Konik Kesme Makineleri Kaynak Sürecinizi Nasıl Kolaylaştırır ve İşgücünü Nasıl Azaltır 40%

Struggling with slow, inconsistent, and costly weld preparation? This manual bottleneck creates weak joints and expensive rework, holding your entire production line hostage. A perfect weld starts with perfect preparation.

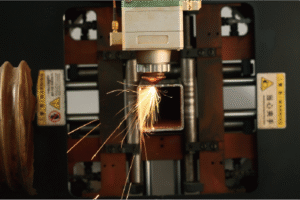

Bevel cutting machines streamline welding by automating the creation of precise, angled edges on tubes. This eliminates manual grinding, ensures perfect joint fit-up, reduces welder setup time, and can cut weld-prep labor costs by up to 40%, boosting overall throughput and quality.

For years, I've walked through fabrication shops and seen the same story: highly skilled welders waiting for parts, or worse, spending their valuable time with a grinder trying to manually create a bevel. It's a massive drain on resources and a primary source of quality issues. This inefficiency is no longer a necessary cost of doing business. Technology has provided a direct solution that not only solves these problems but also unlocks a new level of productivity. Let’s dive into how this works, starting with the challenges of the traditional approach.

What challenges do traditional welding processes face without bevel cutting machines?

Manual grinding for weld prep is slow, inconsistent, and physically demanding. This leads to poor fit-up, wasted materials, and potential structural weaknesses in the final product.

Traditional welding faces challenges like inconsistent joint fit-up, excessive manual grinding, and high labor costs. This results in longer production cycles, increased material waste from filler metals and rework, and a heavy reliance on highly skilled, expensive welders to compensate for preparation inaccuracies.

When I visit a facility that still relies on manual weld preparation, the inefficiencies are immediately clear. The entire process is built on a foundation of variability. You have an operator with a hand grinder trying to create a consistent angle on a piece of metal—a task that is nearly impossible to replicate perfectly every time. This creates a cascade of problems down the line.

The Bottlenecks of Manual Preparation

First, there's the sheer amount of time and labor involved. You need a dedicated team just for grinding, a physically taxing job with high employee turnover. This team becomes a bottleneck, and your expensive welders are often left waiting for parts. Second is the issue of inconsistent quality. A poorly prepared joint with an uneven gap forces the welder to compensate by using more filler material[^1], which not only increases costs but can also introduce stresses and weaknesses into the weld itself. This leads to higher rejection rates and costly rework.

The Hidden Costs

Finally, there's the material waste. Beyond the excess filler metal, every minute a skilled welder spends fixing a bad fit-up is a minute they aren't completing a new assembly. In today’s competitive market, these hidden costs add up quickly. Relying on this outdated method is like trying to win a race with one foot tied to the starting line. It’s the direct opposite of the smart, digitalized systems we champion at MZBNL, where every step is optimized for precision and efficiency.

How do bevel cutting machines address the inefficiencies in welding processes?

Production line inefficiencies are silent profit killers. Every minute your team wastes on manual part prep is a direct loss, slowing down your entire operation and delaying customer orders.

Bevel cutting machines address inefficiencies by automating weld preparation. They produce precise, repeatable angled cuts directly on the tube, ensuring perfect joint fit-up. This eliminates manual grinding, reduces setup time, and creates a consistent V-groove for stronger, more efficient welding with less filler material.

The solution to manual inefficiency is automation that delivers absolute precision. A bevel kesme maki̇nesi̇ integrates this critical preparation step directly into the cutting process itself. Instead of a multi-step, multi-person workflow, you have a single, automated operation that produces a part ready for welding in seconds. I've seen this transformation firsthand. A process that once took 10-15 minutes of manual labor is completed in under a minute by the machine, and the result is flawless every single time.

The Power of Integrated Automation

This is where the real magic happens. Our machines at MZBNL take this a step further by simplifying the entire workflow from design to execution. Here’s how it breaks down:

- Precision by Design: The machine’s laser head tilts to the exact angle required—whether it's 30°, 45°, or a custom angle—and cuts a perfect, clean bevel as it profiles the tube. There is no guesswork and zero variability.

- Flawless Repeatability: The 100th part is identical to the first. This consistency is something manual labor can never achieve, and it's the key to high-quality, high-volume production.

- Unmatched Speed: The cutting process is incredibly fast, turning a major bottleneck into a smooth, continuous flow.

What I find most impactful for our clients is how easy we've made it. With our No-CAD Sistemi, an operator doesn't even need a complex 3D drawing for standard bevels. They can simply input the tube dimensions and desired angle directly into the system. The machine handles the rest. This drastically lowers the technical barrier and makes advanced fabrication accessible to any workshop.

What impact do bevel cutting machines have on labor reduction in welding?

Skilled labor is one of the biggest costs and constraints in manufacturing. Relying on manual preparation for welding creates a major dependency that drives up expenses and limits your scalability.

Bevel cutting machines can reduce labor associated with weld preparation by up to 40%. By automating the creation of angled edges, they eliminate the need for manual grinding operators. This also allows welders to focus purely on welding, not prep work, increasing their productivity and throughput.

When we talk about a 40% reduction in labor, it's not just about eliminating a position. It's about optimizing your entire team's output. By automating the beveling process, you free up skilled workers to perform higher-value tasks. The grinder operator can be retrained to operate the cutting machine or assist in assembly, and your highly paid welder can spend nearly 100% of their time welding. This shift fundamentally changes your operational math.

To illustrate, let's compare the workflows:

| Traditional Workflow | Bevel Cutting Workflow |

|---|---|

| 1. Cut tube to length | 1. Load tube onto machine |

| 2. Manually grind bevel | 2. Machine cuts tube with bevel |

| 3. Deburr and clean | 3. Part is ready for welding |

| 4. Welder fits parts | |

| 5. Welder welds joint |

The traditional path involves multiple steps and handoffs, each a potential point of delay. The automated path is a single, streamlined process. Furthermore, we’ve pushed this efficiency beyond just the cut. We looked at the entire process and identified another labor-intensive step: loading the material. That’s why we developed our Ön Besleme Mekanizması. This automated system loads tubes from the front, increasing feeding efficiency by about 40% and reducing the operator's physical workload by a similar amount. When you combine automated cutting with automated loading, the impact on labor reduction is truly transformative.

How can implementing bevel cutting machines enhance overall welding quality?

Inconsistent welds are a critical point of failure. A single bad joint can compromise the structural integrity of an entire product, leading to safety risks and costly recalls.

Bevel cutting machines enhance welding quality by creating a uniform, precise V-groove for the weld seam. This ensures deeper weld penetration, a stronger joint, and consistent results across all parts. It minimizes defects like porosity or lack of fusion that arise from poor fit-up.

Perfect preparation is the foundation for a perfect weld. I can't stress this enough. When two tubes meet with a perfectly matched, machine-cut bevel, you create the ideal conditions for a strong, reliable weld. A clean, consistent V-groove allows for optimal heat distribution and deep penetration of the filler material, fusing the two pieces into a single, monolithic joint. This isn't just about looking good; it's about fundamental structural integrity.

The Science of a Stronger Weld

When a welder has to fight against a poor fit-up—with uneven gaps or inconsistent angles—they are forced to make compromises. They might use more heat or pile on extra filler material to bridge the gap. This can introduce impurities, create internal stresses, and lead to common defects like porosity (air bubbles) or incomplete fusion. These defects are often invisible to the naked eye but can lead to catastrophic failure under load. Automated bevel cutting eliminates this entire category of risk. Every joint is prepared to the exact same specification, removing the human variable and ensuring that every weld can perform to its maximum designed strength. This commitment to quality and efficiency is at the core of everything we do. It’s the same thinking that led us to develop our Sıfır Atık Kuyruk Malzemesi technology. By optimizing the cutting path to eliminate tailing waste, we ensure that every inch of raw material is used effectively. A perfect bevel on a perfectly utilized tube is the start of a flawless, cost-effective final product.

What are the best practices for integrating bevel cutting machines into existing welding systems?

Adopting new technology can feel disruptive. A poorly planned integration can create bottlenecks and cause more problems than it solves, leading to frustration and a poor return on investment.

Best practices include analyzing your current workflow to identify bottlenecks, choosing a machine that matches your material types and production volume, and ensuring proper operator training. Start with a pilot project to refine the process and measure ROI before a full-scale rollout into your production line.

Bringing a bevel cutting machine into your facility is a strategic upgrade that, when done right, pays for itself very quickly. Over the years, I’ve helped hundreds of clients navigate this process, and I’ve found that a structured approach is the key to a seamless and profitable transition. It's not about just buying a machine; it's about integrating a solution.

Here are the steps I always recommend:

- Workflow Audit: Before you do anything, map your current process from raw material storage to the final welded assembly. Identify exactly where the delays are. Is it grinding? Material handling? Part fit-up? This data will build the business case for the investment.

- Choose the Right Solution: Don't get distracted by features you don't need. Select a machine that is designed for your specific material types, thicknesses, and production volumes. Your goal is to solve your problem, not buy the biggest machine on the market.

- Prioritize Operator Training: The best machine in the world is useless if your team can't operate it efficiently. This is an area where we've invested heavily. Our No-CAD Sistemi is a game-changer for integration because it radically simplifies operation. We can train an operator to be proficient in just one day, compared to the 15 days often required for complex CAD/CAM systems. This dramatically shortens the learning curve and speeds up your time to value.

- Start Small, Scale Fast: I often advise clients to integrate the new machine into a single production cell first. Use it as a pilot project. Measure the improvements in speed, quality, and cost. Once you have clear data demonstrating the ROI, use that success story to roll the technology out across the rest of your facility.

Sonuç

Integrating automated bevel cutting is a foundational upgrade for modern fabrication. It directly attacks the slow, costly, and inconsistent nature of manual weld preparation, reducing labor costs and production time while dramatically improving the quality, strength, and consistency of your final product.

Sorularınız mı var veya daha fazla bilgiye mi ihtiyacınız var?

Kişiselleştirilmiş yardım ve uzman tavsiyesi için bizimle iletişime geçin.