Tüp Lazer Kesim Makinelerinin Geleneksel Yöntemlere Göre Avantajları

Metal imalatınızda yavaş üretim, yüksek malzeme israfı ve tutarsız kalite ile mi mücadele ediyorsunuz? Pek çok işletme tam da bu zorluklarla karşılaşıyor ve bu da ölçeklerini büyütmelerini ve rekabetçi kalmalarını engelliyor. Bu hayal kırıklıklarını anlıyorum ve verimliliğinizi ve karlılığınızı artırmak için güçlü bir çözüm olduğuna inanıyorum.

Tüp lazer kesim makineleri, testere, zımbalama veya delme gibi geleneksel yöntemlere kıyasla üstün hassasiyet, daha yüksek üretim hızları ve önemli ölçüde malzeme tasarrufu sunar. Bunu otomatik süreçler, gelişmiş yazılımlar ve yüksek odaklı enerji sayesinde başararak genel üretim verimliliğini ve ürün kalitesini önemli ölçüde artırırlar.

Metal imalatındaki 25 yıllık deneyimimde, en son teknolojiyi benimsemenin işletmeleri nasıl dönüştürdüğünü ilk elden gördüm. Geleneksel yöntemlerden tüp lazer kesime geçiş sadece bir yükseltme değildir; operasyonel yeteneklerinizi ve pazar konumunuzu temelden yeniden şekillendiren stratejik bir hamledir. Nasıl olduğunu keşfedelim.

BAE'li metal imalat girişimcisi Ahmed Al-Farsi gibi işletme sahipleriyle konuştuğumda, öncelikli endişeleri genellikle verimlilik ve vasıflı işgücünün artan maliyeti etrafında dönüyor. Geleneksel yöntemler tanıdık olsa da, modern üretimin karşılayamayacağı sınırlamalar taşıyor. Elle taşıma, çoklu işleme adımları ve biriken kaçınılmaz malzeme atıklarını düşünün. MZBNL'deki yolculuğum tam da bu sorunlu noktaları çözerek başladı. Sadece daha hızlı kesen değil, aynı zamanda tasarımdan bitmiş ürüne kadar tüm iş akışında devrim yaratan makineler geliştirdik. Bu sadece eski bir aleti değiştirmekle ilgili değil; Ar-Ge, üretim, satış ve hizmeti entegre eden ve müşterilerimizin benzeri görülmemiş verimlilik ve doğruluk seviyelerine ulaşmasını sağlayan özel çözümler sunan bir paradigma değişikliğini benimsemekle ilgili. Bu, işletmelerin geleneksel darboğazların ötesine nasıl geçebileceğinin ve gerçekten nasıl yenilik yapabileceğinin kritik bir incelemesidir.

Tüp lazer kesim ile geleneksel kesim yöntemleri arasındaki temel farklar nelerdir?

Manuel süreçlerden, takım değişikliklerinden ve geleneksel kesimin doğasında var olan sınırlamalardan bıktınız mı? Geleneksel yöntemler genellikle yoğun iş gücü ve birden fazla makine gerektirir, bu da operasyonel darboğazlara ve daha yüksek maliyetlere yol açar. Sayısız şirketin bu verimsizliklerle mücadele ettiğini gördüm.

Tüp lazer kesim, birden fazla işlemi tek bir makineye entegre ederek testere, zımbalama veya delme gibi geleneksel yöntemlere kıyasla üstün hız, hassasiyet ve otomasyon sunar. Ayrı işlemlere ve özel aletlere olan ihtiyacı ortadan kaldırarak işçilik ve malzeme israfını önemli ölçüde azaltırken kaliteyi ve verimi artırır.

Geleneksel ve lazerli boru kesimi arasındaki fark, kesme mekanizmasının çok ötesine geçer; üretim felsefesinde temel bir değişimi temsil eder. Geleneksel prosesler genellikle sıralıdır ve malzemenin kesme, delme ve şekillendirme için farklı iş istasyonları arasında hareket etmesini gerektirir. Bu da kaçınılmaz olarak gecikmelere, kullanım hatalarına ve kurulum sürelerine neden olur. Bunun aksine, tüp lazer kesim1 bu adımları birleştirerek üretimi kolaylaştıran ve karmaşık tasarımlar ve gelişmiş verimlilik için yeni olanaklar sunan hepsi bir arada bir çözüm sunar. Bu temel farklılıkları anlamak, lazer teknolojisinin dönüştürücü potansiyelini gerçekleştirmeye yönelik ilk adımdır.

Hassasiyet ve Malzeme Bütünlüğü

Geleneksel olarak metal borular aşındırıcı testere, şerit testere veya mekanik delme gibi yöntemler kullanılarak kesilir. Bu teknikler genellikle çapak, malzeme deformasyonu ve ısıdan etkilenen bölgeler gibi önemli zorlukları beraberinde getirir ve çapak alma, taşlama veya doğrultma gibi zaman alan ikincil işlemleri gerektirir. İlgili mekanik kuvvetler, özellikle ince duvarlı veya karmaşık profillerde boyutsal yanlışlıklara da yol açabilir. Örneğin, dikişsiz bağlantılar arayan bir mobilya üreticisi, düzensiz kesimler veya hafif bozulmalar nedeniyle geleneksel yöntemlerle işlem sonrası büyük bir darboğazla karşılaşır.

Bunun tam aksine, tüp lazer kesim, malzemeyi hassas bir şekilde eritmek ve buharlaştırmak için son derece odaklanmış, yüksek güçlü bir lazer ışını kullanır ve bu da minimum çapaklı veya çapaksız son derece temiz kesimlerle sonuçlanır. Prosesin temassız yapısı, malzeme üzerindeki mekanik gerilimi ortadan kaldırarak bütünlüğünü ve boyutsal kararlılığını korur. Bu, parçaların makineden montaja hazır olarak çıkması ve işlem sonrası ihtiyacı önemli ölçüde azaltması hatta ortadan kaldırması anlamına geliyor. MZBNL'deki 25 yıllık deneyime sahip ekibim, bu hassasiyet seviyesini sunmaya öncelik vererek müşterilerimizin daha az çabayla daha yüksek kalitede bitmiş ürünler elde etmesini sağladı.

Ayrıca, lazerin çok dar bir çentik (kesim genişliği) oluşturma yeteneği, kesim işlemi sırasında daha az malzeme kaybı anlamına gelir. Bu, özellikle yüksek değerli malzemeler veya karmaşık yerleştirme uygulamaları için faydalıdır ve doğrudan malzeme tasarrufuna katkıda bulunur. Elde edilen hassasiyet aynı zamanda daha sıkı toleranslara olanak tanır; bu da bileşenlerin birbirine mükemmel şekilde uyması gereken otomotiv parçaları üretimi gibi endüstriler için çok önemlidir, montaj süresini azaltır ve nihai ürünün genel kalitesini artırır.

Otomasyon ve İş Akışı Verimliliği

Geleneksel boru işleme genellikle birden fazla manuel adım içerir: ölçme, işaretleme, kelepçeleme, kesme, çapak alma ve ardından parçayı bir delme veya zımbalama istasyonuna taşıma. Her adım el emeği gerektirir ve insan hatası potansiyelini beraberinde getirir. Orta ölçekli metal imalat işletmesinde mevcut manuel iş akışlarını otomatikleştirmeyi planlayan Ahmed Al-Farsi için bu manuel darboğazlar sürekli bir sorun noktasıdır ve yüksek operatör devrine ve yeniden eğitim yüküne katkıda bulunur. Karmaşık tasarımlar için yetenekli CAD operatörlerine duyulan ihtiyaç, değişikliklerin tasarım ofisine geri dönmeyi gerektirmesi nedeniyle sorunu daha da kötüleştiriyor.

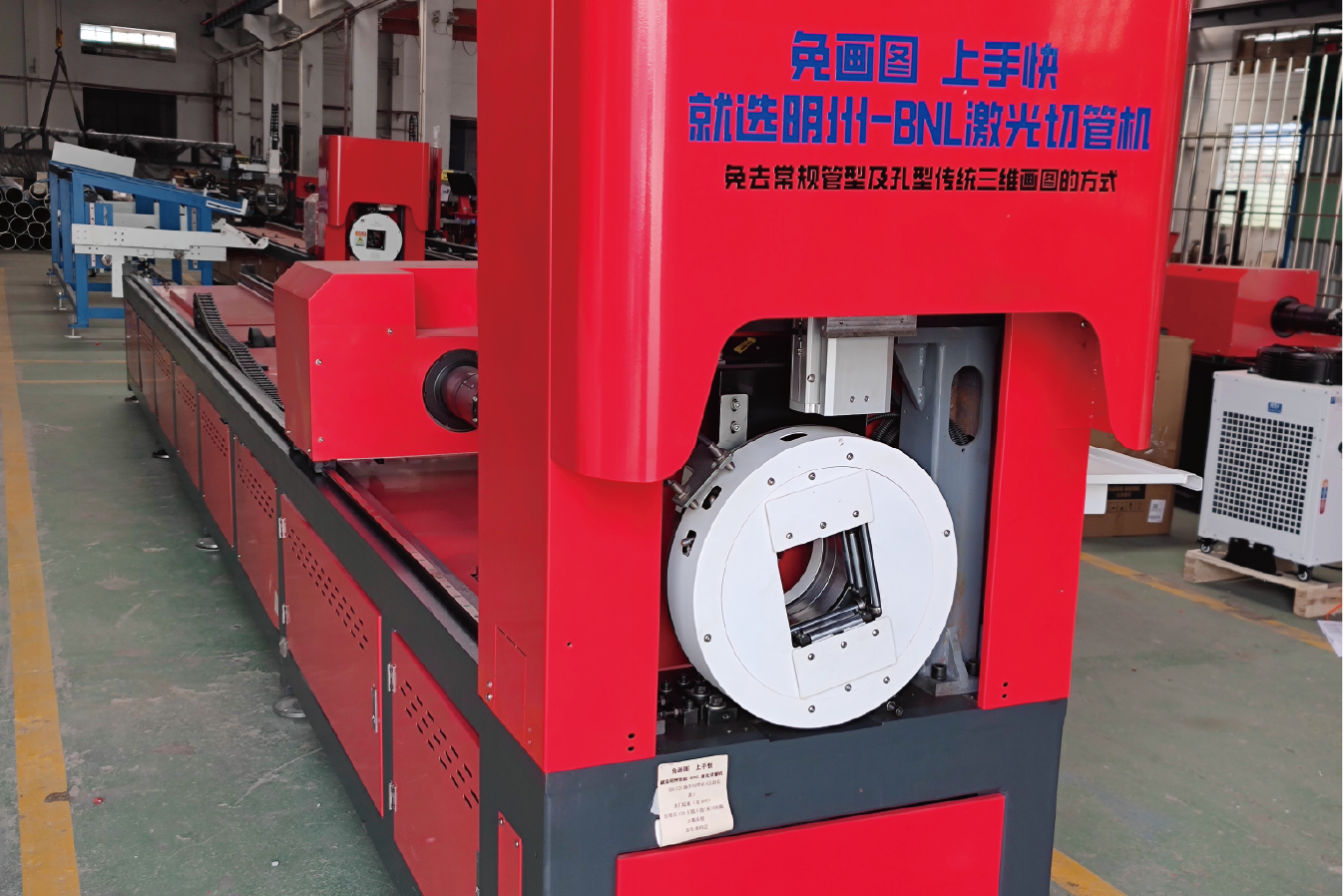

BNL lazer tüp kesme makineleri, gelişmiş otomasyon sayesinde bu iş akışında devrim yaratır. Öncü No-CAD İşletim Sistemimiz, operatörlerin sadece parametreleri girerek standart boru tiplerini ve delik modellerini işlemesine olanak tanıyarak karmaşık 3D çizimlere olan ihtiyacı ortadan kaldırır. Bu, kurulum süresini önemli ölçüde kısaltır ve beceri eşiğini düşürür; operatörlerin artık ekipman fabrikasında 15 gün yerine yalnızca 1 günlük yerinde eğitime ihtiyacı vardır. Tüpü otomatik olarak içeri çeken optimize edilmiş ön besleme mekanizmamızla birlikte, besleme verimliliği yaklaşık 40% artar ve operatörün iş gücü yoğunluğu yaklaşık 40% azalır.

Bu otomasyon seviyesi, daha yüksek verim ve minimum insan müdahalesi ile sürekli çalışma anlamına gelir. Geleneksel kurulumlar farklı aşamalar için birkaç operatör gerektirebilirken, tek bir operatör sofistike bir lazer kesim makinesini yönetebilir. Bu sadece işçilik maliyetlerini düşürmekle kalmaz, aynı zamanda makine görevleri sarsılmaz bir hassasiyetle yerine getirdiği için büyük partilerde tutarlı kalite sağlar. Örneğin, büyük ölçekli bir teşhir rafı üreticisi, her bileşenin tutarlı kalitesinden emin olarak daha az personelle sürekli vardiya çalıştırabilir.

Malzeme Kullanımı ve Atık Azaltımı

Geleneksel kesim yöntemlerindeki en önemli gizli maliyetlerden biri, özellikle hatalar veya hassas olmayan kesimler nedeniyle kuyruk malzemeleri, kesilmiş parçalar ve ıskartaya çıkarılan parçalar şeklinde malzeme israfıdır. Uzun boruları keserken, geleneksel makineler genellikle etkili bir şekilde işlenemeyen bir "kuyruk" bölümüne sahiptir ve bu da her ham borunun sonunda önemli miktarda malzeme kaybına yol açar. Bu atık birikerek, özellikle pahalı malzemelerle çalışan işletmeler için karlılığı etkiler.

BNL, tam da bu zorluğun üstesinden gelmek için Sıfır Atık Kuyruk Malzemesi İnovasyonu2. Boru başından başlayan ve kullanılamayan kuyruk malzemesi bırakan geleneksel sistemlerin aksine, kesme mantığını arka aynadan başlangıç noktası olarak hesaplayacak şekilde yeniden tasarladık. Bu, kalan bölüm ürün uzunluğundan daha küçük olduğu sürece sistemin artık kuyruk malzemesini ortadan kaldırmasına olanak tanıyarak malzeme kullanımını en üst düzeye çıkarır. Malzeme maliyetleri üzerindeki bu doğrudan etki, müşterilerimiz için yatırım getirisinde genellikle önemli bir faktördür.

Geleneksel bir kurulumun kesiklerden ve kuyruk bölümlerinden 5-10% malzeme atığı üretebileceği bir senaryo düşünün. BNL'nin sistemi ile bu, kuyruk için neredeyse sıfıra indirilebilir ve hassas yerleştirme ve minimum çentik sayesinde genel malzeme kullanımı büyük ölçüde iyileştirilir. Ahmed'inki gibi mimari metal işleri ve araç parçaları için yüksek hacimli metal borular işleyen bir işletme için hammaddede 2-3%'lik bir tasarruf bile yılda yüz binlerce dolara dönüşebilir. Bu tablo bazı önemli farkları göstermektedir:

| Özellik | Geleneksel Boru Kesme (Testere/Delme) | Tüp Lazer Kesim (BNL) |

|---|---|---|

| Hassasiyet | Orta, çapaklanma ve deformasyona eğilimli | Yüksek, temiz kesimler, minimum çapak |

| Kurulum Süresi | Yüksek, çizim ve kalıp değişiklikleri gerektirir | Düşük, CAD'siz sistem, parametre tabanlı |

| Malzeme Atıkları | Önemli kuyruk malzemesi ve kesimler | Sıfıra yakın kuyruk malzemesi, optimize edilmiş yuvalama |

| Otomasyon | Manuel veya yarı manuel | Yüksek, otomatik besleme ve işleme |

| İşgücü Yoğunluğu | Yüksek vasıflı operatörlere ihtiyaç var | Daha düşük, kullanıcı dostu, daha az eğitim |

| Karmaşık Şekiller | Sınırlı, çok adımlı süreç | Yüksek kapasiteli, tek adımlı |

Lazer kesim malzeme israfını azaltırDoğru

Lazer kesimdeki dar çentik ve optimize edilmiş yerleştirme, geleneksel yöntemlere kıyasla malzeme kaybını önemli ölçüde azaltır.

Geleneksel yöntemler daha kesindirYanlış

Lazer kesim, genellikle deformasyona neden olan geleneksel yöntemlerin aksine temiz kesimler ve minimum çapak ile üstün hassasiyet sağlar.

Tüp lazer kesim, üretimde hassasiyeti ve doğruluğu nasıl artırır?

Mevcut kesim yöntemlerinizle katı kalite standartlarını karşılamakta zorlanıyor musunuz? Tutarsız toleranslar ve kaba yüzeyler, maliyetli yeniden işlemlere ve memnuniyetsiz müşterilere yol açabilir. Mükemmelliği hedefleyen işletmeler için hassasiyetin ne kadar önemli olduğuna şahit oldum.

Tüp lazer kesim makineleri, odaklanmış bir lazer ışını kullanarak, ısıdan etkilenen bölgeleri en aza indirerek ve mekanik temas olmadan karmaşık kesimler sağlayarak benzersiz bir hassasiyet ve doğruluk sunar. Bu da üstün parça kalitesi, daha sıkı toleranslar ve daha az işlem sonrası süreç sağlayarak genel üretim güvenilirliğini önemli ölçüde artırır.

Hassasiyet sadece teknik bir özellik değildir; modern üretimde kalite, verimlilik ve yeniliğin temelidir. Parçalar tam boyutlarda ve bozulmamış kenarlarla kesildiğinde, sorunsuz bir şekilde birbirine oturur, montaj süresini azaltır ve nihai ürünün bütünlüğünü iyileştirir. Mobilya imalatı veya tıbbi ekipman gibi estetiğin ve işlevsel kesinliğin çok önemli olduğu bir sektör için bu doğruluk seviyesi tartışılmazdır. Sizlerle tüp lazer kesimin, özellikle de ekibim tarafından gerçekleştirilen ilerlemelerle MZBNL3 üretimin bu kritik yönünü geleneksel yöntemlerin başarabileceğinin ötesine taşıyor.

Boyutsal Sapmaları Minimize Etme

Temel fark kesme mekanizmasında yatmaktadır. İster mekanik testereler ister zımbalama makineleri olsun, geleneksel yöntemler fiziksel temas ve kuvvete dayanır. Bu da doğal olarak takım aşınması, bıçak sapması ve malzeme sıkıştırma tutarsızlıkları gibi değişkenleri beraberinde getirir ve bunların tümü boyutsal sapmalara yol açabilir. Örneğin, bir testere bıçağı hafifçe kayabilir veya bir zımba deliğin etrafında küçük bir çıkıntı oluşturarak nihai parçanın doğruluğunu etkileyebilir. Bu küçük hatalar binlerce parça üzerinde bir araya geldiğinde önemli ölçüde israfa ve yeniden çalışmaya yol açarak şirketlerin sıkı kalite kontrol gereksinimlerini karşılamasını zorlaştırabilir.

Buna karşılık, tüp lazer kesiminde bir temassız, yüksek konsantrasyonlu ışık demeti4. Bu ışın, gelişmiş yazılım ve optiklerle hassas bir şekilde kontrol edilebilir ve son derece dar çentik genişliklerine ve milimetrenin kesirlerine kadar hassas kesimlere olanak tanır. Fiziksel kuvvetin olmaması, takım sapması veya malzeme bozulması olmadığı anlamına gelir ve kesim profilinin dijital tasarımla tam olarak eşleşmesini sağlar. Bu, özellikle bileşenlerin mükemmel bir şekilde birbirine geçmesi gereken otomotiv ve motosiklet parçaları sektörü veya hassasiyetin kelimenin tam anlamıyla bir ölüm kalım meselesi olabileceği tıbbi ekipman üretimi gibi dar toleranslar gerektiren endüstrilerde çok önemlidir. MZBNL makinelerimiz, her gün parça parça bu tutarlı hassasiyeti korumak üzere tasarlanmıştır.

Ayrıca, gelişmiş sensörlerin ve gerçek zamanlı geri bildirim sistemlerinin modern lazer kesim makinelerine entegre edilmesi, kesim işlemi sırasında dinamik ayarlamalara olanak tanır. Bu, küçük malzeme tutarsızlıklarını veya sıcaklık değişikliklerini telafi ederek optimum performans sağlar ve bir üretim çalışması boyunca en yüksek boyutsal doğruluk seviyelerini korur. Bu tutarlılık, "ilk seferde doğru" üretimi hedefleyen, hurda oranlarını önemli ölçüde azaltan ve müşterileri için öngörülebilir kalitede çıktı sağlayan işletmeler için oyunun kurallarını değiştiren bir unsurdur.

Karmaşık Geometriler ve Karmaşık Tasarımlar Elde Etmek

Geleneksel kesme yöntemleri, borular üzerinde karmaşık şekiller, karmaşık desenler veya standart olmayan profiller üretmek söz konusu olduğunda önemli sınırlamalarla karşılaşır. Testereler öncelikle düz veya açılı kesimlerle sınırlıdır, delme makineleri ise her benzersiz delik şekli için özel takımlar gerektirir, bu da onları düşük hacimli, yüksek çeşitlilikte üretim veya standart olmayan kesiklere sahip tasarımlar için pratik ve pahalı hale getirir. Yuvalar, çentikler veya estetik desenler oluşturmak genellikle birden fazla kurulum, ek makineler ve yüksek vasıflı operatörler gerektirir, bu da hem maliyeti hem de üretim süresini artırır.

Tüp lazer kesim, tek bir kurulumla inanılmaz derecede karmaşık ve girift tasarımlar gerçekleştirme kabiliyetiyle öne çıkar. Lazer ışını, CAD yazılımı tarafından tanımlanan herhangi bir yol boyunca hareket edebilir ve gönye kesimleri, eğimler, yuvalar ve hatta "tırnak ve yuva" tasarımları için karmaşık kilitleme özellikleri dahil olmak üzere tüp yüzeyinde neredeyse her türlü 2D veya 3D şeklin oluşturulmasını sağlar. Bu, ürün tasarımı için tamamen yeni olanaklar sunarak mimarların cepheler için özel estetik unsurlar belirlemelerine veya mobilya tasarımcılarının daha önce üretimi maliyetli olan benzersiz, karmaşık bileşenler oluşturmalarına olanak tanır. Ahmed Al-Farsi, mimari metal işlerine doğru genişlemesiyle, müşterilerine ısmarlama çözümler sunmasına ve rekabetçi bir pazarda işini farklılaştırmasına olanak tanıdığı için bu kabiliyetten büyük ölçüde yararlanıyor.

Bu çok yönlülük aynı zamanda prototip oluşturma sürecini de hızlandırır. Özel kalıplar için haftalarca beklemek yerine, yeni bir tasarım dakikalar içinde programlanabilir ve kesilebilir, böylece hızlı yineleme ve ürün geliştirme mümkün olur. Bu çeviklik, şirketlerin pazar taleplerine hızla yanıt vermesini ve yenilikçi ürünleri pazara daha hızlı sunmasını sağlayan önemli bir rekabet avantajıdır. Mimari projeler için süslü korkuluk tasarımlarından fitness ekipmanları için özel bağlantı parçalarına kadar lazer kesim, tasarım konseptlerini olağanüstü kolaylık ve hassasiyetle fiziksel gerçekliklere dönüştürerek üreticilerin boru imalatıyla mümkün olanın sınırlarını zorlamalarını sağlar.

Malzeme Bütünlüğü ve Yüzey İşlemi

Geleneksel kesme yöntemlerinin malzeme bütünlüğü üzerindeki etkisi, işlem sonrası büyük bir baş ağrısı haline gelene kadar genellikle göz ardı edilir. Mekanik kesme aletleri sürtünme ve ısı üretir, bu da malzemenin özelliklerini değiştiren, potansiyel olarak zayıflatan veya renk bozulmasına neden olan lokalize ısıdan etkilenen bölgelere (HAZ) yol açabilir. Ayrıca, bir testere bıçağının yırtma hareketi veya bir zımbanın kesme kuvveti genellikle malzemede, özellikle de boruların iç çapında pürüzlü kenarlar, çapaklar ve hafif bozulmalar bırakır. Bu kusurlar çapak alma, taşlama ve temizleme gibi kapsamlı ikincil işlemler gerektirir ve üretim döngüsüne önemli ölçüde zaman, işçilik ve maliyet ekler.

Tüp lazer kesim ise malzeme bütünlüğü üzerinde minimum etkiyle üstün bir yüzey kalitesi sağlar. Lazerin yüksek enerji yoğunluğu, konsantre enerji ve hızlı soğutma nedeniyle çok küçük bir HAZ ile malzemeyi kesim hattı boyunca hassas bir şekilde eritir ve buharlaştırır. İşlemin temassız doğası, mekanik deformasyon veya yırtılma meydana gelmediği anlamına gelir, bu da genellikle işlem sonrası gerektirmeyen son derece temiz, pürüzsüz kenarlarla sonuçlanır. Bu, temizliğin ve estetik çekiciliğin çok önemli olduğu tıbbi cihazlar veya üst düzey sıhhi tesisat gibi hassas uygulamalarda kullanılan bileşenler için kritik bir avantajdır.

Mobilya veya elektrikli ev aletleri gibi ürünlerin üreticileri için bu temiz kesim kalitesi, doğrudan daha kısa montaj süresi ve daha iyi ürün estetiği anlamına gelir. Yüzlerce parçanın çapaklarını almak için saatler harcamak gerekmediğinden personel daha yüksek değerli işlere odaklanabilir. Hassas ve pürüzsüz kenarlar aynı zamanda daha güçlü, daha güvenilir kaynaklara ve bağlantılara katkıda bulunur, çünkü yapıştırmaya müdahale edecek daha az kusur vardır. Kesim kalitesinde detaylara gösterilen bu özen, nihai ürünün görsel çekiciliğini artırmakla kalmaz, aynı zamanda yapısal bütünlüğünü ve uzun ömürlülüğünü de geliştirerek son kullanıcıya somut bir fayda ve üretici için rekabet avantajı sağlar.

Lazer kesim ısıdan etkilenen bölgeleri en aza indirirDoğru

Konsantre lazer ışını malzemeyi hızla buharlaştırarak minimum ısı yayılımı yaratır ve malzeme özelliklerini korur.

Testereler karmaşık 3D şekiller üretebilirYanlış

Geleneksel testereler düz veya açılı kesimlerle sınırlıyken, lazerler CAD ile tasarlanmış her türlü 2D/3D geometriyi oluşturabilir.

Tüp lazer kesimin üretim hızı ve verimliliği üzerindeki etkisi nedir?

Üretim hatlarınız yavaş süreçler ve sürekli manuel müdahale nedeniyle tıkanıyor mu? Geleneksel yöntemler genellikle darboğazlar yaratarak çıktınızı sınırlar ve proje teslimatını geciktirir. Üretimin talebe ayak uydurmakta zorlanmasının ne kadar sinir bozucu olduğunu biliyorum.

Tüp lazer kesim, birden fazla süreci birleştirerek, kurulum sürelerini azaltarak ve sürekli, otomatik çalışma sağlayarak üretim hızını ve verimliliğini önemli ölçüde artırır. MZBNL'nin No-CAD sistemi ve otomatik besleme mekanizmaları gibi yenilikler, manuel işçiliği en aza indirerek önemli ölçüde daha yüksek verim ve daha hızlı proje tamamlama sağlar.

Günümüzün hızlı tempolu üretim ortamında, hız ve verimlilik sadece avantaj değil; hayatta kalmak ve büyümek için ön koşullardır. Tasarruf edilen her dakika, kolaylaştırılan her süreç, kârlılığa ve pazar duyarlılığına doğrudan katkıda bulunur. MZBNL'deki çalışmalarım sürekli olarak müşterilerimiz için bu operasyonel ölçütleri dönüştürmeye odaklandı. Daha önce geleneksel yöntemlerin sınırlamaları ile kısıtlanan şirketlerin, tüp lazer kesimin otomatikleştirilmiş, yüksek hızlı yeteneklerini benimsediklerinde nasıl büyük bir potansiyelin kilidini açtıklarına tanık olduk. Bu makinelerin üretim zaman çizelgeleriniz ve genel çıktınız için nelerin mümkün olduğunu nasıl yeniden tanımladığını göstermeme izin verin.

Azaltılmış Kurulum ve Değişim Süreleri

Geleneksel boru işleme genellikle kapsamlı kurulum süreleri içerir. Her farklı parça veya boru boyutu için operatörlerin düzenekleri manuel olarak ayarlaması, aletleri (örneğin testere bıçakları, matkap uçları, zımba kalıpları) değiştirmesi ve potansiyel olarak yeni programlar oluşturması gerekir. Bir tasarımın değiştirilmesi gerekiyorsa, bu genellikle karmaşık 3D çizim ayarlamaları için tasarım ofisine geri dönmek anlamına gelir ve bu da günler hatta haftalar sürebilir. Bu durum, özellikle atölyelerde veya sık değişimlerin yaygın olduğu yüksek karışımlı, düşük hacimli üretim ortamlarında önemli bir kesinti süresi yaratır. Ahmed Al-Farsi'nin yeniden eğitim yüküne neden olan yüksek operatör devir hızı konusundaki endişesi, bu geleneksel kurulumların karmaşıklığı ve zaman yatırımıyla doğrudan ilişkilidir.

BNL lazer tüp kesme makineleri, akıllı otomasyon ve kullanıcı dostu arayüzler sayesinde kurulum ve değiştirme sürelerini önemli ölçüde azaltır. Öncü No-CAD İşletim Sistemimiz, operatörlerin parametreleri doğrudan makineye girerek standart boru tiplerini ve delik modellerini işlemesine olanak tanır. Bu, rutin işler için karmaşık 3D CAD çizimlerine olan geleneksel bağımlılığı ortadan kaldırır, yani tasarım değişiklikleri anında yapılabilir. Tek başına bu yenilik bile operatörlerin eğitim süresini ekipman fabrikasında ortalama 15 günden sadece 1 günlük yerinde eğitime indirerek kullanım kolaylığı ve operasyonel hazırlıkta muazzam bir sıçrama olduğunu göstermektedir.

Ayrıca, otomatik yükleme ve boşaltma sistemleriyle, bir önceki boru bittikten sonra neredeyse anında makineye yeni bir boru beslenebilir. Makinenin yazılımı, yeni kesim programlarını hızlı bir şekilde yükleyerek farklı parça geometrileri veya boru boyutları arasında önemli bir manuel müdahale olmadan hızlı geçişlere olanak tanır. Bu çeviklik, üreticilerin daha çeşitli işleri daha verimli bir şekilde işleyebileceği, özel siparişler için teslim sürelerini azaltabileceği ve makinenin çalışma süresini en üst düzeye çıkarabileceği anlamına gelir; bu da doğrudan imalat hizmetleri için daha yüksek genel üretkenlik ve karlılığa dönüşür.

Optimize Edilmiş Verim ve Sürekli Çalışma

Geleneksel yöntemler, mekanik eylemlerin hızı ve her adımda insan müdahalesine duyulan ihtiyaç nedeniyle doğal olarak sınırlıdır. Bir testere sadece bu kadar hızlı kesebilir ve her delme veya zımbalama işlemi kendi ayrı zamanını alır. Bu sıralı süreç, iş istasyonları arasında manuel taşıma ile birleştiğinde, genel verimi kısıtlayan darboğazlar yaratır. Büyük hacimli bir sipariş için bu, müşteri memnuniyetini ve iş büyümesini etkileyen uzun teslim süreleri ve kaçırılan son tarihler anlamına gelebilir.

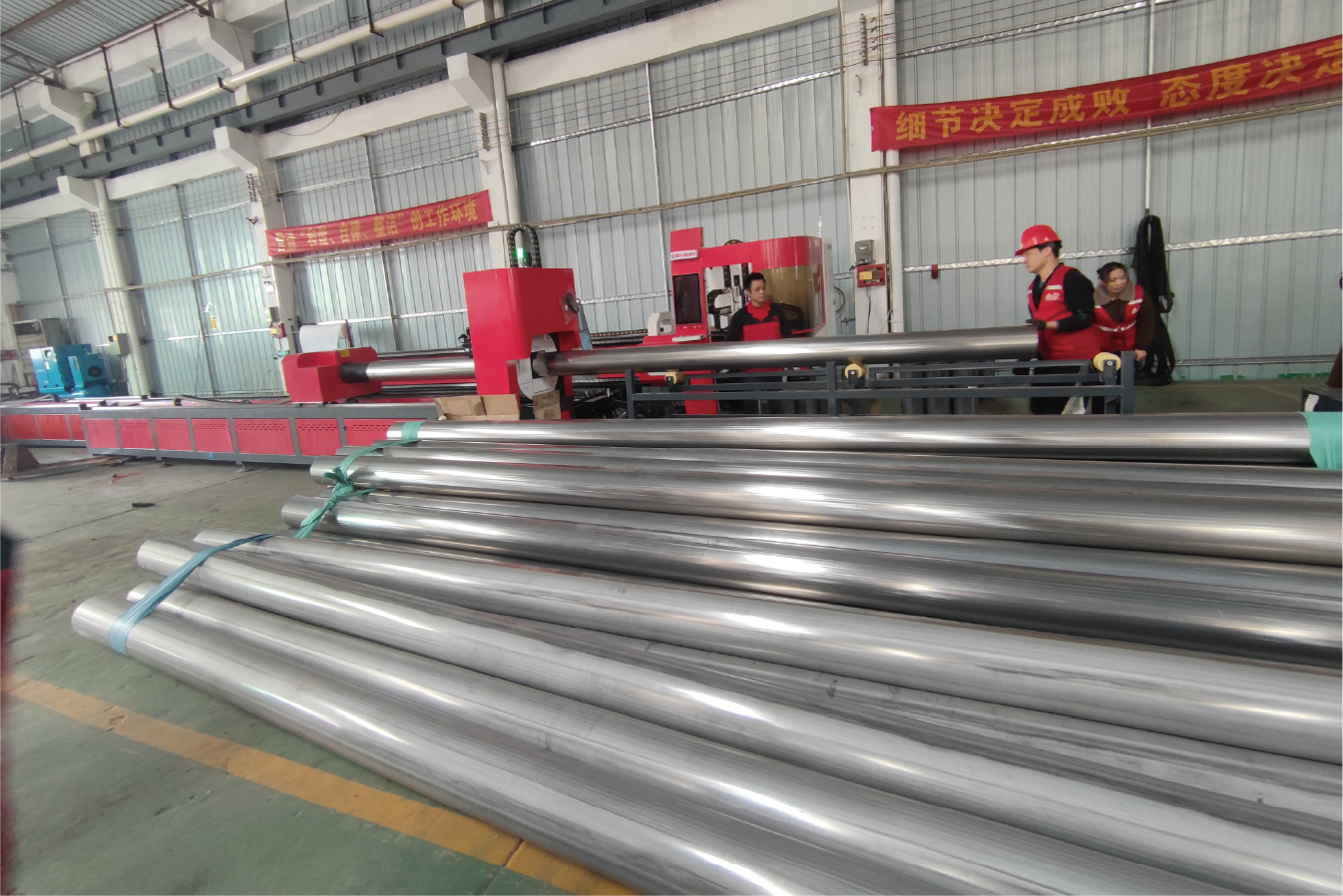

Tüp lazer kesim makineleri, özellikle de MZBNL'ninkiler, yüksek hızlı, sürekli çalışma için tasarlanmıştır. Lazer ışını inanılmaz yüksek hızlarda kesim yapar ve entegre otomasyon malzeme yükleme, işleme ve boşaltma işlemlerini sorunsuz bir şekilde gerçekleştirir. Örneğin optimize edilmiş önden besleme mekanizmamız, boruyu otomatik olarak önden çekerek besleme verimliliğini yaklaşık 40% artırır ve operatör iş yoğunluğunu 40% azaltır. Bu, makinenin minimum gözetimle uzun süre çalışmasına olanak tanır ve genellikle mesai saatleri dışında "ışıklar kapalı" üretim yapılmasını sağlayarak toplam çıktı kapasitesini önemli ölçüde artırır.

Bu yüksek hızlı, otomatikleştirilmiş süreç, tek bir lazer makinesinin genellikle birden fazla geleneksel makinenin ve bunları çalıştırmak için gereken operatörlerin yerini alabileceği anlamına gelir. Her bir parça için hızlı döngü süreleri, azaltılmış kesim dışı süre ile birleştiğinde, toplam üretimde önemli bir artışa yol açar. Örneğin, çit ve korkuluk bileşenleri üreten bir üretici, vardiya başına önemli ölçüde daha fazla doğrusal fit malzeme işleyebilir, bu da daha büyük sözleşmeler üstlenmelerine ve projeleri daha hızlı teslim etmelerine olanak tanır. Bu verimlilik doğrudan bir rekabet avantajıdır ve işletmelerin fiziksel ayak izlerini genişletmeden veya işgücünü orantılı olarak artırmadan artan talebi karşılamasına olanak tanır.

Uçtan Uca Otomasyon için Entegrasyon

Modern tüp lazer kesim makinelerinin gerçek gücü, bireysel çalışma hızlarının ötesine geçer; daha büyük, otomatik üretim sistemlerine sorunsuz entegrasyon kapasitelerinde yatar. Geleneksel kurulumlar genellikle birbirinden kopuk makinelerden oluşur - burada bir testere, orada bir matkap presi - her adım arasında parçaların manuel olarak aktarılmasını gerektirir, bu da çok sayıda potansiyel hata ve gecikme noktası yaratır. Bu parçalı yaklaşım, bütünsel üretim optimizasyonu ve izlenebilirlik potansiyelini sınırlamaktadır.

BNL lazer kesim makineleri, "Akıllı ve dijitalleştirilmiş sistemler" ve "Çoklu süreç entegrasyonu" göz önünde bulundurularak tasarlanmıştır. Bu, tam otomatik bir üretim hattının parçasını oluşturarak yukarı ve aşağı akış süreçleriyle ağa bağlanabilecekleri anlamına gelir. Örneğin, parçalar lazer kesiciden robotik kaynak istasyonlarına veya otomatik montaj hatlarına otomatik olarak aktarılabilir ve böylece yalın, sürekli bir akış oluşturulur. Bu entegrasyon seviyesi, aşamalar arasında manuel elleçlemeyi ortadan kaldırır, devam eden iş envanterini azaltır ve hammaddeden bitmiş ürüne kadar genel teslim sürelerini önemli ölçüde kısaltır. Ahmed Al-Farsi'nin anahtar teslim çözümlere ve mevcut manuel iş akışlarını otomatikleştirmeye olan ilgisi bu kabiliyetle mükemmel bir uyum içindedir.

Ayrıca, lazer kesimin dijital yapısı sorunsuz veri alışverişine olanak tanır. Parça sayıları, makine durumu ve enerji tüketimi gibi üretim verileri gerçek zamanlı olarak izlenebilir, böylece proaktif bakım, optimize edilmiş planlama ve gelişmiş kalite kontrolü sağlanabilir. Otomasyona yönelik bu bütünsel yaklaşım yalnızca verimliliği ve üretimi en üst düzeye çıkarmakla kalmaz, aynı zamanda sürekli iyileştirme için değerli içgörüler sağlar. Asansör ekipmanı entegratörleri veya otomasyon sistemi çözüm sağlayıcıları gibi şirketler için makinelerimizi entegre etmek, benzersiz operasyonel mükemmellik seviyelerine ulaşmalarına ve karmaşık projeleri daha yüksek hız ve güvenilirlikle sunmalarına olanak tanır ve sonuçta sözleşmeye dayalı üretim hizmetlerine dayalı kar modellerini geliştirir.

Lazer kesim, kurulum sürelerini kısaltırDoğru

No-CAD sistemi karmaşık 3D çizimleri ortadan kaldırarak anında tasarım değişiklikleri yapılmasını sağlar ve operatör eğitimini 15 günden sadece 1 güne indirir.

Geleneksel yöntemler daha hızlıdırYanlış

Lazer kesim, sürekli otomasyon ile çok daha yüksek hızlarda çalışırken, geleneksel yöntemler mekanik eylemler ve manuel kullanım ile sınırlıdır.

Tüp lazer kesim makineleri maliyet tasarrufuna ve malzeme kullanımına nasıl katkıda bulunur?

Geleneksel imalattan kaynaklanan yüksek malzeme maliyetleri ve aşırı atıklarla sürekli mücadele mi ediyorsunuz? Yeniden işleme ve verimsiz süreçlerden kaynaklanan gizli masraflar kâr marjlarınızı önemli ölçüde aşındırabilir. Bu sorunların işletmeleri nasıl felce uğrattığını gördüm.

Tüp lazer kesim makineleri, sıfır atıkla kesim ve hassas yerleştirme yoluyla malzeme kullanımını en üst düzeye çıkararak, otomasyon yoluyla işçilik maliyetlerini azaltarak ve işlem sonrası gereksinimleri en aza indirerek önemli maliyet tasarrufları sağlar. Verimlilikleri ve minimum malzeme israfı, daha yüksek yatırım getirisine ve gelişmiş karlılığa doğrudan katkıda bulunur.

Her türlü üretim operasyonunda kârlılık esastır. Gelişmiş makinelere yapılan ilk yatırım göz korkutucu görünse de, ön maliyetin ötesine geçerek uzun vadeli finansal faydalara bakmak çok önemlidir. Ahmed Al-Farsi gibi müşteriler de dahil olmak üzere müşterilerimle MZBNL'nin tüp lazer kesim makinelerinin getirdiği somut maliyet tasarrufu ve iyileştirilmiş malzeme kullanımı hakkında çok sayıda görüşme yaptım. Mesele sadece daha hızlı kesim yapmak değil; daha akıllıca kesim yapmak, israfı en aza indirmek ve toplam üretim maliyetini düşürmektir. Gelin bu teknolojinin ekonomik modelinizi nasıl temelden dönüştürdüğünü inceleyelim.

Malzeme Atıklarını ve Kesintileri En Aza İndirmek

Geleneksel metal imalatında en önemli ve genellikle hafife alınan maliyetlerden biri malzeme israfıdır. Testere gibi yöntemler tipik olarak her çubuğun sonunda "kuyruk malzemesi" olarak bilinen, sonraki parçalar için kullanılamayacak kadar kısa olan ve bu nedenle hurdaya ayrılan önemli kalıntılar bırakır. Ayrıca, hassas olmayan kesimler veya manuel hatalar yanlış kesilmiş parçalara yol açarak yüksek hurda oranına daha da katkıda bulunabilir. Yüksek değerli metallerle veya büyük üretim hacimleriyle uğraşan işletmeler için bu israf, zaman içinde önemli mali kayıplara dönüşebilir ve sözleşmeye dayalı imalat hizmetlerinin karlılığını doğrudan etkileyebilir.

MZBNL'nin Sıfır Atık Kuyruk Malzemesi İnovasyonu, bu kritik sorunu doğrudan ele almaktadır. Boru kafasından başlayan ve tipik olarak işlemin sonunda kullanılamaz kuyruk malzemesi üreten geleneksel lazer kesim sistemlerinin aksine, makinelerimiz başlangıç noktası olarak arka aynadan hesaplama yapar. Bu, kalan bölüm ürün uzunluğundan daha küçük olduğu sürece sistemin artık kuyruk malzemesini ortadan kaldırmasına olanak tanır. Bu devrim niteliğindeki tasarım, malzeme kullanımını en üst düzeye çıkararak işletmelerin satın alınan her ham borudan daha fazla kullanılabilir parça elde etmesini sağlar ve hammadde tüketimini ve ilgili maliyetleri önemli ölçüde azaltır.

Örneğin, tipik bir geleneksel kurulum, kuyruk uçlarından ve kesiklerden 3-5% malzeme atığına neden oluyorsa, sıfıra yakın kuyruk atığı olan bir sisteme geçmek önemli tasarruflar sağlayabilir. Aylık tonlarca çelik boru kullanan bir metal boru işleme fabrikası için malzeme maliyetlerinde 3%'lik bir tasarruf, yıllık on binlerce dolara eşit olabilir. Bu, her iş için kâr marjını doğrudan artırarak gelişmiş lazer teknolojisine yatırımı oldukça cazip hale getirir. Bu gelişmiş malzeme kullanımı sadece para tasarrufu sağlamakla kalmaz, aynı zamanda çevresel sorumlulukla uyumlu olarak daha sürdürülebilir üretim uygulamalarına da katkıda bulunur.

Azaltılmış İşçilik ve İşlem Sonrası Maliyetleri

Geleneksel boru işleme yöntemleri doğası gereği yoğun emek gerektirir. Her bir ayrı işlem için (kesme, çapak alma, delme, zımbalama) vasıflı operatörlere ihtiyaç duyarlar ve genellikle aşamalar arasında önemli ölçüde manuel kullanım içerirler. Ahmed Al-Farsi'nin bir sorun noktası olarak deneyimlediği gibi, karmaşık tasarımlar oluşturmak için deneyimli CAD operatörlerine duyulan ihtiyaç, başka bir maliyet katmanı ekler ve operatör devri ve sürekli yeniden eğitim ihtiyacı ile ilgili zorlukları ortaya çıkarır. Ayrıca, geleneksel kesimlerin ürettiği pürüzlü kenarlar ve çapaklar, çapak alma, taşlama veya temizleme gibi zaman alıcı ve genellikle manuel işlem sonrası süreçleri gerektirmekte, bu da çalışma saatlerini artırmakta ve üretim döngülerini uzatmaktadır.

Tüp lazer kesim makineleri, yüksek otomasyon seviyeleri ve entegre yetenekler sayesinde işgücü gereksinimlerini önemli ölçüde azaltır. MZBNL'nin No-CAD İşletim Sistemi ile standart süreçler için yüksek vasıflı CAD operatörlerine duyulan ihtiyaç büyük ölçüde azaltılarak beceri eşiği ve ilgili işçilik maliyetleri düşürülür. Makine, kesme, delme ve şekillendirme gibi birden fazla işlemi tek bir kurulumda gerçekleştirerek her adım için ayrı makinelere ve operatörlere olan ihtiyacı ortadan kaldırıyor. Bu çoklu işlem entegrasyonu, iş akışını kolaylaştırır ve baştan sona manuel müdahaleyi azaltır.

Ayrıca, lazer teknolojisinin sağladığı üstün kesim kalitesi (minimum ısıdan etkilenen bölgelere sahip temiz, çapaksız kenarlar), işlem sonrası adımların genellikle tamamen ortadan kaldırıldığı veya önemli ölçüde azaltıldığı anlamına gelir. Bu da doğrudan çapak alma, taşlama ve yeniden işleme için harcanan işçilik saatlerinden önemli ölçüde tasarruf anlamına gelir. Büyük bir mobilya veya sıhhi tesisat üreticisi için, yüz binlerce parçada azaltılmış işçilikten elde edilen kümülatif tasarruf muazzam olabilir ve vasıflı çalışanların montaj veya kalite güvencesi gibi daha yüksek değerli görevlere odaklanmasını sağlar. Bu maliyet verimlilikleri, müşterimiz Ahmed'in de belirttiği gibi, yüksek maliyet-performans oranına ulaşmada önemli bir faktördür.

Enerji Verimliliği ve Bakım Tasarrufu

Geleneksel mekanik kesme makineleri daha basit görünse de, özellikle enerji tüketimi ve bakımla ilgili işletme maliyetleri artabilir. Eski makineler daha az enerji tasarruflu olabilir ve kesme aletlerindeki (bıçaklar, matkaplar, zımbalar) sürekli aşınma ve yıpranma, sık sık değiştirme, bileme ve buna bağlı duruş süreleri gerektirir. Mekanik bileşenler sürtünme ve titreşime maruz kalır, bu da daha sık arızalara ve maliyetli onarımlara yol açar. Bu bakım döngüleri ve enerji talepleri genel işletme giderlerine katkıda bulunarak karlılığı azaltır.

MZBNL tarafından geliştirilenler gibi modern tüp lazer kesim makineleri, enerji verimliliği ve bakım kolaylığı göz önünde bulundurularak tasarlanmıştır. Lazerler güç tüketirken, gelişmiş lazer kaynakları (fiber lazerler gibi) eski CO2 lazerlere veya aynı anda çalışan birden fazla geleneksel makineye kıyasla yüksek enerji verimliliğine sahiptir. Lazer kesimin temassız yapısı, aşınacak veya değiştirilecek fiziksel aletlerin olmadığı anlamına gelir ve sarf malzemesi maliyetlerini ve bakımla ilgili arıza sürelerini önemli ölçüde azaltır. "Kullanımı ve bakımı kolay" konusuna odaklanmamız, müşterilerimiz için toplam sahip olma maliyetini azaltmaya yönelik bu taahhüdümüzü yansıtmaktadır.

Ayrıca bu makineler, olası sorunları genellikle arızaya yol açmadan önce tespit edebilen ve proaktif bakıma olanak tanıyan akıllı tanılama ve uzaktan izleme özellikleriyle donatılmıştır. Bu da beklenmedik arıza sürelerini en aza indiriyor ki bu da proje teslim zaman çizelgelerine uymak için çok önemli. Örneğin, ekibim genellikle sorunları uzaktan teşhis edip yardımcı olabiliyor ve böylece maliyetli yerinde servis ziyaretlerine olan ihtiyacı azaltıyor. Daha düşük sarf malzemesi maliyetleri, daha az enerji tüketimi ve daha az sıklıkta, daha öngörülebilir bakım döngülerinin bu kombinasyonu, lazer tüp kesme makinelerini geleneksel, daha az verimli ve bakım gerektiren makinelerden oluşan bir filoyu yönetmeye kıyasla çok daha uygun maliyetli uzun vadeli bir yatırım haline getiriyor.

Lazer kesim malzeme israfını azaltırDoğru

MZBNL'nin sıfır atık yeniliği, arka aynadan kesimleri hesaplayarak kuyruk malzemesini ortadan kaldırır ve malzeme kullanımını en üst düzeye çıkarır.

Geleneksel kesim daha fazla işçilik gerektirirYanlış

Tüp lazer kesim, tek bir kurulumda birden fazla işlemi otomatikleştirerek her adım için ayrı operatörler gerektiren geleneksel yöntemlere kıyasla işçiliği önemli ölçüde azaltır.

Geleneksel kesim yöntemlerinden lazer kesim yöntemlerine geçiş yapan işletmeler için ne gibi öneriler var?

Önemli bir teknolojik yükseltmeyi düşünmek ürkütücü olabilir ve yatırım, entegrasyon ve eğitimle ilgili soruları gündeme getirebilir. Birçok işletme, kesintiye uğramaktan veya yanlış seçim yapmaktan korkarak tereddüt ediyor. Bu endişeleri anlıyorum, ancak doğru geçiş büyük bir büyümenin kilidini açabilir.

Tüp lazer kesime geçiş yapan işletmeler kapsamlı bir yatırım getirisi analizi yapmalı, kanıtlanmış teknolojiye ve güçlü desteğe sahip saygın bir tedarikçi seçmeli ve aşamalı uygulama için plan yapmalıdır. Kapsamlı eğitime yatırım yapmak ve entegre çözümleri araştırmak, geleneksel yöntemlerden gelişmiş lazer teknolojisine sorunsuz ve kârlı bir geçiş sağlayacaktır.

Yeni bir teknolojiyi, özellikle de tüp lazer kesim gibi dönüştürücü bir teknolojiyi benimsemek, dikkatli bir planlama ve stratejik bir yaklaşım gerektirir. Mesele sadece yeni bir makine satın almak değil; güçlü bir aracı mevcut ekosisteminize entegre etmek, iş akışlarını optimize etmek ve ekibinizi geleceğe hazırlamaktır. Şirketlere bu geçiş sürecinde rehberlik ettiğim yılların deneyimine dayanarak, iyi uygulanan bir planın potansiyel zorlukları önemli rekabet avantajlarına dönüştürebileceğine inanıyorum. Ahmed Al-Farsi gibi müşterilerimle paylaştığım ve geçişlerinin mümkün olduğunca sorunsuz ve faydalı olmasını sağlayan temel önerileri inceleyelim.

Kapsamlı İhtiyaç Değerlendirmesi ve ROI Analizi

Önemli bir yatırım yapmadan önce, işletmelerin mevcut üretim süreçlerinin kapsamlı bir değerlendirmesini yapmaları, belirli darboğazları, verimsizlikleri ve yüksek maliyetli alanları belirlemeleri çok önemlidir. Bu, mevcut malzeme kullanımının, farklı kesim işlemleri için işgücü harcamalarının ve çapak alma veya taşlama gibi işlem sonrası faaliyetler için harcanan zamanın analiz edilmesini içerir. Örneğin, bir mobilya üreticisi kusurlu kesimler veya manuel finisaj nedeniyle ne kadar zaman ve malzeme kaybedildiğini ölçmelidir. Bu temel ölçümleri anlamak, bir lazer kesim makinesinin potansiyel etkisini değerlendirmek için çok önemlidir.

İhtiyaç değerlendirmesinin ardından, detaylı bir Yatırım Getirisi (ROI) analizi5 çok önemlidir. Bu, lazer makinesinin ilk satın alma fiyatının ötesine geçmektedir. Azalan malzeme atığı (örneğin MZBNL'nin sıfır atık kuyruk özelliğinden), azalan işçilik maliyetleri (otomasyon ve basitleştirilmiş operasyon nedeniyle), ortadan kaldırılan işlem sonrası adımlar ve artan üretim kapasitesinden öngörülen tasarrufları hesaba katmalıdır. Ayrıca, iyileştirilmiş ürün kalitesinin değerini ve daha karmaşık, daha yüksek marjlı projeleri üstlenebilme yeteneğini de göz önünde bulundurun. Yüksek bir maliyet-performans oranına öncelik veren Ahmed Al-Farsi için bu ayrıntılı finansal projeksiyon, yatırımı paydaşlarına gerekçelendirmek açısından kritik önem taşıyor.

MZBNL'deki ekibim, özelleştirilmiş çözümler ve şeffaf yatırım getirisi hesaplamaları sağlamak için potansiyel müşterilerle yakın bir şekilde çalışmaktadır. Makinelerimizin nasıl uygun maliyetli özelleştirilmiş bir çözüm haline gelebileceğini göstermek için özel malzemelerinizi, üretim hacimlerinizi ve istediğiniz çıktıyı dikkate alıyoruz. Bu analitik yaklaşım, yüksek teknolojili bir lazer makinesine yapılan ilk yatırımın operasyonel tasarruflar ve artan karlılıkla nasıl hızla dengeleneceğini açıkça göstermeye yardımcı olur ve bunun sadece bir sermaye harcaması değil stratejik bir harcama olduğunu kanıtlar.

Satıcı Seçimi ve Eğitim Yatırımı

Doğru tedarikçiyi seçmek tartışmasız doğru teknolojiyi seçmek kadar önemlidir. Pazar seçeneklerle doludur ve tüm tedarikçiler aynı düzeyde kanıtlanmış teknoloji, güvenilirlik veya satış sonrası destek sunmaz. Uzun süreli bir geçmişe, önemli Ar-Ge yatırımlarına ve sağlam bir küresel destek ağına sahip bir yüksek teknoloji kuruluşuyla ortaklık kurmak kritik önem taşır. Örneğin, MZBNL'nin metal imalatındaki 25 yıllık deneyimi, 30'dan fazla patenti ve 4000'den fazla küresel kurumsal müşterisi, Güneydoğu Asya, Orta Doğu, Avrupa ve Kuzey Amerika gibi ana ihracat ülkelerindeki kanıtlanmış uzmanlığımızı ve güvenilirliğimizi göstermektedir.

Makinenin ötesinde, kapsamlı eğitim programları ve satış sonrası hizmet sunan tedarikçilere öncelik verin. Ahmed Al-Farsi'nin yerel servis desteğinden yoksun ekipmanla ilgili sıkıntısının vurguladığı gibi, bir makine ancak arkasındaki destek kadar iyidir. MZBNL, "kullanımı ve bakımı kolay" vurgusunu yapmakta ve operatörler için öğrenme eğrisini önemli ölçüde azaltan No-CAD sistemi için 1 günlük yerinde eğitimimiz de dahil olmak üzere sağlam satış sonrası eğitimler sunmaktadır. Ayrıca, arıza süresini en aza indirmek ve sürekli çalışmayı sağlamak için çok önemli olan yedek parça bulunabilirliğini sağlıyor ve uzaktan teşhis sunuyoruz.

Potansiyel alıcılar, ideal olarak kendi sektörlerindeki mevcut müşterilerden aktif olarak referans almalı ve tedarikçinin uzun vadeli ortaklıklara olan bağlılığını sorgulamalıdır. Ahmed'in Körfez bölgesi için düşündüğü gibi, yerel temsilci veya distribütör seçeneklerinin araştırılması, zamanında destek ve hizmetin kullanılabilirliğini daha da artırabilir. Makine tedarikçinizle güçlü bir ilişki, başarılı bir geçişin temel taşıdır ve yatırımınızı kullanım ömrü boyunca en üst düzeye çıkarmak için gereken teknik yardım ve uzmanlığa sahip olmanızı sağlar.

Aşamalı Uygulama ve İş Akışı Entegrasyonu

Ani bir "sök ve değiştir" yaklaşımı yerine, lazer kesime geçiş yapan işletmeler için aşamalı bir uygulama stratejisi genellikle daha tavsiye edilir. Bu, mevcut iş akışlarına daha sorunsuz bir entegrasyon sağlar, devam eden üretimdeki kesintileri en aza indirir ve operatörlerin yeni teknolojiye uyum sağlamaları için zaman tanır. Örneğin, bir şirket başlangıçta lazer makinesini yeni ürünler veya belirli yüksek hassasiyetli bileşenler için kullanırken, güven ve uzmanlık arttıkça iş yükünü kademeli olarak daha fazla kaydırabilir. Bu ölçülü yaklaşım, büyük bir teknolojik yükseltme ile ilişkili riski önemli ölçüde azaltabilir.

Yeni lazer kesim makinesini daha geniş üretim ekosisteminize entegre etmek çok önemlidir. Bu, ham madde besleme, parça işleme ve sonraki süreçlerin (kaynak, bükme veya montaj gibi) lazer kesici ile nasıl etkileşime gireceğini değerlendirmeyi içerir. Modern lazer makineleri "akıllı ve dijitalleştirilmiş sistemler" ve "çoklu süreç entegrasyonu" ile tasarlanmıştır ve diğer otomatik sistemlerle sorunsuz veri akışı ve fiziksel bağlantı sağlar. İşletmeler lazer kesicinin sadece kesim aşamasını değil tüm üretim zincirini nasıl optimize edebileceğini düşünmelidir. Ahmed'in mevcut manuel iş akışlarını otomatikleştirmeye ve anahtar teslim çözümlere olan ilgisi, bu tür bir bütünsel entegrasyon arzusuna işaret ediyor.

Son olarak, Ahmed gibi hırslı müşteriler için sadece ekipman satın almanın ötesindeki fırsatları keşfetmek faydalı olabilir. Bölgesel bir distribütör olmayı veya Körfez bölgesi için ortak markalaşma seçeneklerini takip etmeyi düşünmesi, uzun vadeli stratejik bir vizyonu göstermektedir. Küresel distribütör ağlarına ve uzun vadeli ortaklıklara değer veren MZBNL gibi tedarikçiler bu tür düzenlemeleri tartışmaya açıktır. Bu yaklaşım, işlemsel bir satın almayı stratejik bir işbirliğine dönüştürerek karşılıklı fayda sağlar ve tedarikçinin müşterinin kendi pazarındaki uzun vadeli başarısına olan bağlılığını güçlendirir.

ROI analizi malzeme tasarruflarını içerirDoğru

Metinde, ROI analizinin malzeme atıklarının azaltılmasından elde edilmesi öngörülen tasarrufları hesaba katması gerektiği açıkça belirtilmektedir.

Tedarikçi seçimi teknolojiden daha az önemlidirYanlış

Metinde, doğru tedarikçiyi seçmenin "doğru teknolojiyi seçmek kadar önemli olduğu" belirtilmektedir.

Sonuç

Tüp lazer kesim makineleri, üstün hassasiyet, daha hızlı üretim ve önemli maliyet tasarrufları sunarak geleneksel yöntemlerden temelde daha iyi performans gösterir. İşletmeler, MZBNL'nin No-CAD sistemi ve sıfır atıkla kesim gibi yenilikleri benimseyerek verimliliği artırabilir, malzeme israfını azaltabilir ve benzersiz bir kalite elde ederek modern üretimde rekabet avantajı sağlayabilir.

-

Tüp lazer kesimin birden fazla prosesi nasıl entegre ettiğini, verimliliği ve tasarım yeteneklerini nasıl geliştirdiğini öğrenin ↩

-

BNL'nin Sıfır Atık Kuyruk İnovasyonunun malzeme kullanımını nasıl en üst düzeye çıkararak atıkları önemli ölçüde azalttığını anlayın ↩

-

MZBNL'nin gelişmiş üretim verimliliği için lazer kesim alanında sunduğu en son yenilikleri keşfedin. ↩

-

Temassız lazer ışınlarının kesme işlemlerinde hassasiyeti nasıl artırdığını ve hataları nasıl azalttığını öğrenin. ↩

-

Lazer teknolojisine yatırım yapmanın finansal faydalarını değerlendirme konusunda içgörü kazanın. ↩

Sorularınız mı var veya daha fazla bilgiye mi ihtiyacınız var?

Kişiselleştirilmiş yardım ve uzman tavsiyesi için bizimle iletişime geçin.