Comparing Metal Tube Cutting Machines: Which Method Fits Your Budget?

Are you struggling to select the perfect metal tube cutting method within your budget? I understand that a wrong choice can lead to significant financial setbacks and operational inefficiencies. This guide will help you navigate the complexities and make an optimal investment for your business.

Metal tube cutting involves methods like sawing, plasma, and laser cutting, each with distinct cost implications. Laser cutting, while a higher initial investment, often provides superior precision and efficiency, leading to lower per-part costs and enhanced long-term profitability for businesses like ours at MZBNL.

I've seen countless manufacturers wrestle with this critical decision. My 25 years at MZBNL, helping over 4000 enterprise clients globally, confirm that the right choice isn't just about the lowest price; it's about finding the perfect blend of cutting-edge technology, operational efficiency, and long-term value. Let's explore the options and how they align with your financial goals.

In the dynamic landscape of metal fabrication, selecting the appropriate tube cutting technology is more than a technical decision; it's a strategic financial one. Businesses often face the daunting task of balancing immediate capital expenditure with long-term operational efficiency and profitability. From my vantage point at MZBNL, where we integrate R&D, manufacturing, sales, and service, I've observed a significant shift from traditional, labor-intensive methods to sophisticated, automated solutions. Take clients like Ahmed Al-Farsi, for instance, a savvy owner of a mid-sized metal fabrication business in the UAE. He understands that while manual workflows might seem cheaper upfront, they are plagued by high operator turnover and the need for skilled CAD professionals—a pain point I frequently hear. His goal is to automate existing processes to boost efficiency and expand into high-demand sectors like architectural metalwork and vehicle parts, which demand precision. The challenge lies in critically assessing how each cutting method not only performs but also contributes to the total cost of ownership. A deeper dive reveals that initial investment is only one piece of the puzzle; factors like material waste, energy consumption, post-processing requirements, and the skill level of operators ultimately dictate a project's true cost-effectiveness. My experience tells me that while a lazer tüp kesme maki̇nesi̇1 might represent a larger upfront cost, its unparalleled precision, speed, and minimal material waste often translate into substantial long-term savings, making it a superior choice for businesses aiming for sustainable growth and high-quality output.

What are the various metal tube cutting methods available today?

Feeling overwhelmed by the array of metal tube cutting options? I understand that choosing incorrectly can impact your precision and overall productivity. Let me demystify the core methods available in today's market, guiding you towards an informed decision.

Modern metal tube cutting encompasses traditional abrasive saw, band saw, plasma, and advanced laser cutting. Each method offers unique advantages in terms of speed, precision, material compatibility, and operational complexity, catering to diverse industrial requirements across various sectors.

At MZBNL, we've witnessed the evolution of these technologies firsthand over our 25 years in the industry. From rudimentary manual cuts to sophisticated automated systems, understanding each method's nuances is crucial for optimizing your operations and achieving the precision your projects demand. My team and I regularly help clients, including those with needs similar to Ahmed Al-Farsi, navigate these choices. I'll share my insights on how each technique stands up in real-world scenarios, helping you identify the most suitable cutting solution for your specific applications and long-term business goals.

In the realm of metal tube fabrication, the choice of cutting method significantly dictates the outcome in terms of precision, speed, and overall cost-effectiveness. As an expert from MZBNL, I often guide clients through the various options, from the most basic to the highly advanced, ensuring they select technology that aligns with their production needs and budget.

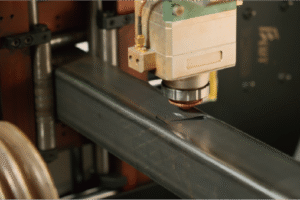

Mechanical Cutting Methods: Traditional Yet Limited

Mechanical cutting, primarily encompassing band saws and cold saws, represents the foundational techniques for tube cutting. These methods involve physical contact with the material, using a blade to slice through the tube. They are characterized by their relatively low initial investment costs, making them appealing to smaller workshops or operations with very low volume and less stringent precision requirements. For example, a basic band saw might cost around $5,000 to $15,000, significantly less than advanced alternatives. However, their limitations are pronounced: precision is often compromised, typically yielding tolerances of +/- 0.5mm to 1.5mm, which is unsuitable for applications requiring high accuracy, like those in the automotive or medical equipment sectors. Furthermore, mechanical cutting often results in burrs and significant material waste, necessitating additional post-processing steps such as deburring and cleaning. This adds to labor costs and extends lead times, impacting overall efficiency. For instance, if a project requires a smooth, clean edge for welding, the time spent on secondary finishing can negate any initial savings from the low machine cost.

Consider a small furniture manufacturer who primarily uses simple cuts for basic frames. While a band saw might fulfill their immediate need, as their business grows and demands for intricate designs or higher production volume increase, they quickly encounter bottlenecks. The slower production rate, potentially 50-100 cuts per hour depending on tube size and material, cannot keep up with modern manufacturing paces. This often leads to increased labor costs per part and delays in project delivery, demonstrating that "cheap" doesn't always translate to "cost-effective" in the long run.

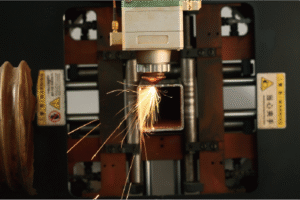

Thermal Cutting Methods: A Step Towards Versatility

Thermal cutting methods, primarily plasma cutting and oxy-fuel cutting, offer a step up in terms of speed and ability to handle thicker materials compared to mechanical methods. Plasma cutting, in particular, is widely used for cutting various conductive metals, including steel, stainless steel, and aluminum. It works by generating an arc that ionizes gas into plasma, which then melts and expels the material. Plasma cutters offer faster cutting speeds than saws for thicker tubes and can handle larger diameters, making them suitable for heavy fabrication industries like construction or large-scale structural work. A typical industrial plasma tube cutter might range from $30,000 to $80,000.

However, plasma cutting comes with its own set of trade-offs. While faster, the precision is still considerably lower than laser cutting, typically ranging from +/- 0.5mm to +/- 1mm, and it produces a larger heat-affected zone (HAZ). This HAZ can alter the material properties near the cut edge, potentially leading to warping or requiring further heat treatment. More importantly, plasma cutting often leaves dross and slag, which demand time-consuming post-processing for a clean finish. For instance, an automotive parts producer, similar to what Ahmed Al-Farsi might supply, would find plasma cutting insufficient for high-tolerance components due to the dross and less precise cuts, which would then require extensive grinding and deburring, increasing labor costs and material handling.

Energy consumption is another factor; while modern plasma systems are more efficient, they generally consume more power per cut than laser systems for thinner materials, and the need for compressed air adds to utility costs. The quality of the cut, while acceptable for certain applications, falls short for industries where intricate geometries and smooth finishes are paramount.

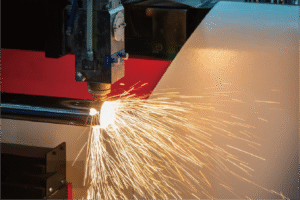

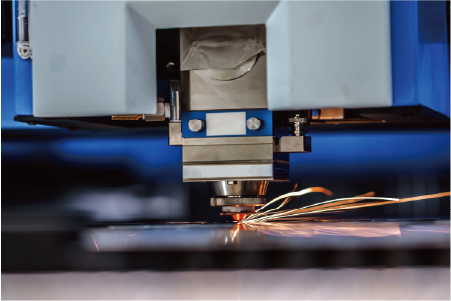

Advanced Laser Cutting: Precision, Efficiency, and Innovation

Fiber laser tube cutting represents the pinnacle of current metal tube cutting technology, offering unparalleled precision, speed, and versatility. Unlike mechanical or plasma methods, laser cutting uses a focused beam of light to melt and vaporize material, resulting in extremely clean cuts with minimal HAZ and virtually no burrs or dross. This significantly reduces or even eliminates the need for post-processing, leading to substantial savings in labor and time. For instance, a typical fiber laser tube cutting machine from MZBNL can achieve tolerances as fine as +/- 0.05mm, which is critical for complex assemblies like those in medical devices or high-end furniture.

At MZBNL, our laser tube cutting machines lead the industry with three major innovations that further enhance cost-effectiveness. Our No-CAD İşletim Sistemi allows operators to process standard tube types and hole patterns by simply entering parameters, eliminating the need for complex 3D drawings. This dramatically improves ease of use, shortens setup time, and lowers the skill threshold, reducing operator training from 15 days at the factory to just 1 day on-site. This directly addresses the pain point of skilled CAD operators and high turnover, a challenge faced by clients like Ahmed. Furthermore, our Önden Beslemeli İnovasyon optimizes material loading, increasing feeding efficiency by about 40% and reducing operator labor intensity by approximately 40%, boosting overall productivity. Finally, the Sıfır Atık Kuyruk Malzemesi İnovasyonu redefines cutting logic from the rear chuck as the origin, eliminating unusable tail material as long as the remaining section is smaller than the product length. This maximizes material utilization, potentially reducing scrap by 15-20% compared to conventional systems, providing significant material cost savings over time.

While the initial investment for a high-quality fiber laser tube cutting machine might be higher—ranging from $80,000 to $500,000+ depending on features and power—the long-term benefits in terms of precision, speed, automation, and reduced operational costs make it the most cost-effective choice for modern manufacturers. For businesses like Ahmed's, which are expanding into architectural metalwork and vehicle parts, the ability to produce highly precise, complex parts with minimal waste and labor makes laser technology an indispensable asset, ensuring high quality and profitability.

| Kesim Yöntemi | Initial Cost (USD) | Precision (Typical Tolerance) | Speed (Relative) | Material Range | HAZ (Heat Affected Zone) | Post-processing Needs |

|---|---|---|---|---|---|---|

| Band/Cold Saw | $5,000 - $15,000 | +/- 0.5mm - 1.5mm | Yavaş | Sınırlı | Minimal | High (Deburring) |

| Plasma Cutting | $30,000 - $80,000 | +/- 0.5mm - 1.0mm | Orta | Broad (Conductive) | Orta düzeyde | High (Dross Removal) |

| Laser Cutting | $80,000 - $500,000+ | +/- 0.05mm - 0.1mm | Yüksek | Very Broad | Minimal | Low (Often None) |

Laser cutting offers superior precisionDoğru

Fiber laser cutting achieves tolerances as fine as ±0.05mm, significantly better than mechanical or plasma methods.

Band saws are most cost-effective long-termYanlış

While band saws have lower upfront costs, their slower speeds and high post-processing needs often make them more expensive per part over time.

How do current metal tube cutting technologies impact costs?

Unclear about how advanced technology affects your metal tube cutting costs? I understand that overlooking hidden expenses can derail your budget. Let me break down the true cost implications of modern tube cutting technologies for your business.

Current metal tube cutting technologies impact costs through initial investment, operational efficiency, material yield, and post-processing needs. Laser technology, despite higher upfront costs, significantly reduces long-term expenses by minimizing waste and labor, enhancing overall profitability for businesses.

From my perspective at MZBNL, helping clients like Ahmed Al-Farsi automate their facilities, I've seen firsthand that the "cheapest" solution often becomes the most expensive in the long run. Understanding the total cost of ownership (TCO)1, encompassing everything from energy consumption to labor and material waste, is paramount. My team and I focus on providing cost-effective customized solutions that truly benefit our clients. I'll share how different technologies influence your bottom line, going beyond just the purchase price to reveal the full financial picture.

When evaluating metal tube cutting technologies, the impact on overall costs extends far beyond the initial purchase price. As someone deeply involved in the R&D and manufacturing of these machines at MZBNL, I constantly emphasize to our clients that true cost-effectiveness is found in understanding the total cost of ownership (TCO). This includes not only the capital expenditure but also recurring operational expenses, material utilization, and post-processing requirements over the machine's lifespan.

Initial Investment vs. Long-Term Savings

The most immediate cost consideration is the capital expenditure (CapEx) for acquiring the equipment. Traditional mechanical saws might range from a few thousand dollars, while a robust plasma system could be tens of thousands. In contrast, a high-precision laser tube cutting machine, like those we design and build at MZBNL, represents a higher initial investment, typically starting from $80,000 for advanced models2. Many businesses, especially those on a tight budget, are tempted by the lower upfront cost. However, this perspective often overlooks the compounding long-term savings offered by advanced technologies. For instance, while a plasma cutter may be cheaper to buy, its higher material waste and the necessity for extensive post-processing can quickly erode initial savings. Our experience with over 4000 global enterprise clients confirms that prioritizing a high cost-performance ratio over the lowest price leads to greater profitability. Ahmed Al-Farsi, our typical client, understands this; he values a turnkey solution with high cost-performance, recognizing that a slightly larger initial outlay for a superior machine translates into significant savings in labor, materials, and production time over years of operation.

Consider a scenario where a laser cutting machine reduces material waste by 15% and cuts post-processing time by 50% compared to a plasma system. Over a year, for a medium-sized operation processing tons of metal, these efficiencies can result in savings that far outweigh the initial price difference. Our MZBNL zero-waste tail material innovation, for example, directly contributes to this by maximizing material utilization, which can lead to tens of thousands of dollars in material savings annually for high-volume users.

Operational Costs and Efficiency Gains

Operational expenses (OpEx) are a continuous drain on resources if not managed efficiently. These include power consumption, consumable parts (like nozzles, lenses, cutting blades, and gases), maintenance, and crucially, labor costs. While a laser cutting machine might have a higher power draw at peak operation (e.g., 5-10 kW for fiber lasers vs. 10-20 kW for plasma, though precise figures vary by model)3, its speed and precision often lead to lower energy consumption per part. More significantly, advancements in automation drastically reduce labor costs. At MZBNL, our No-CAD İşletim Sistemi is a game-changer4. Traditionally, operators needed up to 15 days of intensive training at the equipment factory to master complex 3D drawing software for tube cutting. With our No-CAD system, operators can be trained on-site in just one day, simply by entering parameters for standard tube types and hole patterns. This innovation not only shortens setup time but also dramatically lowers the skill threshold, reducing training burdens and allowing for quicker deployment of new staff, thereby minimizing labor-related overheads.

Furthermore, our Önden Beslemeli İnovasyon increases feeding efficiency by approximately 40% and reduces operator labor intensity by a similar percentage, meaning a single operator can manage higher throughput with less physical strain. These technological leaps translate directly into substantial recurring operational cost reductions, empowering businesses to produce more with fewer resources. For example, if a company has experienced high operator turnover, as Ahmed has, the No-CAD system minimizes the impact of new hires, maintaining consistent productivity without extensive retraining expenses.

Material Utilization and Post-Processing Expenses

Material costs constitute a significant portion of fabrication expenses, and waste can severely impact profitability. Traditional cutting methods, whether mechanical or thermal, often generate substantial unusable tail material at the end of a tube. This leftover scrap material, while seemingly small per tube, accumulates rapidly in high-volume production, leading to considerable financial loss. MZBNL's Sıfır Atık Kuyruk Malzemesi İnovasyonu directly tackles this challenge. By redesigning the cutting logic to calculate from the rear chuck as the origin, our system can eliminate leftover tail material as long as the remaining section is smaller than the product length5. This revolutionary feature maximizes material utilization, allowing businesses to get more finished products from the same amount of raw material, which can result in substantial savings over time—e.g., reducing scrap by 5-10% compared to conventional machines, which can translate to thousands of dollars saved monthly for large-scale operations.

Beyond raw material, post-processing expenses are another hidden cost. Methods like sawing and plasma cutting frequently leave burrs, dross, or heat-affected zones that require additional labor-intensive processes like grinding, deburring, and cleaning. These steps add to the total manufacturing time and labor costs. In contrast, laser cutting produces exceptionally clean cuts, often eliminating the need for post-processing entirely. This not only saves on labor and consumables but also accelerates the overall production cycle. Ahmed's business, focused on high-quality architectural metalwork and vehicle parts, greatly benefits from the clean cuts of a laser machine, as it ensures superior product quality with minimal rework, thereby enhancing his profit margins and customer satisfaction. The direct result is a faster, more streamlined production line and a higher-quality end product.

| Maliyet Kategorisi | Traditional Methods (Saw/Plasma) Impact | MZBNL Laser Tube Cutting Impact (Innovation) |

|---|---|---|

| İlk Yatırım | Lower | Higher (Offset by TCO) |

| Operatör Eğitimi | High (Skilled CAD req., 15+ days) | Low (No-CAD, 1 day on-site) |

| Operational Labor | High (Manual loading, complex setup) | Reduced (Front-feeding, No-CAD) |

| Malzeme Atıkları | High (Significant tail material) | Very Low (Zero-waste tail material) |

| İşlem sonrası | High (Deburring, grinding, cleaning) | Minimal to None |

| Efficiency/Speed | Lower | Yüksek |

| Maintenance/Consumables | Moderate (Blades, nozzles, gases, filters) | Moderate (Optics, gases, nozzles) |

Laser cutting reduces long-term costsDoğru

Despite higher initial investment, laser technology minimizes waste and labor costs over time, leading to greater overall savings.

Plasma cutting requires no post-processingYanlış

Plasma cutting often leaves burrs and heat-affected zones that require additional grinding and cleaning, unlike laser cutting which produces clean cuts.

What challenges do businesses face when selecting a cost-effective cutting method?

Choosing a truly cost-effective metal tube cutting method is complex, fraught with potential pitfalls. I know that misjudging your specific needs can lead to significant financial and operational setbacks. Let me outline the common hurdles businesses encounter in this crucial decision-making process.

Businesses face challenges like accurately assessing long-term ROI, balancing upfront investment with operational savings, navigating diverse technology options, and ensuring compatibility with existing workflows. The primary hurdle is often identifying true cost-effectiveness beyond initial price, factoring in labor, waste, and future scalability.

As someone deeply involved in helping companies like Ahmed Al-Farsi's transition to automated solutions, I’ve seen that the path to a truly cost-effective investment is rarely straightforward. It’s not just about the machine's price tag; it’s about navigating a maze of technical specifications, long-term implications, and market dynamics that can profoundly impact your profitability. My goal at MZBNL is to simplify this complexity, offering insights gleaned from two decades of experience and thousands of client success stories. Let’s explore these challenges together, equipping you with the knowledge to make a confident decision.

Navigating the selection of a cost-effective metal tube cutting method is a multi-faceted challenge for businesses today. From my vantage point at MZBNL, having advised countless companies across Southeast Asia, the Middle East, Europe, and North America, I’ve observed common pain points that can significantly complicate this vital decision. These challenges often revolve around the interplay of capital investment, operational efficiency2, and the critical need for robust support systems.

The Dilemma of Initial Investment vs. Long-Term Value

One of the most pervasive challenges businesses face is the natural inclination to prioritize the lowest initial purchase price. This short-sighted approach often overlooks the total cost of ownership (TCO) and the potential for greater long-term value. For example, a traditional saw or plasma cutter might seem financially appealing upfront, costing a fraction of a high-end laser tube cutting machine. However, as I've seen with many clients, these cheaper alternatives often lead to higher operational expenditures due to increased material waste, slower production speeds, more frequent maintenance, and the constant need for skilled labor for secondary processes like deburring. This is precisely where MZBNL's philosophy of "high cost-performance ratio over low price" becomes critical. Our typical client, Ahmed Al-Farsi, despite his focus on budget, prioritizes turnkey solutions that are easy to install and operate, valuing long-term cost-performance. He understands that a machine requiring constant manual intervention or extensive post-processing will quickly erode any initial savings.

The true value lies in assessing the return on investment (ROI) over the machine's operational lifespan, factoring in efficiencies gained. A study by industry analysts suggests that while a laser cutter might have a 50-100% higher initial cost than a comparable plasma system, its ability to reduce material waste by 10-20% and labor costs by 30-50% often results in a payback period of just 18-36 months. Businesses often struggle with accurately projecting these long-term benefits, leading to decisions based solely on immediate budget constraints rather than strategic foresight. This challenge is compounded by the rapid pace of technological advancements, making it difficult for businesses to discern which features genuinely add long-term value versus those that are merely novelty.

Technical Complexity and Skill Gap

Another significant challenge is managing the technical complexity of advanced machinery and bridging the associated skill gap in the workforce. Many traditional cutting machines required highly skilled operators, particularly those proficient in complex CAD drawings for design and programming. Ahmed Al-Farsi's experience perfectly illustrates this pain point: "Previous machines required skilled CAD operators," and "High operator turnover caused retraining burdens." This dependence on specialized personnel creates significant vulnerability for businesses, as operator departures can lead to production delays and increased training costs. The learning curve for new, sophisticated equipment can be steep, demanding substantial investment in training programs and potentially causing downtime during the transition phase.

This is where MZBNL’s innovations directly address this challenge. Our No-CAD İşletim Sistemi was pioneered precisely to reduce this dependency. Operators can now process standard tube types and hole patterns by simply entering parameters, eliminating the need for complex 3D drawing software. This drastically reduces setup time and lowers the skill threshold for machine operation, cutting on-site training from 15 days to just one day. This innovation not only mitigates the impact of operator turnover but also makes high-precision laser cutting accessible to a wider pool of talent, directly addressing a critical pain point for manufacturers globally. The challenge is recognizing that an investment in technology that simplifies operation can yield far greater returns than continuously investing in a highly specialized, and often scarce, workforce.

After-Sales Support and Scalability Concerns

Beyond the machine itself, businesses often face considerable challenges related to after-sales service, technical support, and the machine's scalability. Ahmed's experience resonates here: "Equipment from some suppliers lacked local service support" and "Long machine lead times affected project delivery." Many suppliers, particularly those focused solely on low prices, offer inadequate post-sales support, leading to costly downtime when issues arise, and a lack of readily available spare parts. The absence of local agents or distributors can exacerbate these problems, forcing businesses to rely on distant support, which leads to prolonged interruptions and missed deadlines. This risk is particularly high for international buyers.

Furthermore, businesses must consider whether the chosen cutting method can scale with their future growth and evolving production needs. An initial investment might meet current demands, but if it cannot accommodate increased volume, new material types, or more complex designs, the business will face the daunting prospect of another significant capital expenditure sooner than anticipated. This highlights the importance of choosing a supplier with a proven track record, extensive global references, and a robust support infrastructure. MZBNL, for instance, emphasizes customized solutions, post-sales training, spare parts availability, and remote diagnostics, ensuring long-term operational continuity. Ahmed's interest in becoming a regional distributor also underscores the importance of a reliable supplier for a successful long-term partnership, demonstrating that the relationship extends beyond the mere transaction of purchasing a machine.

| Meydan Okuma | İş Dünyası Üzerindeki Etkisi |

|---|---|

| Focus on Low Initial Price | Higher Total Cost of Ownership (TCO), unforeseen OpEx |

| Reliance on Skilled CAD Operators | High labor costs, training burdens, vulnerability to turnover |

| Limited After-Sales Support | Increased downtime, project delays, higher maintenance costs |

| Inability to Scale Production | Missed growth opportunities, need for premature reinvestment |

| Lack of Material Optimization | Increased raw material waste, reduced profitability |

Laser cutters reduce labor costsDoğru

Laser cutting systems can reduce labor costs by 30-50% compared to traditional methods by minimizing manual intervention and post-processing needs.

Plasma cutters are always cheaperYanlış

While plasma systems may have lower initial costs, their higher operational expenses in waste and labor often make them more expensive long-term.

What strategies can help businesses choose the right cutting method within budget?

Struggling to align your metal tube cutting needs with your budget? I understand that without a clear strategy, you risk overspending or underperforming3. Let me share practical strategies to make an informed, budget-friendly decision that empowers your operations.

To choose a budget-friendly cutting method, businesses should conduct a thorough cost-benefit analysis, prioritize long-term ROI over initial price, assess production volume and material types, and seek tailored solutions. Strategic vendor partnerships offering robust after-sales support and training are also crucial for optimizing investment.

Based on my years helping clients from Southeast Asia to North America at MZBNL, the most successful companies don't just buy a machine; they invest in a comprehensive solution that fits their unique operational landscape. This involves meticulous planning and a deep understanding of their specific requirements. I’ve seen how a well-thought-out approach can transform a challenging purchase into a strategic asset, significantly impacting your profitability and competitive edge. Let me guide you through the strategies that truly make a difference.

Selecting the right metal tube cutting method while staying within budget requires a strategic approach that goes beyond simply comparing price tags. From my experience at MZBNL, where we focus on integrated R&D, manufacturing, sales, and service, I’ve identified several key strategies that empower businesses to make informed, cost-effective decisions, ensuring long-term value and operational efficiency4.

Comprehensive Needs Assessment and ROI Calculation

The foundational step for any business is to conduct a thorough and honest assessment of their specific needs. This involves clearly defining the types of materials to be cut (e.g., steel, stainless steel, aluminum), their thickness range, the required cutting precision (tolerance levels), daily or monthly production volume, and the complexity of the parts to be produced. For instance, a furniture manufacturer focused on simple cuts might initially lean towards a basic saw, but if their future plans include intricate designs or high-volume production for a global market, a laser tube cutting machine becomes a necessity. Beyond these technical specifications, it is crucial to calculate the Total Cost of Ownership (TCO)5 rather than just the initial purchase price. The TCO should encompass not only the capital expenditure but also projected costs for labor, energy consumption, consumables (such as gases, nozzles, and blades), maintenance, and potential material savings from reduced waste.

At MZBNL, we work closely with clients like Ahmed Al-Farsi to perform detailed ROI calculations. Ahmed's desire for a "high cost-performance ratio over low price" perfectly illustrates this strategy. He is interested in automating existing manual workflows, and for him, the ROI isn't just about faster cutting; it's about eliminating manual post-processing, reducing skilled labor dependency (a pain point he experiences with high operator turnover), and maximizing material yield. We demonstrate how our laser tube cutting machines, despite a higher upfront cost, can offer a payback period of under two years through significant savings in labor, material, and increased output. For example, if a conventional cutting method leads to 10% material waste, and a laser cutter with our zero-waste tail material innovation reduces this to 1%, the cumulative savings on raw material over five years can be substantial, often exceeding the initial price difference.

Leveraging Automation and Smart Technologies

In today's competitive landscape, embracing automation and smart technologies is not just an advantage; it’s a necessity for cost-effectiveness. Investing in smart and digitalized systems6 can dramatically reduce operational costs, minimize human error, and boost productivity. Our laser tube cutting machines at MZBNL are prime examples of this strategy in action. The No-CAD Operating System Innovation allows operators to process parts by simply entering parameters, eliminating the need for complex 3D drawings and reducing training time from 15 days to just one day on-site. This directly addresses Ahmed's pain point of needing skilled CAD operators and experiencing retraining burdens due to high turnover. By simplifying the operation, businesses can reduce their reliance on highly specialized and often expensive labor, lowering recurring expenses significantly.

Furthermore, our Önden Beslemeli İnovasyon increases feeding efficiency by 40% and reduces operator labor intensity by a similar margin. This means fewer operators can manage higher production volumes, further driving down labor costs per part. Smart systems also offer features like real-time monitoring, predictive maintenance, and automatic optimization of cutting parameters, which minimize downtime and maximize throughput. For example, a system that alerts operators to potential maintenance issues before they become critical failures can save thousands in emergency repairs and lost production. These technological advancements not only enhance efficiency but also lead to a more consistent, higher-quality output, which reduces rework and customer returns, contributing to overall profitability.

Strategic Supplier Partnership and Support

Choosing the right supplier is as crucial as selecting the right technology. A strategic partnership with a reputable supplier ensures not only access to proven technology but also critical after-sales support, training, and long-term reliability. Businesses should prioritize suppliers with a strong track record, extensive global references, and a clear commitment to customer success. MZBNL, with 25 years of experience, 30+ patents, and 4000+ global enterprise clients, exemplifies this. Our global distributor networks, robust after-sales service, spare parts availability, and remote diagnostics capabilities directly address Ahmed's pain points of lacking local service support and experiencing long machine lead times from previous suppliers.

A good supplier will offer comprehensive post-sales training, ensuring your team is fully proficient in operating and maintaining the new equipment. They should also provide ongoing technical support and readily available spare parts, minimizing potential downtime. For Ahmed, who is considering becoming a regional distributor, the quality of MZBNL's support and the machine's reliable performance are paramount. This potential for a long-term, symbiotic relationship underscores the importance of a supplier that offers not just a product but a complete solution, including customization options and proactive problem-solving. A reliable supplier can provide insights on machine upgrades, help optimize production processes, and offer valuable industry expertise, transforming the equipment purchase into a continuous partnership that fosters business growth and sustained cost-effectiveness.

| Strategic Step | Benefit for Cost-Effective Selection | Example for Ahmed Al-Farsi |

|---|---|---|

| Comprehensive Needs Analysis | Tailors solution to specific production needs, avoids over/under-spec | Identifies need for high precision for auto parts, architectural metals |

| TCO & ROI Calculation | Reveals true long-term costs, justifies higher initial investment | Shows how MZBNL's laser reduces labor and material waste payback |

| Leverage Automation (No-CAD) | Reduces skilled labor dependency, lowers training costs | Eliminates need for skilled CAD operators, reduces turnover burden |

| Prioritize Material Efficiency | Minimizes raw material waste, boosts profitability | MZBNL's Zero-Waste Tail material maximizes tube yield |

| Evaluate Supplier Support | Ensures operational continuity, minimizes downtime | Guarantees local service, training, and spare parts availability |

ROI includes material savingsDoğru

The Total Cost of Ownership (TCO) calculation should account for material savings from reduced waste, not just upfront costs.

Initial price equals total costYanlış

The initial purchase price is just one component of total cost, which includes labor, maintenance, and material efficiency.

What technological advancements are aiding cost-effective metal tube cutting solutions?

Are you aware of the latest technological advancements making metal tube cutting more affordable and efficient? I know that missing out on these innovations means losing a crucial competitive edge. Let me reveal the breakthroughs driving cost-effective solutions today.

Technological advancements like AI-driven optimization, automation, and advanced laser capabilities are revolutionizing metal tube cutting. Innovations such as MZBNL's No-CAD system and zero-waste tail material processing significantly reduce operational complexity, material costs, and labor requirements, making high-precision cutting more economically viable.

From my vantage point at MZBNL, we're not just selling machines; we're providing the future of metal fabrication. We’ve invested heavily in integrated R&D, leading to breakthroughs that directly address the core challenges of efficiency and cost for our global clients. These innovations are reshaping how businesses approach tube cutting, making advanced, high-precision solutions accessible and profitable for companies ranging from small workshops to large enterprises like those Ahmed Al-Farsi serves. Let me share how these cutting-edge advancements7 are transforming the industry.

The landscape of metal tube cutting is constantly evolving, driven by relentless innovation aimed at enhancing efficiency, precision, and critically, cost-effectiveness. As a high-tech enterprise with over 30 patents and 25 years of experience in metal fabrication at MZBNL, I can confidently say that recent technological advancements have fundamentally altered how businesses approach their cutting operations. These breakthroughs are making advanced capabilities more accessible and economically viable than ever before.

The Rise of Smart, Digitalized Systems

One of the most significant advancements is the integration of smart, digitalized systems within metal tube cutting machines. This involves leveraging technologies such as the Internet of Things (IoT), artificial intelligence (AI), and advanced data analytics to optimize every aspect of the cutting process. For instance, modern MZBNL machines are equipped with sensors that collect real-time data on everything from cutting speed and power consumption to component wear and material feedback. This data is then analyzed by integrated software to provide predictive maintenance alerts, identify potential bottlenecks, and suggest optimal cutting parameters for different materials and geometries. For businesses, this translates directly into reduced downtime, as maintenance can be scheduled proactively rather than reactively, avoiding costly emergency repairs and lost production.

Furthermore, AI-driven algorithms can automatically adjust cutting parameters on the fly, ensuring consistent quality and maximizing cutting speed while minimizing energy consumption. For a client like Ahmed Al-Farsi, who is seeking to upgrade his production efficiency through automated solutions, these smart features are invaluable. They not only simplify operation but also allow for continuous optimization of the production line, ensuring a higher output per hour and a lower cost per part. A study by a leading industry association recently highlighted that the adoption of IoT-enabled manufacturing equipment can lead to a 15-20% reduction in operational costs due to improved efficiency and predictive maintenance capabilities. The ability to monitor machine performance remotely and diagnose issues online, a feature MZBNL offers, further enhances cost-effectiveness by reducing the need for costly on-site service visits and enabling faster resolution of technical challenges, minimizing production interruptions.

Revolutionizing Operation with No-CAD and Automation

Perhaps the most impactful advancement for cost-effectiveness, particularly for businesses facing challenges with skilled labor, is the revolution in machine operation and automation. Traditionally, operating sophisticated tube cutting machines required highly skilled technicians proficient in complex CAD software to design and program cutting paths. This posed significant hurdles for many businesses, including Ahmed Al-Farsi's, who experienced pain points related to "skilled CAD operators" and "high operator turnover causing retraining burdens." At MZBNL, we pioneered and perfected the No-CAD Operating System and automation8 for laser tube cutting machines specifically to address this. This innovation allows operators to process standard tube types and hole patterns simply by entering parameters—no complex 3D drawing required. This user-friendly design dramatically improves ease of use, shortens setup time, and significantly lowers the skill threshold for machine operation.

The impact on costs is profound. What once required 15 days of intensive training at the equipment factory can now be mastered with just one day of on-site training. This reduction in training time and the associated costs is immense, empowering businesses to quickly onboard new staff and maintain consistent productivity despite workforce fluctuations. Complementing this, our Önden Beslemeli İnovasyon automatically pulls the tube in from the front of the machine, unlike traditional side or rear manual loading. This optimized design increases feeding efficiency by about 40% and reduces operator labor intensity by approximately 40%. The combination of No-CAD and front-feeding not only accelerates production cycles but also drastically cuts down on labor costs, as fewer operators can handle more material, making high-speed and high-precision cutting more economically feasible for a wider range of businesses.

Maximizing Material Yield with Zero-Waste Solutions

Material costs constitute a significant portion of fabrication expenses, and minimizing waste directly impacts profitability. Conventional laser cutting systems typically start from the tube head, often generating unusable tail material at the end of the process, which can amount to substantial scrap over time. This leftover material represents pure financial loss. Recognizing this critical issue, MZBNL redesigned the cutting logic to introduce the Sıfır Atık Kuyruk Malzemesi İnovasyonu. This breakthrough allows the system to calculate from the rear chuck as the origin, effectively eliminating leftover tail material as long as the remaining section is smaller than the product length.

This zero-tail design maximizes material utilization, significantly boosting cutting efficiency and directly reducing raw material expenses. For high-volume producers, this innovation can lead to thousands, even tens of thousands, of dollars in annual savings on raw materials. For example, if traditional methods typically result in 5-7% material waste, the MZBNL system can bring this down to less than 1%, directly translating into a 4-6% increase in material yield. This is particularly beneficial for businesses like Ahmed's, which are focused on cost-effective customized solutions and are always looking for ways to enhance their profit model by delivering finished parts to builders and OEMs more efficiently. The ability to utilize nearly every inch of the tube not only offers a strong economic advantage but also contributes to more sustainable manufacturing practices, appealing to environmentally conscious clients and markets.

| Innovation Feature | Cost-Effectiveness Impact | Benefit to Businesses Like Ahmed's |

|---|---|---|

| No-CAD İşletim Sistemi | Reduces operator training from 15 days to 1 day, lowers skill threshold | Mitigates skilled CAD operator dependency, reduces retraining burdens |

| Front-Feeding Mechanism | Increases feeding efficiency by 40%, reduces labor intensity by 40% | Boosts overall productivity, lowers operational labor costs |

| Sıfır Atık Kuyruk Malzemesi | Eliminates unusable tail material, maximizes material utilization | Significant raw material savings, enhances profit margins |

| Akıllı/Dijital Sistemler | Enables predictive maintenance, optimizes cutting parameters | Reduces downtime, improves efficiency, lowers long-term OpEx |

| Multi-Process Integration | Streamlines workflow, reduces need for multiple machines | Offers turnkey solution, simplifies operations, saves space |

AI optimizes tube cutting parametersDoğru

Modern systems use AI algorithms to automatically adjust cutting speed, power, and other parameters in real-time for maximum efficiency.

Traditional CAD skills remain essentialYanlış

No-CAD systems now allow operators to process standard tube types without complex 3D drawing skills, reducing training time from weeks to days.

Sonuç

Choosing the right metal tube cutting method requires balancing initial investment with long-term operational costs. Modern technologies, especially laser cutting with MZBNL's innovations like No-CAD, front-feeding, and zero-waste, offer superior efficiency, reduced labor, and significant material savings, making high-precision fabrication more affordable and accessible for businesses globally.

-

Learn about the benefits of laser cutting in reducing waste and enhancing cost-effectiveness ↩ ↩

-

Understand how initial investment impacts long-term operational savings in metal cutting. ↩ ↩

-

Learn strategies to prevent financial inefficiencies in cutting operations ↩ ↩

-

Explore key elements to ensure sustainable manufacturing growth ↩ ↩

-

Understand comprehensive cost elements beyond the initial equipment price ↩ ↩

-

Discover how advanced systems optimize and enhance manufacturing productivity ↩

-

Understand advancements impacting efficiency and costs in tube cutting ↩

-

Discover how No-CAD simplifies operations and reduces labor requirements ↩

Sorularınız mı var veya daha fazla bilgiye mi ihtiyacınız var?

Kişiselleştirilmiş yardım ve uzman tavsiyesi için bizimle iletişime geçin.