Metal Tube Cutting Machines with Front-Feeding: Key Advantages

The traditional methods of loading metal tubes into cutting machines often lead to frustrating inefficiencies, slowing down production and wasting valuable time. This ongoing struggle not only impacts output but also significantly increases operational costs and burdens your workforce. However, with the advent of advanced front-feeding systems, these issues are elegantly solved, transforming productivity.

Front-feeding systems revolutionize metal tube cutting by enhancing material utilization, dramatically boosting productivity, and significantly improving operator safety and reducing labor intensity compared to conventional loading methods. They offer a streamlined, automated, and highly efficient solution for modern fabrication needs.

As I've seen over my 25 years in the metal fabrication industry at MZBNL, the efficiency of a laser tube cutting machine isn't just about the laser itself, but profoundly tied to how material is handled. For businesses like Ahmed Al-Farsi’s, a mid-sized metal fabrication company in the UAE, upgrading production efficiency is a constant priority. While many focus on cutting speed, the true bottleneck often lies in the archaic feeding mechanisms. This article will peel back the layers to reveal how front-feeding technology1 is not just an incremental improvement, but a transformative shift for the entire industry.

Working closely with thousands of global enterprise clients, including those in demanding markets like the Middle East and North America, has shown me that the journey towards optimal efficiency is ongoing. We consistently observe that innovative approaches to fundamental processes, such as material feeding, unlock unparalleled performance gains. The critical thinking required to identify and address these foundational challenges is what truly differentiates high-tech enterprises2 like MZBNL. We don't just sell machines; we develop solutions that challenge conventional wisdom, analyze real-world operational data, and integrate feedback from diverse industry applications to redefine what's possible in metal fabrication. This dialectical approach allows us to not only solve immediate problems but also to anticipate future industry needs, driving continuous improvement and setting new benchmarks for productivity and precision.

What is the history and evolution of feeding mechanisms in tube cutting machines?

Many of us in the industry have experienced the limitations of outdated tube feeding methods, struggling with their inherent inefficiencies and high labor demands. This continuous challenge often hindered our ability to meet tight production schedules and maintain competitive pricing in dynamic markets. Yet, a clear evolution marks the journey from rudimentary manual loading to today’s sophisticated automated systems.

The history of tube feeding mechanisms in cutting machines evolved from purely manual loading and basic chain-driven systems to semi-automatic pushers and eventually to fully automated, intelligent front-feeding and material handling solutions, driven by the persistent need for increased efficiency, precision, and operator safety.

Looking back at the history of metal tube processing, the methods for feeding material into cutting machines have undergone a profound transformation, directly mirroring advancements in automation and precision engineering. Early on, the focus was simply on getting the tube into position, often requiring significant physical effort and multiple operators. However, as manufacturing demands grew and precision became paramount, the industry recognized the critical need for more streamlined and less labor-intensive feeding solutions. This recognition spurred a wave of innovation, leading to a gradual shift from manual brute force to integrated, intelligent systems designed to optimize the entire cutting workflow. Understanding this evolution is key to appreciating the current state-of-the-art technologies and their impact on modern fabrication.

The Era of Manual and Semi-Manual Loading

In the early days of metal tube cutting, manual loading was the norm. Operators physically lifted and positioned raw tubes onto the machine’s bed or into simple roller systems. This approach, while straightforward, was incredibly labor-intensive and prone to inaccuracies. Imagine a team like Ahmed Al-Farsi's, with 100+ staff, relying on such methods for their railing and shelving projects – the sheer physical demand and the risk of injuries would be immense. The constant heavy lifting and awkward maneuvering not only led to rapid operator fatigue but also increased the likelihood of musculoskeletal injuries, impacting long-term workforce health and increasing absenteeism.

Early advancements introduced basic mechanical assistance, such as simple chain-driven or roller systems, designed to reduce the sheer physical burden. While these systems provided some leverage, they still required significant manual intervention for precise alignment, pushing the tube through the machine, and monitoring the process to prevent jams. This reliance on human precision meant that the speed and accuracy of the feeding process were inherently limited by the operator’s skill and endurance, leading to inconsistent output and frequent pauses for adjustments.

Moreover, these rudimentary systems often struggled with handling diverse tube geometries or varying lengths efficiently. Each new batch of material might require different setup adjustments, consuming valuable production time. The lack of integrated control meant that operators had to constantly monitor the feeding process, leading to a fragmented workflow where the cutting machine often sat idle, waiting for the next segment of material to be manually positioned. This era highlighted the significant bottlenecks inherent in non-automated material handling, underscoring the urgent need for more intelligent and integrated solutions.

The Advent of Basic Automation

As technology progressed, the industry saw the introduction of more automated feeding solutions. These included pusher mechanisms and early gripper systems designed to automatically advance tubes into the cutting zone. A significant improvement over purely manual methods, these systems began to reduce the physical labor required and improved feeding consistency to some extent. For instance, a hydraulic or pneumatic pusher could consistently move a tube at a predefined rate, which was a clear step forward in process control.

However, these early automated systems often loaded material from the side or rear of the machine, which, while reducing direct manual handling, introduced new inefficiencies. Workshop layouts had to accommodate long side-loading areas, potentially wasting valuable floor space. More critically, these systems frequently resulted in unavoidable "tail material" waste. A tube would be pushed from one end, and the final segment, gripped by the chuck at the end of the cut, would remain as scrap simply because the machine couldn’t process it further. This inefficiency meant a measurable loss of expensive raw materials; a typical 6-meter tube might yield a 0.5-meter unusable tail, equating to nearly 8% material waste on every tube.

While these automated systems offered faster feeding speeds than purely manual methods, they often lacked the intelligence to truly optimize material utilization or seamlessly integrate with advanced cutting logic. They were primarily mechanical solutions to a physical problem, rather than intelligent systems designed for overall workflow optimization. The need for precise alignment and the persistent issue of tail waste remained significant challenges, pushing the industry to seek even more sophisticated solutions that could not only move material but also maximize its value.

The Rise of Smart Front-Feeding Innovation

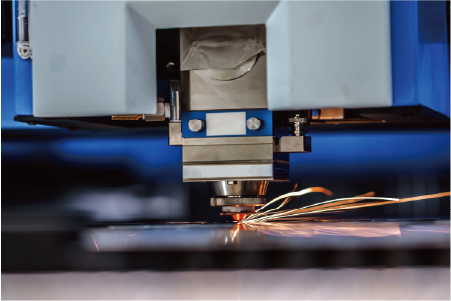

The current pinnacle of feeding mechanism evolution is the smart front-feeding system, a technology that we at MZBNL have pioneered and perfected. This innovation represents a leap forward, directly addressing the pain points of previous generations by integrating advanced automation with intelligent control. Instead of relying on manual side/rear loading or inefficient pushers, front-feeding automatically pulls the tube in from the front of the machine, leveraging precision sensors and synchronized gripping mechanisms.

This re-engineered approach brings several critical benefits: it significantly boosts feeding efficiency by approximately 40% and drastically reduces operator labor intensity by about 40%, enhancing overall productivity and workplace ergonomics. For a business like Ahmed Al-Farsi’s, this means a substantial increase in output without overburdening his skilled workforce. The immediate ergonomic improvement frees operators from strenuous tasks, allowing them to focus on higher-value activities like machine monitoring and quality control.

Most importantly, MZBNL's front-feeding system enables "zero-waste tail material." By redesigning the cutting logic to calculate from the rear chuck as the origin, our system can process virtually the entire tube, eliminating unusable remnants as long as the remaining section is larger than the product length. This intelligent material optimization translates directly into significant cost savings, maximizing the return on investment for expensive raw materials. This innovation is a game-changer for businesses prioritizing high cost-performance ratios and seeking to maximize material utilization in every project, transforming a labor-intensive, wasteful process into a highly efficient, automated, and sustainable operation.

| Özellik | Manual/Semi-Manual Loading | Early Automated (Side/Rear) | MZBNL Front-Feeding |

|---|---|---|---|

| Besleme Verimliliği | Düşük | Orta | High (Up to 40% Inc.) |

| İşgücü Yoğunluğu | Çok Yüksek | Orta | Very Low (Up to 40% Red.) |

| Malzeme Atıkları | Yüksek | Moderate (Tail Waste) | Near Zero (Tail Optimized) |

| Operatör Becerisi | Orta düzeyde | Orta düzeyde | Low (1-day training) |

| Kurulum Süresi | Long | Orta düzeyde | Short |

Front-feeding boosts productivityDoğru

Front-feeding systems increase feeding efficiency by up to 40% compared to traditional methods.

Manual loading wastes materialYanlış

While manual loading is inefficient, material waste is actually higher with early automated side/rear systems due to tail waste.

How does the current front-feeding system work in metal tube cutting machines?

Understanding the inner workings of an advanced front-feeding system might seem complex, but its design is rooted in streamlining the entire tube processing workflow, making it remarkably efficient. The magic lies in its integration of automation and intelligent control. This system effectively automates what was once a highly manual and error-prone task.

A modern front-feeding system operates by automatically pulling the tube from the front of the machine using a synchronized combination of rollers, clamps, and intelligent sensors, ensuring precise positioning and continuous material flow directly into the cutting zone, thereby eliminating manual handling and optimizing cutting efficiency.

The sophistication of today's front-feeding systems is a testament to years of research and development, a journey we at MZBNL have been at the forefront of. Unlike the rudimentary pushers or manual placements of the past, these systems employ a delicate ballet of mechanics and digital intelligence. The core principle is seamless, continuous material flow, but achieving this requires precise synchronization between multiple components and an intuitive control interface. For a busy facility owner like Ahmed Al-Farsi, knowing that a machine can autonomously handle material loading not only frees up his skilled workforce but also significantly enhances the reliability and consistency of his production lines. This is the difference between a machine that cuts and a solution that optimizes.

Automated Loading and Alignment

The process begins with the raw tube being placed onto a loading platform at the front of the machine. This platform is typically equipped with robust rollers or conveyors3 that minimize friction, allowing even heavy or long tubes to be easily staged. Once positioned, an array of precision sensors — including optical, proximity, and sometimes laser-based sensors — accurately detect the presence, length, and even diameter of the tube. This initial data collection is crucial for the machine's control system to prepare for the incoming material.

Following detection, automated clamps and synchronized rollers, often hydraulically or pneumatically actuated, gently but firmly grip the tube. These gripping mechanisms are designed to provide consistent pressure without deforming the material, ensuring the tube maintains its integrity throughout the feeding process. The system then intelligently pulls the tube forward, feeding it into the main cutting chuck. This pull-based feeding mechanism is inherently more stable and precise than push-based systems4, as it eliminates buckling or misfeeding issues that can occur when pushing long, slender tubes.

This initial pull and alignment are critical for precision. They ensure the tube is perfectly centered and positioned for subsequent processing, compensating for minor irregularities in the raw material or placement. For our MZBNL No-CAD Operating System, this automated alignment is fundamental. Operators don't need to manually adjust for tube variations; the machine intelligently handles it, significantly reducing setup time from days to just moments. This automation dramatically lowers the skill threshold for operation, enabling someone with just one day of on-site training to manage what previously took 15 days at the equipment factory, ensuring rapid deployment and operator proficiency.

Integrated Processing Flow

Once loaded, the front-feeding system works in perfect concert with the laser cutting head and the main and auxiliary chucks. As the cutting process progresses, the feeding system continuously and precisely advances the remaining length of the tube into the active cutting zone. This continuous motion is not a simple feed, but a highly synchronized movement where the feeding speed is dynamically adjusted to match the cutting speed and the specific geometry being processed. For instance, during intricate cuts or rapid movements, the feed might momentarily pause or slow, while during straight cuts, it maintains a brisk, steady pace.

This integrated flow eliminates the common pauses for manual repositioning that plague traditional systems, which can lead to significant idle time. The synchronization is paramount: the feeding speed, chuck rotation, and laser activation are all managed by a central control unit, preventing any lag or overfeeding. This holistic approach ensures that from the moment the raw tube is introduced, to the final cut part being ejected, the entire operation is a fluid, highly synchronized process. This not only maximizes actual cutting time but also reduces wear and tear on the machine by preventing abrupt stops and starts.

The system's ability to seamlessly integrate feeding with the cutting and unloading processes means that production can run virtually unattended for extended periods, especially with automated bundling or sorting systems downstream. This level of integration is paramount for high-volume production environments and for achieving turnkey solutions that clients like Ahmed Al-Farsi value. It ensures consistent output quality and maximizes throughput, directly contributing to increased profitability by minimizing non-productive intervals and optimizing the entire manufacturing chain.

Smart Control and Feedback Systems

The brain behind the front-feeding system is its smart control and feedback mechanism, typically managed by a sophisticated industrial-grade PLC (Programmable Logic Controller) and an intuitive HMI (Human-Machine Interface). These systems continuously monitor various parameters in real-time, such as the exact position of the tube, its remaining length, the cutting parameters, and even the type of material being processed. They receive data from an array of sensors, including encoders for precise linear movement, proximity sensors for material detection, and current sensors on motors for load monitoring.

This constant stream of data allows the control system to provide instantaneous feedback to the operator via the HMI, displaying current status, progress, and any potential alerts. More critically, the system automatically adjusts feeding parameters on the fly to optimize performance and prevent errors. For instance, if a slight material warp is detected, the system might subtly adjust gripping pressure or feeding speed to compensate, ensuring a perfect cut. This proactive adjustment minimizes human intervention and ensures consistent quality, even with minor material imperfections.

A standout feature of our MZBNL machines, for instance, is the "Zero-Waste Tail Material Innovation." The control system plays a crucial role here: it intelligently calculates from the rear chuck as the origin point, rather than a fixed front-end. This advanced algorithm allows the machine to precisely determine if the remaining unutilized section of the tube is large enough to produce another part. If it is, the system will adjust its cutting path to maximize the use of this "tail," ensuring that virtually every inch of expensive raw material is converted into a finished product. This intelligent calculation, combined with precise feeding and real-time monitoring, represents a significant leap in operational intelligence and directly addresses the cost concerns of clients like Ahmed, turning what was once inevitable waste into valuable output.

Front-feeding uses pull mechanismDoğru

Modern front-feeding systems pull tubes forward using rollers/clamps rather than pushing them, preventing buckling issues.

Tail material is always wastedYanlış

Advanced algorithms repurpose tail sections when feasible, unlike traditional systems that discard them.

What challenges did traditional feeding mechanisms present in metal tube cutting?

Many of us have firsthand experience with the frustrating inefficiencies of traditional tube feeding mechanisms. The daily grind often involved labor-intensive processes, significant material wastage, and the constant headache of production bottlenecks. These challenges were not just minor inconveniences; they directly impacted profitability and operational agility.

Traditional feeding mechanisms in metal tube cutting presented significant challenges including high labor intensity leading to increased operational costs and safety risks, substantial material waste from unusable tail ends, and frequent production bottlenecks due to slow setup times and reliance on highly skilled operators for manual adjustments.

My journey alongside MZBNL’s clients, particularly those in rapidly expanding sectors, has frequently highlighted the deep-seated issues that conventional feeding systems impose. These aren't merely technical quirks but fundamental roadblocks that hinder a company's ability to scale5, innovate, and remain competitive. For a business owner like Ahmed Al-Farsi, who is actively expanding into architectural metalwork and vehicle parts supply, mitigating these challenges is not just about incremental gains; it's about securing future growth. The critical analysis of these pain points reveals why the industry desperately needed a revolutionary approach to material handling, moving beyond stop-gap solutions to truly transform productivity6 and workplace safety.

High Labor Intensity and Safety Risks

One of the most immediate and impactful challenges of traditional feeding mechanisms was their inherent labor intensity. Manually loading heavy and often long metal tubes required significant physical exertion, often involving multiple operators for larger diameters or lengths. This constant heavy lifting, pushing, and positioning not only inflated labor costs but also posed substantial safety risks, including musculoskeletal strains, repetitive stress injuries, and the ever-present danger of crushing injuries or cuts from sharp edges. The physical toll on the workforce was immense, leading to chronic fatigue and a higher incidence of workplace accidents.

I’ve personally witnessed the fatigue and stress this puts on a workforce, leading to decreased morale and productivity over time. For businesses like Ahmed’s, with established operations and a focus on upgrading manual workflows, high operator turnover caused by such demanding tasks became a significant retraining burden. The constant cycle of finding, training, and retaining staff for physically demanding roles was not sustainable, directly impacting operational consistency and overall business efficiency. New hires often faced a steep learning curve, not just in machine operation but in the arduous physical techniques required for safe manual loading, increasing the risk of early-stage injuries.

Furthermore, the need for human proximity to moving machinery during manual loading increased the risk of accidents. Operators had to be in close contact with heavy, potentially swinging, and fast-moving tubes, especially during initial positioning and feeding into the machine chuck. This created inherent safety hazards that were difficult to mitigate fully, even with strict safety protocols. The financial and human costs associated with workplace injuries, even minor ones, could quickly escalate, leading to compensation claims, increased insurance premiums, and, most importantly, the disruption of production7 and the loss of valuable human capital.

Substantial Material Waste and Inefficiency

Traditional feeding systems, particularly those that pushed material from the side or rear, were notorious for generating unusable tail material. Regardless of how efficiently the machine cut, a significant portion of the tube at the very end would be left as scrap because the chuck or gripper couldn't hold it securely enough to process further. This "tail waste" accumulated quickly, representing a direct and substantial loss of expensive raw materials. For operations processing large volumes of tubes, the financial impact of this waste was considerable; for example, a company processing 10,000 tubes annually, with each tube leaving just a 0.5-meter scrap tail, could be wasting thousands of meters of valuable material per year, directly eroding profit margins.

Beyond the sheer volume of scrap, the inefficiency extended to the cutting process itself. The manual or semi-manual nature of these systems often led to slower feeding speeds and frequent interruptions. Operators had to pause the machine to reposition or adjust the tube, particularly when dealing with long tubes or complex cutting programs. These non-cutting periods added up, significantly extending overall production times and reducing the machine's effective throughput. The inability to fully utilize the raw material and the constant interruptions meant that the production process was far from optimal, directly hindering the achievement of cost-effective customized solutions that clients like Ahmed Al-Farsi seek.

Moreover, the lack of precise, automated control over material flow often resulted in misfeeds, jams, or imprecise positioning. These errors necessitated stopping the machine, clearing the issue, and potentially scrapping partially processed tubes, further contributing to material waste and production delays. This compounded inefficiency made it challenging for manufacturers to maintain consistent quality and deliver projects on time, especially when working with high-value materials or tight production schedules. The cumulative effect of these inefficiencies created a significant drag on profitability and operational agility, making it difficult for businesses to scale or compete effectively in a demanding market.

Production Bottlenecks and Skill Dependency

Another critical challenge was the tendency of traditional feeding mechanisms to create significant production bottlenecks within the entire fabrication workflow. The time-consuming and often complex process of manually loading, aligning, and frequently adjusting tubes meant that the laser cutting machine, despite its inherent speed and precision, often sat idle, waiting for material. This 'wait time' directly limited the machine’s overall output capacity, regardless of its cutting capabilities. For instance, if a machine can cut for 55 minutes out of every hour but spends 15 minutes on manual loading and adjustments, its true efficiency drops significantly, impacting overall production targets and extending lead times for client projects.

Furthermore, these systems often required a high level of skill and experience from operators to ensure accurate loading and prevent errors. The nuance of handling different tube sizes, weights, and material types, combined with the need for precise alignment, meant that only seasoned personnel could reliably manage the feeding process. This reliance on highly specialized skills created a significant dependency, making operations vulnerable to staff shortages due to illness, vacation, or turnover. Ahmed Al-Farsi’s experience with previous machines requiring skilled CAD operators and the subsequent retraining burdens highlights this pain point perfectly; finding and retaining such specialized staff proved to be a continuous challenge and a costly endeavor for his business.

The skill dependency also meant that scalability was a major issue. Expanding production would necessitate finding and training more highly skilled operators, a process that is both time-consuming and expensive. Without automated, intelligent feeding, the entire production line suffered from reduced flexibility and scalability, hindering a business's ability to adapt quickly to fluctuating market demands or sudden increases in order volume. This bottleneck in material handling ultimately constrained the overall growth potential of the fabrication enterprise, forcing businesses to turn down lucrative contracts or delay deliveries, directly impacting their revenue and reputation.

Traditional feeding caused material wasteDoğru

Unusable tail ends from manual feeding systems resulted in significant scrap accumulation, directly impacting material costs.

Manual feeding improved safetyYanlış

Manual loading actually increased safety risks due to operator proximity to moving machinery and heavy lifting hazards.

What are the significant advantages of using front-feeding in metal tube cutting machines?

For anyone in metal fabrication, the quest for higher efficiency, precision, and cost savings is constant. Traditional methods often present more hurdles than solutions, leaving us searching for a better way to optimize our production lines and elevate our competitive edge. The good news is, a transformative solution exists.

Front-feeding systems offer significant advantages in metal tube cutting by dramatically improving feeding efficiency and reducing labor intensity, virtually eliminating material waste through innovative zero-tail technology, and enhancing overall machine intelligence for greater ease of use and consistent high-precision output, leading to substantial cost savings and productivity gains.

Over the past quarter-century at MZBNL, I’ve had the privilege of witnessing and contributing to revolutionary changes in metal fabrication. What stands out most profoundly is how targeted innovations in core processes8, like front-feeding, can cascade into monumental benefits across an entire operation. This isn't just about faster machines; it's about building a smarter, more sustainable, and ultimately more profitable production ecosystem. For someone like Ahmed Al-Farsi, who values high cost-performance ratios and seeks proven technology, the advantages of front-feeding are directly aligned with his business objectives. It offers a tangible pathway to automate existing manual workflows and achieve the turnkey solutions he prefers. Let's delve into how this technology delivers on its promise.

Enhanced Productivity and Throughput

The most immediate and tangible advantage of front-feeding systems is the substantial boost in productivity and throughput, fundamentally transforming the rate at which parts can be produced. By automating the entire material loading process—from tube recognition to precise feeding—these systems virtually eliminate the idle time associated with manual handling, allowing the machine's laser cutting head to operate almost continuously. This seamless, uninterrupted flow of material means that the machine is actively cutting for a much higher percentage of its operational hours, directly translating into a significant increase in output.

We at MZBNL have seen our optimized front-feeding mechanism increase feeding efficiency by approximately 40% compared to traditional manual or semi-automatic methods. For a fabrication plant, this efficiency gain doesn't just mean a slight improvement; it translates directly into a higher volume of finished parts per hour, more jobs completed per shift, and ultimately, a substantial increase in overall production capacity. For a bustling fabrication business like Ahmed's, which handles contract-based services for railing, shelving, and auto parts, this increase in throughput is a critical competitive advantage. It means they can take on more projects simultaneously, meet tighter deadlines without compromising quality, and deliver finished parts faster to builders, decorators, and OEMs, thereby enhancing client satisfaction and securing repeat business.

This heightened productivity also empowers companies to better utilize their existing assets. Instead of investing in multiple machines to handle increased demand, a single front-feeding equipped laser cutter can often meet the expanded production requirements, optimizing capital expenditure. The ability to churn out more products in less time not only boosts revenue potential but also improves overall operational fluidity, reducing backlogs and allowing for greater flexibility in managing diverse project portfolios. This agility is paramount in today's fast-paced manufacturing environment, ensuring that the bottleneck isn't the machine waiting for material, but rather the machine consistently producing at peak performance.

Superior Material Utilization and Cost Savings

One of the most compelling advantages of front-feeding, particularly when integrated with our MZBNL "Zero-Waste Tail Material Innovation," is the unparalleled optimization of material utilization. Conventional side or rear-feeding systems inherently create unusable tail material—often several inches to a foot or more—because the chuck or gripper cannot securely hold the very last segment of the tube for cutting. This scrap, though small per tube, accumulates rapidly in high-volume operations, representing a direct and significant loss of expensive raw materials. For a company processing thousands of meters of high-value stainless steel or aluminum tubing annually, even a 5% reduction in material waste can result in tens of thousands of dollars in annual savings.

Our redesigned cutting logic within the front-feeding system addresses this critical inefficiency head-on. By calculating the cutting path from the rear chuck as the origin, our system can process material right down to the last practical segment. This means that as long as the remaining unutilized section of the tube is larger than the required product length, it can be precisely cut and converted into a usable part, virtually eliminating leftover tail material. This intelligent material optimization is not merely an incremental improvement; it's a revolutionary approach to resource management that maximizes the return on investment for every stick of tubing purchased.

For a business owner like Ahmed Al-Farsi, who prioritizes high cost-performance ratios and seeks to minimize operational expenses, the financial impact of zero-waste technology is immense. It directly impacts the bottom line, turning what was once inevitable waste into valuable output. This competitive edge, derived from reduced material costs per part, allows companies to offer more aggressive pricing to their clients or enjoy higher profit margins on existing contracts, solidifying their market position and promoting sustainable growth through responsible resource management.

Improved Operator Experience and Safety

Beyond the direct production benefits, front-feeding systems dramatically enhance the operator experience and significantly improve workplace safety, contributing to a healthier and more sustainable work environment. The automated nature of the feeding mechanism fundamentally transforms the physical demands placed on operators by significantly reducing manual labor intensity—often by as much as 40%, as observed with MZBNL’s innovations. Operators are no longer required to manually lift, push, or precisely position heavy and awkward tubes, which are typically long and can be several hundred kilograms. This elimination of strenuous physical tasks minimizes the risk of musculoskeletal strains, repetitive stress injuries, and fatigue, leading to a much safer and more comfortable working condition.

This ergonomic improvement translates directly to a more comfortable and safer working environment. When workers are less physically drained, they are more alert, focused, and less prone to accidents. For example, the risk of crush injuries, which are common when handling heavy tubes manually around machinery, is virtually eliminated as the automated system handles the material handling within a controlled safety zone. This reduction in physical burden also addresses a critical pain point for businesses like Ahmed Al-Farsi’s, which face high operator turnover and the associated retraining burdens. By making the job less physically demanding and more about supervision and system management, it becomes easier to attract and retain skilled personnel, leading to greater workforce stability.

Furthermore, with MZBNL’s "No-CAD Operating System Innovation" integrated with front-feeding, the learning curve for operators is drastically reduced. Instead of requiring 15 days of intensive training at the equipment factory to master complex CAD drawings and manual machine setups, operators only need 1 day of on-site training to become proficient in managing the user-friendly interface and overseeing the automated process. This simplification of operation not only accelerates deployment but also empowers a broader range of individuals to operate the machinery safely and efficiently. The combined benefits of enhanced safety, reduced physical strain, and simplified operation foster a positive work culture, improve employee morale, and ultimately contribute to a more productive and resilient fabrication business.

Front-feeding increases productivity by 40%Doğru

MZBNL's optimized front-feeding mechanism demonstrates a 40% efficiency gain over manual methods by eliminating idle time.

Zero-waste tech eliminates all material lossYanlış

While MZBNL's system minimizes waste, it can't eliminate all material loss - only unused segments larger than product length remain.

How does the adoption of front-feeding systems impact productivity and ergonomics in the industry?

The metal fabrication industry is constantly evolving, driven by the twin demands of higher output and better working conditions. Manual processes can hinder both, creating inefficiencies and exposing workers to undue strain. The question then becomes, how can we truly bridge this gap and achieve a harmonious balance?

The adoption of front-feeding systems profoundly impacts industry productivity by enabling higher throughput, reducing material waste, and streamlining workflows, while simultaneously improving ergonomics by significantly decreasing operator labor intensity and enhancing workplace safety, leading to a more efficient, sustainable, and employee-friendly manufacturing environment across the sector.

From my vantage point at MZBNL, working with diverse clients across Southeast Asia, Europe, and North America, I've observed a clear trend: companies that invest in smart automation9 like front-feeding aren't just gaining a temporary edge; they're fundamentally reshaping their operational models. This isn't merely about buying a machine; it's about embracing a philosophy of continuous improvement that elevates both the business's bottom line and the well-being of its workforce. For established businesses like Ahmed Al-Farsi’s, planning to automate existing manual workflows, the impact of such systems extends far beyond immediate production gains, fostering a more robust, adaptable, and attractive work environment. It's about building a future-proof enterprise.

Operational Efficiency and ROI

The adoption of front-feeding systems delivers a robust return on investment by profoundly enhancing operational efficiency across the entire production line. By automating the crucial material handling phase, these systems eliminate common bottlenecks that plague traditional setups, leading to consistent, high-speed, and high-precision cutting. This seamless and uninterrupted flow of material directly translates into significantly increased machine utilization rates and higher overall throughput. For example, a facility that processes 50,000 meters of tubing annually using traditional methods might experience frequent pauses for loading, taking up 20-30% of machine time. With front-feeding, this non-cutting time can be reduced dramatically, enabling the machine to cut for over 90% of its operational hours. Our MZBNL front-feeding system alone can boost feeding efficiency by around 40%, directly impacting hourly output and allowing for a substantial increase in completed parts per shift.

This efficiency gain translates into faster project completion times, allowing companies to take on more contracts and generate revenue quicker. For clients like Ahmed Al-Farsi, who prioritize a "high cost-performance ratio" and seek turnkey solutions that optimize their production, the upfront investment in such advanced technology is rapidly recouped through multiple avenues. Reduced labor expenses due to less manual intervention, minimized material waste (thanks to zero-tail technology that can save thousands of dollars annually on raw material), and the increased capacity to handle higher production volumes without needing to expand their physical footprint or workforce proportionally all contribute to significant financial benefits. The cumulative effect of these savings and increased output creates a compelling financial case for adoption, proving that initial capital outlay quickly yields tangible long-term gains.

Furthermore, improved operational efficiency extends beyond just speed; it also encompasses reduced errors and higher quality output. Automated feeding ensures precise material positioning every time, minimizing miscuts and scrap. This consistency leads to less rework and fewer quality control issues, which further saves time and resources. For a company like MZBNL, boasting over 30 patents and serving 4000+ global clients, the focus on integrated efficiency means that our machines are not just faster, but also more reliable, contributing directly to a client's ability to maintain high standards and meet rigorous industry specifications consistently, thereby bolstering their reputation and market share.

Workforce Empowerment and Skill Shift

Beyond pure productivity metrics, front-feeding systems have a transformative impact on workforce empowerment and fundamentally shift the nature of labor within the metal fabrication industry. By significantly reducing operator labor intensity—up to 40% as seen with our MZBNL innovation—these systems free employees from repetitive, physically demanding, and often hazardous tasks like manually lifting and positioning heavy, long tubes. This ergonomic improvement is profound: less physical strain means reduced fatigue, fewer work-related injuries, lower rates of absenteeism, and a healthier, more engaged workforce overall. Employees can expend their energy on higher-value activities rather than strenuous, low-skill physical labor.

This shift allows workers to transition from manual laborers to skilled machine supervisors, quality control specialists, or even programmers, focusing on optimizing machine performance, monitoring production, and troubleshooting. Instead of manually feeding tubes, an operator can oversee multiple machines, analyze real-time data from the HMI, or manage inventory. The intellectual demands of the job increase, making it more stimulating and less physically draining. For businesses that experience high operator turnover, like Ahmed’s, this reduction in manual burden, combined with the simplified operation (thanks to our 1-day training compared to 15 days previously required for similar complex machinery), means less time and resources spent on constant retraining. It empowers existing staff to grow professionally, enhancing their skill sets and career prospects within the company.

Moreover, a more ergonomic and technologically advanced workplace naturally becomes more attractive to a new generation of workers. Young talent is often drawn to roles that involve smart systems and digital interfaces rather than purely manual labor. By adopting front-feeding technology, companies can not only retain valuable experienced personnel but also attract new, tech-savvy individuals interested in operating advanced machinery. This fosters a positive work culture, improves employee morale, and ultimately contributes to a more productive, stable, and resilient fabrication business that is well-equipped for the future.

Industry Competitiveness and Sustainability

The strategic adoption of front-feeding systems directly bolsters a company's competitiveness in the global market while simultaneously advancing its environmental sustainability efforts. With significantly enhanced productivity and drastically reduced material waste, businesses can offer more competitive pricing to their clients, accelerate project turnaround times, and maintain higher profit margins, all of which are crucial for expanding market share. For MZBNL, having served over 4000 global enterprise clients across various continents, we've observed that companies embracing such innovations are better positioned to penetrate new markets, manage fluctuations in demand, and maintain profitability even during economic shifts or supply chain disruptions. The ability to produce more efficiently at a lower cost per unit fundamentally strengthens their position against competitors, whether local or international.

Furthermore, the "Sıfır Atık Kuyruk Malzemesi İnovasyonu10" inherent in many front-feeding systems significantly contributes to environmental sustainability by minimizing scrap metal. Every kilogram of metal saved from becoming waste reduces the demand for virgin raw materials, the energy consumed in their extraction and processing, and the carbon footprint associated with manufacturing and waste disposal. This commitment to efficiency and waste reduction resonates with increasingly environmentally conscious markets and regulations, offering a dual advantage of economic competitiveness and responsible manufacturing. By demonstrating a tangible commitment to sustainable practices, companies can also enhance their brand reputation and appeal to clients who prioritize eco-friendly suppliers, opening up new business opportunities.

The move towards automated, efficient systems like front-feeding also aligns with broader industry trends towards digitalization and smart manufacturing. Companies that embrace these technologies become part of a more advanced, integrated ecosystem, capable of leveraging data for further optimization and innovation. This forward-thinking approach ensures long-term viability and growth, preparing businesses for future technological shifts and market demands. Ultimately, the adoption of front-feeding is not just an equipment upgrade; it is a strategic investment in a company's future, enhancing its operational resilience, market standing, and commitment to a more sustainable industrial landscape.

Front-feeding reduces material wasteDoğru

The text mentions "zero-tail technology" that saves thousands annually on raw material by minimizing scrap.

Manual feeding is more preciseYanlış

The text states automated feeding ensures precise material positioning, minimizing miscuts compared to manual processes.

Sonuç

Front-feeding mechanisms in metal tube cutting machines mark a pivotal advancement, drastically boosting productivity and material utilization while enhancing operator safety and reducing labor intensity. These innovative systems directly address industry pain points, offering a smarter, more cost-effective, and ergonomically superior solution for modern metal fabrication, driving a profound industry transformation.

-

Discover how front-feeding technology improves productivity and efficiency in metal fabrication. ↩

-

Learn how high-tech enterprises innovate in metal fabrication to improve efficiency and precision. ↩

-

Learn about conveyor types that minimize friction and enable efficient tube staging ↩

-

Understand the stability and precision advantages of pull-based feeding mechanisms ↩

-

Learn about the constraints on scaling production in metal tube cutting processes ↩

-

Discover the benefits of innovative feeding systems on productivity and safety in manufacturing ↩

-

Understand the impact of production halts on manufacturing efficiency and costs ↩

-

Discover the impact of process innovations on fabrication efficiency ↩

-

Discover the role of smart automation in streamlining workflows and improving outcomes. ↩

-

Understand how this technology reduces material waste and contributes to sustainability. ↩

Sorularınız mı var veya daha fazla bilgiye mi ihtiyacınız var?

Kişiselleştirilmiş yardım ve uzman tavsiyesi için bizimle iletişime geçin.