2025 Тенденции в области станков для резки металлических труб, о которых вы должны знать

Are you struggling to keep pace with rapid advancements in metal fabrication? The landscape of tube cutting technology is evolving dramatically, and staying informed is crucial for competitiveness. Discover the critical trends shaping the industry in 2025 and beyond.

The metal tube cutting machine industry in 2025 is set to be characterized by advancements in automation, AI integration, and sustainable practices. These trends aim to boost efficiency, reduce waste, and lower operational costs for manufacturers globally.

As someone deeply embedded in the metal fabrication industry, I’ve witnessed firsthand the transformative power of innovation. The upcoming trends in tube cutting machines aren't just incremental improvements; they represent a fundamental shift that will redefine productivity and profitability for businesses like yours and mine.

In my 25 years of experience at MZBNL, a high-tech enterprise with over 30 patents and 4000 global enterprise clients, I've observed that the metal tube cutting industry is at a pivotal crossroads. Traditional methods, while once sufficient, are increasingly becoming bottlenecks in a world demanding higher precision, speed, and efficiency. The shift towards интеллектуальные, цифровые системы1 is not merely a technological upgrade but a strategic imperative for survival and growth. We must critically assess how these emerging trends will impact operational workflows, material management, and workforce development. For instance, the push towards integrating AI and automation, while offering immense benefits in terms of throughput and accuracy, also necessitates a re-evaluation of current skill sets and training methodologies. This evolution demands that we, as industry leaders and participants, adopt a forward-thinking approach, continuously investing in R&D and tailored solutions, much like MZBNL does, to remain at the forefront of innovation.

Background introduction: How has the metal tube cutting machine industry evolved over the years?

Have you ever considered how far metal tube cutting has come? From rudimentary methods to sophisticated laser systems, the industry's journey reflects a relentless pursuit of precision and efficiency. Let's explore its fascinating evolution.

The metal tube cutting industry has evolved from manual, labor-intensive processes to highly automated and intelligent laser systems. Early methods prioritized basic shaping, while modern innovations focus on precision, speed, and integrated digital control for complex geometries.

Tracing the lineage of metal tube cutting machines2 reveals a compelling narrative of continuous innovation driven by evolving industrial demands. From my perspective at MZBNL, having seen decades of this transformation, it’s clear that each era built upon the last, progressively tackling challenges related to accuracy, speed, and material handling. Understanding this historical context isn't just an academic exercise; it provides crucial insights into why today's machines are designed the way they are, and what capabilities we can expect to see integrated into future iterations for a company like Ahmed Al-Farsi’s, who is looking to upgrade his production efficiency from manual workflows.

The journey of metal tube cutting machines from their humble beginnings to the high-tech marvels we see today is a testament to human ingenuity and the relentless pursuit of industrial efficiency. This evolution can broadly be categorized into distinct phases, each marked by significant technological leaps that addressed the prevailing challenges of their time. For instance, early fabrication was almost entirely reliant on manual labor, a situation still faced by some businesses today, like Ahmed's, who is actively planning to automate his existing manual workflows.

Early Manual Processes: The Foundation of Fabrication

In the earliest days of metal fabrication, tube cutting was largely a manual, labor-intensive process, relying on basic tools like hacksaws, band saws, or abrasive cutting wheels. This approach, while simple and low-cost in terms of initial investment, suffered from significant drawbacks in terms of accuracy, consistency, and speed. Quality was highly dependent on operator skill, and production rates were inherently slow, making large-scale manufacturing impractical. Material waste was also a considerable issue, as precise cuts were difficult to achieve, leading to higher scrap rates.

From a business perspective, the limitations of manual processes meant higher labor costs per unit, longer lead times, and an inability to meet the increasingly stringent quality requirements of industries like automotive and construction. This created a strong demand for more efficient and precise methods, paving the way for the first wave of automation.

Even today, in some smaller workshops or for highly specialized, low-volume tasks, manual cutting still exists. However, its inherent inefficiencies mean that any business aiming for scalability, consistent quality, or competitive pricing must move beyond these foundational methods. The desire to overcome these inherent limitations became the driving force for subsequent technological advancements.

The Semi-Automated Era: Introducing Mechanical Advantage

The late 20th century saw the emergence of semi-automated solutions, which began to integrate mechanical power and rudimentary control systems into the cutting process. This phase introduced machines like hydraulic shears, circular saws with automated feeding mechanisms, and early plasma or oxy-fuel cutting systems. These innovations significantly improved cutting speed and consistency compared to purely manual methods. Operators still played a crucial role in machine setup, material handling, and quality control, but the physical labor was greatly reduced, and production throughput saw a noticeable increase.

This era marked the beginning of specialized machinery for tube cutting, moving beyond general-purpose metalworking tools. The introduction of these machines allowed for greater uniformity in cuts and a reduction in operator fatigue, translating into more predictable output. For companies transitioning from purely manual operations, these semi-automated machines represented a substantial leap in productivity and laid the groundwork for future digital integration.

However, these systems often lacked the precision required for intricate designs or the flexibility to handle diverse tube geometries without extensive manual adjustments. The reliance on operator expertise for programming and fine-tuning remained a bottleneck, highlighting the need for more intelligent and autonomous solutions. Businesses began to recognize that while speed had improved, true efficiency and versatility still remained elusive.

The Rise of Digitalization: Precision and Integration

The turn of the millennium ushered in the era of digitalization, spearheaded by the widespread adoption of CNC (Computer Numerical Control) technology and, most notably, laser cutting. This phase has been revolutionary, transforming tube cutting into a highly precise, versatile, and automated process. CNC laser tube cutting machines can handle complex geometries, intricate cuts, and multiple processes (like cutting, drilling, and marking) in a single setup, with minimal human intervention. Data-driven design and real-time process monitoring became standard.

At MZBNL, our 25 years of experience have shown us that this shift is profoundly impactful. Our No-CAD Operating System, for example, is a direct response to the pain points of this digital age, where traditional CAD-dependent systems created inefficiencies for operators like Ahmed's team. By allowing simple parameter entry, we've reduced setup time and lowered the skill threshold, dramatically improving ease of use and cutting down operator training from 15 days to just 1 day on-site. This innovation perfectly exemplifies the industry's shift towards smarter, more user-friendly, and integrated solutions, addressing the core needs of modern metal fabrication businesses for high-speed, high-precision, and cost-effective customized solutions, making them a preferred choice in demanding markets like Southeast Asia, the Middle East, Europe, and North America.

This continuous drive for higher precision, efficiency, and intelligence in tube cutting is why companies like MZBNL lead the industry, offering solutions that maximize material utilization, enhance productivity, and support global enterprise clients in automating their operations. The integration of advanced sensors, robotics, and sophisticated software has made today's machines incredibly powerful, laying the groundwork for the even more advanced trends we expect to see by 2025.

Laser cutting improved precisionПравда

CNC laser tube cutting machines enabled complex geometries and multiple processes with minimal human intervention, significantly improving precision compared to manual methods.

Manual cutting was more efficientЛожь

Manual processes were slower, less consistent, and produced more material waste than automated solutions, making them inherently less efficient for production.

Current situation: What is the current state of technology in metal tube cutting machines?

Ever wondered what’s powering today's most advanced tube cutting operations? Current technology is revolutionizing efficiency and precision like never before. I'll take you through the innovations setting new industry benchmarks.

The current state of metal tube cutting machine technology is characterized by sophisticated laser capabilities, integrated smart systems, and user-centric designs. These advancements enable high-speed, high-precision, and multi-process integration, significantly boosting productivity and material utilization in manufacturing.

Having navigated the complexities of metal fabrication for decades, I've observed that the current technological landscape in metal tube cutting machines is nothing short of revolutionary. We're witnessing an unprecedented convergence of cutting-edge laser technology, smart digital systems, and innovative design philosophies that are reshaping how metal pipes are processed globally. For clients like Ahmed Al-Farsi, who prioritize turnkey solutions that are easy to install and operate, understanding these advancements is key to making informed investment decisions. My company, MZBNL, is at the forefront of this evolution, developing proprietary solutions that address long-standing industry pain points, ensuring our clients receive machines that are not just high-performing but also remarkably user-friendly and efficient, leading the industry with three major innovations in particular.

The contemporary metal tube cutting machine industry is defined by an impressive array of technological advancements that have fundamentally transformed fabrication processes. From my vantage point at MZBNL, where we integrate R&D, manufacturing, sales, and service, I can confidently state that today's machines are intelligent, efficient, and increasingly autonomous, offering capabilities that were once unimaginable. This era is marked by a focus on maximizing output while minimizing waste and operational complexity, directly addressing the demands of our 4000+ глобальных корпоративных клиентов3.

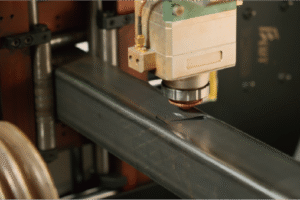

Advanced Laser Capabilities: Precision and Speed Redefined

At the core of modern tube cutting machines are advanced laser capabilities, primarily fiber laser technology, which has become the gold standard due to its exceptional power, precision, and efficiency. Fiber lasers offer superior beam quality, allowing for incredibly narrow kerf widths and highly accurate cuts on a wide range of materials, including stainless steel, carbon steel, aluminum, and brass, all of which are crucial for our customers in automotive parts and architectural metalwork. This precision minimizes material deformation and creates clean edges, often eliminating the need for secondary finishing processes, which directly translates to cost savings and faster production cycles for our clients.

Furthermore, the high-speed cutting capabilities of fiber lasers significantly reduce production times. For a business like Ahmed's, which handles contract-based fabrication services for railings and auto parts, increased cutting speed directly impacts project delivery times and overall profitability. Our MZBNL machines are specifically designed for high-speed and high-precision cutting, enabling quick turnaround on orders and boosting competitiveness in demanding markets. This is critical when you're delivering finished parts to builders, decorators, and OEMs, where deadlines are tight and quality is paramount.

The versatility of these advanced laser systems also means they can perform complex geometries and intricate designs that were previously impossible or extremely difficult with traditional methods. This opens up new possibilities for product design and customization, allowing manufacturers to create more innovative and value-added products, meeting the diverse needs of sectors ranging from furniture to medical equipment.

Integrated Smart Systems: Beyond Simple Cutting

The current generation of tube cutting machines are no longer just cutting tools; they are integrated smart systems. This integration involves sophisticated CNC controllers, advanced software, and a network of sensors that enable real-time monitoring, diagnostics, and intelligent process optimization. At MZBNL, our focus on smart and digitalized systems is a cornerstone of our product philosophy. This is precisely what clients like Ahmed are looking for, as he actively pursues automated solutions to upgrade production efficiency.

A prime example of this is the push towards "start cutting without CAD drawings," a revolutionary feature pioneered by MZBNL with our No-CAD Operating System. Traditionally, operators like those at Ahmed's factory faced the pain point of requiring skilled CAD operators and experiencing high operator turnover, leading to retraining burdens. Our No-CAD system dramatically simplifies operations: standard tube types and hole patterns can be processed by simply entering parameters, reducing training time from 15 days at the factory to just 1 day of on-site training. This innovation not only makes the machines easy to operate but also significantly lowers the skill threshold, addressing a major industry challenge head-on.

Moreover, features like automatic feeding and multi-process integration—which combine cutting with punching or drilling—mean that a single machine can perform multiple operations, reducing handling, improving accuracy, and streamlining the entire workflow. Our Front-Feeding Innovation, for instance, increases feeding efficiency by about 40% and reduces operator labor intensity by approximately 40%, directly enhancing overall productivity and workplace ergonomics, a significant benefit for any metal pipe processing factory.

User-Centric Design: Simplifying Complex Operations

While technology has become more complex, the trend in machine design has paradoxically shifted towards user-friendliness. The goal is to make these powerful machines accessible to a wider range of operators, minimizing the need for highly specialized skills. This user-centric approach is critical for businesses in countries like the UAE, where skilled labor can be a challenge. At MZBNL, we've invested heavily in this area, recognizing that ease of operation is a key purchasing preference for clients like Ahmed, who values turnkey solutions.

Our Zero-Waste Tail Material Innovation exemplifies this design philosophy. Conventional systems often leave unusable tail material, leading to waste. Our redesigned cutting logic, which calculates from the rear chuck as the origin, eliminates leftover tail material as long as the remaining section is smaller than the product length. This design choice directly addresses material utilization pain points, boosting cutting efficiency and maximizing profitability without requiring complex adjustments from the operator. It reflects a deep understanding of practical operational challenges and a commitment to providing solutions that are not only technologically advanced but also intuitively designed for real-world application.

This commitment to ease of use, coupled with high cost-performance ratio and robust post-sales training and support, positions companies like MZBNL as preferred suppliers for sophisticated clients like Ahmed, who are looking to automate their existing manual workflows and ensure spare parts availability and remote diagnostics, ensuring long-term operational success and potentially even considering regional distribution partnerships. The current state of tube cutting technology is about empowering manufacturers with intelligent, efficient, and remarkably easy-to-use solutions.

Fiber lasers are the gold standardПравда

Fiber laser technology is currently the industry benchmark for metal tube cutting due to its superior precision and efficiency.

CAD drawings are always requiredЛожь

Advanced systems like MZBNL's No-CAD Operating System allow cutting without traditional CAD drawings by using parameter inputs.

Challenges analysis: What are some existing challenges facing the metal tube cutting industry?

Despite advancements, the metal tube cutting industry faces significant hurdles. Are you grappling with rising costs, skill gaps, or efficiency bottlenecks? I'll analyze the pressing challenges demanding innovative solutions.

The metal tube cutting industry faces persistent challenges including a shortage of skilled operators, high material waste impacting costs, and bottlenecks in operational efficiency. These issues necessitate innovative solutions focused on automation, optimized material utilization, and streamlined workflows to maintain competitiveness.

While the current technological landscape of metal tube cutting machines offers incredible capabilities, it would be disingenuous to overlook the persistent challenges that continue to face the industry. From my discussions with countless clients, including decision-makers like Ahmed Al-Farsi, it's clear that despite advancements, several pain points remain critical. These are not merely technical glitches but systemic issues that impact profitability, productivity, and the ability to scale operations effectively. Addressing these challenges requires more than just faster machines; it demands holistic solutions that integrate smart technology4 with practical operational strategies, something MZBNL is deeply committed to providing through our tailored solutions and comprehensive support.

Despite remarkable progress in laser technology and automation, the metal tube cutting industry continues to grapple with a set of deeply entrenched challenges. These issues are not theoretical; they are daily realities for manufacturers globally, impacting everything from profit margins to lead times. Through my work with MZBNL's diverse clientele5, from furniture manufacturers to automotive parts producers, I've identified several key pain points that demand innovative and integrated solutions. These challenges often compound each other, creating a complex web of obstacles for businesses striving for efficiency and competitiveness.

Skilled Labor Shortage & Training Burden: A Growing Dilemma

One of the most critical and pervasive challenges facing the metal tube cutting industry is the increasing shortage of skilled labor, particularly operators proficient in complex CAD programming and machine operation. This issue is something I frequently hear from clients like Ahmed Al-Farsi. He explicitly mentioned that his "previous machines required skilled CAD operators" and that "high operator turnover caused retraining burdens" for his 100+ staff. The demand for highly specialized technical skills often outpaces the supply of trained professionals, leading to significant recruitment difficulties and escalating labor costs.

Even when new operators are hired, the traditional learning curve for mastering sophisticated CNC laser tube cutting machines can be extensive, often requiring weeks or even months of intensive training. This extended training period translates directly into lost productivity, increased training expenses, and a higher risk of operational errors. The high operator turnover rates further exacerbate this problem, creating a perpetual cycle of recruitment and retraining that drains resources and disrupts workflow. For a business seeking to automate existing manual workflows, this skill gap presents a formidable barrier6.

At MZBNL, we recognized this critical pain point early on, which led us to pioneer our No-CAD Operating System. This innovation directly addresses the skilled labor shortage by dramatically simplifying machine operation. By allowing standard tube types and hole patterns to be processed through simple parameter entry—no complex 3D drawing required—we've reduced the skill threshold for machine operation. Consequently, new operators now only need 1 day of on-site training instead of the traditional 15 days at the equipment factory, a game-changer for businesses like Ahmed's that value ease of use and seek to minimize retraining burdens. This approach not only makes our machines easier to operate but also helps mitigate the impact of operator turnover, ensuring smoother and more continuous production.

Material Waste & Cost Pressures: The Silent Profit Drain

Another significant challenge is the ongoing issue of material waste and its direct impact on operational costs. Conventional laser cutting systems often start cutting from the tube head, which invariably generates unusable tail material at the end of the process. This leftover material, though seemingly small per cut, accumulates rapidly in high-volume production environments, leading to substantial financial losses over time. For businesses operating on contract-based fabrication services, where material costs are a major component, every inch of wasted material directly erodes profit margins.

Furthermore, inefficient nesting strategies or imprecise cutting can lead to scrap parts that fail quality control, necessitating re-fabrication and further increasing material consumption. With fluctuating metal prices in global markets, maximizing material utilization is not just a best practice; it's an economic imperative. The pressure to reduce production costs while maintaining high quality is constant, making waste reduction a top priority for any competitive manufacturer.

MZBNL's Zero-Waste Tail Material Innovation directly tackles this pervasive problem. We redesigned the cutting logic to calculate from the rear chuck as the origin. This allows the system to eliminate leftover tail material as long as the remaining section is smaller than the product length. This patented "zero-tail" design maximizes material utilization, significantly reduces scrap, and boosts cutting efficiency. For a business like Ahmed's, which produces high volumes of railings, shelving, and auto parts, this innovation translates into tangible cost savings and improved profitability, a clear example of how technological solutions can directly address financial pain points.

Operational Efficiency Bottlenecks: Hindering Productivity

Even with advanced cutting capabilities, many metal tube cutting operations face significant bottlenecks in overall operational efficiency. These bottlenecks often stem from inefficient material handling, excessive manual intervention, and sub-optimal workflow integration. Traditional machines that rely on side or rear manual loading require considerable operator effort and time to load and position tubes, creating a non-value-added delay in the production cycle. This high labor intensity not only reduces feeding efficiency but also contributes to operator fatigue and potential workplace injuries.

Moreover, a lack of seamless integration between different stages of the fabrication process—such as design, cutting, and subsequent processing—can lead to communication breakdowns, data transfer errors, and increased setup times. These inefficiencies result in lower throughput, increased lead times, and an inability to adapt quickly to changing production demands, impacting project delivery and overall customer satisfaction. Ahmed's preference for turnkey solutions that are easy to install and operate underscores the industry's need for streamlined, end-to-end efficiency.

At MZBNL, our Front-Feeding Innovation directly addresses these operational bottlenecks. While traditional machines rely on manual loading, our optimized front-feeding mechanism automatically pulls the tube in from the front of the machine. This design increases feeding efficiency by about 40% and reduces operator labor intensity by approximately 40%, significantly enhancing overall productivity and workplace ergonomics. This innovation, combined with our machines' high-speed and high-precision cutting capabilities, ensures that our clients can achieve maximum output with minimal effort, transforming their production lines into highly efficient and productive operations. This systematic approach to overcoming challenges is why MZBNL maintains a leading position, offering solutions that genuinely improve the operational realities of our diverse global clientele.

| Категория вызова | Традиционный подход | MZBNL Innovation (Solution) | Impact on Businesses Like Ahmed's |

|---|---|---|---|

| Skilled Labor & Training | Requires 15 days of factory training for CAD operators | No-CAD Operating System; 1 day on-site training | Reduced operator training burden, addressed turnover issues |

| Использование материалов | Unusable tail material, significant waste | Инновационный безотходный хвостовой материал | Maximized material utilization, boosted efficiency |

| Operational Efficiency | Manual side/rear loading, high labor intensity | Front-Feeding Innovation (40% efficiency boost, 40% labor reduction) | Increased productivity, improved workplace ergonomics |

Skilled labor shortage is a major challengeПравда

The industry faces significant difficulties in finding operators skilled in CAD programming and machine operation, leading to high training costs and productivity losses.

Material waste doesn't impact costsЛожь

Even small amounts of wasted material accumulate significantly in high-volume production, directly reducing profit margins especially with fluctuating metal prices.

Strategies for the future: What key strategies should industry players adopt to stay competitive?

How can you ensure your business thrives in a rapidly evolving market? Staying competitive in metal tube cutting demands strategic foresight and proactive adaptation. I'll outline essential strategies for future success.

To stay competitive, metal tube cutting industry players should embrace automation and AI, prioritize sustainable manufacturing practices, and strengthen global supply chains. These strategies foster efficiency, reduce environmental impact, and ensure resilient operations amidst market fluctuations.

The challenges we've discussed highlight a clear mandate for the future: stagnation is not an option. For businesses to not only survive but also flourish in the increasingly competitive metal tube cutting market, proactive and forward-thinking strategies are essential. As part of MZBNL, with our integrated R&D, manufacturing, sales, and service model, I constantly emphasize the importance of continuous innovation and adaptability. It's about building resilience and agility into our operations, allowing us to pivot quickly and capitalize on emerging opportunities, while also catering to the specific needs of our clients, like Ahmed Al-Farsi, who values suppliers with proven technology and global references.

In an industry as dynamic as metal tube cutting, simply maintaining the status quo is a recipe for obsolescence. To truly stay competitive and capitalize on the opportunities presented by new technologies, industry players must adopt a multi-faceted strategic approach. This involves not only technological upgrades but also a fundamental rethinking of operational philosophies, environmental responsibilities, and market engagement.

Embracing Automation & AI: The Path to Unprecedented Efficiency

The most crucial strategy for future competitiveness lies in the comprehensive adoption of automation and Artificial Intelligence (AI). This goes beyond merely installing a new machine; it involves integrating intelligent systems across the entire fabrication workflow. For instance, AI-driven software can optimize nesting patterns to minimize material waste even further than current capabilities, predict maintenance needs to prevent costly downtime, and even adapt cutting parameters in real-time based on material properties, ensuring consistent quality. This level of automation addresses critical pain points such as skilled labor shortages and operational bottlenecks.

For our clients at MZBNL, the transition to smarter automation, exemplified by our No-CAD system and automated feeding, is already proving its worth. Businesses like Ahmed's, which are looking to automate existing manual workflows, find immense value in solutions that simplify complex processes and reduce reliance on highly specialized human intervention. The next frontier involves AI-powered analytics that can identify inefficiencies in the production line, suggest workflow optimizations, and even autonomously manage material flow. Research indicates that AI integration in manufacturing can lead to a 15-20% improvement in overall equipment effectiveness (OEE) and a significant reduction in defects. This strategic embrace of AI will be the differentiator between merely functional operations and truly optimized, high-performance manufacturing.

However, embracing AI also means investing in the digital infrastructure to support it, including robust data collection and secure cloud solutions. It also necessitates upskilling the existing workforce to manage and interpret data from these smart systems, shifting roles from manual operators to system supervisors and analysts. This strategic move is not just about cutting costs but about unlocking new levels of precision, speed, and responsiveness to market demands.

Prioritizing Sustainable Practices: Responsibility Meets Profitability

As global environmental awareness intensifies, prioritizing sustainable manufacturing practices is no longer just an ethical choice but a strategic imperative. Consumers, regulators, and even B2B clients are increasingly scrutinizing the environmental footprint of their supply chains. For the metal tube cutting industry, this translates to focusing on energy efficiency, waste reduction, and the responsible sourcing of materials. Implementing solutions that minimize power consumption during operation, such as energy-efficient laser sources, will become standard.

Furthermore, strategies like MZBNL's Zero-Waste Tail Material Innovation are vital. By drastically reducing unusable material, we not only minimize waste disposal costs but also contribute to a greener manufacturing process. A recent industry report suggested that optimizing material utilization can reduce raw material costs by up to 10-15% for typical metal fabrication shops. This direct impact on profitability makes sustainability a compelling business case. Companies that can demonstrate a strong commitment to environmental responsibility will gain a significant competitive advantage, attracting environmentally conscious clients and complying with increasingly stringent regulations in markets like Europe and North America.

Beyond material waste, sustainable strategies include optimizing supply chain logistics to reduce carbon emissions from transportation, implementing robust recycling programs for scrap metal, and exploring the use of renewable energy sources for manufacturing facilities. Businesses that integrate sustainability into their core strategy will not only enhance their brand reputation but also build more resilient and future-proof operations capable of navigating evolving market and regulatory landscapes.

Strengthening Global Supply Chains & Support: Building Resilience

The past few years have underscored the fragility of global supply chains. For the metal tube cutting industry, a key strategy for future competitiveness involves strengthening and diversifying supply chains while ensuring robust global after-sales service and training support. Relying on a single source or region for critical components or raw materials poses a significant risk. Companies must proactively identify alternative suppliers and build resilient networks to mitigate potential disruptions, something that is particularly important for a business like Ahmed's, which sources from China, Germany, and Turkey.

Crucially, excellent after-sales service and training support are non-negotiable for success in the global market. Clients like Ahmed Al-Farsi value suppliers with proven technology and expect customization and post-sales training/support. He also explicitly mentioned that "equipment from some suppliers lacked local service support" and that "spare parts availability and remote diagnostics" are sourcing key points. For an international business like MZBNL, with a strong presence in Southeast Asia, the Middle East, Europe, and North America, establishing a robust global distributor network and providing accessible remote diagnostics is paramount. This ensures that clients receive timely technical assistance, spare parts, and ongoing training, minimizing downtime and maximizing machine uptime.

Furthermore, exploring opportunities for local agent or distributor presence, as Ahmed is considering for the Gulf region, can significantly enhance market reach and customer satisfaction. This localized support builds trust and provides a critical competitive edge. By focusing on resilient supply chains and unparalleled global service, industry players can build stronger customer relationships, enhance their market reputation, and ensure uninterrupted operations, fostering long-term growth and stability in an interconnected world.

AI improves manufacturing efficiencyПравда

AI integration can lead to 15-20% improvement in overall equipment effectiveness by optimizing workflows and reducing defects.

Sustainability increases costsЛожь

Sustainable practices like waste reduction can actually reduce raw material costs by 10-15% while improving brand reputation.

Technological suggestions: What are the potential technological innovations on the horizon for 2025?

What innovations will redefine metal tube cutting in the coming years? The future promises exciting breakthroughs. I'll share my insights on the potential technological advancements poised to emerge by 2025.

By 2025, potential technological innovations in metal tube cutting include AI-driven predictive maintenance, enhanced multi-process integration, and augmented reality for training and support. These advancements aim to elevate automation, improve uptime, and simplify complex operations in manufacturing.

Looking ahead to 2025, the trajectory of technological innovation in metal tube cutting machines is incredibly exciting. Building on the current state of smart, digitalized systems, the next wave of advancements promises to push the boundaries of what's possible, driving even greater efficiency, autonomy, and user accessibility. As someone who's seen MZBNL consistently innovate with features like No-CAD and Zero-Waste, I believe these upcoming technologies will solidify the industry’s shift towards truly intelligent manufacturing solutions, directly benefiting clients like Ahmed Al-Farsi who are seeking to further automate and optimize their operations.

The rapid pace of technological development ensures that the landscape of metal tube cutting machines will continue to evolve significantly by 2025. These impending innovations are not merely incremental upgrades; they represent fundamental shifts driven by the convergence of advanced computing, sensor technology, and robotics, all aimed at creating more intelligent, self-optimizing, and human-centric production environments. At MZBNL, our continuous R&D efforts are already laying the groundwork for many of these future capabilities, further solidifying our position as a leader in cost-effective customized solutions for our diverse clientele.

AI-Driven Predictive Maintenance: Maximizing Uptime and Efficiency

One of the most impactful innovations expected by 2025 is the widespread adoption of AI-driven predictive maintenance systems. Currently, maintenance is often reactive (after a breakdown) or preventive (scheduled, regardless of actual need). Предиктивное обслуживание7, powered by AI, leverages real-time data from machine sensors (vibration, temperature, power consumption, acoustics) to anticipate potential equipment failures before they occur. AI algorithms analyze vast datasets to identify subtle patterns that indicate impending issues, allowing for maintenance to be scheduled precisely when needed, minimizing unscheduled downtime.

For a busy metal fabrication business like Ahmed's, where uptime directly translates to profitability, this innovation is a game-changer. Imagine a scenario where the machine itself notifies you that a specific component shows early signs of wear, recommending a replacement during a planned shutdown, rather than failing unexpectedly mid-production. This capability can reduce maintenance costs by 20-30% and significantly improve overall equipment effectiveness (OEE). MZBNL's focus on smart and digitalized systems already provides the foundation for such capabilities, with remote diagnostics being a key feature clients look for.

The shift towards predictive maintenance will move the industry from a reactive repair model to a proactive, data-driven optimization strategy. This ensures higher machine availability, extends the lifespan of critical components, and ultimately leads to more consistent production schedules and improved customer satisfaction. It embodies the essence of smart manufacturing, where data intelligence drives operational excellence.

Enhanced Multi-Process Integration: Streamlining the Fabrication Workflow

By 2025, we can anticipate a much higher degree of multi-process integration within single tube cutting machines, moving beyond the current cutting and punching combinations. Future machines will likely incorporate advanced operations such as automated deburring, tapping, chamfering, or even robotic welding and assembly, all within a single, continuous workflow. This "one-stop-shop" approach for tube processing will drastically reduce the need for material handling between different workstations, minimizing potential errors, saving valuable floor space, and accelerating overall production cycles.

This level of integration is particularly beneficial for manufacturers producing complex components or finished products. For example, a furniture manufacturer could process a tube from raw stock to a ready-to-assemble component, complete with all necessary cuts, holes, and threads, without manual intervention for transfer between different machines. This dramatically improves throughput and consistency, reducing the risk of human error associated with multiple setups. From MZBNL's perspective, where we pride ourselves on multi-process integration, this future trend aligns perfectly with our vision of providing holistic and highly efficient solutions.

The challenge lies in the sophisticated software and robotics required to manage these diverse operations seamlessly. However, advancements in AI and machine learning will enable these integrated systems to autonomously optimize the sequence of operations, tooling changes, and part handling, delivering a truly streamlined fabrication workflow. This enhanced integration will redefine efficiency, allowing businesses to undertake more complex projects with fewer manual steps and greater precision, becoming indispensable for automotive and motorcycle parts producers seeking high levels of automation.

Augmented Reality (AR) for Training & Support: Empowering Operators

Another significant innovation on the horizon is the widespread application of Augmented Reality (AR)8 for machine training, troubleshooting, and remote technical support. Imagine operators wearing AR glasses that overlay digital instructions, diagrams, or real-time diagnostic information directly onto the machine's components. This technology can revolutionize how new operators are trained, making complex tasks intuitively understandable and significantly reducing the learning curve. For example, instead of just reading a manual, an operator could see animated arrows guiding them through a specific maintenance procedure overlaid on the actual machine part.

This direct, visual guidance can dramatically cut down training time and improve retention, directly addressing the pain point of operator turnover and extensive training burdens. For clients like Ahmed Al-Farsi, who value post-sales training and support, AR offers an unparalleled level of assistance. When a technical issue arises, a remote support engineer from MZBNL could, via AR, see exactly what the on-site operator sees, drawing virtual annotations or highlighting components in real-time, guiding them through troubleshooting steps without the need for an expensive and time-consuming on-site visit. This ensures spare parts availability and remote diagnostics become even more seamless.

Beyond training and support, AR can also enhance quality control by overlaying design specifications onto finished parts, allowing for instant visual verification of accuracy. This technology, combined with the increasing connectivity of machines (IoT), will create a more collaborative and efficient operational environment, empowering the workforce and ensuring maximum uptime. The integration of AR represents a leap forward in user interaction and service delivery, making advanced machinery more accessible and maintainable than ever before.

AI predicts maintenance needsПравда

AI-driven predictive maintenance uses real-time sensor data to anticipate equipment failures before they occur.

AR replaces all training methodsЛожь

While AR enhances training, it complements rather than replaces traditional training methods like manuals and hands-on practice.

Заключение

As Eric Liu from MZBNL, I’ve shared how the metal tube cutting industry is rapidly evolving towards greater automation, intelligence, and sustainability. Embracing innovations like No-CAD, Front-Feeding, and Zero-Waste is crucial for competitiveness. Proactive strategies and cutting-edge technologies are key to thriving in 2025 and beyond.

-

Learn how digital systems improve precision and efficiency in metal fabrication ↩

-

Understand the evolutionary phases and technological advancements in tube cutting machines ↩

-

Discover how cutting-edge machines enhance productivity and reduce waste ↩

-

Learn how smart technology can solve systemic issues in tube cutting operations. ↩

-

Discover the industries benefitting from MZBNL's laser cutting solutions. ↩

-

Gain insights into the challenges posed by skill shortages in metal cutting. ↩

-

Learn how AI predicts equipment failure to optimize maintenance and prevent downtime ↩

-

Explore how AR enhances operator training and remote technical support in factories ↩

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.