Why a Tube and Pipe Laser Cutter is a Smart Investment

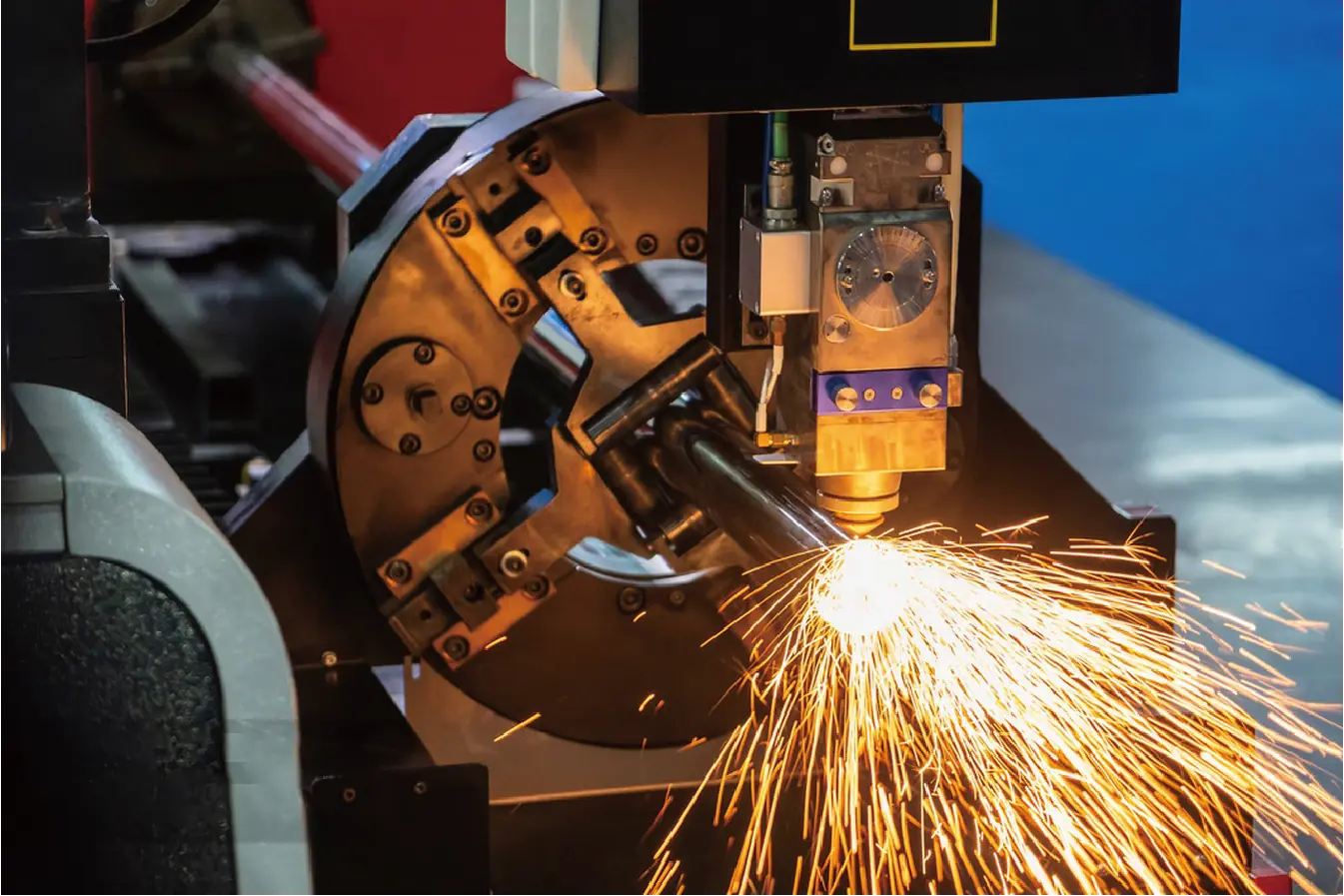

Struggling with slow production, high labor costs, and wasted material? These chronic issues directly attack your profit margins. Our advanced laser cutters offer a precise, efficient, and transformative solution.

A tube and pipe laser cutter is a smart investment because it dramatically increases production speed, reduces material waste to near-zero, and lowers labor costs. It delivers unparalleled precision and adaptability, future-proofing your operations and boosting your ROI from day one.

As the General Manager of MZBNL, I've spent over a decade helping businesses make this exact transition. It's more than just a machine upgrade; it's a fundamental shift in how you manufacture. Let's break down exactly why this technology is such a powerful investment for your company's future.

What are the key benefits of investing in a tube and pipe laser cutter?

Are outdated methods creating production bottlenecks and quality issues? This inefficiency costs you time and valuable contracts. A laser cutter unlocks superior speed, precision, and material savings, transforming your workflow.

The key benefits are unmatched precision for complex designs, significantly faster cutting speeds than traditional methods, and minimal material waste. This leads to higher quality products, increased throughput, and substantial long-term cost savings, giving you a strong competitive edge.

When I visit our clients' facilities, the first thing they often mention is the sheer range of new possibilities the machine opens up. The benefits go far beyond just cutting metal faster. It's about elevating your entire operation.

Unmatched Precision and Complexity

Traditional cutting has limits. But a laser beam does not. Because it's a non-contact process, there is no tool wear or material deformation. This means we can produce incredibly intricate patterns and complex geometries with perfect repeatability. For our clients in the automotive or medical equipment sectors, this level of precision isn't a luxury; it's a requirement. They can now confidently take on jobs they previously had to turn down, opening up new, more profitable markets.

Radical Efficiency Gains

Think about the old way of processing a tube. You might have one station for sawing to length, another for drilling holes, and a third for notching the ends. Each step requires handling, setup, and introduces a chance for error. Our лазерный труборезs consolidate all these processes into a single, automated operation. The machine takes a full-length tube and produces a finished part, ready for the next stage. This massive efficiency gain directly boosts your throughput and shortens lead times.

Future-Proof Adaptability

The market is always changing. Customer demands shift. A laser cutter gives you the agility to respond instantly. Because the machine works from a digital file, switching from producing one part to a completely different one takes only minutes. This adaptability is critical for modern, agile manufacturing. It allows you to handle small batches and custom orders just as efficiently as large production runs, future-proofing your business against market volatility.

Why do traditional cutting methods fall short compared to laser technology?

Are you losing money to material defects, slow manual labor, and secondary finishing processes? Traditional methods are often the root cause. Laser technology automates precision, eliminating human error and costly delays.

Traditional methods like sawing, drilling, and punching are slow, require multiple steps, and often produce burrs and inaccuracies. They lack the precision for complex cuts, lead to higher material waste, and demand more manual labor, making them inefficient for modern manufacturing needs.

For years, I saw factories rely on the same methods they had used for decades. But in today's competitive landscape, "good enough" is no longer good enough. The shortcomings of traditional methods become very clear when you compare them directly to what a modern laser can do.

A Head-to-Head Comparison

| Характеристика | Traditional Methods (Sawing/Drilling) | Laser Cutting |

|---|---|---|

| Скорость | Медленный, многоступенчатый процесс | Extremely fast, all-in-one process |

| Точность | Low to moderate, operator dependent | High, micron-level accuracy |

| Материальные отходы | High (wide kerf, test cuts) | Minimal (thin kerf, nesting software) |

| Труд | High, requires skilled operators | Low, one operator can run machine |

| Сложность | Very limited, simple cuts only | Nearly unlimited, complex geometries |

| Finishing | Requires deburring and grinding | Clean, smooth edges, no finishing |

The data in this table tells a powerful story. Traditional methods are a series of compromises. Saws leave burrs. Drills can wander. Punches can deform the material. Each of these small imperfections adds up to significant costs in the form of rework, scrap, and added labor for finishing. A laser cutter eliminates these compromises. It delivers a perfect part, directly from the machine, in a fraction of the time. This isn't just an incremental improvement; it's a complete change in production capability.

How does a laser cutter enhance production efficiency and precision?

Is your production line struggling to keep up with demand? Are manual adjustments and slow processes holding you back? A laser cutter automates complex tasks, delivering perfect results every single time.

A laser cutter consolidates multiple processes like cutting, drilling, and notching into one automated step. Its CNC control ensures cuts are accurate to the micron level, eliminating rework. This dramatically increases throughput, reduces lead times, and guarantees consistent, high-quality parts.

At MZBNL, we don't just build machines; we engineer solutions to real-world production problems. Efficiency and precision are at the core of everything we do, and we've developed specific technologies to maximize both for our clients.

The Power of Automation

The foundation of a laser cutter's efficiency is its CNC (Computer Numerical Control) system. An operator loads a digital design file, and the machine executes the cuts perfectly. There's no guesswork, no manual measuring, and no chance for human error. This automation allows for "lights-out" manufacturing, where the machine can run with minimal supervision, even overnight. This drastically increases your available production hours without increasing your headcount.

Our No-CAD System Innovation

We noticed a major bottleneck for many companies: the need for highly skilled CAD programmers. This created a dependency and slowed down production. So, we developed our proprietary No-CAD System. It allows an operator with no programming experience to design and program parts directly on the machine's interface using a simple, graphical system. I've personally seen this reduce operator training time from several weeks to a single day. This innovation makes advanced technology accessible and immediately productive for any team.

Achieving Micron-Level Precision

The laser beam itself is incredibly fine, allowing for a very narrow cut (kerf). This, combined with the non-contact nature of the process, means we can achieve tolerances that are impossible with mechanical methods. For components that need to fit together perfectly, like in high-end furniture or automotive frames, this precision is essential. It eliminates the need for post-cut adjustments and ensures the quality of the final product.

What are the cost-saving advantages of using a tube and pipe laser cutter?

Are high material and labor costs eating into your profits? Inefficient processes are a constant drain on your resources. Laser cutting directly targets these major expenses, delivering significant and measurable savings.

The main cost savings come from drastically reduced material waste through smart nesting and minimal scrap. It also lowers labor costs by automating processes and reducing the need for skilled operators. Faster production cycles mean higher output and revenue with the same resources.

When a potential client asks me about ROI, I always start with the direct, tangible cost savings. While the initial investment is significant, the machine quickly begins to pay for itself by cutting your two biggest operational expenses: materials and labor.

Here is how it works:

-

Reduced Material Waste: Our machines use advanced nesting software that automatically arranges parts on a tube to maximize material usage. But we took it a step further. We developed our "Инновационный безотходный хвостовой материал[^1]," a system that allows the machine to use the final few inches of a tube that are normally discarded as scrap. For a furniture client of ours, this single feature saved them over $20,000 in raw material costs in the first year alone.

-

Lower Labor Costs: A laser cutter transforms one operator into a highly productive force. Because the process is automated and our No-CAD system is easy to use, you no longer need a team of specialists for sawing, drilling, and deburring. One person can load the material, select the program, and oversee the machine's operation, freeing up your valuable team members for other tasks like welding and assembly.

-

Elimination of Secondary Processes: The edges of a laser-cut part are smooth and free of burrs. This means you can completely eliminate time-consuming and labor-intensive secondary processes like grinding and deburring. The part comes off the machine ready for the next step, which accelerates your entire production timeline.

-

No Tooling Costs: Traditional methods require a large inventory of saw blades, drill bits, and custom punches. These tools wear out, break, and need to be constantly replaced. A laser cutter has no physical tooling, eliminating this recurring operational expense entirely.

What best practices should be followed to maximize the investment in laser cutting technology?

You've made the investment, but are you getting the most out of it? Without the right strategy, even the best tool can underperform. Following a few key practices ensures you achieve maximum ROI.

To maximize your investment, focus on proper operator training, especially on the machine's software. Implement a regular maintenance schedule to ensure peak performance. And optimize your workflow by using nesting software to minimize material waste and integrating the cutter into your production line.

Buying a powerful machine is only the first step. Creating a system around it is what truly unlocks its potential. Over the years, I've seen our most successful clients adopt a few simple but powerful best practices.

Invest in People, Not Just Machines

A confident operator is an efficient operator. While we design our machines to be incredibly user-friendly, proper training is still the best investment you can make. Ensure your team understands not just how to run the machine, but how to use its software to optimize cut paths and nest parts effectively. This knowledge pays dividends every single day.

Establish a Proactive Maintenance Routine

Downtime is the enemy of profit. A simple daily and weekly maintenance checklist can prevent most common issues. This includes simple tasks like cleaning the lens, checking the nozzle, and verifying assist gas pressures. A few minutes of proactive care each day ensures the machine runs at peak performance and avoids costly, unexpected service calls.

Optimize Your Digital Workflow

The principle of "garbage in, garbage out" applies here. Ensure your design files are clean and properly formatted before sending them to the machine. Spend time learning the features of your nesting software; a small adjustment to the nesting layout can result in significant material savings over a large production run. A smooth digital workflow from design to production is essential.

Заключение

Investing in a tube and pipe laser cutter is a strategic move towards a more efficient, precise, and profitable future. It directly solves key production pains, reduces waste, and positions your business to adapt and thrive in a competitive market. It's a smart investment in your success.

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.