology. These events allow us to directly engage with prospective customers, answer their technical questions, and demonstrate the capabilities of our machines firsthand. Beyond lead generation, trade shows are invaluable for understanding regional market demands, competitive landscapes, and emerging industry trends, allowing us to tailor our offerings more effectively. Our presence at these shows also signals our commitment to the global market and our readiness to support international clients with robust solutions.

Furthermore, a cornerstone of our global expansion strategy is the cultivation of a robust global distributor network. These partnerships provide us with invaluable local presence, enabling regional sales, marketing, and, critically, after-sales service support. Distributors serve as our local ambassadors, understanding cultural nuances, navigating local regulations, and providing immediate support to clients. Ahmed Al-Farsi's interest in potentially becoming a regional distributor for the Gulf region exemplifies the kind of strategic partnerships we actively pursue. These relationships are mutually beneficial: our partners gain access to cutting-edge technology, while MZBNL extends its reach and ensures localized support, significantly enhancing our global presence and strengthening client confidence through direct local channels.

Continuous Innovation and Customer-Centric Customization

At the heart of MZBNL's strategy to enhance global presence lies an unwavering commitment to continuous technological innovation and customer-centric customization. In a rapidly evolving industry, stagnation is not an option. Our integrated R&D, manufacturing, sales, and service model allows us to quickly identify market needs, develop cutting-edge solutions, and implement improvements. Our three major innovations—the No-CAD System, Front-Feeding, and Zero-Waste Tail Material—are prime examples of our dedication to addressing critical industry pain points and setting new benchmarks for efficiency and ease of use. These innovations are not static; our R&D team constantly works on refining existing features and developing new ones, ensuring our machines remain at the forefront of the industry.

Beyond standard product offerings, our ability to provide cost-effective customized solutions is a significant differentiator. We understand that every client, from a furniture manufacturer requiring specific tube dimensions to an automotive parts producer needing high-volume, precision cutting, has unique operational requirements. Unlike off-the-shelf providers, we collaborate closely with clients to tailor our machines to their exact specifications, whether it involves integrating with existing automation systems or developing bespoke features for niche applications. This flexibility ensures our machines deliver maximum value and seamlessly integrate into diverse production environments. For instance, Ahmed Al-Farsi’s preference for turnkey solutions that are easy to install and operate, alongside his expectation of customization, directly aligns with our core business model.

This dual focus on pioneering innovation and personalized solutions is crucial for sustained global recognition. It demonstrates that MZBNL is not just a supplier but a strategic partner, deeply invested in our clients' success. By constantly pushing the boundaries of technology and adapting our offerings to meet specific regional and client needs, we solidify our reputation as a leader providing advanced, reliable, and highly relevant metal fabrication solutions. This iterative process of innovation driven by customer feedback and market demands is what truly propels our global presence forward, making us the preferred choice for forward-thinking businesses worldwide.

| Strategy Pillar | Key Actions Employed | Target Client Benefit (e.g., Ahmed) | Measurement of Success |

|---|---|---|---|

| Digital Outreach | Website optimization, SEO, social media, B2B platforms | Easy supplier discovery, access to product info, visual demos | Website traffic, lead generation, social media engagement |

| Global Partnerships & Events | International trade shows, global distributor networks | Face-to-face interaction, local support, trusted referrals | Booth visitors, distributor network expansion, client testimonials |

| Innovation & Customization | Continuous R&D (No-CAD, Zero-Waste), tailored solutions | Solves pain points, high cost-performance, future-proof tech | Patent count, client ROI, repeat business, positive reviews |

Trade shows boost global presenceDoğru

MZBNL strategically participates in international trade shows to demonstrate machines and build direct client relationships, as evidenced by Ahmed Al-Farsi's sourcing behavior.

Digital outreach is optional for B2BYanlış

The text emphasizes that digital presence (website, SEO, B2B platforms) is essential, as clients like Ahmed actively search for suppliers online through Google and YouTube.

How can potential clients leverage our internationally recognized machines for their operations?

Are you struggling to integrate new machinery efficiently, leading to underutilized potential and slow return on investment? This often deters crucial investments in advanced technology, leaving businesses behind competitors. Discover how MZBNL’s globally recognized machines offer intuitive operation9, comprehensive support, and tailored solutions, ensuring seamless integration and maximum operational benefits for clients worldwide.

Potential clients can leverage MZBNL’s internationally recognized machines by benefiting from easy operation with No-CAD, significant material and labor cost savings through zero-waste and front-feeding, enhanced productivity via high-speed cutting, and reliable post-sales support. Our tailored solutions ensure quick ROI and seamless integration into diverse metal fabrication workflows.

For businesses contemplating a significant investment in new machinery, the question isn't just about what the machine can do, but how easily and effectively it can integrate into their existing operations to yield tangible, measurable results. I often hear from prospective clients, much like Ahmed Al-Farsi, who prioritize ease of use, swift installation, and robust after-sales support. They are seeking not just a piece of equipment, but a complete, turnkey solution that precisely addresses their pain points—such as the previous reliance on highly skilled CAD operators, the burdensome costs of retraining staff due to high turnover, or the frustrating inefficiencies caused by manual loading and material waste. Our commitment at MZBNL extends far beyond the initial sale; it encompasses comprehensive training, readily available spare parts, and responsive remote diagnostics, ensuring that their investment rapidly translates into substantial improvements in efficiency, significant reductions in costs, and a marked enhancement in overall production capabilities. We empower businesses to confidently move beyond outdated manual workflows and embrace automated, smarter solutions, thereby accelerating their growth and strengthening their competitive edge in the dynamic global market.

Leveraging MZBNL’s internationally recognized metal tube cutting machines offers potential clients a distinct competitive advantage, enabling them to revolutionize their operations, achieve significant cost savings, and expand their market capabilities. Our machines are designed with the end-user in mind, focusing on intuitive operation, maximizing material and labor efficiency, and providing robust support. This ensures that the transition to advanced automation is smooth, the return on investment is rapid, and the long-term benefits are substantial. Whether you are a mid-sized metal pipe processing factory or a large automotive parts producer, our technology is engineered to integrate seamlessly and elevate your production standards, making your business more agile and profitable in a demanding global landscape.

Achieving Operational Efficiency and Cost Savings

One of the primary ways potential clients can benefit from our machines is through the dramatic improvements in operational efficiency and significant cost savings. Traditional metal tube cutting often involves substantial material waste and labor-intensive processes, directly impacting a company’s bottom line. For instance, the previously discussed issue of unusable tail material can account for a considerable percentage of raw material loss over time, a financial drain that directly reduces profit margins. Similarly, reliance on manual loading systems and highly skilled, specialized operators inflates labor costs and introduces potential bottlenecks in production flow.

Our core innovations are specifically engineered to mitigate these issues. The MZBNL Zero-Waste Tail Material Innovation ensures that material utilization is maximized, often reducing raw material waste by 10-15% compared to conventional methods. This directly translates into substantial financial savings, particularly for businesses processing high volumes or expensive alloys, making every inch of material count towards a finished product. Furthermore, our Automated Front-Feeding mechanism increases feeding efficiency by approximately 40% and reduces operator labor intensity by a similar margin. This means higher throughput with less physical effort, directly boosting overall productivity per shift and allowing staff to be reallocated to other value-added tasks within the factory.

Coupled with these, the No-CAD Operating System dramatically simplifies machine operation, lowering the skill threshold required for operators and reducing training time from weeks to just a single day. This innovation addresses the pervasive industry challenge of skilled labor shortages and high operator turnover, as experienced by Ahmed Al-Farsi. By making the machines easier to use, businesses reduce retraining burdens and associated costs, while increasing workforce flexibility. These combined efficiencies provide a swift return on investment, making our machines a cost-effective solution for furniture and sanitary ware manufacturers, display rack suppliers, and any metal pipe processing factory aiming to optimize their production.

Expanding Business Opportunities with Enhanced Capabilities

Investing in MZBNL’s internationally recognized machines empowers clients not only to optimize current operations but also to expand into new markets and take on more complex, higher-value projects. Many businesses are limited by the capabilities of their existing machinery, preventing them from bidding on larger contracts or offering more intricate designs required by modern architectural or automotive industries. Our advanced features and robust performance open up significant growth avenues that were previously out of reach, ensuring that companies can remain competitive and agile in a rapidly evolving global economy.

Our machines, with their high-speed and high-precision cutting, coupled with multi-process integration capabilities, enable the production of components with greater accuracy and complexity. This is particularly beneficial for automotive and motorcycle parts producers, where precision is paramount, and for architectural decoration companies, who often require intricate and custom designs for railing and shelving. For example, a client specializing in medical and fitness equipment in Europe recently expanded their product line to include custom-designed ergonomic frames after upgrading to our laser tube cutting machine, which allowed them to achieve previously unattainable design complexity and precision. The ability to handle diverse tube types and execute various cuts (straight, angled, contoured) with a single machine expands a company's service offerings, attracting a wider range of clients.

Furthermore, by automating existing manual workflows—a key objective for Ahmed Al-Farsi’s business—our machines allow companies to increase production capacity without a proportional increase in labor. This scalability is critical for businesses planning to automate, enabling them to take on larger contract-based fabrication services for builders, decorators, and OEMs. The enhanced capabilities and increased efficiency mean clients can meet higher demand, shorten lead times, and deliver finished parts more consistently, thereby enhancing their reputation and securing more lucrative contracts in areas like vehicle parts supply or large-scale architectural metalwork.

Partnering for Long-Term Success and Support

The true value of an industrial machinery investment extends far beyond the initial purchase; it lies in the reliability of after-sales support and the depth of the partnership with the supplier. Many clients, particularly those new to automated solutions or located in international markets, express concerns about support, training, and spare parts availability. Ahmed Al-Farsi, for example, explicitly prioritizes suppliers with comprehensive after-sales service, training support, spare parts availability, and remote diagnostics, recognizing their critical role in ensuring uninterrupted operations and maximizing machine uptime.

MZBNL offers a comprehensive support ecosystem designed to ensure clients’ long-term success. Our commitment begins with providing turnkey solutions, ensuring that installation is seamless and that your team receives thorough on-site training. This hands-on training reduces the learning curve and empowers your operators to confidently manage the machine from day one, effectively addressing pain points related to retraining burdens and operator turnover. We prioritize spare parts availability, stocking essential components to minimize downtime, and our remote diagnostics capabilities allow us to quickly identify and troubleshoot issues, often before they impact production, significantly reducing the need for costly and time-consuming on-site visits.

Moreover, our client relationships often evolve into long-term strategic partnerships. We actively welcome feedback for continuous product improvement and are dedicated to providing ongoing technical assistance. For example, Ahmed Al-Farsi is considering becoming a regional distributor for our machines in the Gulf region, a testament to the trust and reliability we foster. This demonstrates our willingness to explore co-branding options or exclusive distribution rights, strengthening our global network and ensuring that clients not only receive cutting-edge technology but also consistent, reliable support and a pathway for mutual growth in the global metal fabrication industry.

| Client Benefit Area | Specific Advantages for Clients | MZBNL Feature Driving Benefit | Example Client Identity & Need |

|---|---|---|---|

| Operasyonel Verimlilik | Reduced material waste, lower labor intensity, faster setup | Zero-Waste Tail, Front-Feeding, No-CAD System | Metal pipe processing factories: Reduce material costs & processing time |

| Business Expansion | Ability to take on complex projects, increased production capacity | High-precision/speed, Multi-process integration | Automotive parts producers: Achieve intricate designs & high volume |

| Long-Term Support | Reliable after-sales service, comprehensive training, quick issue resolution | Global distributor network, remote diagnostics, spare parts | Mid-sized metal fabrication business: Ensures uptime & operational continuity |

Multi-process integration enables complex cutsDoğru

Single-machine capability for straight/angled/contoured cuts unlocks architectural and automotive project opportunities.

Manuel yükleme daha verimlidirYanlış

Automated front-feeding outperforms manual methods by 40% in efficiency while reducing physical strain on operators.

Sonuç

We at MZBNL have earned global recognition by challenging industry norms. Our No-CAD, front-feeding, and zero-waste innovations provide unparalleled efficiency, ease of use, and cost savings for metal fabrication. We empower clients worldwide through continuous innovation, tailored solutions, and steadfast support, ensuring their long-term success and elevating global manufacturing standards.

-

Discover MZBNL’s history and achievements that transformed metal fabrication ↩

-

Explore how holistic solutions address challenges in metal fabrication ↩

-

Explore technological benefits and practical applications of digital systems in global manufacturing. ↩

-

Understand how smart multi-process integration meets high global manufacturing standards. ↩

-

Understand the benefits of diverse supplier origins in competitive industries ↩

-

Explore strategies for expanding market presence through partnerships and promotion channels. ↩

-

Understand the significance of trade shows in establishing industry connections and gaining market insights. ↩

-

Discover the benefits of a comprehensive digital hub for international client acquisition and service. ↩

-

Learn about operational ease and seamless integration benefits for MZBNL machinery worldwide ↩

Sorularınız mı var veya daha fazla bilgiye mi ihtiyacınız var?

Kişiselleştirilmiş yardım ve uzman tavsiyesi için bizimle iletişime geçin.