Почему производители медицинского оборудования предпочитают прецизионные станки для резки металлических труб

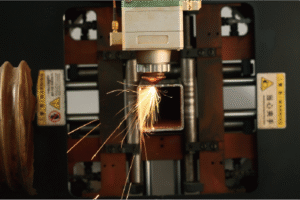

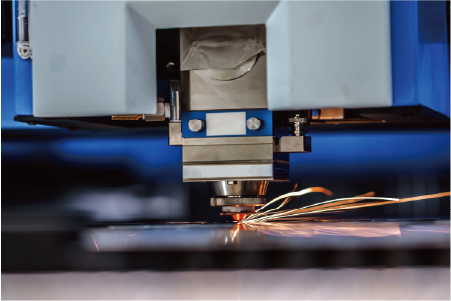

Вы боретесь с жесткими требованиями производства медицинского оборудования и абсолютной необходимостью в точности? Ручная резка или устаревшее оборудование могут привести к дорогостоящим ошибкам, отходам материала и несоблюдению строгих стандартов в этой критически важной области. Узнайте, как современные прецизионные станки для резки металлических труб революционизируют производство для производителей медицинского оборудования.

Прецизионные станки для резки металлических труб жизненно необходимы производителям медицинского оборудования, поскольку в этой отрасли предъявляются строгие требования к точности, целостности материала и воспроизводимому качеству. Они позволяют изготавливать такие сложные компоненты, как стенты и иглы, с микронной точностью, что напрямую влияет на безопасность пациентов и эффективность устройств, а также обеспечивает соблюдение нормативных требований.

Промышленность медицинского оборудования работает под микроскопом, где целостность каждого компонента имеет решающее значение для здоровья пациента. Такое пристальное внимание требует от производственных процессов не только эффективности, но и безупречной точности. Присоединяйтесь ко мне, чтобы узнать, почему внедрение современных технологий резки металлических труб - это не просто модернизация, а фундаментальная необходимость для достижения беспрецедентного качества и соответствия требованиям в этом жизненно важном секторе.

За 25 лет работы в сфере производства металлических изделий я на собственном опыте убедился, что сектор медицинского оборудования выделяется среди других. Это не просто резка металла, это формирование будущего. Компании сталкиваются с огромным давлением со стороны таких регулирующих органов, как FDA и CE, требующих безупречной прослеживаемости и валидации на каждом этапе. Такие условия требуют критического перехода от традиционных, часто подверженных ошибкам методов к высокоавтоматизированным, точным решениям. Рассмотрим возрастающую сложность минимально инвазивных хирургических инструментов или имплантируемых устройств; эти компоненты часто имеют сложную геометрию в крошечных размерах. Достижение такой сложности последовательно, в масштабе и без ущерба для целостности материала (например, предотвращение микротрещин или зон термического воздействия) выходит за рамки возможностей обычного оборудования. Исследования показывают, что дефектные медицинские изделия могут привести к тяжелым последствиям для пациентов и массовым отзывам, которые обходятся в миллиарды. Таким образом, производители не просто ищут машину, они инвестируют в сертифицированный, воспроизводимый и, в конечном счете, спасающий жизнь процесс. Эта критическая потребность подчеркивает ключевую роль передовых технологий резки.

С какими проблемами сталкиваются производители медицинского оборудования, требующие прецизионной резки металлических труб?

Вам приходится сталкиваться с огромной нагрузкой, связанной с соблюдением строгих стандартов на медицинские изделия и управлением сложными конструкциями компонентов? Традиционные методы резки часто оказываются неэффективными, что приводит к высокому уровню брака, отходам материала и значительным рискам, связанным с соблюдением нормативных требований в отрасли с нулевой толерантностью. Прецизионные станки для резки металлических труб напрямую решают эти важнейшие производственные проблемы.

Производители медицинского оборудования сталкиваются с такими проблемами, как строгое соблюдение нормативных требований, необходимость микронной точности в сложных геометрических формах и минимизация отходов материалов. Кроме того, им приходится поддерживать стерильную среду и обеспечивать воспроизводимость производственных партий, что требует высокоточных и надежных решений для резки металлических труб.

Индустрия медицинского оборудования уникальна своим неуклонным стремлением к совершенству. От хирургических инструментов до имплантируемых устройств - каждый компонент должен работать безупречно, часто внутри человеческого тела. Это неотъемлемое требование приводит к возникновению огромного количества производственных проблем, которые обычные процессы просто не в состоянии преодолеть. Производители должны не только добиваться предельной точности, но и управлять дорогостоящими материалами, такими как титан и специализированные нержавеющие стали1Поэтому сокращение отходов имеет первостепенное значение. Стремление к инновациям означает, что конструкции становятся все более сложными, раздвигая границы физически возможного для последовательного и масштабного производства. Понимание этих основных проблем - первый шаг к осознанию незаменимой роли передовых технологий прецизионной резки, которые, как я лично видел, за время моей карьеры произвели революцию на бесчисленных производственных линиях, превратив казавшиеся невозможными спецификации в осязаемую реальность.

I. Строгое соблюдение нормативных требований и обеспечение качества

Индустрия медицинского оборудования, пожалуй, является одной из наиболее жестко регулируемых отраслей в мире. Такие органы, как FDA в США и EMA в Европе, устанавливают строгие правила. Эти нормы, такие как ISO 13485 (Системы менеджмента качества для медицинских изделий) и 21 CFR Part 820 (Положение о системе качества), требуют безупречного качества, отслеживаемости и документации для каждого компонента. Производители выпускают не просто детали; они производят компоненты, которые непосредственно влияют на здоровье и безопасность человека. Любое отклонение от спецификаций, даже на микронном уровне, может иметь катастрофические последствия, привести к отзыву продукции, юридическим обязательствам и непоправимому ущербу для репутации компании. Такая нетерпимость означает, что каждый этап производственного процесса, особенно такой основополагающий, как раскрой материала, должен тщательно контролироваться и проверяться для обеспечения абсолютной согласованности и соблюдения спецификаций проекта.

Достижение такого уровня соответствия при использовании традиционных методов резки, таких как ручная распиловка или абразивная резка, часто бывает проблематичным. Эти методы часто приводят к появлению несоответствий, заусенцев, зон термического влияния (HAZ) и микротрещин, что неприемлемо для материалов медицинского класса. Необходимость последующих этапов обработки, таких как удаление заусенцев, очистка и отжиг, увеличивает время, стоимость и создает дополнительные точки потенциального загрязнения или повреждения. Например, стент с неровным краем среза может привести к раздражению тканей или отказу при имплантации. Проблема заключается еще и в том, чтобы поддерживать постоянство качества от партии к партии; машина должна выполнять один и тот же точный срез миллионы раз на протяжении всего срока службы, в проверенных условиях, чтобы каждое устройство соответствовало одному и тому же высокому стандарту. Стремление к бескомпромиссному качеству - это постоянная борьба, заставляющая производителей искать решения, которые с самого начала минимизируют вариации и максимизируют точность.

С точки зрения MZBNL, мы глубоко понимаем это. Наши станки для лазерной резки труб разработаны с учетом этих нормативных требований. Точность и повторяемость наших систем значительно снижают необходимость в обширной постобработке, сводя к минимуму возможное загрязнение и экономя значительные усилия по валидации. Например, наши Инновационный безотходный хвостовой материал не только повышает эффективность, но и обеспечивает сохранение качества материала по всей длине трубки, снижая риск использования некачественных участков. Это напрямую способствует повышению коэффициента выхода первого продукта и облегчает соблюдение строгих систем управления качеством, требуемых в медицинском секторе.

II. Сложные геометрии и требования к миниатюризации

Современные медицинские устройства характеризуются все более сложной конструкцией и крайней миниатюризацией, особенно в таких областях, как минимально инвазивная хирургия, нейрососудистые вмешательства и имплантируемые датчики. Вспомните сложную решетчатую структуру сердечно-сосудистого стента, сверхтонкий кончик биопсийной иглы или многопросветный дизайн катетера. Эти компоненты часто имеют внутреннюю и внешнюю геометрию, требующую субмиллиметровой точности, а толщина стенок иногда не превышает 100 микрон. Традиционная механическая обработка с трудом справляется с такими тонкими и сложными разрезами, не деформируя материал, не создавая чрезмерного нагрева и не производя неприемлемой ширины пропила. Проблема усугубляется необходимостью вырезать такие формы из экзотических и зачастую дорогих материалов, таких как нитинол (никель-титановый сплав с памятью формы), нержавеющая сталь медицинского класса (например, 316L) и различные титановые сплавы, которые обладают уникальными свойствами, усложняющими процесс обработки.

Переход к миниатюризации обусловлен клиническими преимуществами: уменьшение разрезов, сокращение времени восстановления пациентов и повышение точности хирургических операций. Однако это создает огромную нагрузку на производственные мощности. Для достижения таких сложных геометрических форм требуются режущие инструменты, которые могут работать с хирургической точностью, не оставляя заусенцев или повторных слоев, которые могут повлиять на работу устройства или безопасность пациента. Процесс резки должен быть бесконтактным и недеформируемым, чтобы сохранить целостность и механические свойства материала. Кроме того, дизайн часто быстро меняется, что требует гибких производственных систем, способных быстро адаптироваться к новым прототипам и производственным партиям без длительного переналаживания или простоя в программировании. Такая гибкость крайне важна для ускорения выхода на рынок в конкурентной отрасли, где инновации играют ключевую роль.

Именно в этом случае MZBNL Инновационная система No-CAD дает значительное преимущество. Для прототипов медицинских устройств или мелкосерийного производства возможность обработки стандартных типов трубок и отверстий путем простого ввода параметров, без необходимости создания сложных 3D-чертежей, значительно ускоряет цикл проектирования и производства. Я слышал истории от инженеров, похожих на Ахмеда Аль-Фарси, которые поначалу боролись со сложностью САПР и тратили дни на перевод сложных проектов медицинских устройств в машиночитаемый формат. Наша система сокращает это время до нескольких часов, позволяя быстро итерировать и проверять новые концепции устройств. Такая оперативность в сочетании с точностью лазерной резки делает сложные и миниатюрные компоненты экономически выгодными и неизменно точными.

III. Оптимизация материальных отходов и затрат

Материалы медицинского класса печально известны своей дороговизной. Экзотические сплавы, такие как нитинол, различные платиново-иридиевые сплавы и высокочистые нержавеющие стали, выбираются за их биосовместимость, прочность и особые механические свойства. Следовательно, даже небольшое количество отходов материала из-за неточных срезов, бракованных деталей или чрезмерных хвостовых частей может привести к значительным финансовым потерям. Традиционные методы резки, особенно те, которые предполагают механический контакт, часто приводят к увеличению пропила (ширины разреза) или требуют больше материала для крепления и фиксации, что способствует большему расходу материала. Кроме того, необходимость обширной последующей обработки (например, шлифовки, полировки, химического травления) для удаления заусенцев или достижения окончательных размеров также приводит к потере материала и дополнительным затратам на обработку.

Экономическое воздействие отходов очень велико. В сценарии крупносерийного производства даже улучшение использования материалов на 1% может привести к экономии сотен тысяч или даже миллионов долларов в год. Помимо стоимости сырья, существуют расходы, связанные с утилизацией бракованных деталей, затратами энергии на повторную обработку и временем, потерянным на исправление ошибок. Производители постоянно ищут способы оптимизировать каждый грамм материала не только с точки зрения затрат, но и с точки зрения экологичности и эффективности использования ресурсов. Стремление к внедрению принципов "бережливого" производства в медицинском секторе делает акцент на технологиях резки, которые позволяют минимизировать пропил, максимизировать выход каждой трубки и производить готовые детали напрямую без значительных отходов.

Именно здесь MZBNL Инновационный безотходный хвостовой материал по-настоящему сияет. В отличие от традиционных систем, оставляющих непригодный для использования хвостовой материал, наша переработанная логика резки исключает эти отходы, если оставшийся участок меньше длины изделия. Это, казалось бы, небольшое нововведение со временем может привести к существенной экономии материала, особенно при работе с дорогостоящими медицинскими сплавами. Я вспоминаю одного клиента, похожего на Ахмеда, который поначалу скептически отнесся к заявлению о "безотходности". После внедрения нашей машины они сообщили о снижении расхода сырья на 7-10% для своей линии хирургических инструментов, что напрямую повлияло на их итоговый результат.

| Зона вызова | Влияние на производство медицинских изделий | MZBNL Решение/выгода |

|---|---|---|

| Строгое соблюдение нормативных требований | Высокий процент отказов, юридические обязательства, дорогостоящие отзывы, бремя валидации. | Точность и повторяемость позволяют сократить объем постобработки; Безотходный материал хвостовой части обеспечивает стабильное качество материалов, что способствует соблюдению стандарта ISO 13485. |

| Сложные геометрии и миниатюризация | Сложность выполнения сложных разрезов, деформация материала, медленное создание прототипов. | Инновационная система No-CAD Ускоряет цикл от проектирования до производства сложных деталей; бесконтактный лазер обеспечивает целостность материала и точность контуров. |

| Оптимизация материальных отходов и затрат | Значительные финансовые потери из-за дорогостоящих сплавов медицинского назначения. | Инновационный безотходный хвостовой материал максимальное использование материала; прецизионная резка минимизирует пропил и брак, что приводит к существенной экономии средств и бережливому производству. |

Медицинские приборы требуют микронной точностиПравда

Такие компоненты, как стенты и хирургические инструменты, часто имеют допуски менее 100 микрон для обеспечения надлежащего функционирования и безопасности пациента.

Традиционная резка соответствует медицинским стандартамЛожь

Ручные методы часто приводят к образованию микротрещин и зон термического воздействия, что нарушает правила эксплуатации медицинских изделий, требующие первозданной целостности материала.

Почему для резки металлических труб при производстве медицинского оборудования важна точность?

Промышленность медицинского оборудования требует абсолютной точности каждого компонента. Даже незначительные отклонения могут привести к поломке устройства, нанесению вреда пациентам и несоблюдению нормативных требований, что ставит под угрозу как эффективность продукции, так и репутацию бренда. Поэтому точность резки - это не просто преимущество, а непреложное требование для обеспечения безопасности и эффективности.

Точность очень важна для резки медицинских трубок, поскольку она напрямую влияет на безопасность пациентов, эффективность устройств и строгое соблюдение нормативных требований. Она обеспечивает целостность материала, предотвращает загрязнение и гарантирует безупречное функционирование компонентов в человеческом теле, обеспечивая стабильную и надежную работу критически важных для жизни приложений.

Исходя из серьезных задач, стоящих перед производителями медицинского оборудования, становится ясно, что точность - это не просто желаемая характеристика, а основа, на которой строится доверие, безопасность и функциональность. Компоненты, которые мы обсуждаем, от тонких стенты2 и надежные хирургические инструменты, работают в невероятно чувствительной среде человеческого тела. Как я понял за десятилетия работы в этой области, любое, пусть даже незначительное, несовершенство может иметь серьезные последствия. Речь идет не просто об эстетике, а о предотвращении раздражения тканей, обеспечении правильного механического функционирования при нагрузках и сохранении целостности биосовместимых материалов. Эта абсолютная зависимость от безупречного исполнения объясняет, почему точность при резке медицинского оборудования имеет гораздо большее значение, чем в любой другой отрасли.

I. Безопасность пациентов и эффективность устройств

Главная причина, по которой точность имеет первостепенное значение при производстве медицинского оборудования, - это ее прямая связь с безопасностью пациентов и эффективностью устройства. Каждый компонент медицинского устройства, каким бы маленьким он ни был, играет важнейшую роль в его общем функционировании и взаимодействии с биологическими системами. Например, стент с неровным краем или имплантат с дефектами поверхности может привести к повреждению тканей, воспалению или даже тромбозу, что вызовет серьезные осложнения у пациента. Аналогичным образом, неточно откалиброванный хирургический инструмент может привести к неточным процедурам или повышенной инвазивности. Эффективность устройства - его способность надежно выполнять свои функции в течение долгого времени - напрямую зависит от точности размеров и качества обработки поверхности отдельных деталей. Без микронной точности сложные механизмы современных медицинских приборов просто не смогут работать так, как задумано, что может поставить под угрозу точность диагностики или терапевтические результаты.

Кроме того, медицинские устройства часто взаимодействуют с очень чувствительной биологической средой, что требует от материалов идеальной чистоты и отсутствия загрязнений или остатков. Традиционные методы резки, при которых могут образовываться заусенцы, микротрещины или попадать смазочные материалы, требуют длительных и дорогостоящих этапов последующей обработки, таких как очистка, удаление заусенцев и полировка. Каждый из этих этапов создает дополнительный риск загрязнения или повреждения хрупких компонентов. Прецизионная лазерная резка, напротив, предлагает бесконтактный метод, позволяющий получать чистые кромки при минимальном тепловыделении, что значительно снижает необходимость во вторичных операциях и сводит к минимуму возможность попадания инородных частиц. Такой чистый процесс крайне важен для обеспечения биосовместимости и предотвращения негативных реакций после имплантации или внутреннего использования устройства.

В MZBNL мы уделяем первостепенное внимание качеству продукции, которое напрямую влияет на безопасность пациентов. Наши `Высокоскоростная и высокоточная резка3 Благодаря своим возможностям мы гарантируем, что компоненты, например, в сердечно-сосудистых или неврологических устройствах, будут изготовлены с точными техническими характеристиками, что сводит к минимуму риск возникновения неисправностей. Наши системы производят срезы с минимальными заусенцами и зонами термического воздействия, что крайне важно для сохранения целостности чувствительных сплавов медицинского класса. Такое стремление к точности помогает нашим клиентам достичь непоколебимой надежности, которая не подлежит обсуждению в медицинской сфере.

II. Соблюдение нормативных требований и валидация

Строгий нормативный ландшафт, регулирующий медицинские изделия, включая стандарты, установленные FDA, CE и различными организациями ISO (например, ISO 13485 для систем управления качеством), уделяет огромное внимание последовательности, воспроизводимости и документированному качеству. Точность резки металлических труб напрямую способствует соблюдению этих стандартов. Регулирующие органы требуют, чтобы производители демонстрировали контроль над своими процессами и последовательность выпускаемой продукции. Это означает, что каждая произведенная деталь должна соответствовать чрезвычайно жестким допускам, а сам производственный процесс должен быть проверен на соответствие требованиям. Отклонения, даже незначительные, могут привести к отчетам о несоответствии, масштабным расследованиям, отзыву продукции и значительным штрафам.

Процессы валидации, такие как квалификация установки (IQ), эксплуатационная квалификация (OQ) и квалификация производительности (PQ), являются неотъемлемой частью производства медицинских изделий. Эти процессы требуют проверяемых данных, подтверждающих, что оборудование правильно установлено, работает по назначению и стабильно производит продукцию, соответствующую спецификациям. Прецизионный отрезной станок, способный выполнять повторяющиеся разрезы с минимальными отклонениями, значительно упрощает эти процедуры проверки. Его стабильная производительность упрощает сбор данных о процессе и обеспечивает четкое подтверждение контроля, что снижает сложность и время, затрачиваемые на получение и поддержание нормативных разрешений. Такая последовательность также способствует отслеживанию, позволяя производителям точно определить, как и когда был изготовлен каждый компонент, что является критически важным требованием для контроля партий и управления отзывами.

Наши машины MZBNL созданы для того, чтобы соответствовать этим строгим нормативным требованиям. В качестве примера можно привестиИнтеллектуальные и цифровые системы4 Встроенные в наши машины системы обеспечивают точный контроль и возможность регистрации данных, что неоценимо для всесторонней проверки и аудита. Для таких клиентов, как Ахмед Аль-Фарси, который расширяет свой бизнес и рассматривает возможность распространения технологий, демонстрация истории неизменного качества и соответствия нормативным требованиям имеет первостепенное значение для принятия рынком и долгосрочного успеха. Наши машины обеспечивают надежную, основанную на данных производительность, необходимую для получения и поддержания этих важнейших сертификатов, снижая нагрузку на команды контроля качества и обеспечивая более плавный выход на рынок.

III. Целостность и эффективность материала

Помимо обеспечения безопасности пациентов и соблюдения нормативных требований, точность резки металлических труб жизненно важна для сохранения целостности и максимального улучшения характеристик материалов медицинского назначения. Многие сплавы, используемые в медицинских устройствах, такие как нитинол, титановые сплавы и специализированные нержавеющие стали, выбираются за их уникальные механические, термические и биосовместимые свойства. Неправильная техника резки может существенно изменить эти свойства, нарушив при этом эксплуатационные характеристики материала. Например, избыточное тепло, выделяемое при резке, может привести к образованию зоны термического влияния (HAZ) или слоя переплавки, что может изменить микроструктуру материала, снизить его усталостную прочность или изменить его коррозионную стойкость. Для таких устройств, как нитиноловые стенты, сохранение сверхэластичности и памяти формы является критически важным, а эти свойства могут быть сильно нарушены в результате термического повреждения.

Традиционные механические методы резки или даже менее совершенные лазерные системы не могут обеспечить постоянное сохранение этих свойств. Они часто оставляют заусенцы, которые требуют вторичного удаления заусенцев, а этот процесс может привести к дополнительным нагрузкам, удалению материала или даже микротрещинам в хрупких деталях. Альтернативный вариант - химическое травление - добавляет еще один сложный и часто экологически опасный этап. Цель состоит в том, чтобы получить сетчатый срез непосредственно на станке, сведя к минимуму любую дальнейшую обработку, которая может повредить материал. Прецизионная лазерная резка, особенно с оптимизированными параметрами, обеспечивает целенаправленный, бесконтактный термический процесс, который позволяет получить невероятно тонкие срезы с минимальным рассеиванием тепла, сохраняя исходные свойства материала вплоть до края среза.

Станки лазерной резки компании МЗБНЛ разработаны для обеспечения чистых, точных разрезов с минимальным воздействием на целостность материала. Наши передовые системы управления позволяют точно регулировать мощность и скорость, оптимизируя процесс резки для различных медицинских сплавов, чтобы предотвратить неблагоприятные тепловые эффекты и механические искажения. Это означает, что, например, сложная решетка стента сохранит свою гибкость и усталостную прочность, а хирургическая игла - свою точную остроту и долговечность. Эта забота о сохранении характеристик материала является краеугольным камнем нашей технологии, гарантирующим, что каждое изделие, изготовленное на нашем оборудовании, отвечает самым высоким стандартам структурной целостности и функциональной надежности.

Точность предотвращает повреждение тканейПравда

Неровные края медицинских компонентов могут стать причиной воспаления или тромбоза у пациентов.

Смазочные материалы улучшают качество медицинских разрезовЛожь

Традиционные смазочные материалы для резки требуют дорогостоящей последующей обработки и рискуют загрязнить биосовместимые материалы.

Как прецизионные станки для резки металлических труб решают общие производственные задачи?

Обычные производственные трудности при изготовлении медицинских изделий часто приводят к неэффективности и снижению качества. Ручные процессы, как известно, медленны, непоследовательны и подвержены ошибкам, что снижает общую эффективность и контроль качества. Прецизионные станки для резки металлических труб напрямую решают эти проблемы, значительно повышая производительность, согласованность и качество продукции.

Прецизионные станки для резки металлических труб решают производственные задачи, автоматизируя сложные разрезы, значительно снижая человеческий фактор и минимизируя отходы материала. Они обеспечивают высокую повторяемость, повышают производительность и упрощают контроль качества, что напрямую ведет к повышению эффективности, снижению эксплуатационных расходов и постоянному соблюдению строгих стандартов медицинского оборудования.

Мы рассмотрели, почему точность имеет решающее значение, и с какими специфическими проблемами сталкиваются производители медицинского оборудования. Теперь давайте перейдем к конкретным решениям. Как эти сложные машины на самом деле преобразуют производственный цех? За 25 лет работы я лично видел, как производители, подобно Ахмеду Аль-Фарси с его стремлением к автоматизации, переходили от ручных, подверженных ошибкам рабочих процессов к высокоэффективным, высокопроизводительным автоматизированным линиям. Речь идет не просто о добавлении новой единицы оборудования, а об интеграции интеллектуальной системы, которая в корне меняет производственную парадигму, повышая производительность и тщательный контроль качества, требуемый в медицинском секторе.

I. Автоматизация и снижение человеческих ошибок

Одним из наиболее значимых способов решения производственных задач с помощью прецизионных станков для резки металлических труб является передовая технология. автоматизация5что значительно снижает зависимость от ручных процессов и, следовательно, минимизирует человеческий фактор. При традиционном производстве медицинских изделий ручная загрузка, позиционирование и резка тонких трубок требуют больших усилий, времени и очень подвержены отклонениям, вызванным усталостью, неопытностью или несогласованностью действий оператора. В сложных конструкциях или при крупносерийном производстве даже незначительные смещения или неточные измерения могут привести к браку, что повлечет за собой значительные материальные и трудовые затраты. Эта проблема усугубляется в отрасли, где отказ компонентов может иметь последствия для жизни и смерти. Кроме того, высокая текучесть кадров - больная точка многих производителей, включая нашего типичного клиента Ахмеда Аль-Фарси, - означает постоянную нагрузку по переобучению персонала и вечный риск снижения качества.

Автоматизированные станки для прецизионной резки снижают эти риски, исключая человеческий фактор из уравнения при выполнении повторяющихся задач с высокими допусками. Современные системы используют сложные датчики, роботизированную загрузку и программное управление для обеспечения последовательного позиционирования и траектории резки для каждой отдельной трубы. Такая автоматизация не только повышает точность и повторяемость, но и позволяет высвободить квалифицированный технический персонал, чтобы сосредоточиться на более важных задачах, таких как обеспечение качества, обслуживание станка и оптимизация процесса. Система точно следует цифровым проектам, исключая субъективные суждения или ручные ошибки, которые часто встречаются при традиционных методах резки. Последовательность, присущая автоматизированным процессам, неоценима для соответствия строгим требованиям системы управления качеством при производстве медицинского оборудования, где каждая деталь должна быть идентична предыдущей.

В компании MZBNL мы Автоматическая перфорация и резка интегрированная машина является примером такой автоматизации. Наш сайт Инновации на переднем краенапример, автоматически затягивает трубки в машину, повышая эффективность подачи примерно на 40% и снижая трудоемкость работы оператора примерно на 40%. Это не только повышает производительность, но и значительно снижает вероятность ошибок при ручном управлении. В сочетании с нашими Операционная система No-CADБлагодаря упрощению программирования за счет ввода параметров, а не сложных 3D-чертежей, значительно снижается нагрузка на обучение - с 15 дней на заводе до 1 дня обучения на месте. Такая простота использования напрямую решает проблемы смены операторов, обеспечивая сохранение точности и эффективности независимо от того, кто управляет станком.

II. Повышенная пропускная способность и эффективность

Прецизионные станки для резки металлических труб - это не просто точность; это мощный инструмент, позволяющий значительно повысить общую производительность и эффективность производства. Традиционные методы резки, будь то механические или менее совершенные лазерные системы, часто страдают от низкой скорости, длительного времени настройки и необходимости многочисленных этапов последующей обработки (например, снятия заусенцев, очистки или шлифовки), которые загромождают производственную линию. Для компонентов медицинского оборудования, которые часто имеют сложные разрезы и точную отделку, эти вторичные операции могут добавить непропорционально много времени и затрат к производственному процессу, замедляя выход на рынок критически важных устройств. На конкурентном рынке, где инновационные циклы происходят быстро, способность быстро масштабировать производство без ущерба для качества является основным конкурентным преимуществом.

Передовые станки для лазерной резки, такие как разработанные компанией MZBNL, используют сфокусированную энергию для резки сложных геометрических форм на высоких скоростях, часто за один проход. Их бесконтактный характер исключает износ инструмента и снижает необходимость частой смены инструмента, что способствует непрерывной работе. Кроме того, Интеграция нескольких процессовТакие возможности, как комбинированная лазерная резка и штамповка, позволяют выполнять несколько операций на одном станке, избавляя от необходимости переносить детали между различными рабочими местами. Такая интеграция упрощает рабочий процесс, сокращает количество операций и минимизирует запасы незавершенного производства - все это способствует более бережливому и эффективному производственному процессу. Возможность быстрого переключения между различными конструкциями изделий с минимальными затратами на переналадку - особенно благодаря интуитивно понятным программным интерфейсам - также способствует гибкости производства и ускорению создания прототипов.

Обязательства МЗБНЛ по Высокоскоростная и высокоточная резка напрямую связано с увеличением производительности. Наши системы предназначены для быстрой обработки различных типов труб и толщин стенок, что обеспечивает быстрое и точное изготовление большого количества медицинских компонентов. Например, клиент, специализирующийся на производстве ортопедических имплантатов, смог сократить время производства конкретного компонента на 30% после внедрения нашего интегрированного решения для резки и штамповки, в первую очередь благодаря отсутствию межпроцессной обработки и скорости лазера. Такое повышение эффективности не только ускорило выполнение заказов, но и позволило высвободить ценную площадь и трудовые ресурсы для выполнения других важных задач, что представляет собой значительный возврат инвестиций.

III. Превосходный контроль качества и прослеживаемость

Прецизионные станки для резки металлических труб значительно улучшают контроль качества и прослеживаемость, что отвечает двум основным требованиям производства медицинских изделий. При использовании традиционных методов часто требуется ручной контроль каждой детали, что требует больших трудозатрат, чревато человеческими ошибками и может привести к пропуску микроскопических дефектов. Отклонения при резке могут привести к тому, что детали не будут соответствовать строгим допускам по размерам, что повлияет на сборку, посадку и общую производительность устройства. Кроме того, отсутствие данных в реальном времени или автоматизированного отслеживания затрудняет отслеживание проблем до их возникновения, что усложняет анализ первопричины при проведении аудита или в случае отзыва. Возможность обеспечить стабильное качество от первой до последней детали и иметь поддающуюся проверке запись об этом качестве имеет первостепенное значение.

Современные станки для прецизионной резки оснащены передовыми датчиками, системами обратной связи и цифровыми системами управления, которые обеспечивают стабильную производительность. Эти Интеллектуальные и цифровые системы могут отслеживать параметры резки в режиме реального времени, автоматически корректировать незначительные отклонения материала и даже выявлять потенциальные проблемы до того, как они приведут к дефектам. Последовательные и точные срезы, производимые этими станками, сводят к минимуму необходимость в обширном контроле после обработки, так как сам процесс в значительной степени контролируется и проверяется. Более того, многие высококлассные станки оснащены функцией регистрации данных, которая фиксирует каждую деталь процесса резки - от настроек станка и номеров партий материала до условий окружающей среды. Эти данные имеют решающее значение для соблюдения нормативных требований, обеспечивая надежный аудиторский контроль и полную прослеживаемость каждого изготовленного компонента.

Машины MZBNL разработаны с учетом всеобъемлющего контроля качества и возможности отслеживания. Наш сайт Интеллектуальные и цифровые системы предоставляют операторам обратную связь в режиме реального времени и подробные отчеты о производстве, гарантируя, что каждый отрез соответствует точным спецификациям. Эти данные позволяют производителям легко проверять соответствие нормативным требованиям и представляют собой бесценный аудиторский след, упрощающий процесс получения и поддержания сертификатов, таких как ISO 13485. Для такого владельца бизнеса, как Ахмед Аль-Фарси, который ценит поставщиков с проверенными технологиями и глобальными рекомендациями, возможность предложить такой высокий уровень контроля качества и отслеживания означает не только более качественную продукцию, но и более сильное конкурентное преимущество на высокорегулируемом мировом рынке. Эта приверженность качеству, основанному на данных, является свидетельством нашего комплексного подхода к исследованиям и разработкам и производству.

Автоматизация снижает количество человеческих ошибокПравда

Станки для прецизионной резки используют датчики и роботизированные системы управления для устранения несоответствий в работе, которые приводят к дефектам.

Ручная резка обеспечивает лучшее качествоЛожь

Ручные процессы подвержены ошибкам, связанным с усталостью, и не могут сравниться с автоматизированным производством компонентов медицинского класса.

Какие преимущества дают станки для резки металлических труб в соответствии со стандартами медицинской промышленности?

Соблюдение строгих стандартов медицинской промышленности - это постоянная борьба с трудностями для производителей. Несоблюдение этих требований может привести к серьезным штрафам, отзыву продукции и невосполнимой потере доверия рынка, что ставит под угрозу всю вашу деятельность. Прецизионные станки для резки металлических труб обеспечивают важнейшие преимущества, необходимые для постоянного превышения этих высоких стандартов.

Прецизионные станки для резки металлических труб обеспечивают преимущества, необходимые для соблюдения стандартов медицинской промышленности, включая непревзойденную повторяемость для обеспечения стабильного качества, минимизацию отходов материала для обеспечения экономической эффективности и точные разрезы, которые снижают необходимость в последующей обработке. Они обеспечивают соответствие строгим нормативным требованиям, гарантируя безопасность и эффективность продукции для пациентов по всему миру.

Мы рассмотрели значительные производственные проблемы и способы их решения с помощью прецизионных станков, но прямые преимущества, которые дают эти технологии для соблюдения и превышения стандартов медицинской промышленности, не менее убедительны. По моему опыту, помощь клиентам в получении важнейших сертификатов быстрее и с меньшими трудностями - это явный показатель превосходного производственного процесса. Речь идет не только о резке деталей, но и о создании репутации надежности и доверия в отрасли, где на карту поставлены жизни людей. Эти станки упрощают сложный путь к соответствию требованиям, повышают надежность продукции и в конечном итоге укрепляют конкурентоспособность компании на мировом рынке.

I. Неизменная повторяемость и последовательность

Одним из важнейших преимуществ прецизионных станков для резки металлических труб, отвечающих стандартам медицинской промышленности, является их непревзойденная способность обеспечивать Неизменная повторяемость и согласованность6. Регулирующие органы, особенно в отношении критически важных медицинских устройств, требуют, чтобы каждый произведенный компонент был идентичен предыдущему, соблюдая чрезвычайно жесткие допуски по размерам и целостности материала. Любое, даже микроскопическое, отклонение может поставить под угрозу работоспособность устройства и безопасность пациента, что приведет к дорогостоящему отзыву или штрафам со стороны регулирующих органов. Достичь такого уровня единообразия при использовании ручных или менее точных методов практически невозможно, поскольку человеческий фактор и износ оборудования неизбежно вносят свои коррективы.

Однако станки для прецизионной лазерной резки оснащены сложными системами управления, которые обеспечивают идентичные срезы тысяч или даже миллионов деталей. После утверждения программы станок будет выполнять ее с одинаковой точностью каждый раз, независимо от смен, смены оператора или внешних факторов, которые могут повлиять на менее автоматизированные системы. Такая последовательность является основой для внедрения надежного статистического контроля процессов (SPC) и сбора поддающихся проверке данных, требуемых системами управления качеством, такими как ISO 13485. Способность постоянно производить компоненты, соответствующие спецификации, упрощает процессы обеспечения качества, снижает необходимость в обширном послепроизводственном контроле и значительно уменьшает вероятность попадания на рынок бракованной продукции.

В компании MZBNL наши надежные конструкции станков и передовые цифровые системы управления специально разработаны для обеспечения такого уровня повторяемости. Наши клиенты полагаются на то, что наши станки будут выпускать идентичные детали, партия за партией, что имеет решающее значение для их сертификации и репутации на рынке. Такое предсказуемое и высококачественное качество продукции напрямую ведет к повышению коэффициента выхода продукции при первом проходе и значительному снижению количества брака, что является значительным преимуществом в отрасли, где стоимость материалов очень высока. Для компаний, выходящих на новые рынки, например для Ахмеда Аль-Фарси, цель которого - стать региональным дистрибьютором, демонстрация такого стабильного качества является мощным отличительным фактором.

II. Оптимизация использования материалов и экономическая эффективность

Высокая стоимость медицинского сырья, такого как особые сорта нержавеющей стали, титана, нитинола и различных сплавов драгоценных металлов, делает отходы материала значительным финансовым бременем для производителей. Традиционные методы резки с их более широким пропилом, потребностью в дополнительном крепежном материале и склонностью к образованию заусенцев или дефектов, требующих отбраковки, неизбежно приводят к значительным потерям материала. Эти отходы не только увеличивают производственные затраты, но и влияют на усилия по обеспечению экологической устойчивости и маржу прибыли. Соответствие отраслевым стандартам - это не только качество, но и эффективное и экономичное производство высококачественных устройств, обеспечивающее долгосрочную жизнеспособность бизнеса.

Прецизионные станки для резки металлических труб напрямую решают эту задачу, поскольку оптимизация использования материалов7 в беспрецедентной степени. Лазерная резка, по своей природе, дает очень узкий пропил, а это значит, что во время резки испаряется меньше материала. Более того, инновации в конструкции станков, такие как MZBNL Инновационный безотходный хвостовой материалМаксимально возможная длина каждой трубки. Обычные системы часто оставляют на конце трубки непригодную для использования хвостовую часть, поскольку патрон не может достаточно надежно удерживать ее для окончательной резки. Перестроив логику резки таким образом, чтобы расчет производился от заднего патрона, наша система практически исключает этот остаточный хвостовой материал, гарантируя, что каждый миллиметр дорогостоящей трубы будет превращен в готовый продукт.

Такой уровень оптимизации материалов напрямую способствует экономичности, необходимой для конкурентоспособного соответствия стандартам медицинской промышленности. Отраслевые данные постоянно показывают, что даже небольшое процентное сокращение отходов материалов может привести к ежегодной экономии миллионов долларов для крупносерийных производителей. Для наших клиентов это означает значительное повышение рентабельности и укрепление позиций на рынке. Я видел, как компании, подобные бизнесу Ахмеда, которые ценят высокое соотношение цены и качества, получали немедленную отдачу от внедрения этой технологии, доказывая, что прецизионное оборудование - это не просто расходы, а стратегические инвестиции, которые приносят дивиденды как в качестве, так и в финансовых показателях".

III. Содействие соблюдению нормативных требований и сертификации

Строгая нормативная база индустрии медицинского оборудования требует тщательной документации, проверяемых процессов и стабильного качества продукции для первоначальной сертификации и постоянного соответствия требованиям. Прецизионные станки для резки металлических труб играют важнейшую роль в этом сложном процессе. В отличие от ручных операций, где параметры процесса могут быть субъективными, автоматизированные прецизионные станки работают в строго определенных параметрах, с возможностью мониторинга и регистрации данных в режиме реального времени. Эти поддающиеся проверке данные неоценимы при проведении аудита, предоставляя четкие доказательства того, что производственные процессы контролируются, воспроизводятся и соответствуют всем требуемым спецификациям. Меньшее количество несоответствий означает более спокойные аудиты и более быстрое получение разрешений на выпуск новых продуктов или расширение рынка.

Кроме того, чистые и точные срезы, достигаемые этими станками, снижают необходимость в обширных этапах последующей обработки, таких как удаление заусенцев, полировка или химическое травление. Каждая из этих дополнительных операций вносит дополнительные переменные, потенциальные источники загрязнения и этапы, которые должны быть подтверждены. Минимизируя эти этапы, прецизионная резка упрощает общий производственный процесс, снижая риск и значительно упрощая проверку. Более гладкий и контролируемый процесс неизбежно ведет к повышению вероятности получения и поддержания таких сертификатов, как одобрение FDA или маркировка CE, которые необходимы для выхода на рынок по всему миру.

В компании MZBNL мы разрабатываем наши Интеллектуальные и цифровые системы с учетом требований регулирующих органов. Последовательная производительность, подробные данные о процессе и снижение вероятности человеческой ошибки, присущие нашим машинам, напрямую поддерживают усилия наших клиентов по достижению и поддержанию самых высоких отраслевых стандартов. Для наших глобальных корпоративных клиентов и потенциальных дистрибьюторов, таких как Ахмед Аль-Фарси, возможность приобрести оборудование, которое по своей сути поддерживает быстрое соблюдение нормативных требований и надежную послепродажную поддержку, является ключевым отличительным фактором. Это означает не просто оборудование, а партнера в навигации по сложному ландшафту глобальных нормативных требований к медицинскому оборудованию, обеспечивающего соответствие их продукции самым высоким стандартам безопасности и качества во всем мире.

Прецизионная резка обеспечивает повторяемостьПравда

Прецизионные станки для резки металлических труб обеспечивают идентичные технические характеристики тысяч деталей, что крайне важно для соблюдения требований к медицинскому оборудованию.

Ручная резка соответствует медицинским стандартамЛожь

Методы, используемые человеком, не позволяют достичь микронного уровня согласованности, требуемого медицинскими регуляторами, что делает прецизионные машины необходимыми.

Каковы наилучшие методы внедрения прецизионных режущих станков в производство медицинских изделий?

Инвестиции в технологию прецизионной резки - важный стратегический шаг для производителей медицинского оборудования. Однако успешное внедрение является сложной задачей и требует тщательного планирования. Без надлежащей интеграции и оптимизации даже самые лучшие станки могут работать недостаточно эффективно, что приведет к неэффективности и потере рентабельности инвестиций. Применение передовых методов обеспечивает плавный переход и максимальную отдачу от инвестиций.

Внедрение прецизионных режущих станков в производство медицинских изделий требует таких передовых методов, как тщательная валидация, всестороннее обучение операторов и стратегический выбор материалов. Обеспечение беспрепятственной интеграции с существующими рабочими процессами, постоянная оптимизация процессов и надежная послепродажная поддержка также имеют решающее значение для повышения эффективности, обеспечения соответствия требованиям и достижения оптимального возврата инвестиций.

Мы подробно рассмотрели "почему" и "как" прецизионной резки металлических труб в производстве медицинского оборудования, но обладание лучшей технологией - это только половина успеха. Истинная мера успеха заключается в ее бесшовной интеграции и оптимизации работы в производственной среде. За годы работы с многочисленными клиентами я понял, что целостный подход к внедрению - тот, который выходит за рамки простого приобретения оборудования, - является абсолютно критическим. Он включает в себя тщательную проверку, обучение команды специалистов и постоянное совершенствование процессов. MZBNL не просто продает оборудование; мы сотрудничаем с нашими клиентами, чтобы обеспечить не только понимание, но и эффективное внедрение передового опыта, закладывая основу для постоянного совершенствования и максимизации отдачи от ваших инвестиций.

I. Комплексная валидация и квалификация

Одним из наиболее важных передовых методов внедрения прецизионных режущих станков в производство медицинских изделий является проведение всесторонней валидации и квалификации. В отличие от общего производства, каждая единица оборудования и каждый процесс в производстве медицинских изделий должны быть тщательно проверены, чтобы гарантировать, что они будут работать так, как задумано, и соответствовать строгим нормативным требованиям (например, FDA 21 CFR Part 820, ISO 13485). Обычно это включает три этапа: Квалификация установки (IQ), эксплуатационная квалификация (OQ) и квалификация производительности (PQ). IQ проверяет правильность установки и документации; OQ подтверждает, что оборудование работает в пределах заданных параметров; а PQ демонстрирует, что процесс стабильно производит продукцию, соответствующую всем заданным спецификациям в реальных условиях эксплуатации. Без тщательной проверки преимущества прецизионных станков не могут быть полностью реализованы или признаны на законных основаниях.

Установление точных параметры процесса и допуски8 во время OQ и PQ имеет первостепенное значение. Это включает в себя тестирование различных настроек (например, мощности лазера, скорости, давления газа, скорости подачи) для определения оптимального окна, обеспечивающего стабильный и высококачественный результат для каждого конкретного материала и размера трубы. Эти данные должны быть тщательно собраны, проанализированы и задокументированы для создания надежного плана управления процессом. Кроме того, при проверке автоматизированных систем с многочисленными переменными часто возникают проблемы. Производители должны убедиться, что их протоколы валидации достаточно надежны, чтобы учесть все возможные вариации процесса и факторы окружающей среды, которые могут повлиять на конечный продукт. Уровень детализации, необходимый для валидации медицинского оборудования, значительно выше, чем во многих других отраслях, что требует специальных ресурсов и опыта.

В компании MZBNL мы понимаем огромную важность валидации для наших клиентов, работающих с медицинским оборудованием. Мы предоставляем исчерпывающую документацию и поддержку, чтобы помочь с протоколами IQ, OQ и PQ. Наша команда инженеров активно работает с клиентами, чтобы установить начальные параметры процесса, которые соответствуют их конкретным требованиям к материалам и конструкции, что упрощает процесс квалификации. Такое сотрудничество помогает ускорить время выхода на полную производственную мощность, обеспечивая нашим клиентам быструю и уверенную интеграцию нашей продукции. высокоточная резка машины в свои проверенные рабочие процессы, минимизируя нагрузку на регулирующие органы и демонстрируя соответствие требованиям с первого дня работы.

II. Обучение операторов и повышение квалификации

Несмотря на высокую степень автоматизации прецизионных режущих станков, их успешное внедрение в производство медицинских изделий по-прежнему зависит от всестороннего обучения и повышения квалификации операторов. Распространено ошибочное мнение, что автоматизация устраняет необходимость в квалифицированном труде; на самом деле она переносит требуемые навыки с ручной работы на контроль за процессом, программирование, обслуживание и обеспечение качества. Операторы должны понимать не только, как управлять машиной, но и как интерпретировать ее диагностические данные, выполнять плановое техническое обслуживание, устранять мелкие неполадки и распознавать возможные отклонения. В медицинском секторе, где качество не подлежит обсуждению, хорошо обученный оператор может предотвратить дорогостоящие ошибки и обеспечить стабильное, соответствующее требованиям производство.

Решение проблемы высокой текучести кадров, которую разделяет наш типичный клиент Ахмед Аль-Фарси, означает сосредоточение внимания на удобстве использования и эффективных программах обучения. Исторически сложилось так, что освоение сложных систем автоматизированного проектирования и управления станком могло занимать недели или даже месяцы, что создавало значительную нагрузку на обучение и приводило к высоким затратам. Оптимизированный процесс обучения сокращает время простоя и гарантирует, что новые операторы смогут быстро стать продуктивными членами команды. Кроме того, постоянное обучение позволяет операторам быть в курсе возможностей станка, обновлений программного обеспечения и передовых методов оптимизации производственных параметров для различных медицинских компонентов. Расширение возможностей операторов благодаря знаниям снижает зависимость от внешней поддержки при выполнении рутинных задач и способствует созданию более самодостаточной производственной среды.

MZBNL's Инновационная система No-CAD является ярким примером того, как мы используем эту передовую практику. Позволяя обрабатывать стандартные типы труб и шаблоны отверстий простым вводом параметров, наша система резко снижает порог квалификации для работы на станке. Это означает, что операторам теперь требуется всего 1 день обучения на месте вместо 15 дней на заводе по производству оборудования, что является революционным изменением в плане эффективности и сокращения расходов на обучение, связанных с текучестью кадров. Мы обязуемся обеспечить широкое послепродажное обучение и постоянную поддержку, гарантируя, что команды наших клиентов будут полностью компетентны, уверены в себе и способны максимально повысить производительность своих машин MZBNL.

III. Стратегическая интеграция и непрерывная оптимизация

Эффективное внедрение прецизионных режущих станков в производство медицинских изделий требует стратегической интеграции в существующие производственные экосистемы и постоянной оптимизации. Простое внедрение нового станка на заводе редко дает оптимальные результаты. Производители должны продумать, как новое оборудование взаимодействует с общей системой управления производством (MES), системой планирования ресурсов предприятия (ERP) и программным обеспечением для управления качеством. Бесперебойный поток данных, начиная с проектных файлов и заканчивая производственными показателями и записями о качестве, необходим для обеспечения прослеживаемости, мониторинга в режиме реального времени и поддержки принятия решений на основе данных. Нарушения в потоке данных могут привести к образованию информационных "силосов", что снижает эффективность и усложняет соблюдение нормативных требований.

После первоначальной интеграции непрерывная оптимизация имеет решающее значение для максимизации окупаемости инвестиций и адаптации к изменяющимся конструкциям и материалам медицинских изделий. Это предполагает регулярное профилактическое обслуживание, проверку калибровки и обновление программного обеспечения для обеспечения максимальной производительности станка и соответствия отраслевым стандартам. Кроме того, анализ производственных данных позволяет производителям выявлять "узкие места", точно настраивать параметры резки для новых сплавов и постоянно повышать эффективность процесса. Такой итеративный подход, часто основанный на принципах бережливого производства, гарантирует, что прецизионный отрезной станок остается конкурентоспособным активом на протяжении всего жизненного цикла, обеспечивая неизменное качество и эффективность.

MZBNL's Интеллектуальные и цифровые системы разработаны для беспрепятственной интеграции и непрерывного совершенствования. Наши машины обеспечивают надежный вывод данных, которые можно легко включить в более широкую цифровую экосистему производителя, обеспечивая полную прослеживаемость и способствуя эффективному планированию производства. Наша глобальная сервисная сеть имеет решающее значение для поддержки этой непрерывной оптимизации; она обеспечивает своевременное наличие запасных частей, дистанционную диагностику и экспертную техническую поддержку для решения любых проблем. Для таких международных клиентов, как Ахмед Аль-Фарси, надежное присутствие местных агентов или дистрибьюторов и высокое качество послепродажного обслуживания являются ключевыми моментами выбора поставщиков, гарантирующими бесперебойное производство и уверенность в том, что их высокотехнологичные инвестиции будут продолжать работать оптимально долгие годы.

Валидация обязательна для медицинских изделийПравда

Производство медицинских изделий требует тщательной валидации (IQ/OQ/PQ) для соответствия стандартам FDA и ISO 13485.

Автоматизация устраняет необходимость в навыках оператораЛожь

Для прецизионной резки по-прежнему требуются квалифицированные операторы для контроля, обслуживания и обеспечения качества.

Заключение

Прецизионные станки для резки металлических труб незаменимы для производителей медицинского оборудования, стремящихся соответствовать строгим стандартам качества, безопасности и нормативным требованиям. Инновации МЗБНЛ, в том числе No-CAD, Front-Feeding и Zero-Waste Tail Material, напрямую решают проблемы отрасли, обеспечивая высокую точность, эффективность и оптимизацию материалов. Использование этих передовых решений - ключ к будущему успеху и созданию устройств, спасающих жизни.

-

Поймите преимущества этих материалов для соответствия стандартам и требованиям к характеристикам медицинских изделий ↩

-

Узнайте, как стенты поддерживают функции организма, а также о необходимости их точного изготовления ↩

-

Узнайте о преимуществах передовых технологий резки в здравоохранении ↩

-

Понять, как цифровые системы повышают точность и эффективность лазерной резки ↩

-

Узнайте о преимуществах автоматизации для снижения ошибок и повышения производительности. ↩

-

Узнайте о технологии, лежащей в основе последовательного вывода данных, что очень важно для обеспечения безопасности медицинского оборудования. ↩

-

Узнайте о стратегиях минимизации отходов и повышения эффективности использования сырья. ↩

-

Откройте для себя методы оптимизации переменных процесса для поддержания стандартов качества ↩

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.