Понятие о сокращении отходов хвостовой части в станках для лазерной резки труб

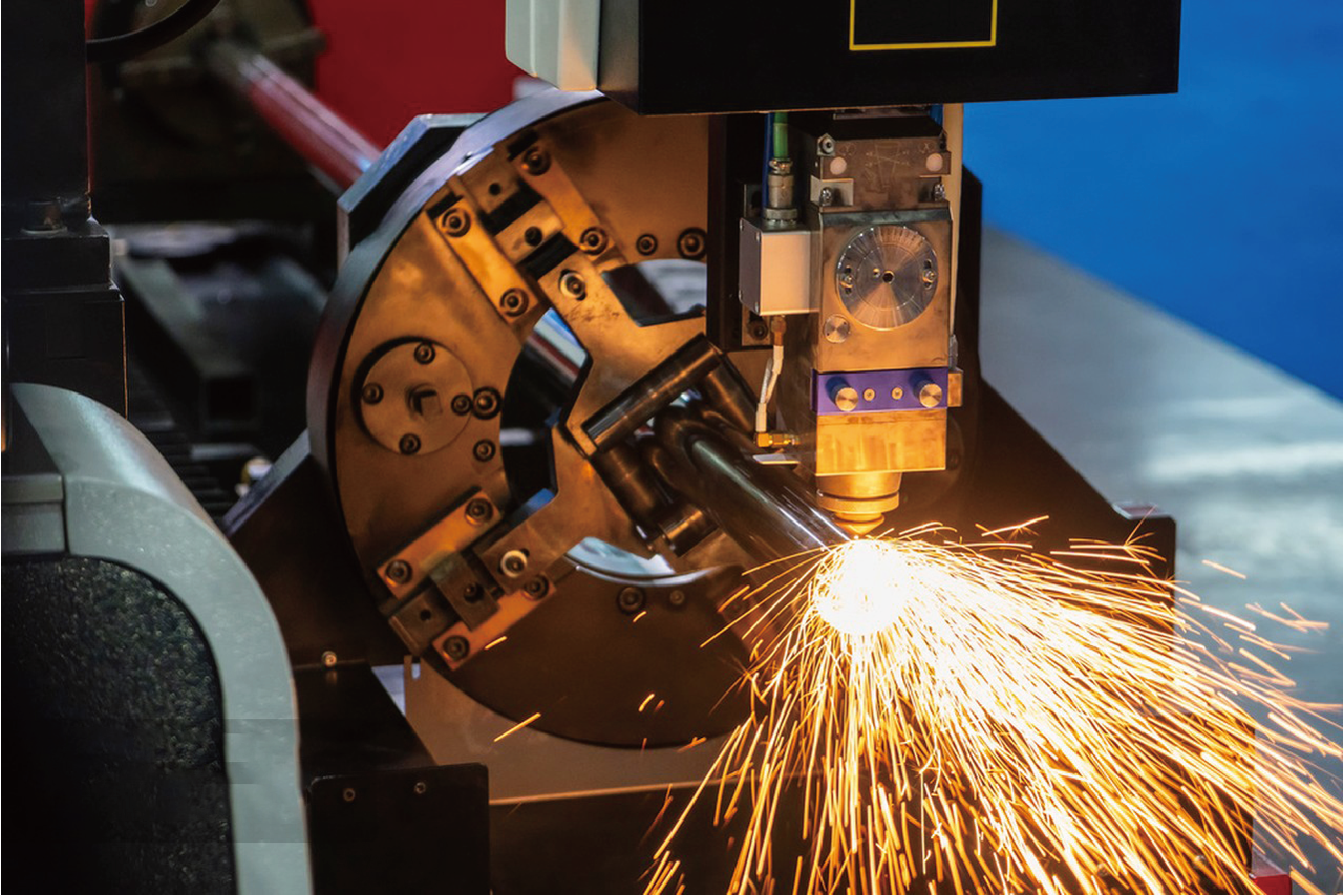

Вы боретесь с чрезмерными отходами материала и растущими производственными затратами в процессе лазерной резки труб? Скрытым виновником может быть неэффективная обработка хвостового материала. Эта распространенная проблема может существенно повлиять на итоговый результат, но я посвятил инновации компании MZBNL поиску более разумного пути решения.

Сокращение отходов при лазерной резке труб относится к стратегиям и технологиям, направленным на минимизацию непригодного материала, остающегося на конце трубы. Оптимизируя логику резки и конструкцию станка, производители могут значительно повысить эффективность использования материала, уменьшить количество брака и снизить эксплуатационные расходы, что в конечном итоге повышает общую эффективность.

влияние хвостовых отходов при лазерной резке труб1 в компании МЗБНЛ можно наблюдать воочию. От небольших мастерских до крупных предприятий - эта упущенная из виду неэффективность подрывает рентабельность. Давайте узнаем, как инновационные решения могут изменить ваше производство, превратив нерационально используемые материалы в сэкономленные ресурсы и увеличенный доход, что в конечном итоге обеспечит вам конкурентное преимущество.

В течение многих лет промышленность часто принимала хвостовые отходы как неизбежный побочный продукт лазерной резки труб. Однако, применяя критическое мышление, мы в MZBNL поставили под сомнение это предположение. Хотя традиционные методы часто ставят во главу угла скорость обработки, они часто упускают из виду совокупный финансовый ущерб от отбракованного материала в течение тысяч резов. Рассмотрим завод Ахмеда Аль-Фарси в ОАЭ, активно развивающийся в сфере производства архитектурных металлоконструкций и поставок деталей для автомобилей. Даже небольшой процент отходов материала на одну трубу быстро накапливается, напрямую влияя на рентабельность проекта. материальные затраты при изготовлении металлоконструкций2 могут составлять значительную часть, иногда до 60%, общих производственных затрат. Поэтому любое сокращение отходов напрямую ведет к существенной экономии и повышению рентабельности. Я и моя команда направили усилия МЗБНЛ в области исследований и разработок на то, чтобы бросить вызов этим традиционным подходам, разрабатывая передовые решения, которые меняют представление об эффективности и использовании материалов, помогая нашим клиентам, таким как Ahmed, достичь лучших финансовых результатов.

В чем заключается проблема хвостовых отходов в станках для лазерной резки труб?

Вы озадачены тем, как именно образуются "хвостовые отходы" при лазерной резке труб? Эта, казалось бы, незначительная проблема часто приводит к значительным материальным потерям и операционной головной боли. Понимание его определения - это первый шаг к существенной экономии средств и повышению устойчивости вашей производственной линии.

Хвостовые отходы при лазерной резке труб означают непригодный для использования короткий отрезок материала, оставшийся на конце трубы после того, как все желаемые детали были вырезаны. Этот остаток часто слишком мал или неправильно зажат для дальнейшей обработки, что приводит к его утилизации и увеличивает материальные затраты и воздействие на окружающую среду.

Знать, что такое хвостовые отходы, очень важно, но еще важнее осознать их повсеместное влияние. Ахмед Аль-Фарси, успешный владелец бизнеса в ОАЭ с более чем 100 сотрудниками, однажды поделился со мной своим разочарованием по поводу, казалось бы, небольших кусков трубного материала, скапливающихся в его мусорных контейнерах. Он понял, что, хотя каждый отдельный кусок незначителен, их совокупный объем в течение месяца представляет собой значительную финансовую потерю. Речь идет не просто о выброшенном материале, а о потерянном потенциале, снижении рентабельности и экологических последствиях неэффективности. Задача состоит не только в том, чтобы выявить отходы, но и в том, чтобы понять Влияние хвостовых отходов на производительность3 и использования материалов на протяжении всего производственного цикла, что требует активного подхода к оптимизации каждого миллиметра дорогостоящего сырья. Моя цель в MZBNL - помочь таким компаниям, как Ahmed's, эффективно справиться с этой проблемой.

Определение понятия "необработанный остаток" и его экономическое влияние

Под хвостовыми отходами понимается часть трубы, которая не может быть полностью обработана системой патрона станка лазерной резки, как правило, из-за ограничений по зажимам или безопасных зазоров в конце пути резки. В традиционных конструкциях, как только режущая головка достигает конца трубы, определенная длина, часто составляющая от 100 мм до 300 мм или даже больше, в зависимости от конструкции станка и диаметра трубы, становится непригодной для использования. Этот "необрезанный остаток" затем выбрасывается. С экономической точки зрения это чистые убытки. Рассмотрим производителя, выпускающего из трубок 100 000 компонентов в год. Если каждая трубка дает 150 мм непригодного материала, а типичная длина трубки составляет 6 метров, это означает тысячи метров неиспользованного сырья в течение года. Для такого среднего завода, как Ahmed's, работающего с различными проектами, от архитектурных перил до автомобильных деталей, накопленные затраты могут быть значительными. Например, если тонна стальных труб стоит $800, а отходы составляют 5% из-за хвостовых частей, то это $40 за тонну, что быстро вырастает до десятков тысяч долларов в год при больших объемах производства.

Это не только денежный эффект, но и влияние на эффективность производства и устойчивое развитие. Переработка отходов требует затрат энергии, труда на обработку и утилизацию, и все это не способствует получению конечного продукта. Предприятия все тщательнее проверяют каждый аспект своей деятельности, в том числе и использование материалов. Мои беседы с клиентами, особенно в регионах со строгими экологическими нормами или высокой стоимостью материалов, постоянно подчеркивают необходимость решений, которые не только сокращают количество деталей, но и максимально увеличивают ценность каждого куска сырья. Эта критическая перспектива выходит за рамки простого "изготовления детали" и позволяет оптимизировать весь жизненный цикл материала в процессе производства.

Совокупный эффект кажущихся незначительными потерь

Хотя отдельные отходы могут показаться незначительными, их суммарный эффект с течением времени, особенно при крупносерийном производстве, просто ошеломляет. Например, если компания обрабатывает 1 000 трубок в день, и каждая трубка имеет 200-миллиметровый хвостовой отход, то это 200 метров материала, теряемого ежедневно. За год это равносильно 50 000 метров отработанных трубок - достаточно, чтобы построить значительные конструкции или сотни тысяч мелких компонентов. Ахмед аль-Фарси обсудил со мной именно эту болевую точку. Расширяющиеся проекты его компании, от масштабных архитектурных каркасов до сложных деталей автомобилей, означают постоянный спрос на обработку труб. Проблема заключалась не только в случайном браке, но и в постоянных, предсказуемых потерях, которые подрывали маржу прибыли. Он понял, что традиционные станки, которые всегда оставляли хвост, по своей сути неэффективны для его бизнес-модели.

Эти совокупные потери также выходят за рамки материальных затрат и влияют на планирование производства и управление запасами. Предприятиям, возможно, придется заказывать больше сырья, чем необходимо, чтобы учесть отходы, что приведет к увеличению затрат на хранение запасов и потенциально более длительным срокам выполнения заказов. Кроме того, утилизация металлолома не бесплатна: она требует затрат на сбор, хранение и зачастую транспортировку на предприятия по переработке. Критический анализ показывает, что "небольшие" хвостовые отходы создают эффект пульсации во всей цепочке поставок и производственной экосистеме. Моя команда в MZBNL понимала, что для решения этой проблемы необходимо фундаментально изменить конструкцию станка и логику резки, перейдя от постепенных улучшений к действительно инновационному решению, которое бросит вызов устоявшимся отраслевым нормам.

Инновации MZBNL: Переосмысление понятия "ноль отходов"

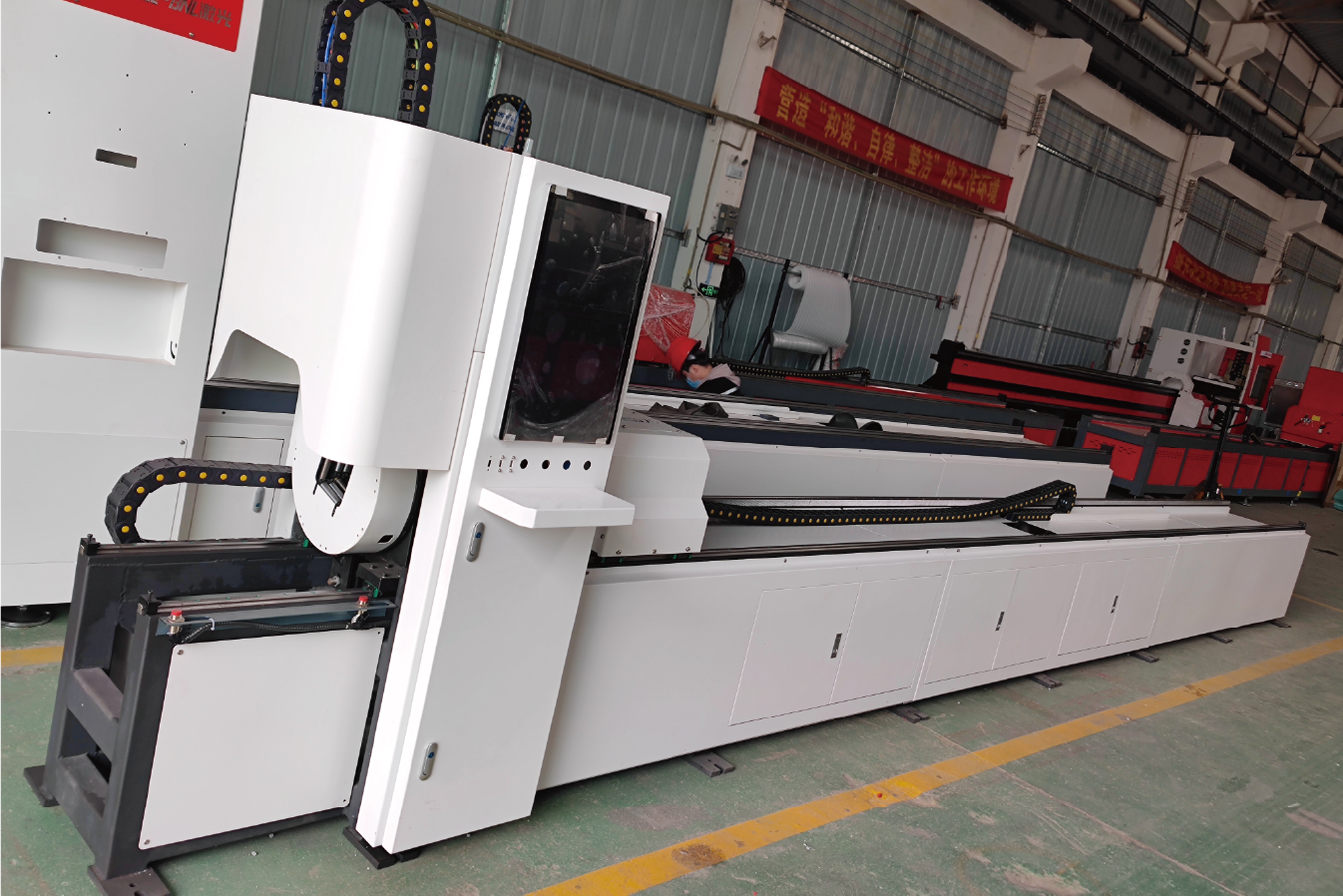

В компании MZBNL мы разработали инновационную технологию "Zero-Waste Tail Material Innovation" именно для устранения этого фундаментального недостатка традиционной лазерной резки труб. В отличие от традиционных систем, которые начинают резку с головки трубы и в конце создают непригодный для использования хвостовой материал, наша переработанная логика резки рассчитывается от заднего патрона в качестве исходной точки. Это позволяет системе избавляться от остатков хвостового материала до тех пор, пока оставшийся участок меньше длины изделия. Такой революционный подход позволяет максимально использовать материал и значительно повысить эффективность резки. Для такого клиента, как Ahmed, который ставит во главу угла высокое соотношение цены и качества и автоматизацию, эта функция напрямую означает ощутимую экономию и повышение конкурентоспособности.

В этой таблице показана потенциальная экономия для типичного клиента, обрабатывающего 500 трубок в день:

| Метрика | Традиционная система (200 мм хвостовой отвод) | Система безотходного производства МЗБНЛ | Экономия / улучшение |

|---|---|---|---|

| Хвостовые отходы на трубку | 200 мм | 0-X мм (минимальный) | Значительное сокращение |

| Годовые отходы (500 трубок/день) | 25 000 метров | < 500 метров | > 98% снижение |

| Экономия затрат на материалы | $X (высокий) | $Y (низкий) | Существенный |

| Эффективность производства | Стандарт | Расширенный | Более высокая производительность |

| Расходы на утилизацию лома | Присутствует | Минимум | Почти ликвидация |

Речь идет не только о сокращении отходов, но и о создании более устойчивой и прибыльной модели производства. Устраняя то, что раньше считалось неизбежным побочным продуктом, MZBNL дает возможность предприятиям достичь большей эффективности использования ресурсов и снизить воздействие на окружающую среду, что полностью соответствует современным требованиям промышленности к устойчивому развитию. Это инновационное мышление лежит в основе стремления MZBNL предоставлять индивидуальные решения, которые действительно решают глубокие операционные проблемы наших клиентов, выделяя нас на мировом рынке оборудования для производства металла.

Хвостовые отходы снижают рентабельностьПравда

Даже небольшие хвостовые отходы со временем накапливаются, что напрямую влияет на стоимость материалов и эффективность работы.

Хвостовые отходы неизбежныЛожь

Инновационные решения, такие как система Zero-Waste компании МЗБНЛ, демонстрируют, что отходы хвостовой части можно практически исключить за счет оптимизации конструкции машины.

Что вызывает отходы хвостов в этих процессах резки?

Вы когда-нибудь задумывались, почему ваш станок для лазерной резки труб неизбежно оставляет после себя непригодный хвостовой материал? Понимание основных причин возникновения отходов хвостового материала имеет решающее значение для любого предприятия, стремящегося оптимизировать свою деятельность и свести к минимуму дорогостоящие потери материала. Давайте рассмотрим технические ограничения и эксплуатационные факторы, способствующие возникновению этой распространенной отраслевой проблемы.

Хвостовые отходы при лазерной резке труб в основном вызваны ограничениями патронов и зажимных механизмов станка, которые требуют определенной длины материала для стабильного захвата и вращения. Кроме того, зазоры безопасности, стабильность оптической траектории и традиционная логика программирования, в которой приоритет отдается фронтальной обработке, также способствуют появлению этих непригодных остатков.

Если глубже разобраться в причинах потери хвостов, то можно обнаружить сочетание механических ограничений и устаревших методик программирования. В моих беседах с инженерами и владельцами заводов, в том числе на предприятии Ахмеда Аль-Фарси в ОАЭ, часто звучит разочарование от этих, казалось бы, неизбежных потерь. Хотя некоторые утверждают, что эти ограничения - это просто "принцип работы машин", я считаю, что именно здесь инновации играют настоящую роль. Традиционные конструкции станков требуют определенного количества материала в патроне для надежного вращения и точной резки, что означает, что самый конец трубы становится недоступным. Эти ограничения, присущие конструкции, долгое время воспринимались как необходимое зло, но в компании MZBNL мы бросили вызов этому предположению, осознав, что преодоление этих ограничений является ключом к открытию нового уровня эффективности и прибыльности для наших клиентов. Нам нужно было коренным образом переосмыслить весь процесс резки.

Механические ограничения и ограничения по зажимам

Основная техническая причина отходов хвоста кроется в механической конструкции традиционных станков для лазерной резки труб, а именно в их системах патронов. Чтобы обеспечить стабильное вращение и точную резку, труба должна быть надежно захвачена патронами, часто одним спереди и одним сзади. Для такого захвата требуется, чтобы минимальная длина материала находилась в зажимных губках патрона. По мере продвижения процесса резки к концу трубки наступает момент, когда оставшаяся длина становится слишком короткой для надежного и эффективного удержания патроном или попадает в "мертвую зону", необходимую для перемещения патрона или зазора лазерной головки. Например, если станок требует 150 мм для надежного зажима, то последние 150 мм каждой трубы становятся недоступными для резки, независимо от того, может ли деталь теоретически туда поместиться. Это конструктивное ограничение присуще многим традиционным конструкциям.

Кроме того, в некоторых станках используется несколько патронов, перемещающихся вдоль трубы. Хотя это позволяет увеличить диапазон резки, между подвижными патронами и концом трубы остается определенное количество материала, который невозможно обработать. Эти ограничения не являются произвольными; они необходимы для поддержания точности резки, предотвращения вибраций и обеспечения безопасности оператора. Однако принятие их как неизменных препятствует истинной оптимизации материала. Ахмед Аль-Фарси явно стремился решить эту проблему, поскольку его разнообразный ассортимент продукции означает, что даже из коротких остатков можно получить ценные компоненты меньшего размера, если только они могут быть обработаны. Он специально запросил машины, способные максимально использовать каждый дюйм сырья, и компания MZBNL смогла удовлетворить это требование благодаря нашему передовому технологическому подходу.

Традиционная логика программирования и операционная практика

Помимо механических ограничений, обычные логика программирования и методы работы4 также вносят значительный вклад в отходы хвостовой части. Многие старые программные системы лазерной резки рассчитаны на начало резки с передней части трубы и последовательное продвижение к задней части. Такой подход "сначала вперед" означает, что по мере уменьшения длины материала система естественным образом оставляет оставшийся короткий сегмент в конце процесса. Такое программирование часто не учитывает возможности использования остатков меньшей длины, полагая, что материал ниже определенного порога непригоден для использования. Это часто связано со сложностью повторного раскроя или переориентации деталей для коротких остатков. Таким образом, производственная практика отбраковки таких хвостов встраивается в рабочий процесс, создавая встроенную неэффективность.

При таком подходе упускается возможность интегрировать усовершенствованные алгоритмы раскроя, которые могут стратегически разместить более мелкие детали в конце трубы, или пересмотреть начало резки. Например, если бы станок мог резать от заднего патрона вперед или если бы он мог обрабатывать всю длину трубы, смещая начало резки, можно было бы избежать значительного количества отходов. Это критическая точка расхождения между традиционными и передовыми системами. Мой опыт показывает, что многие предприятия, даже инвестирующие в новое оборудование, не подвергают критическому анализу стандартное поведение своего программного обеспечения, в результате чего часто упускают возможность существенной экономии материалов. Именно поэтому "Инновации в области безотходного хвостового материала" от MZBNL - это не просто обновление оборудования, а фундаментальный сдвиг в логике программирования.

Преодоление "неизбежности" с помощью инноваций MZBNL

Компания MZBNL в корне опровергла мнение о том, что хвостовые отходы "неизбежны". Наша инновационная технология "безотходного хвостового материала" напрямую связана с механическими и программными ограничениями. Мы переработали логику резания так, чтобы расчет производился от заднего патрона. Это позволяет системе эффективно "тянуть" трубу и резать с задней стороны, используя почти всю длину материала. Если длина оставшегося участка меньше длины изделия, наша система может устранить остатки хвостового материала, включив его в последний возможный разрез. Этот инновационный подход обеспечивает максимальное использование материала и значительно повышает эффективность резки. Для Ахмеда Аль-Фарси это означает, что его станок для лазерной резки труб с функциями автоматической подачи и перфорации теперь может производить больше готовых деталей из того же количества сырья, что напрямую влияет на его модель прибыли при оказании услуг по изготовлению изделий по контракту.

Эффект от этой инновации огромен. Вместо того чтобы просто принять промышленный стандарт от 100 до 300 мм отходов на трубу, наши клиенты могут добиться практически нулевых отходов для многих операций. Это не только снижает затраты на материалы, но и уменьшает объем лома, подлежащего обработке и утилизации, способствуя более чистому и устойчивому производственному процессу. Эта передовая разработка, включающая в себя многопроцессные возможности, предлагает комплексное решение для предприятий, стремящихся автоматизировать и оптимизировать существующие ручные рабочие процессы. Она позиционирует MZBNL как лидера в предоставлении действительно экономически эффективных индивидуальных решений, которые бросают вызов статус-кво в области производства металла, предлагая значительное конкурентное преимущество нашим глобальным корпоративным клиентам.

Ограничения патрона вызывают отходы хвостаПравда

Традиционные станки для лазерной резки труб требуют минимальной длины материала для стабильного захвата, что приводит к неизбежным отходам на концах труб.

Все хвостовые отходы непригодны для использованияЛожь

Благодаря усовершенствованному программированию и конструкции станка, хвостовой материал часто может быть использован для изготовления более мелких деталей, а не пропадать зря.

Как хвостовые отходы влияют на общую эффективность производства и материальные затраты?

Задумывались ли вы когда-нибудь о том, что отходы хвостового хозяйства не ограничиваются только выброшенными материалами? Его влияние распространяется далеко за пределы мусорного контейнера, значительно снижая общую эффективность производства и увеличивая затраты на материалы. Понимание этих взаимоусиливающих эффектов жизненно важно для любого производителя, стремящегося к бережливому производству.

Хвостовые отходы негативно влияют на эффективность производства, увеличивая расход материала, требуя более частой обработки материала и снижая производительность на трубу. Они напрямую повышают стоимость материалов за счет неиспользуемых остатков, увеличивают расходы на утилизацию отходов и косвенно влияют на рентабельность, поскольку связывают капитал с избыточными запасами и неэффективными процессами.

Последствия отходов хвостов гораздо более коварны, чем просто выброс нескольких дюймов металла. Из моих бесед с производителями по всему миру, включая таких потенциальных клиентов, как Ахмед Аль-Фарси из ОАЭ, становится ясно, что совокупное воздействие этих "небольших" потерь может подорвать весь производственный цикл. Речь идет не только о сырье, но и о трудозатратах на обработку лома, энергии, расходуемой на его переработку, и упущенной возможности произвести больше деталей из того же сырья. Такая неэффективность создает "узкие места", увеличивает операционные накладные расходы и напрямую влияет на маржу прибыли, делая предприятия менее конкурентоспособными. Мой опыт работы в MZBNL научил меня тому, что решение проблемы хвостовых отходов5 это не просто экологическая ответственность, это стратегический императив для финансового здоровья и операционного совершенства, напрямую влияющий на итоговый результат.

Прямой финансовый дождь: Расходы на материалы и утилизацию

Самое непосредственное и очевидное влияние хвостовых отходов - это прямой финансовый ущерб, который они наносят за счет затрат на материалы. Каждый сантиметр непригодного материала представляет собой сырьевой капитал, буквально выброшенный на ветер. Для крупносерийных производителей эта сумма быстро возрастает. Давайте вернемся к бизнесу Ахмеда Аль-Фарси, который регулярно обрабатывает трубы различных размеров для архитектурных элементов и автомобильных компонентов. Если его команда обрабатывает, скажем, 10 000 метров труб в месяц, а традиционная машина дает 5% хвостовых отходов, то это 500 метров потерянного материала. При средней стоимости $2-$5 за метр для специализированных стальных труб это может означать $1,000-$2,500 прямых материальных потерь каждый месяц, в общей сложности $12,000-$30,000 в год. Эта цифра значительно возрастает для более дорогих или специализированных сплавов.

Помимо стоимости самого материала, существуют и сопутствующие расходы на утилизацию. Хотя металлолом можно перерабатывать, этот процесс не бесплатен. Он включает в себя трудозатраты на сбор, сортировку и транспортировку лома, а также потенциальные сборы, взимаемые предприятиями по переработке, или упущенную выгоду от менее выгодных цен на лом. Эти, казалось бы, незначительные накладные расходы в сочетании с прямыми материальными потерями создают существенные периодические затраты, которые напрямую снижают рентабельность. Компании часто не обращают внимания на эти "скрытые" расходы, полагая, что они неизбежны. Однако критический анализ, который я часто провожу с нашими потенциальными клиентами, показывает, что эти расходы зачастую значительно выше, чем предполагалось, что является убедительным аргументом в пользу инвестиций в технологии, позволяющие минимизировать отходы. Моя команда в MZBNL осознала это прямое финансовое бремя как критическую проблему, требующую нового решения.

Снижение общей эффективности производства

Хвостовые отходы не только стоят денег, но и влияют на общую эффективность производства несколькими способами. Во-первых, это означает, что на каждую полностью загруженную трубку приходится часть ее потенциальной производительности. Это эффективно снижает "выход" на одну палку сырья. Для достижения производственных целей необходимо закупать и обрабатывать большее количество трубок, что приводит к увеличению объема погрузочно-разгрузочных работ, увеличению количества циклов погрузки/разгрузки и повышению энергопотребления в расчете на одну готовую деталь. Для высокоскоростного производства даже незначительное увеличение времени цикла из-за удаления отходов может привести к значительным задержкам. Рассмотрим сценарий, в котором станок должен изготовить 10 000 деталей. Если каждая трубка дает на одну деталь меньше из-за отходов хвостовой части, станок должен обработать значительно больше трубок, что приведет к увеличению времени работы, повышенному износу компонентов и увеличению потребления электроэнергии.

Во-вторых, управление хвостовыми отходами добавляет в производственный процесс этапы, не связанные с добавлением стоимости. Операторы должны убирать отбракованные остатки с машины, транспортировать их в контейнеры для лома и управлять их утилизацией. Эти задачи отнимают ценное рабочее время, которое в противном случае можно было бы использовать для таких видов производственной деятельности, как контроль качества, обслуживание оборудования или подготовка следующей партии сырья. Этот аспект неэффективности был особенно важен для Ахмеда Аль-Фарси, чей бизнес направлен на автоматизацию существующих ручных рабочих процессов. Его цель - снизить трудоемкость работы оператора и повысить общую производительность, поэтому такие решения, как MZBNL "Инновации на переднем крае"6 и "Инновации в области безотходного производства хвостового материала" очень привлекательны, поскольку они напрямую направлены на устранение этих узких мест в производстве. Например, переход от ручной загрузки сбоку/сзади к оптимизированной фронтальной загрузке повышает эффективность на 40% и снижает трудоемкость работы оператора на 40%, демонстрируя целостный подход МЗБНЛ к повышению эффективности производства.

Влияние на конкурентные преимущества и устойчивое развитие

В условиях современной конкуренции на мировом рынке каждая дополнительная экономия и повышение эффективности способствуют усилению конкурентных преимуществ. Предприятия, которые могут производить детали с меньшим количеством отходов материалов, имеют более низкие затраты на единицу продукции, что позволяет им предлагать более конкурентоспособные цены или добиваться более высокой маржи прибыли. Например, если инновационная технология MZBNL Zero-Waste Tail Material Innovation помогает компании сократить расход материалов на 5%, это напрямую означает преимущество в стоимости сырья на 5% по сравнению с конкурентами, использующими традиционные методы. Это особенно важно для контрактных производственных служб, таких как Ahmed's, где тендеры часто бывают жесткими, а стоимость материалов - одним из основных факторов. Способность предлагать более конкурентоспособные цены, особенно на таких рынках, как Юго-Восточная Азия и Ближний Восток, куда МЗБНЛ активно экспортирует продукцию, позволяет выигрывать новые контракты и расширять долю рынка.

Более того, устойчивое развитие - это уже не просто громкое слово, а стратегический императив для компаний, особенно для тех, кто стремится к долгосрочной стабильности и положительному общественному имиджу. Сокращение количества хвостовых отходов прекрасно согласуется с экологическими целями, поскольку минимизирует потребление ресурсов и уменьшает углеродный след, связанный с производством материалов и утилизацией отходов. Компании, применяющие такую практику, могут использовать свой "зеленый" авторитет, чтобы привлечь клиентов, заботящихся об окружающей среде, и удовлетворить все более жесткие нормативные требования. Такая двойная выгода - финансовая выгода и экологическая ответственность - позиционирует такие компании, как MZBNL, и, соответственно, наших клиентов, как лидеров отрасли, стремящихся к производству, ориентированному на будущее. Это свидетельствует о стремлении не просто производить, а производить разумно и ответственно.

Хвостовые отходы повышают стоимость материаловПравда

Неиспользованные остатки и расходы на утилизацию напрямую повышают материальные затраты, как показано в примере с годовым убытком $12 000-$30 000.

Хвостовые отходы повышают эффективностьЛожь

Хвостовые отходы фактически снижают эффективность, требуя больше погрузочно-разгрузочных работ и создавая для операторов работу, не приносящую добавленной стоимости.

Какие существуют решения для минимизации или устранения хвостовых отходов при лазерной резке труб?

Вы ищете эффективные способы борьбы с постоянной проблемой хвостовых отходов при лазерной резке труб? Хотя эта проблема широко распространена, существуют инновационные решения, которые могут значительно минимизировать или даже устранить эти дорогостоящие остатки. Давайте рассмотрим самые передовые подходы, меняющие использование материалов в отрасли.

Решения по минимизации отходов хвостовой части при лазерной резке труб в основном включают в себя передовые конструкции станков с оптимизированными системами патронов, интеллектуальное программное обеспечение для раскроя и инновационную логику резки. Эти технологии позволяют свести к нулю обработку хвостов, максимизируя использование материала за счет переосмысления способов фиксации и резки труб с самого конца.

В течение десятилетий промышленность принимала определенное количество отходов как неизбежный побочный продукт лазерной резки труб. Однако в компании MZBNL я твердо убежден, что застой перед лицом неэффективности - это не выход. Мы с командой посвятили значительную часть исследований и разработок тому, чтобы бросить вызов этим нормам, сосредоточившись на решениях, которые расширяют границы возможного в использовании материалов. Мы поняли, что настоящие инновации - это не просто более быстрая резка, это более умная резка". Для таких клиентов, как Ахмед Аль-Фарси, которые ценят высокую рентабельность и эффективные решения "под ключ", машина, которая действительно устраняет отходы, становится мощным активом. Позвольте мне рассказать, как запатентованные инновации MZBNL превратили эту задачу в конкурентное преимущество для наших клиентов по всему миру.

Передовые системы патронов и инновации в области проектирования станков

Одно из наиболее эффективных решений по минимизации отходов хвоста заключается в эволюции конструкция станков, в частности, системы патронов7. Традиционные конструкции требуют значительной "мертвой зоны" для зажима и перемещения патрона, что делает значительную часть концов труб непригодной для использования. Однако в современных станках применяются конструкции, которые значительно уменьшают эту мертвую зону. Например, некоторые современные системы оснащены патронами с "нулевым хвостом", в которых задний патрон может перемещаться ближе к режущей головке или даже проходить через нее, что позволяет обрабатывать почти всю длину трубы. Это принципиально отличается от обычных фиксированных патронов.

Например, инновационная система MZBNL "Zero-Waste Tail Material Innovation" напрямую решает эту механическую проблему. Моя команда разработала систему, в которой логика резки рассчитывается от заднего патрона, что позволяет системе эффективно обрабатывать материал до самого конца. Это означает, что станок может резать до тех пор, пока длина оставшегося участка больше или равна длине изделия, устраняя неизбежные ранее остатки материала в хвостовой части. Для такой конструкции требуются надежные, высокоточные патроны, сохраняющие стабильность даже при захвате очень коротких отрезков, что компания MZBNL отработала за 25 лет работы в области производства металлов. Такие технологические достижения приводят к реальной, количественно измеримой экономии; сокращение отходов хвостовой части с 200 мм до менее чем 10 мм на трубу означает сокращение остатков материала более чем на 95% для многих операций. Такой уровень точности и оптимизации материалов устанавливает новый отраслевой стандарт.

Интеллектуальное программное обеспечение для раскроя и оптимизации траектории резания

Помимо физической конструкции станка, решающую роль в минимизации хвостовых отходов играет сложное программное обеспечение. Интеллектуальное программное обеспечение для раскроя предназначено для оптимизации размещения деталей на исходном материале с целью максимального использования материала и минимизации брака. Для резки труб это означает не просто установку деталей на трубу, а их стратегическое расположение таким образом, чтобы извлечь абсолютно последний кусок пригодного для использования материала. При традиционном раскрое может остаться короткий, неудобный конец, но Современное программное обеспечение может динамически регулировать8 чтобы заполнить эти небольшие пробелы.

MZBNL интегрирует в наши машины интеллектуальные и оцифрованные системы, которые включают в себя высоко оптимизированные алгоритмы раскроя. Эти алгоритмы учитывают не только основные производственные детали; они также могут определять и вкладывать более мелкие вспомогательные компоненты (например, прокладки, шайбы или даже короткие ножки для мебели) в то, что традиционно считалось бы отходами. Такая многопроцессная интеграция является ключевой. Кроме того, наши системы, особенно с инновационной операционной системой No-CAD, позволяют на лету вводить параметры для стандартных типов труб и отверстий, устраняя необходимость в сложных 3D-чертежах. Это значительно повышает простоту использования и сокращает время настройки, а также позволяет операторам быстро адаптироваться к небольшим остаткам, эффективно используя их без сложного перепрограммирования. Такой уровень гибкости и интеллектуальности нашего программного обеспечения позволяет нашим клиентам превращать потенциальные отходы в ценные продукты, что очень важно для предприятий, ищущих индивидуальные решения и быстрые сроки выполнения заказа.

Стратегические операционные практики и подход МЗБНЛ

Хотя инновации в оборудовании и программное обеспечение имеют первостепенное значение, стратегические методы работы также способствуют сокращению отходов хвостовой части. Это включает в себя тщательное управление запасами для обеспечения использования труб оптимальной длины для конкретных работ, что сводит к минимуму образование ненужных длинных остатков. Также необходимо обучать операторов, чтобы они понимали экономические последствия отходов и предоставляли им инструменты для их сокращения. Однако наиболее эффективное оперативное решение приходит от машин, которые коренным образом меняют процесс резки.

Три основные инновации MZBNL работают в комплексе, чтобы комплексно решать проблему хвостовых отходов:

- Инновационная система No-CAD: Упрощает работу, обеспечивая эффективное использование всего материала. Операторы могут быстро обрабатывать стандартные типы труб, что позволяет оперативно использовать остатки коротких труб без сложной работы в САПР. Это снижает порог квалификации, то есть операторам требуется всего 1 день обучения вместо 15, что напрямую влияет на эффективную настройку для различных работ и уменьшает количество отходов из-за ошибок.

- Инновации на переднем крае: В первую очередь это повышает эффективность и снижает трудозатраты на 40%, но также косвенно способствует сокращению отходов, обеспечивая более последовательный и контролируемый поток материала, уменьшая количество ошибок, которые могут привести к непригодным секциям.

- Инновационный безотходный хвостовой материал: Это наше прямое решение, пересчитывающее резку от заднего патрона в качестве исходного. Эта новаторская логика позволяет системе устранять остатки хвостового материала, максимизируя его использование". Для Ахмеда Аль-Фарси это означает, что его "станок для лазерной резки труб с автоматической подачей и возможностью перфорации" представляет собой готовое решение, которое по своей сути оптимизирует использование материала, непосредственно влияя на его прибыльность в производстве архитектурных металлоконструкций и деталей автомобилей. Применяя эти интегрированные решения, предприятия могут не только минимизировать отходы, но и полностью их устранить, достигнув беспрецедентного уровня эффективности использования материалов и операционного совершенства.

Патроны с нулевым хвостом уменьшают мертвые зоныПравда

Усовершенствованные системы патронов позволяют обрабатывать материал вплоть до конца трубы, минимизируя мертвые зоны зажима.

Традиционное гнездование не оставляет отходовЛожь

При обычном раскрое часто остаются короткие непригодные концы, в то время как интеллектуальное программное обеспечение может использовать эти остатки.

Каковы наилучшие методы оптимизации сокращения хвостовых отходов в операциях резки?

Готовы ли вы внедрить наиболее эффективные стратегии для минимизации хвостовых отходов в своих процессах лазерной резки труб? Помимо инвестиций в передовое оборудование, внедрение ключевых передовых методов может еще больше оптимизировать использование материалов, значительно повышая рентабельность и эффективность производства. Давайте узнаем, как это сделать.

Лучшие методы оптимизации сокращения хвостовых отходов включают в себя инвестиции в передовую технологию "нулевого хвоста", внедрение интеллектуального раскроя и планирования производства, обеспечение точной калибровки станка и повышение квалификации операторов. Эти комбинированные подходы позволяют максимально использовать материал, сократить количество брака и повысить общую эффективность операций лазерной резки труб.

В то время как инновационные машины MZBNL, такие как наша интегрированная машина для автоматической перфорации и резки, обеспечивают технологическую основу для практически нулевых отходов, путь к настоящей оптимизации распространяется на методы работы завода. Мои беседы с успешными клиентами, в том числе с теми, кто рассматривает возможность долгосрочного партнерства, такого как региональная дистрибуция, неизменно подчеркивают важность интеграции технологий с продуманными операционными стратегиями. Речь идет о создании целостной экосистемы, в которой каждое решение способствует максимальному использованию материалов и повышению эффективности. Для такого предприятия, как Ahmed Al-Farsi, где услуги по изготовлению продукции на заказ и высокая рентабельность имеют первостепенное значение, эти лучшие практики - не просто предложения; они являются важнейшими путями к устойчивому росту и сохранению конкурентных преимуществ на таких требовательных рынках, как Ближний Восток. Давайте узнаем, как по-настоящему раскрыть весь потенциал ваших операций по резке.

Внедрение передовых технологий и интегрированных систем с нулевым хвостом

Наиболее фундаментальная передовая практика оптимизации сокращения хвостовых отходов - это инвестирование в оборудование, оснащенное передовой технологией "нулевого хвоста". Это не просто дополнительная функция; это критический компонент для достижения максимального использования материала. Традиционные станки, независимо от того, насколько хорошо они эксплуатируются, по своей сути ограничены конструкцией патрона и логикой резания, что приводит к неизбежным остаткам хвостов. Поэтому первым шагом является переход на системы, разработанные для решения проблемы хвостовых отходов9. Инновационная технология MZBNL "Zero-Waste Tail Material Innovation" является ярким примером такой технологии. Благодаря пересчету начала резания из заднего патрона наши станки могут обрабатывать материал вплоть до последнего миллиметра, эффективно превращая то, что раньше было отходами, в пригодный для использования продукт.

На предприятиях с большим объемом производства или работающих с дорогостоящими материалами, окупаемость такой технологии происходит очень быстро. Возьмем фабрику, производящую тысячи мебельных деталей или архитектурных элементов. Даже небольшое процентное сокращение отходов материала на одну трубку, суммированное с тысячами трубок в год, приводит к существенной экономии. Кроме того, интеграция машин с многопроцессными возможностями, таких как интегрированная машина для автоматической штамповки и резки MZBNL, позволяет оптимизировать операции. Такая интеграция означает, что после загрузки трубки и резка, и перфорация могут выполняться без дополнительных манипуляций, что сводит к минимуму возможные ошибки и максимизирует пропускную способность. Беспрепятственный поток от сырья до готовой детали с минимальным количеством отходов является воплощением современной эффективности производства и обеспечивает критическое конкурентное преимущество.

Внедрение стратегий интеллектуального планирования производства и раскроя

Помимо возможностей станков, важнейшими передовыми методами оптимизации хвостовых отходов являются интеллектуальное планирование производства и передовые стратегии раскроя. Это предполагает использование сложного программного обеспечения для планирования расположения деталей на трубе с целью минимизации неиспользуемых участков. Это выходит за рамки простой "подгонки" и становится стратегическим стратегии раскроя при резке труб10 которые учитывают переменные размеры деталей, типы материалов и потенциальное использование остатков. Например, если для выполнения задания требуется много коротких деталей, программа раскроя должна уметь группировать их на одном конце трубы, оставляя на другом конце более длинный и пригодный для использования остаток для будущих заданий, а не несколько коротких, непригодных для использования хвостов.

Интеллектуальные и оцифрованные системы MZBNL, дополненные нашей операционной системой No-CAD, способствуют внедрению этой передовой практики. Наши системы обеспечивают высокоскоростную и высокоточную резку при простоте управления. Простота использования означает, что планировщики производства могут быстро адаптироваться к меняющимся требованиям, а операторы - внедрять оптимизированные схемы раскроя без длительного обучения CAD. Например, если для конкретного проекта компании Ahmed Al-Farsi, занимающейся производством архитектурных металлоконструкций, требуется несколько коротких труб, наша система может эффективно раскроить их, чтобы оптимально использовать длину трубы и минимизировать конечный хвост. Эта возможность гарантирует, что даже если останется небольшой остаток, он будет либо действительно непригодным для использования, либо стратегически продуманным, чтобы пригодиться для последующего заказа более мелких деталей. Такой уровень детального контроля над использованием материала отличает эффективные операции от тех, которые просто "режут и выбрасывают".

Непрерывный мониторинг, калибровка и обучение операторов

Наконец, постоянное совершенствование работы достигается за счет непрерывного мониторинга, точной калибровки оборудования и всестороннего обучения операторов. Даже самое современное оборудование требует постоянного внимания для поддержания оптимальной производительности и сокращения отходов. Регулярная калибровка обеспечивает точный захват патронов и точную траекторию лазерного излучения, предотвращая ошибки резки, которые могут привести к браку. Мониторинг показателей использования материалов, таких как "расход материалов на единицу продукции" или "процент отходов", предоставляет критически важные данные для выявления областей, требующих улучшения.

Кроме того, обучение операторов имеет первостепенное значение. Хотя машины МЗБНЛ просты в эксплуатации и требуют всего 1 дня обучения на месте для нашей системы No-CAD, понимание принципов сокращения отходов дает операторам возможность принимать обоснованные решения. Они должны знать, как их действия влияют на использование материалов, и поощрять их к выявлению возможностей для дальнейшей оптимизации. Например, знание того, как лучше загружать трубки, минимизировать перемещение материалов и проверять точность резки, может значительно сократить количество ошибок и, следовательно, отходов. Ахмед Аль-Фарси ценит послепродажное обучение и поддержку, понимая, что хорошо обученная команда максимально повышает ценность передового оборудования. Сочетая передовые технологии MZBNL с этими лучшими практиками, предприятия могут достичь беспрецедентного уровня эффективности использования материалов, укрепив свою конкурентоспособность и долгосрочную устойчивость в отрасли производства металлоконструкций.

Технология "нулевого хвоста" сокращает количество отходовПравда

Передовые технологии с нулевым хвостом, такие как инновационная технология MZBNL, могут обрабатывать материал до последнего миллиметра, значительно сокращая количество отходов хвоста.

Традиционные машины устраняют хвостовые отходыЛожь

Традиционные станки ограничены конструкцией патрона и логикой резания, поэтому без технологии "нулевого хвоста" остатки хвоста неизбежны.

Заключение

Внедрение инноваций, таких как система безотходного хвостового материала MZBNL, имеет решающее значение для современного металлопроизводства. Пересмотрев традиционную логику резки, предприятия могут значительно сократить отходы материалов, повысить рентабельность и эффективность работы. Такой упреждающий подход не только решает насущные проблемы с затратами, но и обеспечивает компаниям, подобным Ahmed's, устойчивый рост и конкурентное преимущество на мировых рынках.

-

Узнайте, как хвостовые отходы влияют на рентабельность операций лазерной резки труб ↩

-

Изучите влияние затрат на материалы при изготовлении металлоконструкций ↩

-

Понять более широкое влияние хвостовых отходов на производительность и эффективность использования материалов ↩

-

Узнайте, как ограничения программного обеспечения способствуют неэффективности материалов и как их преодолеть ↩

-

Узнайте о стратегической важности управления отходами на производстве. ↩

-

Поймите, как фронтальная подача повышает производительность и снижает трудоемкость. ↩

-

Узнайте об эволюции систем патронов для эффективной резки. ↩

-

Поймите, как программное обеспечение влияет на максимальное использование материалов. ↩

-

Узнайте, как современные системы минимизируют хвостовые отходы в процессах резки для повышения эффективности ↩

-

Понять, как стратегии раскроя оптимизируют использование материала и сокращают отходы при операциях резки ↩

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.