Как станки для лазерной резки труб вписываются в Индустрию 4.0

The manufacturing landscape is rapidly evolving, driven by the principles of Industry 4.0. Are you feeling the pressure to modernize your operations and stay competitive? We understand the challenge of integrating new technologies while maintaining efficiency.

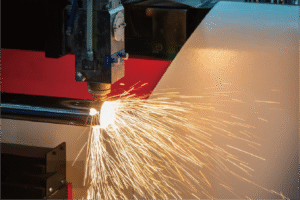

Tube laser cutting machines are crucial components in Industry 4.0, leveraging automation, data exchange, and smart manufacturing. They integrate into connected ecosystems through IoT sensors, real-time data analysis, and seamless communication with other factory systems, enhancing efficiency and flexibility.

In an era where digital transformation is no longer an option but a necessity, understanding how your core machinery fits into the bigger picture is paramount. Let's explore how tube laser cutting machines are not just tools, but integral elements of the Industry 4.0 revolution1, propelling manufacturers towards unprecedented levels of productivity and innovation.

The concept of Industry 4.0, often termed the Fourth Industrial Revolution, fundamentally redefines manufacturing by integrating advanced technologies like the Internet of Things (IoT), artificial intelligence (AI), cloud computing, and cyber-physical systems. This paradigm shift emphasizes interconnectedness, real-time data analysis, and decentralized decision-making, moving away from traditional, siloed production lines. For metal fabrication, this means a significant transformation in how processes are managed, from raw material handling to final product delivery. Consider the automotive industry, which has embraced Industry 4.0 to achieve highly flexible production lines capable of mass customization. Similarly, the aerospace sector utilizes digital twins and predictive maintenance, drastically reducing downtime. These real-world applications underscore the immense potential of Industry 4.0 to drive efficiency, reduce costs, and foster innovation across various industrial domains, fundamentally changing how we approach manufacturing operations.

What is Industry 4.0 and its significance in modern manufacturing?

Are you struggling to grasp the true meaning of Industry 4.0 beyond the buzzwords? Many manufacturers face this dilemma, unsure of its tangible benefits. We understand the confusion and the need for clear insights.

Industry 4.0 represents the convergence of digital and physical technologies in manufacturing, creating smart factories. Its significance lies in enabling real-time data exchange, automation, and intelligent decision-making, leading to enhanced productivity, flexibility, and optimized resource utilization across production processes.

Understanding Industry 4.0 isn't just about knowing its definition; it's about recognizing its profound impact on the entire manufacturing ecosystem. This shift is not merely an incremental improvement but a fundamental re-imagining of how products are designed, produced, and delivered. It transforms traditional workflows into interconnected, intelligent systems, offering unparalleled opportunities for efficiency and innovation. As we delve deeper, we'll uncover the core components and overarching significance of this revolutionary paradigm.

The Pillars of Industry 4.0

Industry 4.0 is built upon several foundational pillars, each contributing to the creation of a smart, interconnected manufacturing environment. These include the Internet of Things (IoT), where machines, products, and components are embedded with sensors and connectivity, allowing them to communicate and exchange data in real-time. This interconnectedness forms the backbone of smart factories, enabling a continuous flow of information. Complementing IoT are cyber-physical systems (CPS)2, which are mechanisms controlled by computer-based algorithms, tightly integrated with the internet and its users. These systems bridge the gap between the physical and digital worlds, allowing for real-time monitoring and control of production processes. For instance, in a large-scale metal fabrication plant, IoT sensors on cutting machines can transmit data on operational parameters, while CPS can then adjust machine settings autonomously to optimize output, reducing human intervention and errors.

Another crucial pillar is Big Data and Analytics. The sheer volume of data generated by interconnected devices in an Industry 4.0 environment requires sophisticated analytical tools to extract meaningful insights. This data can be used for predictive maintenance, quality control, and optimizing supply chains. For example, by analyzing historical performance data from tube laser cutting machines, manufacturers can anticipate potential component failures before they occur, scheduling maintenance proactively and minimizing costly downtime. Research from McKinsey & Company indicates that companies leveraging big data analytics can see up to a 10% improvement in operational efficiency and a 15% reduction in production costs. This data-driven approach moves manufacturing from reactive problem-solving to proactive optimization.

Cloud computing and cybersecurity are also indispensable to Industry 4.0. Cloud platforms provide the scalable infrastructure necessary to store and process the vast amounts of data generated, enabling accessibility from anywhere. This is particularly vital for global operations and distributed teams, allowing for collaborative decision-making and remote monitoring. However, with increased connectivity comes heightened cybersecurity risks. Protecting sensitive manufacturing data and intellectual property from cyber threats is paramount. Robust cybersecurity protocols are essential to ensure the integrity and reliability of the entire Industry 4.0 ecosystem. A notable example is Siemens' MindSphere, an open IoT operating system that provides cloud-based data analytics and connectivity services for industrial applications, demonstrating how cloud computing supports Industry 4.0 while emphasizing the need for secure data environments.

| Pillar | Описание | Ключевые преимущества |

|---|---|---|

| Internet of Things (IoT) | Network of physical objects embedded with sensors, software, and other technologies for connecting and exchanging data with other devices and systems over the internet. | Real-time data collection, enhanced monitoring, improved asset utilization. |

| Cyber-Physical Systems (CPS) | Integration of computation, networking, and physical processes, allowing for control and monitoring of physical entities. | Automated control, increased precision, reduced human error. |

| Big Data & Analytics | Collection, processing, and analysis of large datasets to discover patterns and insights. | Predictive maintenance, optimized processes, informed decision-making. |

| Cloud Computing | On-demand availability of computer system resources, especially data storage and computing power, without direct active management by the user. | Scalability, remote access, cost efficiency. |

| Кибербезопасность | Protection of internet-connected systems from cyberattacks. | Data integrity, operational continuity, intellectual property protection. |

IoT enables real-time data exchangeПравда

IoT sensors on machines allow continuous communication and data sharing between devices in Industry 4.0 systems.

Industry 4.0 eliminates human workersЛожь

Industry 4.0 reduces human intervention but still requires skilled workers to oversee and manage automated systems.

How are tube laser cutting machines currently integrated into Industry 4.0 ecosystems?

Are you wondering how your existing tube laser cutting machines can truly become "smart" in an Industry 4.0 context? Many business owners, like Ahmed Al-Farsi, face this challenge, seeking practical integration methods. We understand this ambition to modernize.

Tube laser cutting machines integrate into Industry 4.0 through IoT sensors for real-time data collection, enabling predictive maintenance and performance monitoring. They utilize networked control systems for remote operation and automation, fostering seamless communication with other factory machinery and software platforms for optimized production workflows.

The integration of tube laser cutting machines into Industry 4.0 is not a futuristic concept; it's a current reality transforming shop floors worldwide. This integration moves beyond simple automation, leveraging connectivity and intelligence to unlock new levels of efficiency and capability. Let's delve into the specific ways these advanced machines are becoming central to the smart factory vision3, showcasing how they contribute to a more agile and data-driven manufacturing environment.

Real-time Data Exchange and Connectivity

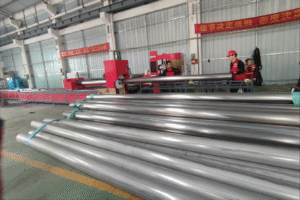

Modern tube laser cutting machines are equipped with an array of sensors that capture critical operational data in real-time. This includes parameters such as cutting speed, power consumption, material utilization, and machine health. This data is then transmitted through secure network connections, often utilizing industrial IoT protocols, to a central data platform or cloud-based system. For instance, at MZBNL, our machines feature advanced sensors that continuously monitor critical components, allowing for early detection of anomalies. This real-time data exchange enables immediate insights into production performance, facilitating proactive adjustments and problem-solving. This shift from reactive maintenance to predictive insights drastically reduces downtime and enhances overall equipment effectiveness (OEE).

Consider a scenario where a tube laser cutting machine experiences a slight deviation in cutting precision. With real-time data, this anomaly is immediately flagged, allowing operators or even automated systems to identify the root cause—perhaps a worn nozzle or a slight material inconsistency. This instantaneous feedback loop prevents costly scrap and ensures consistent quality. According to a report by Deloitte, companies that effectively utilize real-time data analytics in manufacturing can achieve up to a 20% improvement in product quality and a 15% reduction in waste. This level of data-driven control is a cornerstone of Industry 4.0, transforming how manufacturers manage their production processes and uphold product standards.

Automated Workflows and Remote Operation

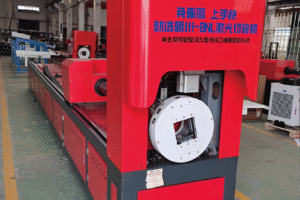

The integration of tube laser cutting machines into Industry 4.0 extends significantly into automated workflows and remote operational capabilities. This is where the true power of interconnected systems comes to life. Our BNL No-CAD Operating System exemplifies this by simplifying complex operations. Traditionally, creating or modifying 3D drawings was a time-consuming bottleneck. Now, with our system, standard tube types and hole patterns can be processed simply by entering parameters—no drawing required. This dramatically improves ease of use and shortens setup time, reducing the skill threshold for machine operation and enabling faster, more automated job processing. This level of automation means that a sequence of operations, from material loading (like our optimized front-feeding mechanism which increases efficiency by 40%) to cutting and unloading, can be orchestrated with minimal human intervention.

Moreover, the ability to monitor and control machines remotely provides unprecedented flexibility. For instance, a production manager can oversee multiple tube laser cutting machines across different locations from a central dashboard, making real-time adjustments and troubleshooting issues without being physically present on the factory floor. This capability is particularly beneficial for global enterprises like our client Ahmed Al-Farsi, who is expanding his business in the architectural metalwork and vehicle parts supply sectors. He values turnkey solutions that are easy to install and operate, and remote diagnostic capabilities are key for his distributed operations. This remote management not only enhances operational efficiency but also provides crucial support for business continuity, allowing for production adjustments to be made even outside of standard working hours. This level of automation and remote control exemplifies the agility and responsiveness central to Industry 4.0 principles, allowing businesses to adapt quickly to changing market demands and optimize resource allocation.

Predictive Maintenance and Enhanced Efficiency

One of the most significant benefits of integrating tube laser cutting machines into Industry 4.0 is the enablement of predictive maintenance. Instead of following fixed maintenance schedules or waiting for a breakdown to occur, machine health is continuously monitored using data from sensors. Algorithms analyze this data to identify patterns and predict potential failures before they happen. For example, our BNL machines can track spindle vibrations or laser power degradation over time, alerting operators to impending issues. This proactive approach allows maintenance to be scheduled precisely when needed, minimizing unexpected downtime and maximizing machine uptime. This is a crucial advantage for businesses like Ahmed's, where high operator turnover often leads to retraining burdens on complex machinery. By simplifying operation and anticipating maintenance needs, the overall cost of ownership is significantly reduced.

Furthermore, Industry 4.0 integration significantly enhances the overall efficiency of tube laser cutting operations. Through data analysis, bottlenecks in the production flow can be identified and eliminated. For instance, by optimizing cutting paths based on real-time material availability and order priorities, material waste can be significantly reduced. Our Zero-Waste Tail Material Innovation, which calculates from the rear chuck as the origin, eliminates leftover tail material as long as the remaining section is smaller than the product length, maximizing material utilization and boosting cutting efficiency. This intelligent optimization, driven by data, ensures that resources are utilized to their fullest potential, leading to substantial cost savings and increased throughput. This level of efficiency, coupled with reduced reliance on highly skilled CAD operators due to innovations like our No-CAD system, makes advanced manufacturing more accessible and profitable for a wider range of businesses, solidifying the economic advantages of Industry 4.0 integration.

IoT enables predictive maintenanceПравда

Sensors on tube laser cutters monitor machine health data to anticipate maintenance needs before failures occur.

Remote operation requires physical presenceЛожь

Industry 4.0 integration allows full machine monitoring and control through digital dashboards without being on-site.

What challenges do manufacturers face when aligning tube laser cutting machines with Industry 4.0 principles?

Are you finding the journey to Industry 4.0 more complex than anticipated, especially when integrating existing machinery? Many manufacturers, like our typical customer Ahmed, encounter hurdles such as data security and skill gaps. We understand these frustrations.

Manufacturers face challenges aligning tube laser cutting machines with Industry 4.0, including integrating legacy systems, ensuring data security, addressing skill gaps, and managing high initial investment costs. Interoperability issues between diverse software platforms and the complexity of data analysis also pose significant hurdles for successful implementation.

While the promise of Industry 4.0 is compelling, its implementation, particularly for specialized equipment like tube laser cutting machines, is not without its difficulties. The transition requires navigating a complex landscape of technological, organizational, and financial considerations. Understanding these challenges is the first step toward developing effective strategies for successful integration. Let's explore the common obstacles manufacturers encounter on their path to Industry 4.0 maturity.

Legacy System Integration and Interoperability

One of the most significant challenges manufacturers face when adopting Industry 4.0 principles for their tube laser cutting machines is the integration of legacy systems. Many existing machines, while still highly functional, were not designed with modern connectivity protocols4 in mind. This often leads to issues with data exchange and communication with newer, smart factory infrastructure. For example, older CNC machines might use proprietary communication protocols that are incompatible with standard IoT platforms, making it difficult to collect real-time performance data. This problem is particularly acute for established businesses like Ahmed Al-Farsi's, who are planning to automate existing manual workflows and have a mix of old and new equipment. Retrofitting older machines with sensors and communication modules can be costly and complex, often requiring specialized expertise.

Furthermore, ensuring interoperability between diverse software platforms is another hurdle. A typical manufacturing environment might use different software for CAD/CAM, ERP (Enterprise Resource Planning), MES (Manufacturing Execution System), and CRM (Customer Relationship Management). Achieving seamless data flow between these disparate systems and the data generated by tube laser cutting machines can be a monumental task. This fragmented IT landscape can hinder the holistic data analysis and automated decision-making that Industry 4.0 promises. Without robust interoperability, the full benefits of connected manufacturing, such as end-to-end process optimization and predictive maintenance, cannot be realized. Addressing this challenge often requires significant investment in middleware solutions, standardized APIs, and careful system architecture planning.

Data Security and Privacy Concerns

As tube laser cutting machines become more interconnected within an Industry 4.0 ecosystem, the volume of data generated and exchanged increases exponentially. This surge in data, while beneficial for optimization, simultaneously introduces significant cybersecurity risks5. Protecting sensitive manufacturing data, including proprietary designs, production processes, and customer information, from cyber threats becomes paramount. A breach could lead to intellectual property theft, operational disruption, or severe financial losses. For instance, a sophisticated cyberattack could manipulate machine parameters, leading to faulty products or even damage to the equipment itself. Ahmed Al-Farsi, valuing proven technology and global references, would certainly be concerned about the security of his data and operations.

Moreover, privacy concerns related to data collection and usage are also a critical consideration. While operational data from machines is vital for efficiency, issues surrounding data ownership, access, and compliance with data protection regulations (e.g., GDPR in Europe) must be carefully addressed. Manufacturers need to establish robust data governance frameworks to ensure that data is collected, stored, and utilized ethically and legally. This involves implementing strong encryption protocols, access controls, and regular security audits. The complexity of securing an entire connected factory, where every device could be a potential entry point for attackers, necessitates a comprehensive and multi-layered cybersecurity strategy, which can be a significant investment in both technology and expertise.

Skill Gaps and Workforce Readiness

The shift to Industry 4.0 demands a new set of skills from the manufacturing workforce, posing a significant challenge for many companies. Traditional roles focused on manual operation and mechanical maintenance are being replaced or augmented by roles requiring digital literacy, data analysis capabilities, and proficiency in operating smart technologies. For tube laser cutting machines, this means operators need to understand not just the mechanics of the machine but also how to interpret data from sensors, troubleshoot software issues, and interact with integrated systems. Ahmed Al-Farsi's concern about high operator turnover causing retraining burdens highlights this very issue. The simplicity of operation offered by our No-CAD system helps mitigate this, but broader digital skills are still crucial.

The existing workforce often lacks these advanced digital skills, creating a substantial skill gap that needs to be bridged through comprehensive training and upskilling programs. Investing in continuous education for employees is essential to ensure they can effectively operate, maintain, and innovate within an Industry 4.0 environment. This includes training in areas such as IoT platform management, data analytics tools, cybersecurity awareness, and advanced automation concepts. Without a skilled workforce capable of leveraging the new technologies, the full potential of Industry 4.0 integration for tube laser cutting machines cannot be realized. This human element is as critical as the technological investment, and neglecting it can severely hamper the success of digital transformation initiatives.

Legacy systems hinder Industry 4.0 integrationПравда

Older tube laser cutting machines often lack modern connectivity protocols, making data exchange with new smart factory systems difficult.

Cybersecurity risks decrease with Industry 4.0Ложь

Increased connectivity actually raises cybersecurity risks as more data is generated and exchanged, requiring stronger protection measures.

What solutions can enhance the integration of tube laser cutting machines within Industry 4.0 frameworks?

Are you seeking concrete strategies to seamlessly integrate your tube laser cutting machines into your Industry 4.0 vision? Many, like Ahmed, are looking for practical, easy-to-implement solutions to overcome integration hurdles. We provide clear pathways to achieve this.

Enhancing tube laser cutting machine integration into Industry 4.0 involves implementing IoT sensors for data, adopting modular software, leveraging cloud platforms, and investing in workforce upskilling. Solutions include retrofitting legacy machines, standardizing data protocols, and ensuring robust cybersecurity measures to foster seamless connectivity and intelligent automation.

The challenges of Industry 4.0 integration are real, but so are the innovative solutions available to overcome them. By strategically implementing key technologies and approaches, manufacturers can unlock the full potential of their tube laser cutting machines within a smart factory ecosystem. Let's explore the practical steps and technological advancements that can significantly enhance this integration, paving the way for more efficient, agile, and data-driven manufacturing operations.

Adopting Modular and Open Architecture Systems

A fundamental solution for enhancing Industry 4.0 integration of tube laser cutting machines lies in adopting modular and open architecture systems. This approach contrasts sharply with proprietary, closed systems that limit connectivity and data exchange. Open architecture allows different machines, software platforms, and devices to communicate seamlessly, fostering true interoperability. For instance, our MZBNL machines are designed with smart and digitalized systems that are inherently compatible with broader industrial networks. This means that data from the machine’s sensors can be easily integrated into a manufacturer's existing MES or ERP system, regardless of the vendor. This flexibility is crucial for businesses like Ahmed's, who prioritize turnkey solutions and expect customization.

Furthermore, modular design enables phased implementation and scalability. Instead of a costly and disruptive overhaul, manufacturers can integrate Industry 4.0 components incrementally, starting with critical areas and expanding as needed. This reduces the initial investment barrier and allows for a more controlled transition. Implementing standardized communication protocols like OPC UA6 ensures that data from the tube laser cutter can be understood and utilized by various applications across the factory floor and even beyond to supply chain partners. This creates a cohesive data ecosystem where insights from one part of the operation can inform and optimize others, leading to a truly integrated and responsive manufacturing environment.

Leveraging Cloud-Based Platforms and Edge Computing

The strategic use of cloud-based platforms combined with edge computing offers a powerful solution for optimizing data management and processing in Industry 4.0 environments with tube laser cutting machines. Cloud platforms provide scalable storage and computational power, enabling manufacturers to collect, store, and analyze vast amounts of data from their machines without significant on-premise infrastructure investment. This allows for advanced analytics, predictive modeling, and remote monitoring capabilities. For instance, a cloud platform can host an AI algorithm that continuously analyzes cutting data from multiple machines, identifying efficiency improvements or predicting maintenance needs across an entire fleet. This is especially beneficial for companies with distributed operations or those looking to expand globally, like MZBNL with its main export countries including Southeast Asia, Middle East, Europe, and North America.

Edge computing complements cloud platforms by processing data closer to the source—at the machine level or on the factory floor. This reduces latency, minimizes bandwidth usage, and ensures real-time responsiveness for critical operations. For example, an edge device connected to a tube laser cutting machine can perform immediate data validation and pre-processing, sending only aggregated or critical data to the cloud for deeper analysis. This hybrid approach optimizes data flow and enables rapid decision-making, which is vital for high-speed, high-precision cutting operations. For Ahmed Al-Farsi, who is interested in becoming a regional distributor, reliable remote diagnostics and spare parts availability, facilitated by cloud and edge computing, would be key considerations. The ability to quickly identify and resolve issues, even from a distance, significantly enhances operational continuity and service support, a major pain point for him with previous suppliers.

Workforce Development and Collaborative Ecosystems

Addressing the skill gap through robust workforce development programs is a critical solution for successful Industry 4.0 integration of tube laser cutting machines. This involves investing in continuous training and upskilling initiatives that equip employees with the digital literacy, data analysis skills, and technical expertise required to operate and maintain smart machinery. Our BNL No-CAD Operating System, which reduces operator training from 15 days to just 1 day, exemplifies a design philosophy that simplifies machine operation, thereby easing the burden of training. However, broader skills in connectivity, data interpretation, and cybersecurity remain essential. Companies can partner with educational institutions or technology providers to develop customized training modules, ensuring their workforce is prepared for the evolving demands of smart manufacturing. This proactive approach to talent development ensures that the human element of Industry 4.0 is as robust as the technological infrastructure.

Furthermore, fostering collaborative ecosystems is vital. This involves engaging with technology providers, system integrators, and even competitors to share best practices, develop industry standards, and co-create innovative solutions. For MZBNL, our business model focuses on integrated R&D, manufacturing, sales, and service, with a strong emphasis on technological innovation and tailored solutions. This collaborative approach extends to working with our clients, understanding their unique needs, and providing customized solutions and post-sales training/support. By participating in industry forums and B2B platforms, companies can leverage collective knowledge and accelerate their Industry 4.0 journey. Ahmed's preference for suppliers with proven technology and global references, and his interest in co-branding or exclusive distribution rights, highlights the value of strong supplier partnerships and a collaborative ecosystem for long-term success. This synergy between technology adoption and human capital development, within a collaborative framework, is essential for unlocking the full potential of Industry 4.0.

Open architecture enables interoperabilityПравда

Modular open systems allow different machines and software to communicate seamlessly, unlike proprietary closed systems.

Edge computing replaces cloud platformsЛожь

Edge computing complements cloud platforms by processing data locally while still utilizing cloud for deeper analysis.

What strategic approaches can optimize tube laser cutting machine operations in Industry 4.0 environments?

Are you looking for strategic ways to maximize the potential of your tube laser cutting machines within your Industry 4.0 framework? Many manufacturers, including discerning buyers like Ahmed, seek optimized operations that deliver tangible results. We offer proven strategies to achieve this.

Strategic approaches to optimize tube laser cutting in Industry 4.0 include data-driven decision-making for predictive maintenance and quality control, integrating machines into a centralized digital twin for simulation and optimization, and implementing flexible, adaptive manufacturing systems. This maximizes efficiency, reduces waste, and enhances overall productivity.

Optimizing tube laser cutting machine operations within an Industry 4.0 environment goes beyond mere integration; it involves a strategic re-thinking of how these machines contribute to the broader manufacturing goals. It's about leveraging the interconnectedness and intelligence to unlock peak performance, agility, and profitability. Let's delve into the strategic approaches that can transform your tube laser cutting operations into a truly optimized and future-ready asset.

Implementing Predictive Analytics for Proactive Maintenance

A key strategic approach to optimize tube laser cutting machine operations in an Industry 4.0 environment is the robust implementation of predictive analytics for proactive maintenance. Rather than adhering to fixed maintenance schedules or waiting for equipment failure, predictive analytics leverages real-time data from sensors on the machines to anticipate potential issues before they occur. For example, our BNL Laser Tube Cutting Machines are designed with smart and digitalized systems that can continuously monitor parameters like laser power output, cooling system efficiency, and motor vibrations. By analyzing trends in this data, the system can predict when a component is likely to degrade or fail, allowing maintenance to be scheduled precisely when needed, minimizing unexpected downtime. This proactive approach significantly reduces maintenance costs and extends the lifespan of critical components.

Consider the common pain point Ahmed Al-Farsi faced with previous machines: lack of local service support and long machine lead times affecting project delivery. With predictive maintenance capabilities, potential issues are identified early, allowing for timely ordering of spare parts and scheduling of repairs without disrupting production. This avoids costly emergency repairs and ensures continuous operation, enhancing overall productivity and reliability. According to a report by Accenture on predictive maintenance7, predictive maintenance can reduce maintenance costs by 10% to 40% and improve asset availability by 5% to 20%. This data-driven strategy not only optimizes machine uptime but also contributes to higher output quality by ensuring that machines are always operating within optimal parameters, a critical factor for businesses delivering finished parts to builders, decorators, and OEMs.

Leveraging Digital Twins for Simulation and Optimization

The creation and utilization of digital twins represent a powerful strategic approach for optimizing tube laser cutting machine operations in an Industry 4.0 context. A digital twin is a virtual replica of a physical asset, process, or system. For a tube laser cutting machine, this means creating a precise digital model that mirrors its physical counterpart in real-time, receiving data from its sensors. This digital twin can then be used to simulate various scenarios, test new cutting parameters, and optimize production processes without affecting the actual machine's operation. For instance, before a new product design is sent to the physical machine, its cutting paths and material utilization can be simulated on the digital twin to identify any inefficiencies or potential errors. This "try before you buy" approach dramatically reduces material waste and setup times.

Moreover, digital twins enable continuous optimization. By feeding real-time operational data back into the digital model, it can learn and adapt, continuously refining its simulations and recommendations. This allows for predictive optimization of schedules, material flow, and energy consumption. For Ahmed's business, which prioritizes high cost-performance ratio and seeks automated solutions to upgrade production efficiency, a digital twin can be invaluable. It can simulate the impact of integrating a new laser tube cutting machine with existing punching capabilities, ensuring seamless workflow and maximizing throughput. The ability to virtually experiment and fine-tune operations before physical implementation reduces risks, accelerates innovation, and ensures that the physical machine is always operating at its peak efficiency, delivering tailored solutions and maximizing output for contract-based fabrication services.

Implementing Flexible and Adaptive Manufacturing Systems

A crucial strategic approach for optimizing tube laser cutting operations in Industry 4.0 is the implementation of flexible and adaptive manufacturing systems8. This goes beyond just automating individual machines; it involves creating a dynamic and responsive production environment that can quickly adapt to changing market demands, product variations, and unforeseen disruptions. For tube laser cutting machines, this means integrating them into a broader system that can automatically reconfigure production lines, adjust cutting programs, and manage material flow based on real-time orders and inventory levels. Our BNL machines are designed with multi-process integration capabilities, offering cost-effective customized solutions that fit into such flexible systems.

This flexibility is particularly valuable for businesses like Ahmed's, which are actively expanding into diverse sectors such as architectural metalwork and vehicle parts supply. The ability to seamlessly switch between producing custom railing components and mass-producing automotive parts without significant retooling or downtime provides a substantial competitive advantage. This adaptability is driven by data-driven insights and advanced automation, allowing the entire factory to operate as a cohesive, intelligent unit. For example, if there's a sudden surge in demand for a specific type of tube, the system can automatically prioritize those orders, adjust machine schedules, and even order additional raw materials through an integrated supply chain. This level of responsiveness minimizes lead times, optimizes resource allocation, and allows manufacturers to thrive in a volatile market, ensuring they can deliver finished parts efficiently and profitably.

Predictive analytics prevents downtimeПравда

Predictive analytics uses real-time data to anticipate maintenance needs before failures occur, significantly reducing unplanned downtime.

Digital twins replace physical machinesЛожь

Digital twins are virtual replicas used for simulation and optimization, but they don't replace the need for actual physical machines in production.

Заключение

The integration of tube laser cutting machines into Industry 4.0 is not merely an upgrade but a transformative leap. By embracing data-driven insights, advanced automation, and flexible systems, manufacturers can unlock unprecedented efficiency, optimize operations, and secure a competitive edge in the evolving landscape of smart manufacturing.

-

Understand Industry 4.0's broad influence on productivity and innovation ↩

-

Explore the role of CPS in bridging digital and physical manufacturing ↩

-

Discover how these machines enhance production agility and data-driven manufacturing ↩

-

Discover how standard protocols improve data communication and machine integration ↩

-

Explore advanced cybersecurity measures to protect manufacturing systems and data ↩

-

Discover how OPC UA facilitates seamless communication within smart factories ↩

-

Learn how predictive analytics can transform maintenance strategies and operational efficiency ↩

-

Explore dynamic strategies for responsive production and inventory management in competitive markets ↩

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.