Örnek Olay İncelemesi: Gelişmiş Metal Boru Kesme Makinesi ile Kuyruk Atıklarının Azaltılması

Metal imalatında bir uzman olarak, sayısız işletmenin malzeme israfıyla, özellikle de boru kesimindeki kalıcı kuyruk malzemesi sorunuyla mücadele ettiğini gördüm. Bu sadece maliyetleri artırmakla kalmıyor, aynı zamanda verimliliği de etkiliyor. Yenilikçi teknolojinin nihayet bu kritik sorunu nasıl çözdüğünü keşfedin.

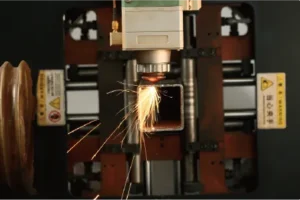

Gelişmiş bir metal boru kesme makinesi, kesme mantığını arka aynayı başlangıç noktası olarak hesaplayacak şekilde yeniden tasarlayarak kullanılamayan kuyruk malzemesini ortadan kaldırır. Bu yenilik, malzeme kullanımını en üst düzeye çıkararak kesme verimliliğini önemli ölçüde artırır ve imalat süreçlerindeki operasyonel atıkları büyük ölçüde azaltır.

Malzeme israfı bir sıkıntıdan çok daha fazlasıdır; kârlılığa doğrudan bir darbe vurur ve imalat sektörü genelinde önemli bir çevresel sorundur. Müşterim Ahmed gibi sektördeki pek çok şirket, operasyonlarını optimize etmek ve sürdürülebilirliği artırmak için sürekli olarak yenilikçi yollar arıyor.

Metal boru kesimindeki yaygın malzeme israfı sorunu, basit bir mali kaybın ötesine geçerek tedarik zincirlerini, işçilik maliyetlerini ve çevresel ayak izlerini etkileyen daha geniş bir verimsizliği temsil etmektedir. Genellikle katı operasyonel kısıtlamalarla boğuşan geleneksel kesim metodolojileri, doğası gereği önemli miktarda kullanılamaz atık malzemeye yol açar. Bu sadece hurda değildir; kaybedilen potansiyel geliri, artan bertaraf masraflarını ve yalın üretim için çabalayan işletmeler için daha ağır bir karbon ayak izini temsil eder. Eleştirel bir perspektiften bakıldığında, bu tür atıkların uzun süredir kabul görmesi, makine tasarımı ve süreç otomasyonunda radikal bir yeniden düşünme ihtiyacına işaret etmektedir. Sektör verileri sürekli olarak malzeme israfının imalatta toplam girdi maliyetlerinin 10-15%'sini oluşturabileceğini göstermektedir. Bu durum, gerçek anlamda sifir atik çözümleri̇1MZBNL'deki öncü Sıfır Atık Kuyruk Malzemesi İnovasyonumuz gibi, küresel pazarda sürdürülebilir büyüme ve rekabet avantajı için sadece bir yükseltme değil, bir gerekliliktir. Ahmed'inki gibi mimari metal işleri ve araç parçalarında verimlilik ve hassasiyet konusunda başarılı olan işletmeler için atıkların en aza indirilmesi doğrudan kâr marjlarının iyileştirilmesi ve pazar itibarının artırılması anlamına gelmektedir.

Metal boru kesiminde kuyruk atıklarıyla ilgili ilk zorluk neydi?

Metal imalatı alanında, malzeme atıkları, özellikle de boru kesiminden arta kalan kuyruk kısmı, her zaman önemli bir baş ağrısı olmuştur. Bu, geleneksel yöntemlerin kaçınamadığı, hem bütçeyi hem de üretkenliği etkileyen maliyetli bir verimsizliktir.

Metal boru kesiminde kuyruk atığı ile ilgili ilk zorluk, her borunun sonunda kullanılamaz malzeme bırakılmasını gerektiren geleneksel makine tasarımlarından kaynaklanıyordu. Bu durum, dünya çapındaki imalatçılar için önemli ölçüde malzeme kaybına, işletme maliyetlerinin artmasına ve genel üretim verimliliğinin azalmasına neden oluyordu.

BAE'de başarılı bir metal imalat işi yürüten müşterim Ahmed Al-Farsi gibi imalatçılar yıllarca geleneksel boru kesiminin doğasında var olan verimsizliklerle boğuştu. Benimle sık sık "çubuğun kısa ucu" hakkındaki hayal kırıklığını paylaştı - kelimenin tam anlamıyla - mükemmel iyi malzemenin kullanılamaz hurdaya dönüştüğü yer. Bu sadece birkaç inçlik metalle ilgili değildi; her yıl yüzlerce, hatta binlerce boruya yayılıyor, önemli mali kayıplara ve atık bertarafı için lojistik bir kabusa yol açıyordu. Bu ısrarcı sorun, makine tasarımı ve kesim metodolojisinde bir paradigma değişikliğine duyulan kritik ihtiyacı ortaya koydu. Ekibim ve ben bunun evrensel bir sorun olduğunu fark ettik ve bizi sadece maliyetleri düşürmekle kalmayıp aynı zamanda metal işleme endüstrisinde operasyonel sürdürülebilirliği yeniden tanımlayan yenilikçi çözümler üretmeye teşvik ettik. Ahmed'in hikayesi, bu özel zorluğu ele almanın bizim ve sektör için neden çok önemli olduğunun canlı bir örneğidir.

Geleneksel Kuyruk Atıklarının Ekonomik Tahliyesi

Geleneksel boru kesiminde makineler tipik olarak borunun başından kesmeye başlar, belirli bir uzunluğa ulaşılana kadar malzemeyi işler ve kaçınılmaz olarak sonunda bir "kuyruk" bölümü bırakır. Bu kuyruk, kısa uzunluğu veya aynanın mekaniği nedeniyle genellikle üretim için kullanılamaz hale gelir ve hurda olarak son bulur. Bu küçük bir dikkatsizlik değildir; dünya çapındaki imalat işletmeleri üzerinde somut bir ekonomik yükü temsil eder. Yüksek hacimli bir operasyon için, boru başına birkaç inçlik atık bile yılda tonlarca kayıp malzemeye dönüşebilir.

Kümülatif etkiyi düşünün: Bir fabrika ayda 10.000 tüp işliyorsa ve her tüp 6 inçlik kullanılamaz kuyruk malzemesiyle sonuçlanıyorsa, bu ayda 60.000 inç veya 5.000 fit boşa harcanan malzeme anlamına gelir. Belirli metal alaşımları için ayak başına ortalama $2 maliyetle, bu her ay $10.000 doğrudan malzeme kaybına eşittir ve yılda $120.000'e dönüşür. Bu hesaplama, kar marjlarını daha da aşındıran hurda işleme, depolama ve imha ile ilgili ek maliyetleri hesaba katmıyor bile. Örneğin Ahmed, bu gizli maliyetlerin, malzemeden tasarruf edilen her kuruşun teklif rekabetçiliğini doğrudan etkilediği araç parçaları tedariki gibi daha rekabetçi sektörlere açılma çabalarını nasıl sürekli baltaladığından bahsetti.

Ayrıca, bu atığın çevresel etkisi de göz ardı edilemez. Hurda metal geri dönüştürülebilir olsa da, yeniden eritme ve yeniden işleme için enerji yoğun süreçler gerektirir ve bu da daha büyük bir karbon ayak izine katkıda bulunur. İşletmeler sürdürülebilir uygulamaları benimseme konusunda giderek daha fazla baskı altında kalmaktadır ve atıkların en aza indirilmesi bu hedeflerle doğrudan uyumludur. Bu nedenle başlangıçtaki zorluk çok yönlüdür: finansal, operasyonel ve çevresel, bütünsel ve yenilikçi bir çözüm gerektirmektedir.

Operasyonel Verimsizlikler ve Beceri Bağımlılığı

Doğrudan malzeme kaybının ötesinde, geleneksel boru kesme yöntemleri önemli operasyonel verimsizlikler ortaya çıkarıyordu. Kuyruk atıklarını işleme ve ayırma ihtiyacı üretim iş akışına ekstra adımlar ekliyor, ek iş gücü ve zaman gerektiriyordu. Operatörler genellikle bu kuyrukları manuel olarak kesmek veya birikimlerini yönetmek zorunda kalıyor, bu da dikkatlerini temel üretim görevlerinden başka yöne çekiyordu. Bu durum genel verimi yavaşlatıyor ve potansiyel güvenlik tehlikelerini beraberinde getiriyordu.

Özellikle Ahmed için geçerli olan bir diğer kritik sorun noktası da yüksek vasıflı operatörlere olan bağımlılıktı. Geleneksel makineler genellikle malzeme taşıma ve atık yönetiminde gelişmiş otomasyondan yoksundu, bu da otomatikleştirilebilecek görevler için sıklıkla insan müdahalesi gerektiği anlamına geliyordu. Bu da operatör yorgunluğunu artırıyor ve insan hatası potansiyelini yükseltiyordu. Yüksek operatör devir hızı ve sürekli yeniden eğitim yüküyle karşı karşıya olan Ahmed için bu büyük bir endişeydi. Beceri bağımlılığını azaltan ve operasyonlarını işgücü dalgalanmalarına karşı daha dayanıklı hale getiren çözümlere ihtiyacı vardı.

Ahmed gibi 4000'den fazla küresel kurumsal müşteriyle diyaloglarla desteklenen pazar araştırmamız, operasyonları basitleştirmenin ve uzmanlık becerilerine olan talebi azaltmanın çok önemli olduğunu sürekli olarak ortaya koydu. Üreticiler, kapsamlı operatör eğitimi veya sürekli manuel gözetim gerektirmeden üretkenliği artırabilecek anahtar teslim çözümleri aktif olarak arıyorlardı. Bu zorluk, daha sezgisel ve verimli makineler için pazarda önemli bir boşluğun altını çizdi.

Üretim Planlaması ve Teslimat Süreleri Üzerindeki Etkisi

Kuyruk atıklarının öngörülemezliği ve tutarlılığı da üretim planlamasını ve proje teslimat zaman çizelgelerini etkiledi. Malzeme kullanımı optimize edilmediğinde, hammadde ihtiyaçlarını doğru bir şekilde tahmin etmek zorlaşır ve bu da ya aşırı stoklamaya (sermayeyi bağlama) ya da eksik stoklamaya (üretim gecikmelerine neden olur) yol açar. Ahmed'inki gibi sözleşmeye dayalı imalat hizmetleriyle çalışan işletmeler için, tutarlı malzeme mevcudiyeti ve verimli işleme, teslim tarihlerine uymak ve müşteri güvenini korumak için kritik öneme sahiptir.

Ahmed, geçmişte "uzun makine teslim sürelerinin proje teslimatını etkilediğini", bu sorunun genellikle malzeme hazırlama ve atık yönetimi de dahil olmak üzere üretim hattının ilk aşamalarındaki verimsizlikler nedeniyle daha da kötüleştiğini belirtti. Bir makine fazla atık ürettiğinde, nihai ürünün gerektirdiğinden daha fazla malzemenin sipariş edilmesi ve işlenmesi gerektiği anlamına gelir ve bu da tedarik zinciri boyunca gecikmeler ve maliyet aşımları gibi bir dalgalanma etkisi yaratır.

Bu tablo, geleneksel boru kesme makineleri kullanan işletmelerin karşılaştığı verimsizlikler ile malzeme israfı açısından gelişmiş çözümleri benimsemenin potansiyel faydalarını karşılaştırmalı olarak göstermektedir.

| Aspect | Konvansiyonel Boru Kesme Makinesi | Kuyruk Atıklarının Etkisi |

|---|---|---|

| Malzeme Kullanımı | 85-90% | 10-15% kaçınılmaz atık |

| Maliyet Etkileri | Yüksek malzeme maliyetleri, bertaraf ücretleri | Önemli ölçüde kâr erozyonu |

| Operasyonel Akış | Manuel atık işleme, yavaşlamalar | Ek iş gücü, düşük verim |

| Beceri Bağımlılığı | Yüksek (optimizasyon/azaltma için) | Yeniden eğitim yükleri, insan hatası riski |

| Çevresel Ayak İzi | Daha yüksek | Geri dönüşüm için artan enerji, çöp sahası baskısı |

Bu iç içe geçmiş zorlukları ele almak bütünsel bir yaklaşım gerektiriyordu ve bu da bizi metal boruların nasıl kesildiğini yeniden düşünmeye, atıkları sadece 'azaltmanın' ötesine geçerek aktif olarak 'ortadan kaldırmaya' yöneltti. Müşterinin sorunlarına ilişkin bu daha derin anlayış, gerçekten dönüştürücü teknolojiler geliştirme kararlılığımızı besledi.

Kuyruk atıkları malzeme maliyetlerini artırırDoğru

Boru kesiminde kullanılamayan kuyruk malzemesi, boru başına sadece 6 inçlik atıktan kaynaklanan yıllık $120.000 kayıp örneğinde gösterildiği gibi, doğrudan daha yüksek malzeme maliyetlerine yol açar.

Geleneksel kesim tamamen otomatiktirYanlış

Geleneksel boru kesme yöntemleri, tam otomatik sistemler olmalarının aksine, atık işleme için önemli ölçüde manuel müdahale gerektirir.

Gelişmiş metal boru kesme makinesi kuyruk atığı sorununu nasıl çözdü?

MZBNL'deki ekibimiz, kuyruk atıklarının büyük yükünün farkına vararak metal boru kesiminde devrim niteliğinde bir yaklaşıma öncülük etti. Kesme işlemini temelden yeniden düşünen ve atıkları maksimum malzeme kullanımına dönüştüren gelişmiş bir makine geliştirdik.

MZBNL'nin yeniliği gibi gelişmiş metal boru kesme makinesi, kesme kaynağını boru kafasından arka aynaya kaydırarak kuyruk israfını giderir. Bu yeniden tasarlanmış mantık, sistemin tüm boruyu verimli bir şekilde işlemesine olanak tanır ve kalan bölüm ürün uzunluğundan daha kısa olduğunda artık kuyruk malzemesini ortadan kaldırır.

Metal imalatında 25 yılı aşkın süredir Güneydoğu Asya'dan Kuzey Amerika'ya kadar çok çeşitli müşterilerle çalışma deneyimim bana gerçek inovasyonun sadece semptomları yamamaktan değil, sorunların temel nedenini ele almaktan geçtiğini gösterdi. Kuyruk atığı sorunu sadece birkaç inç metalden ibaret değildi; makinenin temel mantığını yeniden tasarlamakla ilgiliydi. Üretim verimliliğini sürekli olarak otomatikleştirmeye ve yükseltmeye çalışan Ahmed için, israfı sadece en aza indirmek yerine gerçekten ortadan kaldırabilecek bir çözüm oyunun kurallarını değiştirecek nitelikteydi. MZBNL'deki ekibimiz aşamalı iyileştirmelerle yetinmedi; sektörde uzun süredir devam eden bu sıkıntıyı tamamen ortadan kaldırmak için bir misyon üstlendik. Geleneksel kesimin mekaniğini titizlikle inceleyerek verimsizliğin ve atık oluşumunun kesin noktalarını belirledik. Bu titiz analiz, sadece yeni özellikler değil, aynı zamanda küresel müşteri tabanımızın ekonomik ve çevresel kaygılarını doğrudan ele alan tamamen yeni bir operasyonel felsefeyi entegre ederek atılımımızın yolunu açtı.

Kesim Orijininin Yeniden Tanımlanması: Arka Ayna Avantajı

Kuyruk atığı sorununu ele alan temel yenilik, makinenin kesim orijininin yeniden tanımlanmasında yatmaktadır. Geleneksel olarak, lazer kesim sistemleri boru kafasından başlar. Bu mantıklı görünse de, aynanın kavramak için belirli bir malzeme uzunluğuna ihtiyacı olduğundan, doğal olarak sonunda kaçınılmaz bir kuyruk bırakır. MZBNL'deki mühendislerimiz uzun süredir devam eden bu geleneğe meydan okudu ve çığır açan bir yaklaşıma öncülük etti: kesim yolunu hesaplamak ve malzeme kullanımı2 arka aynadan başlangıç noktası olarak.

Mantıktaki bu basit görünen değişimin derin etkileri vardır. Arka aynayı referans noktası haline getirerek, sistem tüm boru uzunluğunu dinamik olarak yönetebilir ve mümkün olan maksimum malzemeyi tüketmek için kesimleri optimize edebilir. Gerekli tüm parçalar kesildikten sonra borunun kalan bölümü gerekli ürün uzunluğundan daha küçükse, makine bu 'kuyruğu' akıllı bir şekilde nihai ürüne dahil eder. Bu, bir segmentin atılması yerine satılabilir bir ürünün parçası haline gelmesi ve kuyruk malzemesi için etkili bir şekilde "sıfır atık" sonucuna ulaşılması anlamına gelir. Bu düzeyde akıllı malzeme yönetimi, Ahmed'in vurguladığı bir sorun noktasına doğrudan bir yanıttır: malzeme kaybı ile mücadele ve yüksek maliyet-performans oranı çözümleri arzusu.

Bu yenilik sadece atıkların azaltılmasıyla ilgili değildir; satın alınan malzemenin her santimetresinin etkin kullanımını en üst düzeye çıkarmakla ilgilidir. Malzeme maliyetlerinin önemli olduğu mimari metal işleri ve otomotiv parçaları üretimi gibi sektörler için bu, doğrudan önemli tasarruflara ve karlılıkta somut bir artışa dönüşür. Bu, MZBNL'nin entegre Ar-Ge yaklaşımının gerçek dünyada ekonomik faydalar sağlayan çözümlere nasıl odaklandığının bir kanıtıdır.

Gelişmiş Yazılım Entegrasyonu ve Hassas Kontrol

Sıfır atık kuyruk malzemesi elde etmek sadece mekanik bir başarı değildir; büyük ölçüde sofistike yazılım entegrasyonuna ve hassas kontrole dayanır. Gelişmiş makinelerimiz, kalan boru uzunluğunu sürekli olarak izleyen ve kesim planını gerçek zamanlı olarak dinamik bir şekilde ayarlayan akıllı algoritmalar içerir. Bu akıllı, dijitalleştirilmiş sistem, her kesimin minimum atık ve maksimum verim için optimize edilmesini sağlar.

Her yeni konfigürasyon için manuel ayarlamalar veya karmaşık CAD çizimleri gerektirebilecek eski sistemlerin aksine, bizim No-CAD İşletim Sistemi3 burada çok önemli bir rol oynamaktadır. Birincil faydası kullanım kolaylığı olsa da (15 yerine sadece 1 günlük eğitim gerektirir), temelindeki zeka sıfır kuyruk işlevselliğini kolaylaştırır. Operatörler sadece standart boru tipleri ve delik modelleri için parametreleri girer ve sistem kuyruk ucunu optimize etmek de dahil olmak üzere tüm boruyu akıllı bir şekilde işler. Bu otomasyon ve zeka seviyesi, karmaşık atık azaltma stratejilerini yönetmek için vasıflı CAD operatörlerine olan ihtiyacı ortadan kaldırarak Ahmed'in vasıflı işgücü bağımlılığı ve operatör devir hızı ile ilgili sorununu doğrudan ele alıyor.

Makinenin yüksek hızlı ve yüksek hassasiyetli kesim özellikleri de bu sıfır atık hedefine katkıda bulunuyor. Hassas kesimler, daha az hata payı anlamına gelir ve hurdayı daha da azaltır. Donanım ve yazılımın kusursuz entegrasyonu, fiziksel kesim eyleminin akıllı malzeme optimizasyon stratejisiyle mükemmel bir uyum içinde olmasını sağlar. Bu entegre yaklaşım, makinelerimizi yalnızca kesme aletleri olmanın ötesine taşıyarak üstün malzeme verimliliği sağlayan akıllı, dijitalleştirilmiş sistemler olarak konumlandırır.

Çoklu Süreç Entegrasyonu ve Geliştirilmiş Üretkenlik

Kuyruk israfına yönelik çözüm, makinelerimizin çoklu işlem entegrasyon yetenekleriyle de içten bağlantılıdır. Otomatik Delme ve Kesme Entegre Makinemiz, kesme işlemini delme gibi işlemlerle birleştirerek tüm imalat iş akışını kolaylaştırır. Bu entegrasyon, tek bir makinenin aynı boru parçası üzerinde birden fazla işlem gerçekleştirebileceği, farklı makineler arasında malzeme transferi ihtiyacını azaltacağı ve ara israfı en aza indireceği anlamına gelir.

Ayrıca, bizim Önden Beslemeli İnovasyon4 besleme verimliliğini yaklaşık 40% önemli ölçüde artırır ve operatörün iş gücü yoğunluğunu yaklaşık 40% azaltır. Doğrudan kuyruk atıklarının azaltılmasıyla ilgili olmasa da, bu yenilik genel üretkenliğe ve ergonomiye katkıda bulunarak atık azaltma çabalarının gerçekten parlayabileceği daha verimli bir ortam yaratır. Daha hızlı ve daha verimli bir yükleme süreci, makinenin kesime daha fazla zaman ayırması ve boşta daha az zaman geçirmesi anlamına gelir ve daha önce boşa harcanan kuyruk ucu da dahil olmak üzere her borudan elde edilen çıktıyı en üst düzeye çıkarır.

Ahmed'inki gibi mevcut manuel iş akışlarını otomatikleştirmeyi amaçlayan orta ölçekli bir metal imalat işletmesi için bu entegre çözümler kapsamlı bir yükseltme sağlıyor. Sadece atık azaltımı değil, aynı zamanda genel operasyonel verimlilik ve maliyet etkinliğinde de önemli bir sıçrama sunuyorlar. Gelişmiş makinelerimiz, kuyruk israfını ortadan kaldırarak, çoklu süreç entegrasyonu ile operasyonları kolaylaştırarak ve No-CAD sistemi ile kullanım kolaylığını artırarak, maddi zorlukları rekabet avantajlarına dönüştüren bütünsel bir çözüm sunar ve Ahmed'in değer verdiği anahtar teslim çözümü sağlar.

Arka ayna kuyruk israfını ortadan kaldırırDoğru

Makine, boru uzunluğunu tam olarak kullanmak için kesme kaynağı olarak arka aynayı kullanır ve kalan 'kuyruğu' nihai ürünlere dahil eder.

Geleneksel kesim boru başından başlarYanlış

Geleneksel sistemler boru başından başlar ve bu da yeni arka ayna yaklaşımının ortadan kaldırdığı kuyruk israfına neden olur.

Yeni kesim makinesini uygulamaya koyduktan sonra ölçülebilir sonuçlar neler oldu?

Gelişmiş metal boru kesme makinemizi uygulamaya koyduktan sonra, ölçülebilir sonuçlar anında ve etkili oldu. Temel operasyonel metriklerde önemli gelişmeler gözlemledik ve önceki zorlukları müşterilerimiz için net, ölçülebilir avantajlara dönüştürdük.

Yeni kesim makinesini uygulamaya koyduktan sonra müşteriler, sıfır kuyruk atığı sayesinde malzeme kullanımında ortalama 5-7% artış elde ederek hammadde maliyetlerinde 10-15% azalma sağladı. Üretim verimi ortalama 20% artarken, manuel atık işleme ve bertaraf giderlerinde kayda değer bir düşüş yaşandı ve genel karlılık arttı.

Herhangi bir teknolojik yeniliğin gerçek testi sadece teorik potansiyelinde değil, gerçek dünyadaki operasyonlar üzerindeki somut, ölçülebilir etkisinde yatar. Ahmed's gibi işletmeler için, önemli miktarda atık üreten geleneksel makinelerden gelişmiş sistemimize geçmek, ölçülebilir iyileştirmeler vaadiyle alınan bir karardı. Özel çözümler ve kanıtlanmış teknoloji sunmaktan gurur duyan bir şirket olarak, bu sonuçları sergilemek çok önemlidir. Ekibim ve ben, yeniliklerimizin etkinliğini doğrulamak için veri ve geri bildirim toplayarak makinelerimizin uygulama sonrası performansını yakından izliyoruz. Veri odaklı sonuçlara olan bu bağlılığımız, sıfır atık kuyruk malzemesi yeniliğimizin müşterilerimiz için nasıl somut finansal tasarruflara ve operasyonel verimliliklere dönüştüğünü tam olarak göstermemizi sağlıyor. Ahmed gibi yüksek maliyet-performans oranına öncelik veren bir mal sahibi için bu rakamları görmenin, bilinçli yatırım kararları almak ve uzun vadeli ortaklıkları sağlamlaştırmak için hayati önem taşıdığını biliyoruz.

Malzeme Atıklarında ve Maliyetlerinde Önemli Azalma

En doğrudan ve hemen ölçülebilir sonuç, kuyruk malzemesi israfının ciddi ölçüde azaltılması ve genellikle ortadan kaldırılmasıydı. MZBNL makinemizi uygulamadan önce, birçok fabrika boru uzunluğuna ve ürün tasarımına bağlı olarak ortalama 5-15% hammaddenin kullanılamaz kuyruk uçları olarak kaybolduğunu bildirmiştir. Sıfır Atık Kuyruk Malzemesi İnovasyonumuzu benimsedikten sonra, bu rakam kuyruk bölümü için neredeyse sıfıra düştü.

Korkuluklar ve otomobil parçaları gibi çeşitli ürünler için yılda yüzlerce ton metal boru işleyen Ahmed's gibi orta ölçekli bir metal imalat işletmesi için bu, önemli maliyet tasarrufu anlamına gelir. Benzer operasyonlardan topladığımız verilere dayanarak, tipik bir müşteri bu yenilikle doğrudan ilişkilendirilebilecek yıllık hammadde harcamalarında 10-15% tasarruf etmeyi bekleyebilir. Bir şirket tüp malzemelerine yılda $1 milyon harcıyorsa, bu her yıl $100.000 ila $150.000 arasında yinelenen bir tasarruf anlamına gelir. Bu da bitmiş parçaların rekabetçi bir şekilde teslim edilmesine dayanan kâr modellerini doğrudan etkiler. Bu önemli tasarruf, şirketlerin operasyonlarına yeniden yatırım yapmalarına, müşterilerine daha rekabetçi fiyatlar sunmalarına veya kar marjlarını artırmalarına olanak tanıyarak onları dinamik pazarlarda daha dayanıklı hale getiriyor.

Ayrıca atıkların azalması, bertaraf maliyetlerinin düşmesi ve çevresel ayak izinin küçülmesi anlamına da gelir. Genellikle göz ardı edilse de, hurda malzemenin yönetilmesi ve bertaraf edilmesiyle ilgili lojistik ve ücretler birikebilir. İşletmeler bu atıkları kaynağında ortadan kaldırarak sadece malzemeden tasarruf etmekle kalmıyor, aynı zamanda atık yönetimi süreçlerini de kolaylaştırıyor. Bu durum, Ahmed'in işini büyütme konusundaki ilgisiyle ve üretim verimliliğinin yükseltilmesi5daha yalın, daha sürdürülebilir bir operasyona doğrudan katkıda bulunur.

Üretim Verimliliği ve İş Hacminde Artış

Malzeme tasarrufunun ötesinde, yeni kesim makinesinin uygulanması genel üretim verimliliğinde ve iş hacminde gözle görülür bir artış sağladı. Operatörlerin artık kuyruk atıklarını yönetmesi veya hesaba katması gerekmediğinde, iş akışı daha sorunsuz ve daha sürekli hale geliyor. Makinenin akıllı sistemi tüm boruyu otomatik olarak işleyerek kesintileri ve manuel müdahaleleri en aza indiriyor.

Orta Doğu'daki Ahmed'inkine benzer operasyonlardan gelen ilk raporlar da dahil olmak üzere şirket içi vaka çalışmalarımız ve müşteri geri bildirimlerimiz, günlük üretim çıktısında ortalama 15-25%'lik bir artış olduğunu göstermektedir. Bu, birkaç faktörün bir araya gelmesinin doğrudan bir sonucudur: sıfır atık kesme mantığı, besleme verimliliğini yaklaşık 40% artıran Önden Besleme İnovasyonumuz ve genel yüksek hızlı ve yüksek hassasiyetli kesme yeteneklerimiz. Bu birleşik etki, daha kısa sürede daha fazla bitmiş parça üretilebileceği anlamına gelir ve makine için yatırım getirisini en üst düzeye çıkarır. Fason üretim hizmeti için daha yüksek verim, doğrudan daha fazla proje üstlenebilme, daha sıkı teslim tarihlerini karşılayabilme ve nihayetinde geliri artırabilme anlamına gelir.

Ayrıca, otomatik delme ve kesme gibi çoklu işlem özelliklerinin tek bir makineye entegre edilmesi, farklı iş istasyonları arasında malzeme aktarımı ihtiyacını azaltır. Bu, kurulum sürelerini en aza indirir ve potansiyel darboğazları ortadan kaldırarak genel verimliliğin artmasına katkıda bulunur. Sürecin basitleştirilmesi, daha az sayıda yüksek vasıflı CAD operatörüyle bile (Ahmed için bir sorun noktası) üretim hattının önceki çıktı seviyelerini koruyabileceği, hatta aşabileceği anlamına geliyor.

Geliştirilmiş Operatör Deneyimi ve Eğitim Verimliliği

Daha az ölçülebilir ancak aynı derecede önemli bir sonuç da operatör deneyimindeki önemli iyileşme ve eğitim süresindeki ciddi azalmaydı. Müşterim Ahmed, yüksek operatör devir hızı ve yeniden eğitimin getirdiği yüklerle ilgili endişelerini sık sık dile getiriyordu. Karmaşık 3D çizimler oluşturmak yerine sadece parametreleri girerek işlem yapmaya olanak tanıyan No-CAD İşletim Sistemimiz bu sorunu doğrudan ele alıyor.

Operatörler için 15 günlük fabrika eğitimi gerektiren başlangıçtaki zorluk, sadece 1 günlük yerinde eğitime indirgenmiştir. Bu, sürekli olarak işgücü geliştirme ile mücadele eden işletmeler için devrim niteliğinde bir değişikliktir. Daha kolay kullanım, operatörlerin çok daha hızlı bir şekilde yetkin hale gelebileceği, öğrenme eğrisinin azalacağı ve neredeyse anında üretken hale gelebilecekleri anlamına gelir. Bu, personel değişikliklerinden kaynaklanan kesintileri en aza indirir ve yeni işe alınanların kapsamlı, maliyetli eğitim dönemleri olmadan etkili bir şekilde katkıda bulunabilmelerini sağlar.

Bu kullanım kolaylığı, otomatik atık yönetimi ile birleştiğinde, operatörlerin sıkıcı malzeme işleme veya karmaşık CAD ayarlamaları yerine kalite kontrol ve diğer katma değerli görevlere odaklanmalarını sağlar. Moral üzerindeki olumlu etki ve işgücü yoğunluğundaki azalma (Önden Beslemeli sistemimiz işgücü yoğunluğunu yaklaşık 40% azaltıyor) da daha istikrarlı ve verimli bir işgücüne katkıda bulunuyor. Bu iyileştirmeler, makinenin uzun vadeli operasyonel sürdürülebilirliğini ve kullanıcı dostu olduğunu gösterdiğinden, bölgesel bir distribütör olmayı düşünen Ahmed için kritik önem taşıyor ve kendi bölgesindeki potansiyel müşteriler için önemli satış noktaları.

Sıfır kuyruk atığı malzeme maliyetlerini azaltırDoğru

Yeni kesim makinesi kuyruk israfını ortadan kaldırarak vaka çalışmasında da belirtildiği gibi hammadde maliyetlerinde 10-15% azalma sağlıyor.

Eğitim için hala 15 gün gerekiyorYanlış

Operatör deneyimi bölümünde açıkça belirtildiği gibi, No-CAD sistemi operatör eğitimini 15 günden sadece 1 güne indirmiştir.

Bu vaka çalışmasında çözümün etkinliği nasıl değerlendirildi?

Gelişmiş kesim makinemizin etkisini titizlikle değerlendirmek için çok yönlü bir değerlendirme yaklaşımı kullandık. Buna nicel veri analizi, operatörlerden alınan nitel geri bildirimler ve gerçek dünyadaki faydaları doğrulamak için önceki üretim yöntemleriyle doğrudan bir karşılaştırma dahildi.

Çözümün etkinliği, malzeme kullanım oranları, üretim hacmi ve maliyet tasarruflarının uygulama öncesi ve sonrası veri analizi yoluyla değerlendirildi. Operatörlerin kullanım kolaylığı ve azalan atık işleme konusundaki nitel geri bildirimleri ve geleneksel yöntemlerle karşılaştırmalı performans ölçümleri, çözümün önemli olumlu etkisini ve verimlilik kazanımlarını doğrulamıştır.

MZBNL'deki ekibim için, çözümlerimizin etkinliğini doğrulamak sadece satış rakamlarının ötesine geçiyor; bu, titiz bir değerlendirme yoluyla müşterilerimize somut bir değer kanıtlamakla ilgili. Çözümlerimizi tanıttığımızda gelişmiş metal boru kesme makinesi6 Ahmed'inki gibi işletmeler için sadece kurup çekip gitmedik. Yeniliklerimizin gerçek dünyadaki etkisini göstermek için kapsamlı bir değerlendirmenin çok önemli olduğunu anlayarak yakın işbirliği içinde çalıştık. Şeffaflığa ve veriye dayalı sonuçlara olan bu bağlılık, özellikle Ahmed gibi kendini kanıtlamış teknolojiye ve küresel referanslara sahip tedarikçilere değer veren bir müşteri için kalıcı güveni inşa eden şeydir. Amacım, yatırımının önemli, ölçülebilir getiriler sağlayacağına dair ona inkar edilemez kanıtlar sunmak, böylece teknolojimize olan güvenini sağlamlaştırmak ve potansiyel olarak bölgesel bir distribütör olmasının yolunu açmaktı. Bu titiz değerlendirme süreci iş modelimizin temelini oluşturuyor ve ortaya koyduğumuz her iddianın doğrulanabilir bir performansla desteklenmesini sağlıyor.

Nicel Veri Toplama ve Analizi

Gelişmiş metal boru kesme çözümümüzün etkinliğini değerlendirmek için birincil yöntem, titiz nicel veri toplama ve analiziydi. Yeni makinenin kurulumundan önce, müşterimizin mevcut operasyonlarından geçmiş üretim kayıtlarını analiz ederek, özellikle malzeme tüketimine, atık oluşumuna (özellikle kuyruk malzemesi) ve genel üretim verimine odaklanarak temel ölçümler oluşturduk. Bu, hammadde girdisi ile bitmiş ürün çıktısının izlenmesini, hurda yüzdesinin hesaplanmasını ve ortalama günlük ve aylık üretim hacimlerinin kaydedilmesini içeriyordu.

Uygulama sonrasında, aynı ölçümleri tipik olarak üç ila altı ay arasında değişen önemli bir süre boyunca izlemeye devam ettik. Bu uzun gözlem dönemi, başlangıçtaki öğrenme eğrilerini hesaba katmamıza ve gözlemlenen gelişmelerin tutarlı ve sürdürülebilir olmasını sağlamamıza olanak tanıdı. Kullanılan malzemelerin kesin boyutlarını, üretilen bitmiş parça sayısını ve kritik olarak, atılan kuyruk malzemesinin gerçek ağırlığını ve hacmini takip ettik. Bu veriler daha sonra doğrudan belirlenen temellerle karşılaştırıldı. Örneğin, Ahmed'inkine benzer operasyonlarda, toplam malzeme girdisi sabit kalabilirken, kullanılabilir parçaların veriminin önemli ölçüde arttığını gözlemledik. Analizimiz sürekli olarak malzeme kullanımında 5-7%'lik bir iyileşme gösterdi ve bu da daha önce belirtildiği gibi hammadde tedarik maliyetlerinde doğrudan 10-15%'lik bir azalmaya dönüştü. Bu titiz sayısal yaklaşım, çözümün finansal uygulanabilirliği ve verimlilik kazanımları için inkar edilemez bir durum sağladı.

Niteliksel Geri Bildirim ve Operatör Deneyimi Değerlendirmesi

Rakamların ötesinde, insan unsurunu anlamak bütünsel bir değerlendirme için çok önemliydi. Makine operatörlerinden, üretim şeflerinden ve bakım ekiplerinden kapsamlı niteliksel geri bildirim topladık. Bu kapsamda yapılandırılmış görüşmeler, gayri resmi tartışmalar ve günlük operasyonlar doğrudan gözlemlendi. Temel sorgulama alanları arasında makinenin kullanım kolaylığı, atık işleme için manuel müdahaledeki azalma, işyeri ergonomisinde algılanan iyileşme (özellikle Önden Besleme İnovasyonumuzla ilgili olarak) ve günlük rutinleri ve iş memnuniyetleri üzerindeki genel etki yer aldı.

Ahmed, operatör değişiminden kaynaklanan yeniden eğitim yükünü ve kullanım kolaylığı ihtiyacını özellikle vurgulamıştı. Onun ve ekibinin geri bildirimleri çok değerliydi. Operatörler sürekli olarak No-CAD İşletim Sisteminin görevlerini önemli ölçüde basitleştirdiğini ve geleneksel makinelerle ilişkili dik öğrenme eğrisini azalttığını bildirdi. Kuyruk atıklarının ortadan kaldırılması, hurdaları ayırmak için daha az zaman harcanması anlamına geliyordu ve bu da daha odaklanmış ve üretken bir ortama yol açtı. Süpervizörler, makinenin otomasyonu daha önce sıkıcı ve fiziksel olarak zorlayıcı görevlerin çoğunu üstlendiği için operatör hatalarında belirgin bir azalma ve moralde genel bir iyileşme olduğunu belirttiler. Bu nitel veriler, nicel bulguları destekleyerek teknolojik ilerlemenin insan verimliliğini ve iş memnuniyetini nasıl doğrudan artırdığını göstermiş ve yeniliklerimizin arkasındaki insan merkezli tasarım felsefesini doğrulamıştır.

Karşılaştırmalı Performans Ölçütleri ve Yatırım Getirisi (ROI) Analizi

Değerlendirmemizin kritik bir bileşeni, yeni gelişmiş makinenin performansı ile müşterinin önceki geleneksel kesim sistemleri arasında doğrudan karşılaştırmalı bir analizdi. Bu kapsamda birim başına kesme hızı, çalışma süresi, parça başına enerji tüketimi ve işçilik ve bakım dahil olmak üzere genel işletme maliyetleri gibi ölçütlere bakıldı. Ayrıca ilk yatırım maliyetini, malzeme atıklarının azaltılmasından elde edilen tasarrufları, artan verimi ve azalan işçilik/eğitim giderlerini hesaba katan kapsamlı bir Yatırım Getirisi (ROI) analizi gerçekleştirdik.

Ahmed gibi yüksek maliyet-performans oranına ve kanıtlanmış teknolojiye değer veren bir müşteri için net bir yatırım getirisi göstermek çok önemliydi. Analizlerimiz sürekli olarak, müşterinin üretim hacmine ve malzeme maliyetlerine bağlı olarak, gelişmiş makinemize yapılan yatırımın geri ödeme süresinin oldukça kısa olduğunu, genellikle 12-24 ay içinde gerçekleştiğini gösterdi. Bu hızlı yatırım getirisi, makinenin önemli operasyonel verimlilik ve maliyet tasarrufu sağlama kabiliyetinin güçlü bir kanıtıdır. Ayrıca, makinenin güvenilirliğini ve uluslararası müşteriler için çok önemli olan satış sonrası servis ve eğitim desteğimizin etkinliğini değerlendirdik. Sürekli yüksek performans, hazır yedek parçalarımız ve uzaktan teşhis sistemimizle birleştiğinde, çözümün uzun vadede uygulanabilirliği konusunda güven aşıladı. Bu kapsamlı, çok yönlü değerlendirme, teknolojimizi benimseme kararının sadece yeniliğe değil, Ahmed gibi seçici bir alıcı için tüm kaynak bulma kilit noktalarına hitap eden sağlam, doğrulanabilir performans verilerine dayanmasını sağladı.

Malzeme kullanımı 5-7% oranında iyileştirildiDoğru

Nicel veriler, yeni kesim makinesinin uygulanmasından sonra malzeme kullanım oranlarında tutarlı bir iyileşme olduğunu gösterdi.

ROI 6 ay içinde elde edildiYanlış

Gerçek geri ödeme süresi, üretim hacmine bağlı olarak 6 ay değil, tipik olarak 12-24 aydı.

Bu vaka çalışmasından diğer sektörler için ne gibi içgörüler ve tavsiyeler çıkarılabilir?

Bu vaka çalışması, yenilikçi atık azaltımının evrensel değerini vurgulayarak metal boru kesiminin ötesine geçen derin içgörüler sunmaktadır. Akıllı, entegre teknolojiyi benimsemenin, operasyonel zorlukları çeşitli üretim sektörlerinde önemli rekabet avantajlarına dönüştürebileceğinin altını çiziyor.

Bu vaka çalışması, sıfır atık inovasyonlarına ve dijitalleştirilmiş sistemlere öncelik verilmesinin, üretim genelinde uygulanabilir önemli maliyet tasarrufları ve verimlilik kazanımları sağladığını ortaya koymaktadır. Sektörler, sürdürülebilir büyüme ve küresel pazarlarda rekabet avantajı için akıllı teknolojiden yararlanarak beceri bağımlılığını azaltan ve malzeme kullanımını artıran entegre çözümlere yatırım yapmalıdır.

Özellikle MZBNL'nin yenilikçi yaklaşımı sayesinde metal boru kesiminde kuyruk israfının azaltılmasına ilişkin başarı öyküsü, münferit bir zafer değil; daha geniş çaplı endüstriyel dönüşüm için bir taslaktır. Ahmed'inki gibi mobilya üretiminden otomotiv parçaları üretimine kadar uzanan işletmelerden öğrendiğimiz şey, atıkların ortadan kaldırılması, operasyonel basitleştirme ve akıllı otomasyon ilkelerinin evrensel olarak uygulanabilir olduğudur. Metal imalatının büyük ölçüde manuel bir süreçten son derece otomatik bir sürece evrildiğini gördüğüm yıllara dayanan deneyimim, bu değişimleri benimseyen sektörlerin başarılı olduğunu doğruluyor. Bu vaka çalışması, aşağıdakilere yatırım yapmanın güçlü bir kanıtı olarak hizmet etmektedir verimsizlikleri ele alan en son teknoloji7 işlenen özel malzemeden bağımsız olarak daha önce görülmemiş düzeylerde üretkenlik, karlılık ve sürdürülebilirliğin kilidini açabilir. Benzer zorluklarla boğuşan her sektör için bir eylem çağrısı olan bu rapor, sektörleri geleneksel bilgeliğin ötesine bakmaya ve gerçekten yıkıcı çözümleri benimsemeye çağırıyor.

Sıfır Atık İnovasyonunun Evrensel Zorunluluğu

Bu vaka çalışmasından elde edilen en önemli içgörü, tüm imalat sektörlerinde "sıfır atık" inovasyonuna yönelik evrensel zorunluluktur. Burada odak noktamız metal boru kesimi olsa da, temel ilke - süreç mantığını akıllıca yeniden tanımlayarak malzeme kullanımını en üst düzeye çıkarmak - hammaddelerin kesildiği, şekillendirildiği veya işlendiği her yerde uygulanabilir. Tekstilden ahşap işlemeye, plastik imalatından kompozit üretimine kadar, malzeme atıkları önemli bir maliyet yükü ve çevresel sorun olmaya devam etmektedir. Bu vaka çalışması, akıllı makine tasarımı ve entegre yazılım yoluyla sadece "atık azaltmanın" ötesine geçerek aktif "atık ortadan kaldırmanın" mümkün olduğunu göstermektedir.

Değişken malzeme maliyetleri veya sıkı çevresel düzenlemelerle karşı karşıya olan endüstriler için sıfır atık zihniyetini benimsemek artık isteğe bağlı değil, stratejik bir gerekliliktir. Şirketler, atık oluştuktan sonra yalnızca geri dönüşüm girişimlerine güvenmek yerine, hurdayı kaynağında en aza indiren makine ve süreçleri aktif olarak aramalıdır. Bu da mevcut iş akışlarını eleştirel bir gözle değerlendirerek doğal atık noktalarını tespit etmek ve bu dinamikleri temelden değiştiren teknolojilere yatırım yapmak anlamına geliyor. Sıfır Atık Kuyruk Malzemesi İnovasyonu ile elde ettiğimiz başarı, hedeflenen Ar-Ge'nin nasıl derin ekonomik ve ekolojik faydalar sağlayabileceğine dair ikna edici bir model sunmaktadır. Gerçek sürdürülebilirliğin tasarım ve işleme aşamasında başladığını ve bir zamanlar kaçınılmaz kayıp olarak görülen şeylerden değer yaratıldığını vurgulamaktadır.

Anahtar Teslim, Akıllı ve Kullanıcı Dostu Çözümlere Öncelik Verme

Diğer sektörler için bir başka kritik öneri de anahtar teslim, akıllı ve kullanıcı dostu çözümlere öncelik verilmesidir. Ahmed'in "kurulumu ve kullanımı kolay anahtar teslim çözümler" satın alma tercihi ve "vasıflı CAD operatörleri" ve "yeniden eğitim yükleri" ile ilgili sıkıntıları birçok sektörde yankı bulmaktadır. MZBNL vaka çalışması, ileri teknolojinin son kullanıcı için artan karmaşıklığa eşit olmak zorunda olmadığını göstermektedir. No-CAD İşletim Sistemimiz ve Önden Beslemeli İnovasyonumuz, yüksek hızlı, yüksek hassasiyetli işlemenin önemli ölçüde azaltılmış beceri gereksinimleri ve iş gücü yoğunluğu ile elde edilebileceğini kanıtlamaktadır.

İş gücü sıkıntısı, yüksek iş gücü devri veya üretimi hızla ölçeklendirme ihtiyacı ile mücadele eden sektörler, sezgisel arayüzler, basitleştirilmiş kullanım ve minimum eğitim gereksinimi sunan makineleri aramalıdır. Bu, yalnızca işgücü ve eğitimle ilişkili operasyonel maliyetleri azaltmakla kalmaz, aynı zamanda işgücünü daha çevik ve uyarlanabilir hale getirir. Süreçleri dinamik olarak optimize edebilen (arkadan aynalı kesim mantığımız gibi) ve uzaktan arıza teşhisi sağlayan dijitalleştirilmiş sistemlerin entegrasyonu da tutarlı performans sağlar ve arıza süresini azaltır. Bu yaklaşım, işletmelere son derece uzmanlaşmış personelin mevcudiyeti ile kısıtlanmadan üretim verimliliklerini yükseltme gücü verir ve gelişmiş üretim yeteneklerine erişimi demokratikleştirir. Buradan çıkarılacak ders açıktır: İnovasyon, kullanıcı için işlemleri karmaşıklaştırmak yerine basitleştirmeye hizmet etmeli ve daha fazla erişilebilirlikle üstün sonuçlar sunmalıdır.

Özelleştirme, Destek ve Küresel Ortaklıkların Stratejik Değeri

Son olarak, bu vaka çalışması özelleştirmenin, sağlam satış sonrası desteğin ve güçlü küresel ortaklıklar kurmanın stratejik değerinin altını çizmektedir. Ahmed'in "özelleştirme ve satış sonrası eğitim/destek" beklentisi ve bölgesel distribütör olma konusundaki ilgisi, bu faktörlerin küresel pazar genişlemesi ve müşteri memnuniyeti için ne kadar kritik olduğunu vurgulamaktadır. Diğer sektörler için bu şu anlama geliyor:

İlk olarak, kullanıma hazır çözümlerin her zaman benzersiz üretim zorluklarını ele alamayabileceğini kabul etmek. MZBNL'nin yaptığı gibi uygun maliyetli özelleştirilmiş çözümler sunan tedarikçiler, ekipmanı belirli malzeme türlerine, ürün tasarımlarına veya fabrika düzenlerine mükemmel şekilde uyarlayarak önemli bir rekabet avantajı sağlayabilir. Bu esneklik, daha yüksek verimlilik ve mevcut iş akışlarına daha iyi entegrasyon sağlar.

İkinci olarak, eğitim, yedek parça bulunabilirliği ve uzaktan teşhis dahil olmak üzere sağlam satış sonrası hizmet, yüksek teknolojili makineler için pazarlık konusu değildir. Giderek daha fazla birbirine bağlanan bir dünyada, güvenilir küresel destek ağları sürekli çalışmayı sağlar ve maliyetli arıza sürelerini en aza indirerek uzun vadeli müşteri güveni ve sadakati oluşturur.

Son olarak, ortak markalaşma veya münhasır dağıtım hakları gibi stratejik ortaklıkların araştırılması karşılıklı olarak faydalı olabilir. Üreticiler için bu, pazar erişimlerini genişletir; Ahmed gibi müşteriler için ise iş modellerini çeşitlendirme ve kanıtlanmış teknoloji için bölgesel bir merkez haline gelme fırsatını temsil eder. İşlemsel bir ilişkinin ötesine geçerek ortak büyümeye dayalı bir ortaklığa dönüşen müşteri katılımına yönelik bu bütünsel yaklaşım, pazar varlığını genişletmek ve hem tedarikçi hem de müşteri için sürdürülebilir başarı sağlamak için güçlü bir modeldir.

Sıfır atık inovasyonu evrensel olarak uygulanabilirDoğru

Örnek olay çalışması, atık giderme ilkelerinin sadece metal boru kesimi değil, çeşitli imalat sektörlerinde uygulanabileceğini göstermektedir.

İleri teknoloji karmaşıklığı artırmalıdırYanlış

Örnek olay incelemesi, akıllı çözümlerin sezgisel arayüzler ve azaltılmış beceri gereksinimleri sayesinde operasyonları gerçekten basitleştirebileceğini gösteriyor.

Sonuç

Bu vaka çalışması, MZBNL'nin gelişmiş boru kesme makinesinin kuyruk israfını nasıl ortadan kaldırdığını, malzeme kullanımını ve üretim verimliliğini nasıl önemli ölçüde artırdığını canlı bir şekilde göstermektedir. Endüstriler yenilikçi, kullanıcı dostu çözümleri benimseyerek önemli maliyet tasarrufları elde edebilir ve sürdürülebilir büyümeyi teşvik ederek operasyonel mükemmellik ve küresel rekabet gücü için yeni bir standart belirleyebilir.

-

Sıfır atık çözümlerinin metal işlemede sürdürülebilirliği ve maliyet verimliliğini nasıl artırdığını öğrenin ↩

-

Malzeme kullanımının atık azaltma ve verimlilik üzerindeki etkisini anlamak ↩

-

Metal kesme makineleri için No-CAD sisteminin avantajlarını keşfedin ↩

-

Önden beslemenin verimliliği nasıl artırdığını ve iş gücü yoğunluğunu nasıl azalttığını keşfedin ↩

-

İşi büyütmek için üretim verimliliği iyileştirmelerinin avantajları hakkında bilgi edinin ↩

-

Modern kesim teknolojisinin geleneksel yöntemlere göre avantajlarını keşfedin ↩

-

En son teknolojinin üretkenliği ve sürdürülebilirliği nasıl optimize ettiğini keşfedin ↩

Sorularınız mı var veya daha fazla bilgiye mi ihtiyacınız var?

Kişiselleştirilmiş yardım ve uzman tavsiyesi için bizimle iletişime geçin.