Real-World Use Cases of Metal Tube Cutting Machines in Construction Projects

Are you struggling with inefficient metal tube processing in your construction projects? The complexities of traditional methods often lead to costly delays and significant material waste. I’ve personally seen how these challenges can bottleneck progress and impact profitability in construction.

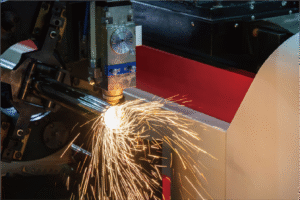

Metal tube cutting machines are vital in construction, enabling precise fabrication of structural elements, architectural features, and infrastructure components. They significantly enhance efficiency by automating complex cuts, improving material utilization, and reducing labor, directly supporting rapid project deployment and quality construction.

As project demands escalate and timelines tighten, relying on outdated methods for metal tube fabrication is no longer sustainable. Modern construction requires speed, precision, and material efficiency to stay competitive. Understanding how cutting-edge machinery revolutionizes these processes is crucial for any business aiming to optimize its operations and deliver superior results in today's dynamic building landscape.

Diving deeper, the transition from conventional manual or semi-automated tube cutting to fully automated laser systems represents a paradigm shift in construction1. I've observed a critical need for solutions that not only cut but also integrate seamlessly into a broader project workflow, addressing challenges like complex designs, tight tolerances, and diverse material requirements. Consider a project requiring intricate facade elements or bespoke railing systems; traditional methods are fraught with errors and delays. The strategic integration of advanced tube cutting machines, like those we develop at MZBNL, becomes indispensable. Our 25 years of experience, combined with a portfolio of 30+ patents, have shown me that these machines don't just cut—they redefine project timelines and quality standards, making complex architectural visions achievable with unprecedented efficiency.

What are some real-world examples of metal tube cutting machines in construction?

Are you curious about the practical applications of advanced metal tube cutting technology in construction? Manual cutting methods often fall short when dealing with complex geometries or high-volume production, leading to inconsistencies and extended fabrication times. I've heard countless stories of frustration from project managers dealing with these exact issues.

Metal tube cutting machines are extensively used in constructing intricate building frameworks, custom architectural features, robust bridge components, and essential infrastructure like HVAC systems and industrial piping, demonstrating their versatility and precision in diverse real-world construction scenarios.

From my vantage point, the sheer breadth of applications for modern metal tube cutting machines in construction is remarkable, spanning everything from the foundational skeleton of a skyscraper to the delicate filigree of a decorative balustrade. Imagine the complexity involved in creating custom staircases with spiral designs or the precision needed for large-scale steel bridge components. These machines are not just tools; they are the backbone of modern, efficient fabrication, enabling architects and engineers to push the boundaries of design. They bridge the gap between ambitious blueprints and tangible structures, making once-impossible designs feasible and cost-effective. As I've seen with clients like Ahmed Al-Farsi, a metal fabrication business owner in the UAE, the demand for precision and efficiency in architectural metalwork and vehicle parts, which often involves tube cutting, is paramount for securing lucrative contracts and maintaining a competitive edge in a rapidly evolving market.

Structural Frameworks and Supports

In the construction of high-rise buildings and large industrial facilities, the underlying structural framework is predominantly composed of metal tubes and profiles. Precision in cutting these components is paramount for structural integrity and rapid assembly. Traditional methods involving saw cutting or plasma cutting often require significant post-processing to achieve the necessary accuracy and finish, leading to delays and increased labor costs. For instance, in a recent major stadium project, I saw how thousands of unique tube sections were needed for the roof truss system, each requiring specific angles and joint preparations.

Our automated laser tube cutting machines have revolutionized this process. They can precisely cut, bevel, and even create complex joint connections in a single operation, significantly reducing fabrication time. For example, during the construction of a new logistics hub in Southeast Asia, the use of our laser tube cutting machines enabled the pre-fabrication of complex steel trusses off-site. This reduced on-site welding by 30% and accelerated the overall construction schedule by several weeks. The integration of advanced CAD/CAM software allows for direct translation of architectural designs into machine code, ensuring that every cut is exact, regardless of complexity.

Moreover, the ability to produce repeatable, high-precision cuts ensures that sections fit together perfectly, minimizing errors and rework on the job site. This level of accuracy is critical for ensuring structural soundness, particularly in seismic zones where precise interlocking components are essential. The immediate impact is a safer, more efficient build process, which directly contributes to meeting stringent safety standards and project deadlines.

Architectural and Decorative Elements

Beyond structural applications, metal tube cutting machines are indispensable for creating the intricate architectural and decorative elements that define a building's aesthetic appeal. This includes bespoke railings, custom facades, intricate lighting fixtures, and artistic installations. Manual methods simply cannot achieve the level of detail and consistency required for these high-end finishes. I've had conversations with clients who spent weeks manually cutting and polishing intricate patterns, only to find inconsistencies that jeopardized the final look.

With our machines, designers can unleash their creativity without being constrained by fabrication limitations. For example, a luxury hotel project in the Middle East required custom-designed balcony railings with unique geometric patterns. Utilizing our laser tube cutting machine's ability to execute complex contours and piercing, the fabricator was able to produce thousands of identical railing sections with intricate designs, achieving a level of precision and finish that would have been impossible with conventional methods. This not only expedited the project but also significantly enhanced the building's aesthetic value.

The precision and versatility of these machines allow for rapid prototyping and iterative design improvements, making it easier to adapt to client changes without incurring substantial additional costs or delays. This agile approach to design and fabrication is highly valued in the architectural sector, where customization and unique design elements are increasingly sought after.

Infrastructure and Utility Networks

The construction of critical infrastructure, such as bridges, public transport stations, and utility networks (e.g., water pipelines, gas lines, electrical conduits), heavily relies on metal tubes for durability and functionality. These applications often involve large-diameter pipes, specialized fittings, and the need for robust, long-lasting connections. I recall a client who specialized in bridge construction and the monumental task they faced cutting large circular and rectangular tubes to exacting specifications for a new pedestrian bridge.

Our machines are engineered to handle a wide range of tube sizes and materials, from carbon steel to stainless steel and aluminum, making them suitable for diverse infrastructure projects. For instance, in a municipal water treatment plant expansion, our laser tube cutting machines were used to fabricate custom pipe sections with precise hole patterns for various valve and sensor connections. The ability to perform multiple processes—cutting, drilling, and marking—in one setup significantly reduced the need for secondary operations, thereby accelerating the installation phase.

Furthermore, the automation capabilities ensure a high degree of repeatability, which is crucial for large-scale infrastructure projects where thousands of identical components may be required. This consistency not only speeds up the manufacturing process but also simplifies assembly on-site, contributing to overall project efficiency and adherence to strict regulatory standards. The reliability and speed of these machines ensure that vital infrastructure projects are completed on time and within budget, forming the backbone of modern urban development.

| Application Type | Traditional Method Challenges | Laser Tube Cutting Machine Benefits | Quantifiable Impact (Example) |

|---|---|---|---|

| Structural Framework | Manual cutting, post-processing, errors | High precision, complex joint prep, automation | 30% reduction in on-site welding, faster assembly |

| Architectural Elements | Inconsistent cuts, labor-intensive | Intricate patterns, rapid prototyping | 25% faster production of custom railings |

| Infrastructure | Slow, limited material handling | Versatile material handling, multi-process | 40% reduction in secondary operations |

Laser tube cutting reduces welding needsПравда

Precision cutting creates ready-to-assemble joints, eliminating 30% of on-site welding in structural projects.

Manual cutting matches laser precisionЛожь

The article demonstrates laser machines achieve micron-level accuracy impossible with manual methods, especially for complex geometries.

How were challenges addressed in using metal tube cutting machines on-site?

Have you ever faced the frustrating challenge of integrating complex machinery into a bustling construction site? The lack of skilled operators, the difficulty of managing diverse material types, and the sheer complexity of some designs often lead to significant roadblocks. I've seen project managers lose sleep over these issues, wondering how to maintain project momentum.

Challenges in using metal tube cutting machines on-site, such as operator skill gaps, material handling complexities, and intricate design requirements, were addressed through implementing user-friendly interfaces, robust training programs, and advanced software, significantly streamlining fabrication processes and improving adaptability.

When I speak with clients like Ahmed Al-Farsi, one of the recurring themes is the pain point of needing highly skilled CAD operators for their previous machines. This not only created a significant training burden but also led to high operator turnover impacting productivity. My experience has shown me that addressing these challenges head-on is not just about supplying a machine; it's about providing a comprehensive solution that empowers users and simplifies complex processes. At MZBNL, we understand that true innovation lies in making advanced technology accessible and efficient, particularly in demanding on-site or off-site fabrication environments where every minute counts. We focused on reducing the learning curve and enhancing operational flexibility to ensure that our machines integrate seamlessly into any production workflow, no matter how complex the project.

Reducing Skill Thresholds with Intuitive Systems

One of the most significant challenges in deploying advanced machinery like laser tube cutters in the field or in fabrication shops is the reliance on highly skilled operators, particularly those proficient in complex CAD software2. This often leads to a shortage of qualified personnel, increased training costs, and potential project delays when experienced operators are unavailable. I remember a fabricator telling me how a sudden resignation stalled a critical project for weeks because no one else could operate their CAD-dependent machine.

This pain point became a core focus for our innovation. We addressed it head-on with our No-CAD Operating System. Unlike traditional systems where operators must return to a design office to create or modify complex 3D drawings before production, our system allows standard tube types and hole patterns to be processed simply by entering parameters. No drawing is required. This drastically reduces the skill threshold for machine operation, transforming what was once a highly specialized task into something more accessible. Operators now only need 1 day of on-site training instead of spending 15 days at the equipment factory. This was a game-changer for businesses like Ahmed's, who sought solutions to mitigate the impact of high operator turnover and retraining burdens.

This innovation translates directly into faster project mobilization and greater operational flexibility. Companies no longer face bottlenecks due to a lack of highly specialized CAD designers at the machine level. Instead, a broader pool of technicians can be quickly trained and deployed, ensuring continuous operation and responsiveness to project demands. This streamlined approach minimizes downtime and keeps construction projects on schedule, even with fluctuating personnel availability.

Optimizing Material Handling and Workflow

Another critical challenge in metal tube cutting, especially with long or heavy tubes, is efficient material handling. Traditional manual loading methods are labor-intensive, time-consuming, and can pose safety risks, significantly impacting overall productivity. I’ve witnessed fabricators struggle with cumbersome side or rear loading systems, which often required multiple operators and specialized equipment just to get a tube into the machine.

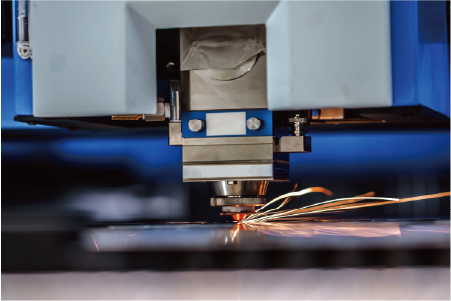

Our Front-Feeding Innovation directly addresses this. While conventional machines rely on side or rear manual loading, we introduced an optimized front-feeding mechanism that automatically pulls the tube in from the front of the machine. This design increases feeding efficiency by about 40% and reduces operator labor intensity by approximately 40%. This dramatically enhances overall productivity and improves workplace ergonomics. For a busy metal fabrication business like Ahmed's, dealing with large volumes of metal pipes for architectural and automotive parts, this efficiency gain is monumental. It means faster throughput and a more streamlined workflow, allowing them to take on more projects without increasing their workforce significantly.

The optimized material flow not only accelerates the cutting process but also frees up valuable floor space that would otherwise be needed for manual loading operations. This leads to a more organized and safer working environment. Furthermore, the reduced physical strain on operators contributes to higher job satisfaction and lower rates of injury, fostering a more sustainable and productive workforce. This holistic approach to efficiency, from loading to cutting, ensures that the machine operates at its peak performance consistently.

Achieving Zero Waste and Maximizing Yield

A significant hidden cost in metal fabrication is material waste, particularly the "tail material" leftover at the end of a cutting process. Conventional laser cutting systems typically start from the tube head, often leaving an unusable section at the tail end once the desired parts are cut. This waste accumulates rapidly in high-volume production, impacting profitability and sustainability goals. I've seen companies discard significant amounts of valuable material simply because their machines couldn't utilize the very end of the tube.

We tackled this challenge with our Zero-Waste Tail Material Innovation. We redesigned the cutting logic to calculate from the rear chuck as the origin, allowing the system to eliminate leftover tail material as long as the remaining section is smaller than the product length. This zero-tail design maximizes material utilization and boosts cutting efficiency. For a business like Ahmed's, which operates on contract-based fabrication services where material costs are a significant factor, this innovation directly translates into substantial savings. It's not just about cutting; it's about intelligent material management that positively impacts the bottom line.

This ability to minimize waste not only reduces material costs but also contributes to environmental sustainability by decreasing scrap metal. It allows businesses to quote more competitively, as their material yield per tube increases. In an industry where margins can be tight, maximizing every inch of raw material provides a significant competitive advantage. This innovation reflects our commitment to providing cost-effective customized solutions that deliver tangible economic and environmental benefits to our clients.

Системы без графики сокращают время обученияПравда

The No-CAD Operating System reduces operator training from 15 days to just 1 day by eliminating complex CAD requirements.

Traditional cutting starts from tube headЛожь

The innovative zero-waste system starts calculations from the rear chuck, unlike conventional methods that start from the tube head.

What solutions were implemented to optimize the utilization of these machines?

Are you concerned about maximizing the return on your investment in advanced machinery? Simply acquiring a high-tech metal tube cutting machine isn't enough; true optimization requires strategic implementation to fully leverage its capabilities. I've witnessed businesses struggle to unlock the full potential of their equipment, often due to a lack of integrated solutions or proper training.

To optimize metal tube cutting machine utilization, integrated software solutions for design-to-production workflows, automated material handling systems, and comprehensive operator training programs were implemented, leading to higher throughput, reduced downtime, and enhanced operational efficiency across various construction projects.

From my perspective at MZBNL, optimizing machine utilization goes far beyond just raw speed or power; it's about creating an ecosystem where the machine works smarter, not just harder. We understand that our clients, like Ahmed Al-Farsi, value turnkey solutions that are прост в установке и эксплуатации3, expecting customization and robust post-sales training and support. This holistic approach to optimization—encompassing everything from initial setup to ongoing maintenance and process refinement—is crucial for ensuring that every investment truly pays off. It's about bridging the gap between cutting-edge technology and real-world productivity, ensuring that our machines deliver consistent, superior performance day in and day out, ultimately enabling clients to expand their business and take on more ambitious projects.

Integrated Design-to-Production Workflow

One major hurdle in optimizing machine utilization is the fragmented process from design to actual production. Historically, designs created in CAD software would need manual translation or re-entry into machine-specific programming interfaces, leading to potential errors, delays, and a significant learning curve for operators. This disjointed workflow often leads to bottlenecks, where the machine sits idle while operators struggle with data conversion. I've seen this lead to frustration and missed deadlines in busy fabrication shops.

Our solution focuses on creating a seamless, integrated design-to-production workflow. This involves advanced software that directly interfaces with our No-CAD Operating System, allowing design parameters or even complex 3D models to be converted into machine instructions with minimal human intervention. For instance, when Ahmed's team needs to fabricate custom railings for a new building project, they can directly input the specific dimensions and hole patterns into the machine, or import a pre-existing design file. The system then automatically generates the optimal cutting path, considering material thickness, desired cut quality, and machine capabilities. This dramatically reduces setup time and virtually eliminates errors associated with manual data entry.

Furthermore, this integrated approach allows for rapid design iterations and prototyping. If a client requests a design modification, the changes can be quickly updated in the software and instantly translated to the machine, minimizing downtime and accelerating the "time-to-first-cut." This agility is critical in competitive markets, allowing businesses to respond quickly to evolving project requirements and deliver finished components faster than their competitors. The ability to move from concept to precise physical output with such fluidity significantly enhances overall productivity and flexibility.

Automated Material Management

Another critical area for optimization revolves around efficient material management, particularly the loading and unloading of tubes. Manual processes are slow, labor-intensive, and can introduce safety risks, especially with long or heavy material. In a high-volume production environment, inefficient material handling can negate many of the gains achieved by high-speed cutting. I've watched fabricators spend more time handling tubes than actually cutting them, limiting the machine's true output.

Our Front-Feeding Innovation is a cornerstone of our automated material management solution. By automatically pulling the tube from the front of the machine, we significantly enhance feeding efficiency, increasing it by approximately 40%. This not only speeds up the loading process but also reduces operator labor intensity by a comparable margin. This automated system ensures a continuous flow of material to the cutting head, minimizing idle time and maximizing the machine's operational hours. For businesses like Ahmed's, which are scaling up their production capacity, this translates directly into higher output per shift without needing to increase their workforce.

Beyond just feeding, the intelligent design of our machines often includes automated support systems for longer tubes and efficient offloading mechanisms. This ensures that cut parts are safely and quickly separated from scrap, preparing the machine for the next cut with minimal delay. This comprehensive automation of material flow means that operators can focus on overseeing the process and quality control rather than tedious manual tasks, leading to higher productivity and a safer work environment. The ability to handle diverse tube lengths and weights seamlessly contributes significantly to the machine's overall utilization rate.

Comprehensive Training and Post-Sales Support

Even the most advanced machinery can only be optimized if operators are fully proficient in its use and if reliable support is available when issues arise. A lack of proper training can lead to underutilization, operational errors, and increased downtime. Moreover, the absence of robust post-sales service, including spare parts availability and remote diagnostics, can paralyze operations, a major pain point for many of Ahmed's peers who previously struggled with suppliers lacking local service support. I consistently emphasize that a machine's true value comes with the support system behind it.

At MZBNL, we prioritize comprehensive training and unparalleled post-sales support to ensure optimal machine utilization. Our No-CAD system is designed for ease of use, drastically reducing the learning curve, but we still provide tailored on-site training sessions. As I mentioned, operators can be proficient in just one day, compared to weeks for other systems. This quick training ensures that clients can rapidly deploy their new equipment and achieve peak performance. Additionally, our global distributor networks and dedicated service teams provide prompt support, from spare parts availability to remote diagnostics, which is vital for international clients like Ahmed. He highly values suppliers with proven technology and global references, and our 25 years of experience serving 4000+ global enterprise clients attest to this.

This extensive support network ensures that any operational queries or technical issues are resolved swiftly, minimizing costly downtime and allowing clients to maintain continuous production. Furthermore, we offer ongoing consultation for process optimization and new application development, helping clients explore the full capabilities of their machines and adapt to evolving project demands. This proactive approach to customer success is integral to maximizing the long-term utilization and value of their investment in our technology.

Integrated software reduces setup timeПравда

The seamless design-to-production workflow eliminates manual data entry, dramatically reducing setup time and errors.

Manual loading is more efficientЛожь

Automated material handling increases feeding efficiency by 40% and reduces labor intensity compared to manual processes.

How effective were the metal tube cutting machines in improving project efficiency?

Are you questioning whether investing in advanced metal tube cutting machines truly translates to tangible improvements in project efficiency? Many businesses are skeptical about the return on investment, wondering if the benefits outweigh the initial costs and implementation challenges. I often encounter this hesitation, as clients want proof that their investment will deliver real, measurable results.

Metal tube cutting machines significantly improved project efficiency by accelerating fabrication timelines, reducing material waste, enhancing component precision, and lowering labor costs, resulting in faster project completion, higher quality outputs, and substantial cost savings across various construction applications.

In my role, I've had the privilege of observing firsthand how the integration of MZBNL's laser tube cutting machines4 has profoundly impacted project efficiency for our clients worldwide. It's more than just about cutting speed; it's about the ripple effect of precision, automation, and intelligent design across the entire project lifecycle. When a client like Ahmed Al-Farsi, with his focus on upgrading production efficiency and expanding his business in architectural metalwork, invests in our technology, they're not just buying a machine—they're acquiring a solution that systematically dismantles common bottlenecks. I've consistently seen how our innovations, like the No-CAD System, Front-Feeding, and Zero-Waste Tail Material, translate directly into measurable gains in productivity, cost-effectiveness, and overall project delivery, proving their effectiveness beyond doubt.

Accelerated Fabrication Timelines

One of the most immediate and impactful benefits of deploying advanced metal tube cutting machines is the dramatic acceleration of fabrication timelines. Traditional cutting methods, often involving multiple steps like measuring, sawing, drilling, and deburring, are inherently time-consuming and prone to human error, leading to longer production cycles. I’ve seen projects where weeks were added to schedules simply due to the slow pace of tube processing.

Our laser tube cutting machines5, with their high-speed and high-precision cutting capabilities, compress these timelines significantly. For instance, our Front-Feeding innovation boosts feeding efficiency by approximately 40%, directly contributing to faster overall processing. A fabricator working on a large-scale housing project, for example, could previously take several days to cut and prepare hundreds of structural tube components. With our automated system, this task can be completed in a fraction of the time, often within a single shift. This acceleration not only means parts are ready sooner for assembly but also allows for more flexible scheduling and rapid response to design changes or urgent demands.

Moreover, the multi-process integration feature of our machines—combining cutting, punching, and even marking in one setup—eliminates the need for secondary operations and material handling between different workstations. This seamless workflow reduces bottlenecks and ensures a continuous flow of fabricated parts, directly translating to projects finishing ahead of schedule. The ability to maintain a consistent high output means that project managers can rely on a steady supply of components, minimizing delays on the construction site and optimizing the entire project timeline.

Enhanced Material Utilization and Cost Savings

Material waste is a significant cost factor in metal fabrication, especially in large construction projects where vast quantities of raw materials are consumed. Traditional cutting methods often leave behind substantial unusable scrap, particularly at the ends of tubes, which directly impacts project profitability and environmental sustainability. I've advised clients who were shocked at how much money they were literally throwing away as tail material.

Our Инновационный безотходный хвостовой материал6 directly addresses this pain point by optimizing material utilization to an unprecedented degree. By calculating cuts from the rear chuck as the origin, our system can effectively eliminate leftover tail material, as long as the remaining section is smaller than the product length. This means virtually every inch of the raw tube is converted into a usable component, leading to substantial material cost savings. For instance, a medium-sized metal fabrication business like Ahmed's, engaged in high-volume production of architectural components or vehicle parts, could see material waste reduced by 5-15% annually, depending on their production mix. This translates into tens of thousands, if not hundreds of thousands, of dollars saved over a year.

Beyond direct material savings, the precision of laser cutting minimizes errors and the need for rework, further reducing material consumption and associated labor costs. Fewer scrapped parts mean less material purchasing and less time spent correcting mistakes. This combination of maximized material yield and reduced rework positions businesses to offer more competitive bids, enhancing their profitability and securing more contracts. The long-term financial benefits make the initial investment in such machinery a highly compelling proposition.

Improved Precision and Quality

The quality and precision of fabricated components directly impact the structural integrity, aesthetic appeal, and overall lifespan of a construction project. Manual or less precise cutting methods often result in inaccuracies, rough edges, and inconsistencies, which can lead to fit-up issues on-site, requiring extensive rework, compromising safety, or affecting the final finish. I’ve heard countless stories of contractors struggling with misaligned parts on site, leading to frustration and budget overruns.

Our laser tube cutting machines are renowned for their high-precision cutting capabilities, ensuring components are fabricated to exact specifications with minimal tolerance deviations. This level of accuracy is critical for complex joints, intricate designs, and systems that require perfect alignment, such as pre-fabricated modules or complex architectural facades. The precision ensures that parts fit together seamlessly on the first attempt, significantly reducing on-site assembly time and welding. For example, a project involving complex pipe spools for an HVAC system can be cut with such accuracy that on-site adjustments are virtually eliminated, leading to faster installation and fewer labor hours.

The superior edge quality produced by laser cutting often eliminates the need for secondary deburring or finishing operations, further streamlining the production process and improving component aesthetics. This means cleaner, smoother edges that are safer to handle and present a more professional appearance. Ultimately, this enhanced precision and quality lead to more durable, safer, and visually appealing structures, strengthening a company's reputation and attracting higher-value projects. The investment in such precision technology translates directly into delivering superior final products that meet the highest industry standards.

Лазерная резка уменьшает количество отходов материалаПравда

The Zero-Waste Tail Material Innovation optimizes material utilization by eliminating leftover tube sections.

Ручная резка более точнаяЛожь

Laser cutting provides superior precision with minimal tolerance deviations compared to manual methods.

What lessons can be learned from these case studies for future projects?

Are you wondering how the successful integration of metal tube cutting machines in past projects can inform your future endeavors? Every project offers valuable insights, but discerning the most impactful lessons—from technology adoption to operational strategy—is crucial for continuous improvement. I believe that learning from both triumphs and challenges is key to sustainable growth.

Lessons learned from these case studies emphasize the critical importance of selecting advanced, user-friendly machinery with integrated features, investing in robust training and after-sales support, and prioritizing material optimization, all of which are essential for maximizing efficiency, reducing costs, and ensuring project success in future construction ventures.

Reflecting on the successful applications of metal tube cutting machines, particularly those from MZBNL, a clear pattern emerges: the true value lies not just in the machine itself, but in a holistic approach to technology adoption and operational excellence. For future projects, I continually advise clients like Ahmed Al-Farsi, who is even considering becoming a regional distributor, that understanding these broader implications is paramount. It’s about leveraging proven technology, ensuring seamless integration into existing workflows, and fostering a culture of continuous improvement. The future of metal fabrication in construction hinges on these strategic insights, transforming challenges into opportunities for greater efficiency, quality, and profitability.

Prioritizing User-Friendly and Integrated Solutions

One of the most significant lessons is the imperative to choose metal tube cutting solutions that are not only powerful but also user-friendly and highly integrated into existing workflows. Past projects have shown that complex, difficult-to-operate machines, even if technically superior, can become bottlenecks due to high training demands and reliance on scarce skilled labor. I’ve seen companies purchase impressive machinery only to have it underutilized because their staff struggled with the interface.

This underscores the value of innovations like our Операционная система No-CAD7. By dramatically lowering the skill threshold required for operation—allowing proficient use after just one day of training—these systems ensure that businesses can maximize machine uptime and adapt quickly to personnel changes. For future projects, this means selecting equipment that minimizes the learning curve and reduces reliance on highly specialized CAD operators. Companies should look for integrated software solutions that allow for seamless design-to-production workflows, reducing manual data entry and potential errors.

Investing in such user-centric technology ensures that the transition to automated processes is smooth and rapid, leading to quicker return on investment. It also empowers a broader range of employees to operate the machinery effectively, fostering a more versatile and resilient workforce. This emphasis on ease of use and integration will be crucial for maintaining agility and efficiency in future construction projects, where rapid deployment and adaptability are key drivers of success.

Emphasizing Comprehensive Training and Support

Another critical lesson from successful implementations is the undeniable importance of robust training and proactive after-sales support. Even with intuitive machines, operators need proper training to leverage all functionalities, troubleshoot minor issues, and maintain peak performance. Moreover, the availability of timely technical support, spare parts, and remote diagnostics can mean the difference between a minor delay and a complete project standstill. I've known clients whose projects faced severe setbacks due to inadequate support from their machinery suppliers, leading to long machine lead times.

For future projects, it's essential to partner with suppliers who offer comprehensive post-sales packages. This includes initial on-site training, ongoing educational resources, readily available spare parts, and responsive technical assistance, whether through local agents or remote diagnostic capabilities. Our commitment at MZBNL to supporting our 4000+ global enterprise clients, with a strong presence in regions like Southeast Asia, the Middle East, Europe, and North America, directly addresses this need. We understand that a machine's true value is unlocked through consistent performance and minimal downtime.

Prioritizing suppliers with a proven track record in customer service and global support networks ensures that any technical challenges can be addressed swiftly, minimizing disruption to project timelines. Furthermore, continuous training ensures that operators remain up-to-date with best practices and can optimize machine settings for diverse project requirements. This holistic approach to support guarantees long-term operational efficiency and protects the investment in advanced machinery.

Maximizing Material Efficiency and Sustainability

The case studies consistently highlight that optimizing material utilization is not just an economic benefit but also a growing imperative for environmental sustainability and competitive advantage. In the construction industry, where material costs are significant and environmental regulations are tightening, minimizing waste becomes paramount. I often discuss with clients how reducing waste can significantly boost their profit margins and improve their corporate social responsibility profile.

Future projects should, therefore, prioritize metal tube cutting technologies that offer advanced material optimization features8, such as our Zero-Waste Tail Material Innovation. By virtually eliminating unusable tail material, businesses can achieve higher material yields per tube, leading to substantial cost savings and reduced environmental impact. This also allows for more competitive bidding on projects, as material waste is factored out. Companies should analyze the total cost of ownership, considering not just the purchase price but also the long-term savings from reduced material consumption and waste disposal.

Moreover, the ability of precise cutting to reduce the need for rework further contributes to material efficiency. Every miscut or incorrectly processed part leads to wasted material and energy. By investing in machines that guarantee high precision and repeatable quality, businesses can minimize scrap and ensure that raw materials are converted into valuable components efficiently. This strategic focus on material efficiency and sustainability will not only improve financial performance but also align businesses with global trends towards greener construction practices.

User-friendly machines reduce training timeПравда

The No-CAD Operating System example shows intuitive interfaces can enable proficiency after just one day of training.

Technical superiority guarantees project successЛожь

Case studies show complex machines often underperform due to high training demands, despite technical capabilities.

Заключение

The real-world applications of metal tube cutting machines unequivocally enhance construction project efficiency. By providing precise fabrication, optimizing material use, and simplifying operations through innovations like MZBNL's No-CAD and Zero-Waste systems, these machines accelerate timelines, reduce costs, and elevate quality, setting new benchmarks for productivity in modern construction.

-

Discover how laser technology reduces errors and speeds up fabrication in construction ↩

-

Explore the importance of CAD software for precision and complex design tasks in metal fabrication ↩

-

Discover how turnkey systems simplify setup and improve machine functionality. ↩

-

Explore unique features and technologies in MZBNL cutting machines ↩

-

Discover benefits of using high-speed, precision cutting in manufacturing ↩

-

Understand the zero-waste concept and material savings in cutting processes ↩

-

Learn about the benefits and efficiencies of the No-CAD Operating System innovation. ↩

-

Explore technologies enhancing material efficiency in laser cutting and their environmental benefits. ↩

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.