From Manual Saws to Metal Tube Cutting Machines: A Transformation Story

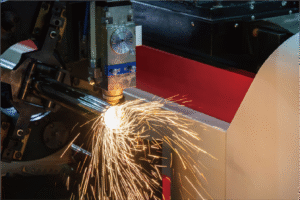

Cutting metal tubes by hand with manual saws is slow, inaccurate, and labor-intensive. This outdated method frustrates businesses aiming for precision and efficiency in a competitive market. But what if there was a way to achieve flawless cuts at unprecedented speeds1, revolutionizing your production?

The evolution from manual saws to automated metal tube cutting machines marks a profound transformation in metalworking, driven by the need for increased precision, efficiency, and safety. This shift has enabled mass production, reduced labor costs, and opened new possibilities for intricate designs and high-volume output across diverse industries globally.

As someone deeply involved in the metal fabrication industry for over 25 years, I’ve personally witnessed this dramatic shift. From the laborious days of hand-cutting to the era of intelligent automation, the journey has been nothing short of revolutionary. This evolution isn't just about new tools; it's about redefining what's possible for businesses like yours, enhancing profitability and expanding capabilities beyond traditional limits.

The transition from rudimentary manual metal tube cutting to sophisticated automated machinery represents a pivotal shift, driven by demands for higher precision, speed, and cost-effectiveness. In the early days, errors were common, productivity was low, and worker fatigue was a significant concern. Today, advanced laser and CNC technologies have fundamentally reshaped the landscape. Consider the experience of many growing enterprises, including some of our clients. For instance, businesses expanding into intricate architectural metalwork or high-volume automotive components, like our typical customer Ahmed Al-Farsi, quickly hit limits with manual processes. His need to automate existing workflows, coupled with a desire for easy-to-operate solutions without reliance on highly skilled CAD operators2, mirrors a widespread industry trend. The pursuit of automated solutions, supported by robust data on efficiency gains—some reports indicating up to 80% reduction in processing time—underscores this irreversible progression towards smarter, more integrated manufacturing. This transformation isn't merely about adopting new equipment; it's about embracing a paradigm shift that integrates R&D, manufacturing, and service to deliver tailored, high-tech solutions, as we at MZBNL have championed over decades, impacting everything from profit margins to global market reach.

What historical backdrop led to the invention of metal tube cutting machines?

Manual metal cutting was once the only option, but its limitations in speed and accuracy severely hindered industrial progress. This bottleneck slowed production and increased costs, creating an urgent demand for a more efficient solution. How did the industry respond to this pressing need?

The invention of metal tube cutting machines arose from the industrial revolution's demand for faster, more precise, and standardized metal processing. Manual methods were slow, inconsistent, and costly for mass production, necessitating automated solutions to meet escalating needs in construction, automotive, and general manufacturing sectors.

Understanding the origins of metal tube cutting machines helps us appreciate their current sophistication. The foundational shift began with basic mechanization, progressing through several pivotal stages of innovation. From the crude, early attempts to automate, we moved towards more refined mechanical systems, then to the integration of hydraulics and finally, the digital revolution of CNC. This historical progression set the stage for the remarkable efficiency we see today, providing a crucial context for businesses like Ahmed's that are always seeking to push the boundaries of productivity and achieve new levels of competitive advantage in their respective markets.

Early Industrialization and the Demand for Scale

The burgeoning industrial revolution in the 18th and 19th centuries created an unprecedented demand for standardized components, including metal tubes. Initially, these tubes were laboriously cut using manual hacksaws, files, and basic hand tools. This process was not only incredibly slow but also highly inconsistent, leading to significant material waste and rework. As factories expanded and production lines became more sophisticated, the limitations of manual cutting became a critical bottleneck, impeding overall manufacturing output, forcing companies to limit their ambitions and scale.

The necessity for higher throughput and uniformity drove the initial innovations. Manufacturers began experimenting with powered saws and abrasive wheels, which, while still far from precise, offered a significant leap in speed over purely manual methods. These early machines were rudimentary, often requiring extensive manual setup and calibration, but they represented the first fundamental step towards automating a critical industrial process. The focus during this period was primarily on increasing volume rather than fine-tuning accuracy, reflecting the era's emerging mass production philosophy and the burgeoning need for interchangeable parts for assembly.

This era saw the rise of large-scale infrastructure projects, such as railways, bridges, and burgeoning automotive industries, all of which consumed vast quantities of metal tubing. The economic pressures to reduce labor costs and accelerate production cycles pushed engineers to develop more robust and reliable cutting solutions. The significant labor input for manual cutting often meant skilled workers were tied up in repetitive, low-value tasks. This shift was not just technological; it was an economic imperative, laying the groundwork for the more advanced systems that would emerge in the 20th century, seeking to optimize every aspect of the production chain.

The Emergence of Mechanical and Hydraulic Systems

The early 20th century witnessed significant advancements with the integration of mechanical and hydraulic systems into cutting technology. Mechanical saws became more powerful and precise, utilizing geared mechanisms, improved blade materials, and stronger support structures. These machines could cut thicker materials and maintain better tolerances than their predecessors, albeit still requiring substantial operator input and calibration. The introduction of hydraulic clamping and feeding mechanisms further enhanced efficiency by automating parts of the loading and securing process, significantly reducing physical effort and improving consistency.

This period was marked by a gradual increase in automation, notably in the feeding and clamping of tubes, reducing the physical strain on operators and improving repeatability. While still far from "smart" machines, these mechanical and hydraulic systems represented a critical evolutionary step, allowing for faster processing of longer tube lengths and heavier gauges. They enabled industries to scale up production of items like bicycle frames, simple furniture, and basic piping systems with greater consistency, opening doors to new product designs that demanded slightly higher precision.

However, the lack of real-time control and feedback meant that complex cuts or rapid changes in production runs were still challenging and time-consuming. Operators had to manually adjust settings for each new batch, which introduced its own set of potential errors and inefficiencies. Despite these limitations, the pursuit of greater efficiency led to the development of specialized cutting techniques, such as improved cold saws and band saws, which offered enhanced cut quality and material handling capabilities for different metal types. For businesses like Ahmed's, which started with more traditional approaches, this era highlighted the tangible potential for significant gains through even partial automation.

The Digital Revolution: CNC Technology Takes Hold

The most transformative phase began with the advent of Computer Numerical Control (CNC) technology in the mid-20th century. Initially developed for machining complex aerospace components, CNC soon found its way into tube cutting. This innovation replaced manual operation with programmed instructions, allowing for unprecedented precision, repeatability, and the ability to produce intricate geometries that were impossible with previous methods. CNC machines could follow complex paths, compensate for material variations, and execute cuts with microscopic accuracy, fundamentally changing what was possible in metal fabrication.

The integration of CNC ushered in an era of "lights-out" manufacturing, where machines could operate autonomously for extended periods, significantly reducing labor costs and increasing production capacity. For instance, a report by the Fabricators & Manufacturers Association (FMA) noted that CNC adoption could reduce production lead times by 30-50% and waste by 15-25% in tube fabrication, leading to substantial cost savings. This level of efficiency allowed companies to diversify their product offerings and enter new markets requiring tighter tolerances, such as medical devices or precision automotive parts, establishing new competitive advantages.

The shift to CNC was not without its challenges, primarily the need for skilled programmers and significant upfront investment. However, the long-term benefits in terms of productivity, quality, and versatility quickly outweighed these initial hurdles. Our own experience at MZBNL, pioneering solutions like the No-CAD Operating System, directly addresses the historical pain point of needing highly skilled CAD operators. This innovation, which allows processing by simply entering parameters rather than complex drawings, exemplifies how the digital revolution continues to simplify operation and democratize access to high-precision manufacturing, shortening operator training from 15 days at the equipment factory to just 1 day of on-site training for improved efficiency and reduced turnover impact.

| Характеристика | Manual Saws | Early Mechanical Saws | CNC Tube Cutting Machines |

|---|---|---|---|

| Точность | Низкий | Умеренный | Высокий |

| Скорость | Very Low | От низкого до умеренного | Очень высокий |

| Автоматизация | None | Ограниченный | Высокий |

| Мастерство оператора | High (physical) | Умеренный | High (programming) |

| Waste | Высокий | Умеренный | Низкий |

| Versatility | Низкий | Ограниченный | Высокий |

| Cost (Unit) | High (labor) | Умеренный | Low (after setup) |

| Сложность | Simple | Умеренный | High (design/programming) |

CNC revolutionized tube cuttingПравда

CNC technology enabled unprecedented precision and automation in metal tube cutting, transforming manufacturing capabilities.

Manual cutting was efficientЛожь

Manual metal tube cutting was slow, inconsistent, and labor-intensive, creating bottlenecks in industrial production.

How has the transition from manual saws to cutting machines changed the metalworking industry?

Relying on manual saws meant slow production, inconsistent quality, and high labor costs for metalworking businesses. This often resulted in missed deadlines and uncompetitive pricing, holding back growth. How did the shift to automated cutting machinery fundamentally transform these challenges and redefine industry standards?

The transition from manual saws to metal tube cutting machines revolutionized the metalworking industry by dramatically increasing production speed, precision, and efficiency. It enabled complex designs, reduced labor requirements and material waste, and facilitated mass customization, fundamentally reshaping manufacturing processes and supply chains globally.

The impact of this technological leap extends far beyond mere speed and accuracy; it has fundamentally redefined the capabilities and economic models of the metalworking industry. I’ve seen firsthand how companies, from small fabrication shops to large-scale manufacturers, have been able to pursue ambitious projects and expand into new markets precisely because of these advancements. This paradigm shift has enabled a level of innovation and profitability that was once unimaginable, paving the way for intricate architectural designs, lighter automotive components, and even specialized medical equipment. It represents a journey from laborious craftsmanship to precision engineering, where every cut is optimized for performance and cost-effectiveness and new opportunities emerge constantly.

Беспрецедентная точность и согласованность

The most immediate and profound impact of automated metal tube cutting machines is the dramatic improvement in precision and consistency in manufacturing3. Manual sawing, by its very nature, is subject to human error, fatigue, and variability. Achieving exact dimensions, perfect angles, and clean cuts repeatedly was a constant challenge, leading to significant rework and scrap. For example, manual cutting often resulted in dimensional errors of several millimeters, leading to poor fit-up during assembly and increasing welding time by up to 20%. With CNC-controlled machines, however, every cut is executed according to precise digital instructions, resulting in near-perfect repeatability, often within mere micrometers. This has been a game-changer for industries where tight tolerances are critical, such as automotive, aerospace, and medical device manufacturing.

Consider the case of a furniture manufacturer. Before automation, assembling a batch of chairs meant dealing with variations in tube lengths and angles, requiring more fitting and welding time, sometimes leading to outright rejection of parts. With automated machines, components fit together flawlessly on the first try, significantly reducing assembly time and improving overall product quality and aesthetic appeal. This consistency also translates into optimized material utilization. For example, MZBNL's Zero-Waste Tail Material Innovation, which calculates from the rear chuck to eliminate leftover sections, directly addresses this, allowing for maximum material usage and boosting cutting efficiency by preventing waste that could otherwise account for 5-10% of total material costs.

This newfound precision also opens doors for complex designs that were previously impossible. Intricate joint designs, precise holes, and accurate contours can now be cut directly into tubes using laser technology, eliminating secondary processes like drilling, notching, or deburring. This integration of multiple processes within a single machine pass streamlines production, reduces handling, and shortens lead times, providing a significant competitive advantage in demanding global markets. My experience shows that manufacturers like Ahmed, keen on automating workflows for architectural metalwork and vehicle parts, prioritize this high precision to meet demanding client specifications and enhance their reputation for quality.

Enhanced Productivity and Reduced Labor Dependence

The transition to automated cutting machines has dramatically boosted productivity while simultaneously reducing reliance on highly skilled, manual labor. A single automated machine can often perform the work of multiple manual operators, and it can do so continuously, around the clock, without fatigue or the need for breaks. This leads to significantly higher output volumes and faster project completion times. For example, a study by industry analysts found that automated tube cutting systems can increase throughput by 300-500% compared to traditional methods, depending on the complexity of parts, directly impacting a company's ability to take on more orders and expand its market share.

One of the significant pain points for businesses like Ahmed's, as he expressed, was the need for skilled CAD operators and the burden of high operator turnover. Such turnover could lead to weeks of lost productivity as new staff were trained. Our Front-Feeding Innovation directly addresses labor intensity by increasing feeding efficiency4 by about 40% and reducing operator labor intensity by approximately 40% through automated processes, minimizing physical strain. Furthermore, our No-CAD System Innovation significantly lowers the skill threshold, allowing operators to learn the system in just one day of on-site training, compared to 15 days previously required at the equipment factory. This dramatically reduces the retraining burden and ensures consistent productivity even with workforce changes.

The reduced need for manual intervention also translates into lower operational costs and improved workplace safety. Operators can focus on overseeing the machine, monitoring performance, and ensuring quality control rather than engaging in physically demanding and potentially hazardous cutting tasks, such as handling sharp metal or operating loud machinery. This shift allows companies to reallocate skilled labor to more value-added activities like design, engineering, or final assembly, optimizing their human capital and contributing to overall profitability and a safer, more ergonomically sound work environment.

Diversification of Capabilities and Market Expansion

The capabilities introduced by automated tube cutting machines have enabled the metalworking industry to diversify its product offerings and expand into new, more lucrative markets. With the ability to process a wider range of materials (steel, aluminum, copper, brass, stainless steel, etc.) and create highly complex geometries, manufacturers can now produce components for diverse applications that were previously out of reach due to technical limitations or prohibitive costs. This includes everything from specialized components for medical and fitness equipment to intricate parts for display racks, architectural facades, and advanced automotive components, opening up entirely new revenue streams.

This expanded capability means that a metal pipe processing factory is no longer limited to producing simple frames or railings. They can now fabricate custom parts for niche industries, offering unique solutions that command higher margins and differentiate them from traditional shops. For example, a company equipped with a laser tube cutting machine can offer bespoke designs for interior decor, producing unique furniture pieces or artistic installations that require precise, intricate cuts, appealing to a different, higher-end client base. The machine's versatility allows for rapid prototyping and iteration, accelerating product development cycles and enabling faster, more flexible responses to market trends.

The ability to offer customized solutions with speed and precision has become a key competitive differentiator. Companies that invest in these technologies can take on more challenging, higher-value projects, attract higher-profile clients, and differentiate themselves from competitors still relying on older, less capable methods. Our global enterprise clients, spanning Southeast Asia, North America, and Europe, leverage MZBNL's multi-process integration and cost-effective customized solutions to dominate their respective markets, demonstrating the immense potential for market expansion when equipped with cutting-edge technology. This strategic advantage is particularly appealing to forward-thinking owners like Ahmed, who seeks turnkey solutions and values a high cost-performance ratio for his ambitious expansion into architectural metalwork and vehicle parts supply, positioning his business for long-term growth and market leadership.

Automated cutting improves precisionПравда

CNC machines achieve micrometer-level accuracy, eliminating human error in manual sawing.

Ручная резка уменьшает количество отходов материалаЛожь

Automated systems optimize material usage with innovations like zero-waste tail cutting, while manual methods typically waste 5-10% of materials.

What key challenges did manufacturers face during this technological shift?

Adopting advanced metal tube cutting machines wasn't a simple upgrade; manufacturers often grappled with significant upfront costs, a steep learning curve for new technologies, and resistance to change. These hurdles could delay implementation and hinder the realization of efficiency gains. How did businesses navigate these formidable obstacles?

Manufacturers transitioning to advanced metal tube cutting machines faced challenges including high capital investment, the need for skilled operators proficient in new software and machine operation, and integrating new systems into existing workflows. Overcoming these required strategic planning, training, and careful financial management.

While the promise of increased efficiency and precision was clear, the path to adopting advanced tube cutting technology was fraught with significant challenges. From the perspective of a manufacturer, these weren't just technical hurdles but often organizational and financial ones as well. My team at MZBNL has worked with thousands of clients globally, helping them navigate these transitions, and I've seen firsthand how overcoming these challenges requires more than just buying a machine; it demands a holistic approach to integration, training, and long-term support. Understanding these common obstacles is crucial for any business contemplating a similar upgrade, ensuring a smoother and more successful adoption process.

High Capital Investment and Financial Risk

One of the most significant barriers to adopting advanced metal tube cutting machines has always been the substantial upfront capital investment. CNC laser cutters, for instance, represent a major financial outlay, often costing hundreds of thousands to over a million dollars, depending on their capabilities and features. For small to mid-sized metal fabrication businesses, this investment can be daunting, requiring careful financial planning, securing loans, or reallocating significant capital that could otherwise be used for other operational needs or expansion projects. The perceived risk of such a large expenditure, especially without guaranteed returns, often made companies hesitant to make the leap, preferring to stick with lower-cost, albeit less efficient, traditional methods.

Beyond the initial purchase price, there are additional costs associated with installation, infrastructure upgrades (like specialized power supply, dust extraction, and ventilation systems), and specialized tooling. These hidden costs can inflate the total investment by 10-20%, making it even more challenging for budget-conscious manufacturers. This was certainly a concern for many, including clients like Ahmed Al-Farsi, who while valuing cost-performance, still needed assurances of a strong return on investment for his substantial purchase of a Laser Tube Cutting Machine. He sought turnkey solutions and global references precisely to mitigate these financial uncertainties and justify the investment to his stakeholders and finance teams.

Moreover, the depreciation of high-tech machinery and the continuous need for software upgrades, specialized maintenance, and spare parts add to the long-term financial burden. Manufacturers had to carefully weigh the projected efficiency gains and cost savings from reduced labor and waste against these ongoing expenses. This required a robust business case and often a long-term strategic vision, focusing not just on immediate costs but on the cumulative benefits over the machine's operational lifespan, thereby transforming the financial outlay from a simple expense into a strategic investment for future growth and competitive advantage. Accessing government subsidies or industry-specific grants could also play a crucial role in de-risking this initial capital outlay for many businesses.

Skill Gap and Workforce Training

Another critical challenge during the technological shift was the significant skill gap within the existing workforce. Traditional metalworkers were proficient with manual tools and basic machinery, but operating and programming sophisticated CNC laser tube cutting machines required an entirely different set of skills. This included proficiency in CAD/CAM software, understanding complex machine interfaces, interpreting digital designs, troubleshooting technical issues, and performing preventative maintenance. The lack of such expertise meant that companies either had to invest heavily in training their current employees or face the difficult task of recruiting new, specialized talent in an already competitive market, often leading to bidding wars for scarce skills.

The training process itself presented a challenge. It could be lengthy, expensive, and disrupt ongoing production, leading to lost revenue. Employees needed time away from their duties to attend courses, often requiring weeks or even months of dedicated learning before they could operate the new machines independently and efficiently. This was a pain point Ahmed Al-Farsi specifically highlighted: his previous machines required skilled CAD operators, and high operator turnover caused constant retraining burdens, impacting his operational stability and profitability. This direct feedback guided MZBNL's innovation to solve a critical industry problem.

Our pioneering No-CAD Operating System was developed precisely to address this. By allowing operators to process standard tube types and hole patterns by simply entering parameters without requiring complex 3D drawings, we dramatically shortened the skill threshold and training time from 15 days of intensive factory training to just one day of on-site training. This user-friendly design significantly lowered the barrier to entry for machine operation, making advanced technology accessible to a broader workforce. Furthermore, effective change management strategies, emphasizing the benefits of the new technology and providing comprehensive support, became crucial to ensuring smooth adoption and buy-in from the workforce, transforming initial apprehension into skilled proficiency and enthusiastic participation in the technological evolution.

Integration with Existing Workflows and Production Lines

Integrating advanced metal tube cutting machines into established manufacturing workflows and production lines presented a complex set of operational challenges. Factories often had decades-old layouts designed for manual or semi-automated processes, making it difficult to seamlessly incorporate large, high-tech equipment that required specific power, space, and material handling systems. The disruption to ongoing production during installation and commissioning could be substantial, leading to temporary dips in output and missed delivery deadlines, sometimes for weeks. Companies needed to meticulously plan the physical layout, material flow, and data exchange between new and existing systems to avoid bottlenecks and optimize overall efficiency across the entire factory.

Beyond the physical integration, there was the challenge of data flow and connectivity. Modern cutting machines often rely on digital models and production schedules. Ensuring that design files from the engineering department could be seamlessly translated into machine code, and that production data could be fed back into enterprise resource planning (ERP) systems for inventory management, scheduling, and quality control, required significant IT infrastructure development and software integration. For many businesses, this meant overcoming legacy system limitations, investing in new network capabilities, and addressing cybersecurity concerns, adding another layer of complexity to the transition.

Moreover, the multi-process integration offered by advanced machines, while a significant advantage, also meant rethinking the entire production sequence. For example, if a machine could now cut and punch simultaneously, upstream processes (like material preparation) and downstream processes (like welding or assembly) needed to be re-evaluated and potentially adjusted to keep pace, preventing new bottlenecks. This required a holistic approach to process optimization, often involving expert consultants, pilot projects, and iterative adjustments to fine-tune the new workflow. My personal experience with MZBNL's integrated R&D, manufacturing, sales, and service model has shown me that providing tailored solutions is key. This approach allows us to address the unique integration challenges of each client, ensuring their new machines become a seamless and powerful component of their existing production ecosystem rather than a standalone island of automation.

High capital investment was a major barrierПравда

Advanced metal tube cutting machines required substantial upfront costs, often exceeding $1 million, plus additional installation and infrastructure expenses.

Traditional workers could easily operate new machinesЛожь

CNC laser cutting required new skills in CAD/CAM software and machine programming that traditional metalworkers didn't possess, necessitating extensive retraining.

What strategies helped overcome these challenges in metal tube cutting?

The significant investment, skill gaps, and integration hurdles associated with advanced metal tube cutting machines often deterred manufacturers, leading to stagnation. Businesses struggled to realize the full potential of these technologies without a clear roadmap for adoption. What practical strategies proved most effective in overcoming these complex challenges?

Overcoming challenges in metal tube cutting technology adoption involved strategic investments in comprehensive operator training and skill development, prioritizing modular metal tube cutting solutions, and fostering strong supplier partnerships for technical support. Phased implementation and robust financial planning also proved crucial for successful integration.

Having witnessed the challenges and triumphs of countless manufacturers in this technological shift, I can attest that overcoming these hurdles wasn't accidental; it was the result of deliberate and often innovative strategies. From my perspective at MZBNL, a high-tech enterprise specialized in laser cutting machines5 with 25 years of experience, we've actively developed solutions specifically designed to ease these transitions. The success stories often involved a combination of smart technological choices, proactive human resource management, and strategic partnerships, all aimed at maximizing the return on investment and minimizing disruption, ensuring long-term profitability and sustained growth.

Strategic Investment and Financial Planning

To mitigate the high capital investment challenge, manufacturers adopted several strategic approaches. One common method was conducting thorough cost-benefit analyses, projecting long-term savings from reduced labor, material waste, and increased throughput against the initial outlay. This allowed them to build a strong business case and secure financing from banks, private equity, or even venture capital firms. Many companies also explored leasing options, which offered more flexible payment structures and lower upfront costs, or leveraged government incentives and technology upgrade grants6, which could significantly reduce the immediate financial burden and free up capital for other operational needs. This pragmatic financial planning ensured that the investment was seen not as an expense, but as a long-term asset contributing to sustainable growth and competitive advantage.

Furthermore, some manufacturers adopted a phased implementation strategy to de-risk the transition. Instead of immediately replacing all manual operations, they would invest in one or two advanced machines for specific high-volume or complex product lines. This allowed them to test the technology, train their staff in a controlled environment, and gradually integrate the new capabilities without disrupting their entire production. Once the benefits were proven and the staff proficient, they could then scale up their investment by acquiring more machines or expanding their automated lines. This cautious yet progressive approach minimized financial and operational risk while still allowing them to reap the benefits of automation.

For instance, a mid-sized metal fabrication business, much like Ahmed Al-Farsi's, might start with a single Laser Tube Cutting Machine7, focusing on its automatic feeding and punching capabilities for their architectural metalwork projects. They could utilize this initial machine to train their team, refine workflows, and demonstrate tangible ROI. Once they see the verifiable benefits in terms of precision, speed, and reduced labor, they might consider expanding to other production lines or even replacing more legacy equipment across their facilities. This measured approach, backed by robust financial projections, clear performance metrics, and a deep understanding of the long-term ROI, transformed a daunting capital expenditure into a manageable and highly profitable strategic move for sustainable business growth.

Comprehensive Training and Skill Development Programs

Addressing the skill gap was paramount, and manufacturers implemented comprehensive training and skill development programs. This involved both internal and external training initiatives. Internally, experienced operators or engineers might be trained as "super-users" or internal trainers, who could then disseminate knowledge to their colleagues through workshops and hands-on sessions. Externally, companies often partnered directly with machine manufacturers, like MZBNL, to provide in-depth training sessions, both at the factory and on-site, ensuring practical application. These programs typically covered machine operation, programming (CAD/CAM), advanced maintenance, and troubleshooting, ensuring a holistic understanding of the new equipment and its full capabilities.

A key innovation in this area, directly from MZBNL, is our Операционная система No-CAD8. Recognising Ahmed's pain points around skilled CAD operators and high turnover, which often cost businesses significant time and resources in recruitment and retraining, we revolutionized the training process. Instead of the traditional 15 days of intensive factory training required for complex CAD operations, our system allows operators to be proficient after just one day of on-site training. This dramatically reduces the learning curve and the associated costs of downtime and skilled personnel, making advanced technology accessible and reducing the burden of finding highly specialized staff.

Beyond formal training, fostering a culture of continuous learning and cross-training became vital. Encouraging operators to share best practices, setting up mentorship programs, and providing access to online resources, simulation software, or internal knowledge bases helped maintain and upgrade skills over time, adapting to new software versions or machine functionalities. This proactive approach to human capital development not only ensured operational efficiency but also boosted employee morale and retention by investing in their professional growth, transforming initial apprehension or resistance into enthusiasm for mastering new, valuable capabilities.

Strong Supplier Partnerships and After-Sales Support

Establishing strong, long-term partnerships with reputable machine suppliers proved to be one of the most effective strategies for overcoming technological challenges. A reliable supplier offers more than just equipment; they provide critical after-sales support, comprehensive technical assistance, readily available spare parts, and sometimes even remote diagnostics and service capabilities. This ongoing support is invaluable, especially during the initial integration phase and when unforeseen technical issues or performance optimization needs arise, minimizing costly downtime. Manufacturers learned that prioritizing suppliers with a strong global presence and a proven track record, like MZBNL with 4000+ global enterprise clients and main export countries across Southeast Asia, North America, and Europe, was crucial for sustained operational success.

For customers like Ahmed Al-Farsi, the availability of robust after-sales service and training support, along with guaranteed spare parts availability and remote diagnostics capabilities, were key sourcing points. He specifically noted that equipment from some suppliers lacked local service support, highlighting this as a significant pain point that could lead to extended machine downtime and missed project deadlines. MZBNL directly addresses this by offering comprehensive post-sales training and support, which is critical for turnkey solutions, ensuring that clients can quickly get their machines up and running and maintain peak performance.

These partnerships also facilitate crucial knowledge transfer and continuous improvement. Suppliers can provide valuable insights into industry best practices, new applications, and future technological trends, helping manufacturers stay competitive and innovate their own product lines. For example, if Ahmed were to become a regional distributor for MZBNL, it would exemplify the depth of such a partnership, moving beyond a simple transactional relationship to a strategic alliance focused on mutual growth and market leadership. This collaborative approach, where the supplier acts as a technological partner and problem-solver, significantly de-risks the adoption process and accelerates the realization of the full benefits of advanced metal tube cutting technology, ensuring long-term operational excellence and market relevance.

Phased implementation reduces riskПравда

The article explains how starting with one machine allows controlled testing and training before full-scale adoption.

CAD training takes 15 daysЛожь

MZBNL's No-CAD system reduces training to just one day, contrary to traditional CAD systems.

Which cutting-edge technologies are shaping the future of tube cutting?

The rapid pace of technological innovation means current tube cutting machines, while efficient, may soon be surpassed, leaving businesses to grapple with outdated systems and losing their competitive edge. Staying ahead requires understanding the next wave of advancements. What groundbreaking technologies are set to redefine tube cutting in the coming years?

The future of tube cutting is being shaped by advanced laser technologies like fiber and ultra-fast lasers, enhanced automation with robotics and AI, and integrated smart manufacturing systems. These innovations promise even greater precision, speed, efficiency, and adaptability for complex production needs.

As someone immersed in the research and development side of metal fabrication, I'm continually excited by the pace of innovation. The future of tube cutting isn't just about faster machines; it's about smarter, more integrated, and ultimately, more autonomous systems. We at MZBNL are actively at the forefront of this evolution, constantly pushing boundaries with our own patented technologies. These cutting-edge advancements promise to further revolutionize manufacturing, addressing the growing demands for customizability, sustainability, and ultra-high precision, ensuring businesses can meet the challenges of tomorrow's market head-on.

Advanced Laser Technologies and Ultra-High Precision

The future of tube cutting is undeniably centered on increasingly sophisticated laser technologies. While CO2 lasers were once dominant, fiber lasers have taken center stage due to their superior efficiency, smaller footprint, and ability to cut highly reflective materials like copper and brass with greater ease. Fiber lasers offer higher beam quality, enabling faster cutting speeds (e.g., up to 30% faster than CO2 lasers for certain materials) and finer kerf widths, which translates to minimal material loss and improved edge quality, often eliminating the need for secondary deburring. This is crucial for industries demanding ultra-high precision, such as medical device manufacturing or micro-electronics, where even micron-level accuracy can impact product functionality and safety.

Beyond standard fiber lasers, the emergence of ultra-fast lasers9 (picosecond and femtosecond lasers) is pushing the boundaries of precision and minimizing heat-affected zones. These lasers deliver energy in extremely short pulses (trillionths or quadrillionths of a second), vaporizing material with very little thermal impact on the surrounding area. This results in virtually burr-free cuts, eliminating the need for secondary finishing processes and preserving the material's integrity, even for highly sensitive or complex alloys. For specialized applications like thin-walled tubes for aerospace components or delicate medical implants, these lasers are becoming indispensable, ensuring superior quality and drastically reducing post-processing costs. Their ability to process new composite materials and advanced alloys also opens up entirely new design possibilities.

At MZBNL, our focus on high-speed and high-precision cutting is directly aligned with these advancements, drawing on our 25 years of experience. Our commitment to integrated R&D ensures that our machines leverage the latest in laser technology to deliver optimal performance and maintain a competitive edge. For instance, achieving incredibly fast cuts while maintaining minute tolerances, which is a key feature of our products, relies heavily on these cutting-edge laser innovations. This allows clients like Ahmed to meet strict architectural specifications and deliver high-quality components for vehicle parts, staying competitive in a market that increasingly values precision above all else and demands complex, clean cuts for high-value applications.

Robotics, Automation, and AI Integration

The seamless integration of robotics, advanced automation, and artificial intelligence (AI) is transforming tube cutting into a highly autonomous process. Robotic loading and unloading systems are becoming standard, significantly increasing throughput by minimizing human intervention and maximizing machine uptime. These robots can handle tubes of varying lengths and weights, feeding them precisely into the cutting machine and then sorting finished parts, further enhancing efficiency and safety on the factory floor by removing operators from hazardous areas. This level of automation reduces labor costs, ensures consistent operation around the clock, and allows for flexible batch sizes, particularly in high-volume production environments.

AI is poised to revolutionize process optimization and predictive maintenance in tube cutting. AI algorithms10 can analyze cutting data in real-time, adjusting parameters (like laser power, cutting speed, and assist gas pressure) to maintain optimal cut quality and compensate for material variations or machine wear, often without human input. This smart digitalization leads to fewer errors, less scrap, and extended tool life. Furthermore, AI-powered predictive maintenance systems can monitor machine health through sensor data, anticipating potential failures before they occur, scheduling maintenance proactively, and minimizing costly downtime, often reducing unscheduled downtime by 50% or more. MZBNL's focus on smart and digitalized systems aligns perfectly with this trend, providing easy-to-operate and maintain solutions for our clients.

Our No-CAD System Innovation, for example, embodies a step towards AI-driven simplicity. While not yet full AI, it utilizes intelligent parameter-based processing to simplify complex operations, showing the direction of user-friendly, intelligent automation where machines perform more complex tasks with simpler inputs. Furthermore, our Front-Feeding Innovation, which increases feeding efficiency by 40% and reduces operator labor intensity by 40%, leverages advanced automation principles to optimize workflow ergonomics and productivity, laying the groundwork for even greater autonomy. The future will see more sophisticated AI controlling every aspect, from design optimization to supply chain integration, making the entire tube cutting ecosystem incredibly efficient and responsive. This comprehensive automation is particularly attractive to clients like Ahmed, who are actively pursuing automated solutions to upgrade their production efficiency and desire turnkey systems that are easy to install and operate with minimal skilled labor.

Smart Manufacturing and Industry 4.0 Connectivity

The future of tube cutting is deeply embedded within the broader context of Smart Manufacturing and Industry 4.0 principles. This involves creating interconnected ecosystems where machines, sensors, and software communicate seamlessly, sharing data to optimize the entire production chain. Tube cutting machines11 will be key nodes in these intelligent factories, not just executing cuts but also providing real-time data on material consumption, production rates, machine status, quality metrics, and energy usage. This data enables managers to make informed decisions, identify bottlenecks, continuously improve processes, and respond dynamically to market changes.

The concept of "digital twins" is gaining traction, where a virtual model of the physical machine or entire production line exists, allowing for simulations, testing of new parameters, and predictive analysis without impacting live production. This enables manufacturers to optimize their cutting strategies, experiment with new designs, and troubleshoot issues in a risk-free virtual environment before deploying them in the real world. For complex and customized production, this greatly reduces development time, material waste, and the risk of costly errors. Our own integrated R&D, manufacturing, sales, and service model allows us to tailor solutions that fit into these evolving smart factory environments, providing a holistic approach to manufacturing excellence.

Finally, the trend towards mass customization and just-in-time production is heavily reliant on this level of connectivity and flexibility. Future tube cutting machines will be capable of rapidly switching between different product designs and material types with minimal setup time, responding instantly to changing customer demands and even executing unique, one-off orders efficiently. This agility, combined with enhanced traceability of parts through the production process, ensures higher quality control, compliance with increasingly stringent industry standards, and a competitive edge in global markets. Ahmed's interest in customization and efficient workflows is a prime example of a client who will benefit immensely from these future-proof, interconnected manufacturing systems, allowing his business to evolve with dynamic market demands and explore new profit models like regional distribution.

Волоконные лазеры режут быстрее, чем CO2-лазерыПравда

Fiber lasers offer up to 30% faster cutting speeds for certain materials due to their superior beam quality and efficiency.

Ultra-fast lasers require secondary finishingЛожь

Picosecond and femtosecond lasers produce virtually burr-free cuts, eliminating the need for secondary finishing processes.

Заключение

The shift from manual saws to automated tube cutting machines profoundly transformed metalworking. Driven by precision and efficiency, this evolution empowers businesses with unprecedented capabilities. As an industry leader, I anticipate advanced automation and AI will continue to redefine production, securing your future success.

-

Discover how automated cutting boosts speed, precision, and reduces labor costs significantly. ↩

-

Explore solutions that simplify operations without needing skilled CAD operators. ↩

-

Discover the advantage of exact repeatability in product quality and assembly. ↩

-

Understand the impact of automation on reducing labor and enhancing production volume. ↩

-

Learn more about MZBNL's innovations and leadership in the laser cutting industry. ↩

-

Explore financial incentives that reduce costs for adopting advanced manufacturing technology. ↩

-

Understand the improvements in precision and speed offered by laser cutting technology. ↩

-

Uncover the advantages of MZBNL's innovative No-CAD system in reducing training time. ↩

-

Discover how ultra-fast lasers achieve burr-free cuts and minimize heat-affected zones. ↩

-

Explore how AI improves cut quality and predictive maintenance in tube cutting systems. ↩

-

Understand the role of tube cutters in smart manufacturing and data-driven decision-making. ↩

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.