Tube Laser Cutting Machines: 5 Essential Questions You Need to Know

Are you facing production bottlenecks or struggling with rising material costs in your metal fabrication business? Many manufacturers grapple with outdated methods, limiting their growth. We believe embracing advanced technology like tube laser cutting is the definitive answer to boosting efficiency and profitability.

Tube laser cutting machines offer unmatched precision, speed, and material optimization, revolutionizing metal fabrication by significantly reducing labor and waste. They efficiently process various metals and tube shapes, providing a cost-effective and highly automated alternative to traditional methods.

Navigating the landscape of modern metal processing can be complex, but understanding the core capabilities of advanced machinery1 is key to making informed decisions. As someone who has spent 25 years immersed in this industry, I’ve seen firsthand how the right technology can transform a business. Let’s explore the crucial questions you need to ask about tube laser cutting machines to unlock their full potential for your operations.

In today's competitive manufacturing world, merely keeping up isn't enough; true success lies in forward-thinking investment and strategic innovation. I recall countless conversations with business owners, much like Ahmed Al-Farsi, a seasoned entrepreneur from the UAE, who is constantly seeking automated solutions to upgrade his production efficiency. Ahmed’s journey reflects a broader industry trend: the shift from conventional, often labor-intensive, methods to smart, integrated systems. Traditional approaches, while familiar, often lead to limitations in precision, speed, and material utilization. This isn't just about replacing old machines; it’s about fundamentally rethinking the production workflow. For instance, the demand for intricate architectural metalwork or precision automotive parts necessitates technology that can deliver consistent quality at high volumes, something conventional methods struggle to achieve without significant human intervention and associated errors. This deep dive into tube laser cutting isn't just about technical specifications; it’s about understanding the paradigm shift that MZBNL, through our 30+ patents and 25 years of experience, has championed—a shift towards smarter, more sustainable, and ultimately more profitable manufacturing.

What are the primary benefits of using tube laser cutting machines?

Struggling with slow, imprecise cuts and high material waste? Traditional methods often fall short, limiting your production capabilities. Tube laser cutting machines offer a transformative solution, providing unparalleled precision and efficiency for your fabrication needs.

Tube laser cutting machines offer superior precision, higher cutting speeds, and significant material waste reduction compared to conventional methods. They enhance productivity, enable complex designs, and lower operational costs, leading to a substantial return on investment for fabricators.

My experience over the past two decades has consistently shown that the most successful fabrication businesses are those that proactively embrace efficiency and precision. Take Ahmed Al-Farsi, for example. As the owner of a mid-sized metal fabrication business expanding into architectural metalwork and vehicle parts, his primary goal is to automate existing manual workflows. He understands that the inherent benefits of tube laser cutting machines directly address his need for higher output, superior quality, and cost control. This isn't just about cutting faster; it’s about cutting smarter, which profoundly impacts everything from product quality to profit margins. The advantages ripple through the entire production chain, from design flexibility to final assembly, ultimately enhancing your competitive edge.

When we talk about the primary benefits of tube laser cutting machines, we're not just discussing incremental improvements; we're describing a fundamental leap in manufacturing capability. These machines represent a cornerstone of modern fabrication, driving efficiency and opening up new design possibilities.

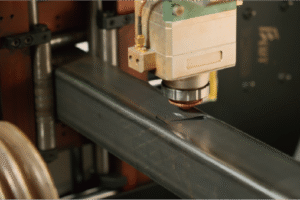

Enhanced Precision and Quality for Complex Geometries

For years, I've observed businesses like Ahmed's struggle with achieving consistent quality and tight tolerances using conventional cutting tools. Saw cutting, for instance, often leaves burrs and requires secondary finishing, while traditional punching can deform the material. Tube laser cutting, by contrast, utilizes a highly focused laser beam that vaporizes material with extreme accuracy, resulting in clean, precise cuts with minimal heat-affected zones. This precision is critical for intricate designs and tight-fitting assemblies, which are increasingly common in sectors like architectural decoration and automotive parts – exactly where Ahmed is expanding.

Our MZBNL laser tube cutting machines, born from 25 years of dedicated R&D, exemplify this. We've seen clients produce complex structures, like custom display racks or precision components for medical equipment, with a level of accuracy that was previously unimaginable or prohibitively expensive. This high-quality output not only reduces post-processing work but also ensures a superior final product, which is vital for maintaining a reputation for excellence and securing higher-value contracts. The ability to cut complex contours, slots, and holes with single-pass precision directly contributes to the overall structural integrity and aesthetic appeal of the fabricated parts.

Furthermore, the consistency delivered by laser cutting minimizes batch-to-batch variations, crucial for large-scale production runs. Imagine producing hundreds of identical fence panels or furniture frames; with a laser, each piece aligns perfectly, reducing assembly time and errors. This consistency is a hallmark of quality and reliability, directly translating into customer satisfaction and repeat business for companies like MZBNL's 4000+ global enterprise clients.

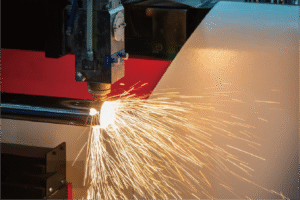

Increased Speed and Throughput for Higher Productivity

One of the most immediate and tangible benefits of tube laser cutting is the dramatic increase in cutting speed. Compared to mechanical saws or drills, which require physical contact and slower processing, laser technology operates at speeds that significantly reduce per-part cycle times. This speed is compounded by automated loading and unloading systems, which minimize idle time between operations. Our MZBNL Automatic Punching & Cutting Integrated Machine, for instance, is designed for high-speed and high-precision cutting, enabling a much greater throughput compared to manual or semi-automatic methods.

I often share the story of a client in Southeast Asia who, much like Ahmed, was bogged down by slow production cycles. After implementing our laser tube cutting solution, they saw an immediate jump in their daily output, enabling them to take on more orders and shorten lead times for their customers. For a contract-based fabrication business like Ahmed's, the ability to deliver finished parts faster directly impacts their profit model and reputation. This accelerated workflow translates into a quicker return on investment, making the initial capital expenditure a truly strategic move rather than just a cost.

Moreover, the integration of multiple processes—like cutting and punching—into a single machine enhances overall throughput by eliminating the need to transfer parts between different workstations. This multi-process capability, a key feature of our MZBNL solutions, reduces material handling time and the risk of errors, streamlining the entire fabrication process. The overall impact is a leaner, more agile manufacturing operation capable of responding quickly to market demands and achieving ambitious production targets.

Material Optimization and Waste Reduction

Material costs constitute a significant portion of manufacturing expenses, making waste reduction a critical factor in profitability. Traditional cutting methods often result in considerable scrap material due to limitations in nesting efficiency or the need for large clamping areas. Tube laser cutting machines, however, offer superior material utilization through advanced nesting software and precise cutting capabilities. This allows for more parts to be cut from a single tube, minimizing leftover material.

One of MZBNL's proudest innovations is our Sıfır Atık Kuyruk Malzemesi İnovasyonu2. While conventional systems typically generate unusable tail material at the end of the process, our redesigned cutting logic calculates from the rear chuck as the origin. This allows the system to eliminate leftover tail material as long as the remaining section is smaller than the product length, maximizing material utilization. For a business processing large volumes of tubes, even a small percentage reduction in waste can translate into substantial cost savings annually. This innovation directly addresses a pain point for businesses like Ahmed's, where optimizing every inch of raw material directly impacts the bottom line.

Consider the following comparison of material waste:

| Cutting Method | Typical Material Waste (%) | Features Contributing to Waste Reduction |

|---|---|---|

| Traditional Saw Cutting | 10-15% | Kerf width, clamping area, limited nesting |

| Punching Machine | 5-10% | Sheet utilization, punch tool size |

| Conventional Laser Cutting | 3-5% | Tail material, nesting algorithms |

| MZBNL Laser Cutting | <1% | Zero-Waste Tail Material Innovation, advanced nesting, precise kerf |

Beyond just material savings, reduced waste also means less scrap to dispose of, which can lower waste management costs and contribute to a more sustainable manufacturing practice. This holistic approach to efficiency — from speed and precision to material optimization — cements tube laser cutting as an indispensable tool for modern metal fabrication, addressing the core needs of our clients for cost-effectiveness and high performance.

Lazer kesim malzeme israfını azaltırDoğru

Advanced nesting software and precise cutting capabilities allow tube laser machines to optimize material usage, often reducing waste to less than 1%.

Traditional methods are faster than laser cuttingYanlış

Laser cutting operates at significantly higher speeds than mechanical saws or drills, with automated systems further reducing cycle times.

How do tube laser cutting machines differ from traditional cutting methods?

Are your existing cutting methods slowing you down and limiting your design possibilities? Traditional techniques often present significant bottlenecks and quality inconsistencies. Tube laser cutting3 offers a revolutionary leap forward, redefining precision and efficiency in metal fabrication.

Tube laser cutting machines provide unparalleled precision, automation, and material versatility compared to traditional methods like sawing or punching. They achieve faster processing, complex geometries, and superior edge quality while significantly reducing labor, waste, and secondary operations.

In my 25 years in this industry, I've witnessed a dramatic evolution from manual, labor-intensive processes to sophisticated automated solutions. This shift is particularly evident when comparing traditional cutting methods to the capabilities of modern tüp lazer kesim makineleri4. For businesses like Ahmed Al-Farsi’s, who are looking to automate their manual workflows and achieve higher quality in their architectural metalwork and vehicle parts, understanding these differences is paramount. It’s not just about what a machine olabilir do, but how it fundamentally changes the way you operate, the quality of your output, and your overall profitability. The distinction lies in precision, speed, and the seamless integration of technology that minimizes human error and maximizes resource utilization.

The contrast between tube laser cutting and traditional methods is stark, highlighting why modern manufacturers are increasingly investing in this advanced technology. It represents a paradigm shift from brute-force cutting to precise, digitally controlled fabrication.

Technological Superiority in Accuracy and Flexibility

Traditional cutting methods, such as band sawing, cold sawing, or abrasive cutting, rely on mechanical force to remove material. While effective for simple, straight cuts, they often struggle with precision, especially on complex shapes or when tight tolerances are required. These methods typically involve significant material deformation, heat generation leading to material distortion, and rough cut edges that necessitate time-consuming secondary finishing processes like deburring or grinding. For parts requiring exact fitment, such as components for medical equipment or automotive chassis, these limitations can be costly and time-consuming.

In stark contrast, tube laser cutting machines use a focused beam of light to melt, vaporize, or burn through the material, resulting in exceptionally clean, precise, and burr-free cuts. This non-contact process minimizes material distortion and heat-affected zones, preserving the material's integrity and mechanical properties. The digital control (CNC) of laser machines allows for intricate geometries, complex patterns, and precise holes to be cut with ease, often in a single operation. This level of flexibility and accuracy is simply unattainable with conventional mechanical methods. For example, creating intricate slots for interlocking furniture components, which would require multiple steps of drilling and milling traditionally, can be achieved seamlessly and precisely with a laser, enabling innovative product designs.

Furthermore, the ability of laser cutting to handle various cutting paths, including highly acute angles and intricate curves, distinguishes it significantly. I've observed countless cases where clients, previously restricted by the capabilities of their mechanical saws, were able to introduce entirely new product lines – from custom-designed railings for luxury properties to specialized components for automation systems – all thanks to the geometric freedom offered by laser technology. This directly speaks to Ahmed's goal of expanding his business and delivering finished parts with high quality to builders and OEMs.

Operational Efficiency and Labor Impact

One of the most significant pain points I’ve heard from clients like Ahmed, who previously relied on manual workflows, is the high operator turnover and the associated retraining burdens. Traditional methods often require a highly skilled operator for each machine, especially for tasks involving complex setups or precise measurements. Manual loading, clamping, and repositioning of tubes for multiple cuts are time-consuming and physically demanding, leading to operator fatigue and increased risk of errors.

Tube laser cutting machines, particularly those with advanced features like MZBNL's, dramatically transform this operational landscape. Our pioneering No-CAD Operating System exemplifies this shift. Traditionally, operators had to return to a design office to create or modify complex 3D drawings before production could start—an inefficient and time-consuming process that required specialized CAD skills. With BNL’s system, standard tube types and hole patterns can now be processed simply by entering parameters—no drawing required. This innovation dramatically improves ease of use, shortens setup time, and lowers the skill threshold for machine operation. We've seen that operators now only need 1 day of on-site training instead of spending 15 days at the equipment factory, directly addressing Ahmed’s pain point regarding skilled CAD operators and retraining.

Moreover, our Front-Feeding Innovation, which automatically pulls the tube in from the front, increases feeding efficiency by about 40% and reduces operator labor intensity by approximately 40%. This not only boosts productivity but also creates a safer and more ergonomic working environment, contributing to higher job satisfaction and reduced turnover. The automation inherent in laser cutting, from material loading to precise cutting and part ejection, significantly reduces the need for constant human intervention, allowing staff to be reallocated to higher-value tasks, thereby optimizing the entire workforce.

Cost Implications and Return on Investment (ROI)

While the initial investment in a tube laser cutting machine might be higher than for conventional equipment, the long-term cost implications and ROI paint a very different picture. Traditional methods often entail hidden costs: higher material waste, slower production leading to longer project lead times, increased labor costs due to manual operations and secondary processing, and higher consumables costs (e.g., saw blades, drill bits that wear out quickly).

Laser cutting minimizes these hidden costs. The superior material utilization, thanks to features like our Zero-Waste Tail Material Innovation, directly translates into significant savings on raw materials. The increased speed and automation mean higher throughput with fewer operators, drastically reducing labor costs per part. Furthermore, the precision of laser cutting often eliminates the need for secondary finishing operations, saving time, labor, and additional equipment costs. For a company like Ahmed's, which operates on a contract-based profit model, faster project delivery and reduced production costs directly enhance profitability and competitiveness.

My team at MZBNL has worked with countless clients to demonstrate how the seemingly higher upfront cost is quickly offset by these operational efficiencies. We've shown how a machine that cuts faster, wastes less, and requires less skilled labor can achieve payback in a surprisingly short time, particularly for high-volume operations. The ability to handle complex orders and deliver with superior quality also allows businesses to command higher prices or secure more lucrative contracts, further accelerating the ROI. This strategic investment is not merely an expense; it is a catalyst for long-term growth, efficiency, and market leadership, making it a preferred choice for stable, long-term businesses planning to automate existing manual workflows.

Lazer kesim malzeme israfını azaltırDoğru

Tube laser cutting's precision and features like Zero-Waste Tail Material Innovation significantly improve material utilization compared to traditional methods.

Traditional methods offer better edge qualityYanlış

Laser cutting produces cleaner, burr-free edges while traditional methods often require secondary finishing processes to achieve acceptable quality.

What materials can be processed with tube laser cutting technology?

Worried your current machinery can't handle diverse material types or complex tube shapes? Traditional methods often limit your fabrication capabilities, hindering your ability to serve a wide market. Tube laser cutting offers unparalleled versatility, processing a broad spectrum of materials with precision.

Tube laser cutting technology is highly versatile, capable of precisely processing a wide range of common metals including carbon steel, stainless steel, aluminum, brass, and copper. It effectively handles diverse tube shapes like round, square, rectangular, and oval, enabling complex geometries for various industries.

The flexibility of a manufacturing solution is often as critical as its speed or precision. I've encountered numerous instances where businesses were forced to turn down lucrative projects simply because their existing machinery couldn't handle the required material or tube shape. This bottleneck stifles growth and innovation. For a dynamic entrepreneur like Ahmed Al-Farsi, who is actively expanding his business in architectural metalwork and vehicle parts, the ability to process a wide variety of materials and tube profiles is not just a benefit—it’s a fundamental requirement. Our MZBNL machines are engineered precisely to address this versatility, ensuring that our clients can confidently tackle diverse projects without limitations.

One of the most compelling aspects of tube laser cutting technology is its exceptional versatility, allowing fabricators to work with a wide array of metals and tube profiles. This broad capability means that a single machine can serve multiple industries and applications, significantly expanding a business's market reach.

Versatility Across Common Metals in Fabrication

Tube laser cutting machines are adept at processing a comprehensive range of metals that are mainstays in various industries. The most common materials include carbon steel, stainless steel, aluminum, brass, and copper. Each of these materials has unique properties—from the strength and weldability of carbon steel, often used in structural components and general fabrication, to the corrosion resistance and aesthetic appeal of stainless steel5, favored in architectural decoration, sanitary ware, and medical equipment. Aluminum, known for its lightweight and excellent strength-to-weight ratio, is crucial for automotive and aerospace components, while brass and copper are valued for their electrical conductivity and decorative applications in lighting and plumbing.

The beauty of laser technology lies in its ability to adapt to these different material characteristics. By adjusting power, speed, and gas settings, the laser can achieve optimal cuts on various thicknesses and alloys, maintaining high quality across the board. For MZBNL, our 25 years of experience have allowed us to fine-tune our machines to precisely handle these diverse metals, ensuring that clients like Ahmed can transition seamlessly between different project requirements. For example, if Ahmed needs to produce stainless steel railings one day and carbon steel automotive parts the next, our machine can accommodate both with minimal setup changes, demonstrating true operational agility.

This material versatility is not just a convenience; it’s a strategic advantage. It reduces the need for multiple specialized machines, thereby lowering capital expenditure and floor space requirements. Furthermore, it enables businesses to diversify their service offerings, attracting a broader client base and mitigating risks associated with reliance on a single market segment. This comprehensive material handling capability ensures that clients can meet varied demands from industries such as furniture manufacturing, electrical appliances, and medical equipment, maximizing their potential revenue streams.

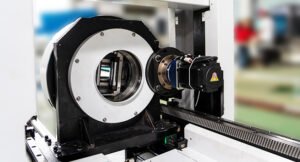

Handling Diverse Tube Shapes and Sizes for Broad Applications

Beyond the type of metal, the geometric flexibility of tube laser cutting machines is equally crucial. Traditional methods often require specific tooling for each tube shape—a round tube cutting setup differs significantly from a square tube setup, for example. This adds complexity, cost, and changeover time. Tube laser cutting, however, uses a universal laser beam, making it incredibly adaptable to various tube profiles without requiring extensive retooling.

Our MZBNL laser tube cutting machines are designed to process a wide array of tube shapes, including round, square, rectangular, oval, and even more complex profiles like D-shaped or custom-extruded sections. This capability is paramount for companies serving diverse sectors. Consider a furniture manufacturer needing square tubes for table frames and round tubes for chair legs, or an automotive supplier requiring custom oval tubes for exhaust systems. A single tube laser cutting machine can efficiently handle all these variations.

This ability to process diverse tube shapes and sizes directly correlates with the range of products a business can offer. For Ahmed Al-Farsi, this means he can confidently pursue contracts for both display racks (often using square or rectangular tubes) and motorcycle parts (which might involve various round and custom profiles). The precision gripping and rotation systems on modern laser cutters ensure that even non-standard shapes are held securely and rotated accurately during cutting, guaranteeing consistent results. This adaptability ensures that the investment in a tube laser cutting machine remains valuable across evolving project demands and industry trends, future-proofing a fabrication business against changing market needs.

Beyond Basic Cutting: Complex Geometries and Advanced Fabrication

The true power of tube laser cutting extends far beyond simple straight cuts or basic holes. The precise control offered by CNC systems allows for the creation of incredibly complex geometries, intricate patterns, and specialized features that are difficult, if not impossible, to achieve with traditional methods. This includes creating slots for interlocking designs, complex cutouts for cable management, chamfers, bevels, and even engraving.

For instance, in architectural decoration, designers are constantly pushing boundaries with custom perforations for aesthetic screens or intricate railing designs. In the fitness equipment industry, complex joint designs allow for stronger, lighter, and more visually appealing products. Our MZBNL machines, with their high-precision capabilities, empower our clients to tackle these challenging designs. I’ve seen projects where a single laser-cut tube could replace multiple welded components, simplifying assembly and improving structural integrity. This not only speeds up production but also enhances the overall quality and innovation of the final product.

The ability to integrate multiple processes, like creating holes and complex cuts in a single setup, further elevates the value proposition. This is particularly beneficial for OEMs and component suppliers who require finished parts ready for immediate assembly, minimizing post-processing and reducing overall manufacturing costs. By enabling such advanced fabrication capabilities, tube laser cutting machines are not just tools for cutting; they are platforms for innovation, allowing businesses to differentiate themselves in a competitive market by delivering superior, high-value components.

Laser cutting handles multiple metalsDoğru

Tube laser cutting can process carbon steel, stainless steel, aluminum, brass, and copper by adjusting machine settings.

Each shape needs special toolingYanlış

Laser cutting uses a universal beam that adapts to round, square, rectangular and oval tubes without retooling.

How does operating without CAD drawings simplify tube laser cutting?

Are you struggling with lengthy design cycles and the need for highly skilled CAD operators? Traditional manufacturing often creates bottlenecks, slowing your production and increasing labor costs. Operating without CAD drawings revolutionizes this process, dramatically simplifying tube laser cutting.

Operating a tube laser cutting machine without requiring complex CAD drawings significantly simplifies the fabrication process by allowing direct parameter input for standard shapes. This innovation reduces setup time, lowers the skill threshold for operators, and accelerates production workflows, enhancing efficiency and flexibility.

One of the most significant advancements I've witnessed in metal fabrication, particularly with our MZBNL solutions, is the shift away from reliance on complex CAD drawings for routine operations. I frequently hear from clients, much like Ahmed Al-Farsi, about the pain points associated with needing skilled CAD operators and the burdens of retraining due to high turnover. This isn’t just an inconvenience; it’s a critical bottleneck that directly impacts project delivery times and operational agility. Our No-CAD System Innovation was born precisely from this understanding—to streamline the process, reduce dependency on specialized design personnel, and empower manufacturers to achieve greater efficiency and responsiveness on the shop floor.

The traditional workflow in metal fabrication has long been tethered to the design office, where every intricate cut or hole pattern originated as a CAD drawing. While CAD is indispensable for complex, custom designs, its necessity for standard or repetitive tasks has historically been a significant source of inefficiency.

The Traditional CAD Bottleneck: A Historical Challenge

In the past, and still in many conventional fabrication setups, the process for cutting metal tubes began with an engineer or a highly skilled CAD operator creating a detailed 3D drawing. Even for simple shapes like a square tube with standard holes, this involved drafting, dimensioning, and potentially iterating on designs. Once approved, these CAD files then needed to be converted into machine-readable G-code6, a process that itself could be complex and prone to errors. Any minor modification, even a change in hole diameter or position, often required the operator to return to the design office, wait for a revised drawing, and then re-upload it to the machine. This iterative loop created a significant bottleneck, extending setup times, delaying production starts, and requiring a high level of specialized technical expertise on the shop floor.

I vividly recall situations where a production line would grind to a halt just because a small design tweak was needed, forcing operators to wait hours for a CAD technician to generate a new file. This not only led to wasted labor time but also severely impacted project delivery schedules, especially for contract manufacturers juggling multiple deadlines. For businesses like Ahmed's, whose profit model relies on delivering finished parts efficiently, such delays are directly detrimental to profitability. The reliance on external design departments or highly specialized in-house CAD personnel meant increased overhead costs and a rigid workflow that lacked the agility demanded by modern manufacturing.

Furthermore, the learning curve for CAD software is steep, requiring extensive training that can take weeks or even months. This translates into significant upfront investment in training and an ongoing challenge when facing skilled labor shortages or high operator turnover. The entire process was cumbersome, prone to human error during file transfer or interpretation, and fundamentally inefficient for repetitive or standardized cutting tasks.

BNL's No-CAD System: A Paradigm Shift in Operation

Recognizing these pervasive challenges, MZBNL pioneered and perfected a No-CAD Operating System for laser tube cutting machines. This innovation fundamentally transforms the way operators interact with the machine, making it remarkably intuitive and efficient. Instead of needing to create or modify complex 3D drawings, operators can now simply enter parameters for standard tube types7 and hole patterns directly into the machine's interface. Imagine needing a square tube with specific drill holes – you just input the tube dimensions, hole diameters, and positions, and the machine processes it. No drawings, no external software, no G-code conversion required.

This direct parameter input capability represents a paradigm shift. It dramatically improves ease of use, making the machine accessible to a broader range of operators without specialized CAD training. Our internal data shows that thanks to this user-friendly design, operators now only need 1 day of on-site training instead of spending 15 days at the equipment factory. This single statistic speaks volumes about the reduction in skill threshold and the acceleration of operator readiness. For a business owner like Ahmed, who faces the challenge of operator turnover, this innovation directly addresses his pain point by significantly reducing the retraining burden and ensuring that his team can quickly become proficient.

The elimination of the CAD bottleneck means quicker setup times, faster prototyping, and the ability to make on-the-fly adjustments without disrupting the workflow. This agility is invaluable for custom fabrication shops or those handling diverse, smaller-batch orders, enabling them to respond swiftly to client requests and optimize production scheduling. The BNL No-CAD system empowers the shop floor, putting control directly into the hands of the operators and fostering a more dynamic and responsive manufacturing environment.

Impact on Production Workflow and Agility

The implications of operating without complex CAD drawings ripple throughout the entire production workflow, leading to enhanced agility and overall efficiency. The most immediate impact is the significant reduction in pre-production time. Without the need to create, convert, and transfer CAD files, machines can begin cutting almost immediately after an order is received or a design modification is requested. This dramatically shortens lead times, allowing businesses to deliver products faster to their customers and improve their reputation for responsiveness.

For contract-based fabrication services, like those offered by Ahmed Al-Farsi, agility is a key competitive differentiator. The ability to quickly set up and run a job, even for small batch sizes or customized components, allows them to accept a wider variety of orders and optimize their production schedule more effectively. This increased flexibility means less downtime between jobs and higher machine utilization rates, directly contributing to greater profitability. Data from our clients shows that streamlined setup processes can lead to a 20-30% reduction in overall project completion time for certain types of jobs.

Furthermore, the simplified operation reduces the potential for human error. When parameters are entered directly, there's less chance of misinterpreting a drawing or incorrectly translating a G-code. This leads to higher first-pass yield and reduces costly scrap material and rework. In essence, MZBNL’s No-CAD System empowers businesses to be more self-sufficient, less reliant on external design resources, and ultimately more efficient and profitable in their daily operations. It’s a testament to how thoughtful innovation can remove long-standing industry obstacles and drive real, tangible improvements in manufacturing output and customer satisfaction.

No-CAD reduces setup timeDoğru

Eliminating CAD drawings allows direct parameter input, cutting pre-production time significantly.

CAD is needed for all cutsYanlış

Standard shapes can be cut without CAD by directly entering parameters into the machine.

What innovations contribute to the efficiency of tube laser cutting machines?

Are your current cutting machines struggling with efficiency, high material waste, or demanding labor? Traditional setups often fall short, hindering your productivity and increasing operational costs. Revolutionary innovations in tube laser cutting are now setting new industry benchmarks for efficiency.

Innovations like BNL’s No-CAD System, Front-Feeding mechanism, and Zero-Waste Tail Material logic significantly enhance tube laser cutting efficiency. They reduce setup time, labor intensity, and material waste, allowing for faster processing, improved ergonomics, and maximized resource utilization in fabrication.

At MZBNL, our 25-year journey has been defined by an unwavering commitment to innovation, holding over 30 patents that push the boundaries of metal fabrication technology. I’ve seen firsthand how incremental improvements, when combined strategically, can lead to revolutionary leaps in efficiency. For businesses like Ahmed Al-Farsi’s, who prioritize automated solutions to upgrade production, these innovations are not just technical features; they are direct answers to real-world operational challenges. Our focus has always been on developing smart, digitalized systems that are not only powerful but also incredibly user-friendly and cost-effective, directly contributing to our clients' success and market leadership.

The evolution of tube laser cutting machines hasn't been static; it's a dynamic process driven by continuous innovation aimed at optimizing every aspect of the fabrication workflow. MZBNL is proud to be at the forefront of this evolution, leading the industry with three major innovations that directly contribute to unparalleled efficiency.

Material Handling Advancements: The Front-Feeding Innovation

One of the most time-consuming and labor-intensive aspects of traditional tube cutting is material loading. Conventional machines often rely on side or rear manual loading, which can be cumbersome, require significant physical effort from operators, and introduce delays between operations. This manual handling directly impacts throughput and can lead to operator fatigue, increasing the risk of errors or even injuries over long shifts. For a busy metal pipe processing factory or a large-scale furniture manufacturer, these inefficiencies accumulate rapidly, stifling overall productivity.

Recognizing this critical bottleneck, MZBNL introduced an optimized front-feeding mechanism. This innovative design allows the machine to automatically pull the tube in from the front, streamlining the loading process significantly. This automated approach not only reduces the physical demands on the operator but also dramatically minimizes the time required to load each new tube. We have meticulously tracked the impact of this innovation, and our data indicates that this design increases feeding efficiency by approximately 40%. This is not a theoretical gain; it translates directly into more tubes processed per hour, leading to a substantial boost in daily production capacity.

Furthermore, the reduction in manual labor intensity by approximately 40% directly addresses workforce challenges. It contributes to a safer, more ergonomic workplace, potentially reducing instances of strain-related injuries and improving operator morale. For a business owner like Ahmed Al-Farsi, whose stable, long-term business employs over 100 staff, enhancing workplace ergonomics and productivity while reducing reliance on strenuous manual tasks is a strategic imperative. This front-feeding innovation showcases our commitment to not just cutting faster but creating a more efficient and sustainable operational environment.

Waste Reduction Logic: The Zero-Waste Tail Material Innovation

Material waste is a significant, often overlooked, cost in metal fabrication. Conventional laser cutting systems typically operate by cutting from the tube head, moving progressively towards the end. This method inherently leaves an unusable section of "tail material" at the very end of the tube because the chuck or clamping mechanism needs a certain length to maintain grip, and the cutting head cannot reach the very last few inches. This leftover material, while small per tube, accumulates quickly in high-volume production, leading to considerable financial loss and environmental impact. For businesses like Ahmed's, where material costs are substantial, even a small percentage of waste can erode profit margins over time.

MZBNL tackled this challenge head-on by redesigning the fundamental cutting logic. Instead of starting from the tube head and generating waste at the end, our system now calculates from the rear chuck as the origin. This innovative approach allows the system to effectively eliminate leftover tail material, as long as the remaining section is smaller than the product length. By prioritizing the utilization of the very end of the tube, we maximize material efficiency to an unprecedented degree. This zero-tail design means that virtually every usable inch of the raw tube is transformed into a sellable product, translating directly into tangible cost savings.

This innovation not only boosts cutting efficiency but also contributes significantly to sustainability efforts by minimizing scrap metal that needs to be recycled or disposed of. For a high-tech enterprise like MZBNL, integrating such eco-friendly and cost-saving features is paramount to our commitment to innovation and client success. Our Zero-Waste Tail Material Innovation is a clear example of how intelligent design can unlock hidden value, improving profitability and environmental stewardship simultaneously, particularly for clients focused on a high cost-performance ratio.

Smart Integration and Digitalized Systems

Beyond mechanical and material handling innovations, the integration of smart and digitalized systems is rapidly transforming tube laser cutting machines into intelligent manufacturing hubs. Modern laser cutters are no longer just cutting tools; they are sophisticated cyber-physical systems capable of seamless data exchange, real-time monitoring, and predictive maintenance. This digitalization extends from the intuitive operator interface, like MZBNL's easy-to-operate system, to complex algorithms managing power output, cutting speed, and material flow.

MZBNL's machines embody this focus on smart digitalization. Our systems are designed for easy operation and maintenance, featuring intelligent controls that can adapt to different cutting scenarios and material types. This reduces reliance on highly specialized technicians for fine-tuning and allows for more consistent performance. The ability to monitor machine performance remotely, coupled with features for automated diagnostics, ensures minimal downtime and efficient troubleshooting, aspects that Ahmed Al-Farsi specifically prioritizes, along with spare parts availability and remote diagnostics.

Furthermore, this digitalization paves the way for deeper integration into broader automation system solutions, which is vital for clients who are themselves automation system solution providers or large enterprises looking to connect their entire production line. The data collected by these smart systems—from processing times and material usage to machine health—provides invaluable insights for optimizing production schedules, improving inventory management, and making data-driven decisions. These smart features elevate the tube laser cutting machine from a standalone piece of equipment to an integral component of an Industry 4.0-ready manufacturing ecosystem, ensuring that investments made today remain relevant and competitive for years to come.

Front-feeding increases efficiency by 40%Doğru

MZBNL's front-feeding mechanism reduces manual labor and speeds up tube loading, directly boosting productivity.

Traditional cutting leaves no tail wasteYanlış

Conventional systems always leave unusable tail material, while MZBNL's zero-waste logic eliminates this.

Sonuç

In summary, tube laser cutting machines offer unparalleled precision, speed, and material efficiency, setting them apart from traditional methods. Innovations like MZBNL's No-CAD System, Front-Feeding, and Zero-Waste Tail Material fundamentally enhance productivity, reduce labor and waste, and simplify operations, empowering businesses to achieve superior output and profitability.

-

Understand the key features that modern machines offer to metal processing businesses ↩

-

Explore this innovation's impact on reducing material waste and enhancing efficiency ↩

-

Learn how tube laser cutting enhances precision and efficiency in metal works ↩

-

Discover how advanced tube laser technology revolutionizes cutting processes ↩

-

Learn about stainless steel's advantages in decorative applications ↩

-

Understand the role of G-code in machine operations and CAD file processing ↩

-

Discover how parameter entry optimizes workflow without CAD drawings in tube cutting ↩

Sorularınız mı var veya daha fazla bilgiye mi ihtiyacınız var?

Kişiselleştirilmiş yardım ve uzman tavsiyesi için bizimle iletişime geçin.