MY-высокоскоростной 3D станок для лазерной резки труб

Быстро, точно, без усилий

Преимущества и особенности

Передовые технологии и инновационные конструктивные особенности отличают наш станок лазерной резки от конкурентов

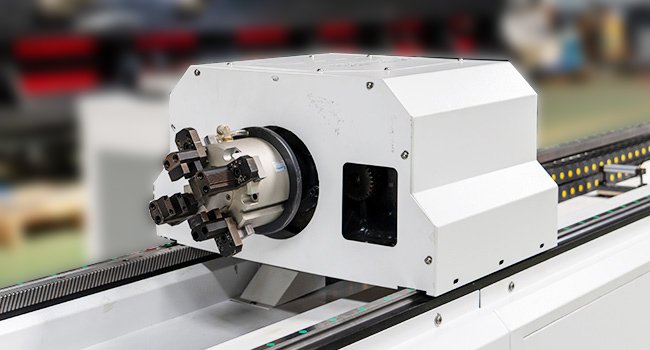

Фронтальный патрон Подвижная резка

Сокращение длины хвостового материала до 35 мм или достижение "нулевого" хвоста, что значительно улучшает использование материала и экономит ресурсы.

Полуавтоматическая система загрузки полосок ключей

Более простая и эффективная загрузка, позволяющая одновременно загружать 5-12 труб.

Система резки труб без протяжки

Обычные операторы могут быстро приступить к работе без необходимости традиционного 3D-черчения для стандартных труб и типов отверстий.

Система управления автобусом

Многоосевая связь с процессами скачкообразной и летучей резки, повышающая эффективность примерно на 30% по сравнению с традиционными импульсными системами.

Патрон с полным ходом

Автоматическое центрирование и установка труб из разных материалов и разной формы без необходимости замены приспособлений.

Задний патрон с автоматической продувкой

Предотвращает заклинивание челюстей, сохраняя стенки трубы чистыми во время работы.

Настройка левого/правого станка

Адаптируется к планировке завода, облегчает работу оператора, экономит место и рабочую силу.

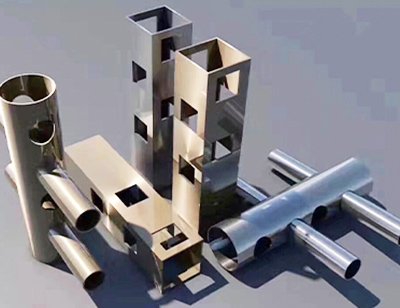

Универсальные виды резки

Совместим с любыми трубами, включая квадратные, круглые, овальные, стальные швеллеры, угловое железо и двутавровые балки.

Универсальное применение

Эффективно выполняет 3D-резку различных типов труб малого и среднего размера, что делает его звездным продуктом в мебельной индустрии!

Подробнее о продукте

Ознакомьтесь с расширенными возможностями и прецизионной конструкцией нашего станка для лазерной резки

Технические характеристики

Подробные технические параметры и спецификации систем лазерной резки MY10 и MY12

| Модель | MY10 | MY12 |

|---|---|---|

|

Мощность лазера (Вт)

|

1500-6000 | 1500-6000 |

|

Диапазон обработки

|

Круглая труба: φ8мм-φ120мм

Прямоугольная труба: Внешняя окружность ≤ φ120 мм

Труба специальной формы: Внешняя окружность ≤ φ120 мм

Качество труб должно соответствовать требованиям стандарта GB/T17395-1998. Для труб специальной формы, пожалуйста, проконсультируйтесь с техническим персоналом нашей компании для получения подробной информации.

|

Круглая труба: φ10mm-φ160mm

Прямоугольная труба: Внешняя окружность ≤ φ160 мм

Труба специальной формы: Внешняя окружность ≤ φ160 мм

|

|

Вес однотрубной трубы

|

Максимальная суммарная грузоподъемность обоих патронов: 100 кг | Максимальная суммарная грузоподъемность обоих патронов: 140 кг |

|

Точность повторного позиционирования (ММ)

|

±0.02 | ±0.02 |

|

Диапазон обработки труб (ММ)

|

≈6250 | ≈6250 |

|

Размер машины (L×W×H MM)

|

8856×1365×2172 | 8856×1365×2172 |

|

Вес машины (Т)

|

≈3.5 | ≈3.5 |

|

Максимальное ускорение (G)

|

≈1.6 | ≈1.3 |

|

Длина материала хвоста (ММ)

|

≈60 | ≈80 |

Примечания

Стандартный лазер мощностью 1500 Вт (мощность настраивается). 1500 Вт: внутренний кулер (малошумный, компактный). Другие: внешний кулер (гибкое размещение)

Внешний вид

Важное уведомление

Изменения внешнего вида и параметров оборудования возможны без предварительного уведомления. Только наши технические решения и подтвержденные условия заказа являются обязательными. Контракт и фактический продукт имеют преимущественную силу.

Дополнительные аксессуары

Усовершенствуйте свою систему лазерной резки с помощью нашего обширного ассортимента дополнительных принадлежностей

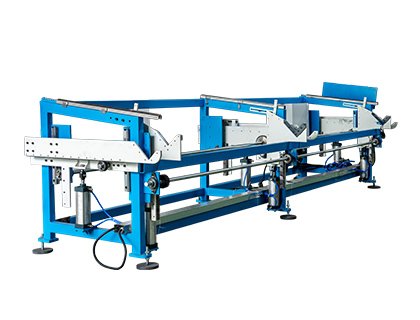

Ручная погрузочно-разгрузочная стойка с фронтальным входом и выходом

Эффективная система ручной загрузки для фронтального входа и выхода, обеспечивающая гибкие возможности обработки материалов.

Полуавтоматическая подающая стойка с задним расположением сторон

Усовершенствованная полуавтоматическая система подачи с задним расположением для непрерывной подачи материала и повышения производительности.

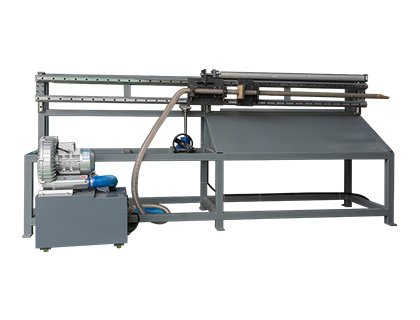

Полуавтоматическая подающая стойка с задней стороны

Специализированная система подачи ключевой ленты для точного позиционирования материала и автоматизированной оптимизации рабочего процесса.

Система извлечения шлака

Эффективная система удаления шлака и мусора обеспечивает чистоту работы и поддерживает оптимальное качество резки.

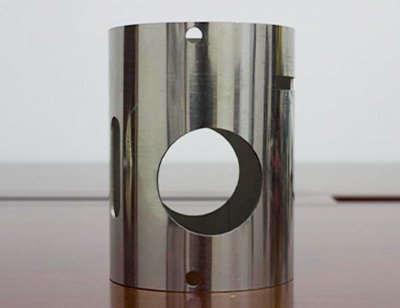

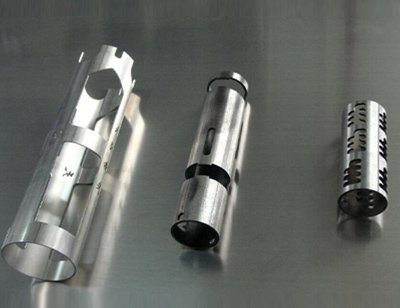

Образцы для резки

Демонстрация результатов точной резки, достигнутых с помощью наших высокоскоростных станков для 3D-лазерной резки труб из различных материалов и в различных областях применения

Технические характеристики резки

Наши станки обеспечивают исключительное качество резки широкого спектра материалов и толщин

Точность резки

Точность позиционирования ±0,02 мм

Диаметр трубы

Диапазон 6 мм - 325 мм

Толщина стенок

Производительность 0,5 мм - 20 мм

Скорость резки

Скорость подачи до 40 м/мин