Laser Tube Cutting in Construction: From Structural Frames to Handrails

Traditional construction methods often face delays and significant material waste, impacting project profitability. This often leads to increased costs and longer timelines. Discover how laser tube cutting offers a precise, efficient alternative, revolutionizing the construction sector by streamlining fabrication.

Laser tube cutting plays a pivotal role in modern construction by enabling the rapid and precise fabrication of complex metal components, from load-bearing structures to decorative elements. This technology significantly improves accuracy, reduces material waste, and accelerates project completion for diverse architectural and infrastructural applications.

In my two decades of experience helping businesses like yours automate their metal fabrication, I've seen firsthand how adopting cutting-edge technologies transforms operations. As the demand for intricate designs and faster project delivery intensifies, understanding the full potential of laser tube cutting becomes crucial. Let’s explore how this innovation is reshaping the very foundations of construction, paving the way for more efficient and sustainable building practices worldwide.

The construction industry is undergoing a significant transformation, driven by a global push for greater efficiency, sustainability, and architectural complexity. Traditional metal fabrication methods, often reliant on manual processes or less precise machinery, frequently lead to material waste, longer production cycles, and costly rework. This inherent inefficiency poses a critical challenge for project managers and fabricators striving to meet tight deadlines and budget constraints. Take, for instance, a recent major infrastructure project in the Middle East, where complex steel structures for a new metro system required precisely cut and fitted steel tubes1. Relying on conventional sawing and drilling would have extended the timeline by months and increased material expenditure due to cutting inaccuracies and post-processing needs. Laser tube cutting emerges as a powerful antidote to these challenges, offering unparalleled precision, speed, and design flexibility. Its ability to produce intricate geometries with minimal human intervention not only streamlines the fabrication process but also opens doors for innovative architectural designs previously deemed too complex or expensive. As we delve into the specific applications and inherent benefits, it becomes clear how this technology is not just an incremental improvement but a fundamental shift in how metal components are brought to life within the built environment. From intricate façade elements to robust structural frameworks, understanding laser tube cutting’s transformative impact is essential for any construction stakeholder looking to gain a competitive edge in today's rapidly evolving market.

What role does laser tube cutting play in the construction industry?

Modern construction demands precision and speed for complex structures. Manual cutting methods often fall short, leading to errors and delays. Laser tube cutting provides the accuracy and efficiency needed2 to meet these stringent industry requirements, revolutionizing fabrication.

Laser tube cutting serves as a cornerstone technology in construction by precisely fabricating metal tubes for structural supports, artistic facades, and functional components like handrails and pipework. Its role encompasses ensuring structural integrity, aesthetic appeal, and faster assembly times by delivering components with exact dimensions and complex geometries.

From the moment I first witnessed the sheer precision of laser cutting over two decades ago, I knew this technology would redefine manufacturing. In the construction sector, where every millimeter counts and project timelines are unforgiving, the capabilities of laser tube cutting are nothing short of revolutionary. It's not just about cutting metal; it's about enabling architects to push design boundaries, helping engineers ensure structural integrity with higher confidence, and allowing fabricators to meet aggressive delivery schedules. This advanced process mitigates common site errors and drastically reduces on-site adjustments, leading to smoother project execution and significant cost savings. The role of this technology extends beyond mere fabrication; it's a strategic asset that underpins the entire construction lifecycle, from initial design conceptualization through to final assembly, solidifying its indispensable position in modern building practices.

Enabling Complex Architectural Designs and Structural Integrity

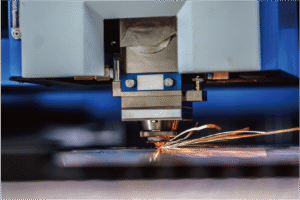

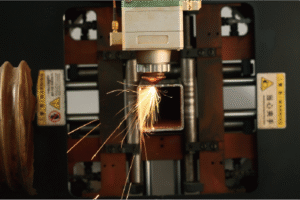

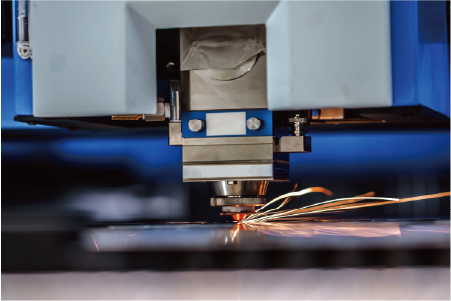

The modern architectural landscape is increasingly characterized by intricate geometries and innovative structural forms, demanding fabrication techniques that can match this complexity. Traditional cutting methods, such as sawing and drilling, often struggle with non-standard angles, tight tolerances, and elaborate patterns, leading to significant manual rework and compromised precision. Laser tube cutting, however, excels in these areas. It uses a high-powered laser beam to cut through various metal tubes—including steel, aluminum, and stainless steel3—with exceptional accuracy, typically ±0.1mm. This precision allows for the creation of components that fit together seamlessly, reducing assembly time on-site and enhancing the overall structural integrity of buildings. For instance, in an iconic stadium project, complex tubular trusses formed the backbone of the retractable roof. Without laser tube cutting, fabricating these thousands of unique, precisely angled intersections would have been an insurmountable challenge, or at best, an incredibly time-consuming and error-prone process. The ability to produce ‘nestable’ parts from a single tube, maximizing material use, further underscores its importance. Research by industry bodies like the Steel Construction Institute consistently highlights that precision fabrication can reduce on-site installation times by up to 20%, directly attributing this efficiency to advanced cutting technologies.

Optimizing Material Utilization and Reducing Waste

Material costs represent a significant portion of any construction project budget, making waste reduction a critical factor for profitability and sustainability. Conventional cutting techniques often result in considerable scrap material due to limitations in optimizing cut paths or the inability to utilize short remnants. Laser tube cutting, particularly with advanced systems like MZBNL’s Zero-Waste Tail Material Innovation, addresses this challenge head-on. By redesigning the cutting logic to calculate from the rear chuck as the origin, our systems eliminate leftover tail material as long as the remaining section is smaller than the product length. This revolutionary approach maximizes material utilization, allowing fabricators to extract more usable parts from each tube. A comparative analysis of projects reveals that traditional methods can yield 5-10% material waste from offcuts and miscuts, whereas laser tube cutting often brings this figure down to less than 1-2%. For a large-scale project requiring hundreds of tons of tubular steel, this translates into substantial savings. Consider Ahmed Al-Farsi, the owner of a mid-sized metal fabrication business in the UAE. His primary concern includes maximizing output and reducing material costs. Implementing a zero-waste system would directly impact his profit model, which relies on delivering finished parts efficiently to builders and OEMs. This technological advancement not only benefits the bottom line but also contributes significantly to environmental sustainability by reducing industrial waste, aligning with global green building initiatives.

Streamlining Fabrication Workflows and Enhancing Productivity

The overall efficiency of a construction project is often dictated by the speed and seamlessness of its component fabrication. Laser tube cutting integrates multiple processes—cutting, drilling, slotting, and notching—into a single machine operation, eliminating the need for multiple workstations and manual transfers. This multi-process integration significantly reduces production bottlenecks and shortens lead times. For example, traditionally, a tube would be cut to length, then moved to a drilling station for holes, then potentially to another station for complex notching. Each transfer introduces potential for error and adds valuable time. With a laser tube cutting machine, all these operations are performed sequentially and automatically, driven by a single program. Our Front-Feeding Innovation, which increases feeding efficiency by about 40% and reduces operator labor intensity by approximately 40%, exemplifies this streamlining. This enhancement directly boosts productivity, allowing companies like Ahmed’s to handle more projects simultaneously and meet tighter deadlines. The reduction in manual handling also improves workplace safety and reduces fatigue. Furthermore, the ease of use, exemplified by MZBNL’s No-CAD Operating System—allowing operators to begin processing standard tube types and hole patterns by simply entering parameters without needing complex 3D drawings—drastically shortens setup time and lowers the skill threshold for machine operation. This means operators only need 1 day of on-site training instead of spending 15 days at the equipment factory, directly addressing Ahmed's pain point of high operator turnover and retraining burdens.

| Категория характеристики | Traditional Tube Fabrication | Laser Tube Cutting (MZBNL) |

|---|---|---|

| Точность | ±1-2mm, prone to manual error | ±0.1mm, highly repeatable |

| Материальные отходы | 5-10% (offcuts, miscuts) | <1-2% (Zero-Waste Innovation) |

| Интеграция процессов | Multiple machines/manual steps | Single machine, multi-process |

| Operator Skill Req. | High (CAD, specialized tools) | Lower (No-CAD system) |

| Время установки | Days (design, programming, setup) | Hours (parameter input) |

| Скорость производства | Slower, sequential tasks | Faster, simultaneous operations |

Лазерная резка уменьшает количество отходов материалаПравда

Laser tube cutting can reduce material waste to less than 1-2% compared to 5-10% with traditional methods, thanks to precise cutting paths and zero-waste innovations.

Традиционные методы более точныЛожь

Laser tube cutting achieves ±0.1mm precision, far surpassing traditional methods' ±1-2mm accuracy, enabling seamless component fitting and structural integrity.

How is laser tube cutting currently applied in construction projects?

Modern construction demands precision for diverse components. Manual methods struggle with complex forms and volume. Laser tube cutting provides the versatility and accuracy for countless applications, from frames to finishes, dramatically enhancing project capabilities.

Laser tube cutting is extensively applied in construction for fabricating structural frameworks, including beams, columns, and trusses, ensuring high load-bearing capacity and precise fit. It also crafts intricate architectural elements like facades, handrails, balustrades, and custom pipework for HVAC and plumbing systems, enhancing both functionality and aesthetic appeal across various project types.

When I consider the incredible structures rising globally, from Dubai's futuristic skylines to urban renewal projects across Europe, the silent workhorse behind their precision often goes unnoticed: advanced fabrication technology4. My work at MZBNL has allowed me to witness firsthand how our machines transform raw materials into complex components with breathtaking accuracy. It's not just about cutting; it's about enabling visions. Laser tube cutting isn't a niche tool; it's a foundational technology that underpins the quality and efficiency of almost every modern building project. From the skeleton of a high-rise to the intricate details of a designer staircase, its applications are incredibly diverse and continually expanding. The seamless integration of this technology into various construction phases underscores its indispensable value, proving that the future of building is built on precision5 and automation. Let’s dive into some specific examples that demonstrate its transformative impact across the industry.

Structural Frameworks and Load-Bearing Components

The core of any robust building lies in its structural integrity, heavily dependent on the precise fabrication of load-bearing elements. Laser tube cutting plays a critical role in manufacturing components such as steel beams, columns, trusses, and connection plates. These are often complex, requiring specific angles, holes for bolted connections, and slots for interlocking systems. The accuracy provided by laser technology, typically within microns, ensures that these structural elements fit together perfectly, minimizing on-site adjustments and enhancing the overall safety and stability of the construction. For instance, in the construction of large-span industrial buildings or intricate bridge structures, thousands of tubular sections6 must interconnect with exact alignment. Traditional methods often require multiple steps—sawing, drilling, punching, and deburring—each introducing potential cumulative errors. Laser tube cutting performs these operations in one pass, directly from the design file, significantly accelerating production and ensuring dimensional consistency across all parts. A case study from a major European prefabrication firm demonstrated a 30% reduction in assembly time for a modular building system after transitioning from conventional methods to laser tube cutting for their primary structural members. This efficiency gain directly translates into faster project completion and reduced labor costs on-site, a significant benefit for a business owner like Ahmed Al-Farsi who seeks to deliver projects swiftly and cost-effectively.

Architectural Facades, Handrails, and Decorative Elements

Beyond structural integrity, modern architecture places a significant emphasis on aesthetic appeal and bespoke design. Laser tube cutting is invaluable for creating intricate architectural facades, decorative screens, balustrades, and handrails that demand high levels of detail and customization. The technology can produce complex patterns, curves, and unique cutouts that would be incredibly difficult or impossible to achieve with traditional methods. Consider the ornate handrails found in luxury hotels or public spaces; these often feature intricate designs that serve both a functional and artistic purpose. Laser cutting allows for the creation of seamless, flowing designs directly from 3D models, ensuring precise alignment and high-quality finishes. For example, a recent project involved fabricating custom stainless steel railings for a high-rise residential building in Dubai. The architect’s design called for a unique geometric pattern with thousands of small, precisely cut openings. Utilizing a laser tube cutting machine not only ensured the fidelity of the design but also completed the fabrication within a fraction of the time and cost compared to manual or conventional CNC machining. This capability to execute complex designs with precision opens new possibilities for architects and designers, allowing them to push creative boundaries while maintaining cost-effectiveness for fabricators.

Specialized Systems: HVAC, Plumbing, and Furniture Components

Laser tube cutting’s versatility extends to various specialized construction components, including pipework for Heating, Ventilation, and Air Conditioning (HVAC) systems, plumbing conduits, and even bespoke furniture elements for commercial interiors. In HVAC and plumbing, precise cuts and perfectly aligned holes for connections are crucial to prevent leaks and ensure optimal system performance. Laser technology can cut tubes with specific angles for ducting, create precise openings for branch lines, and even engrave identification marks for easier installation. This minimizes the need for on-site welding and fitting, which are often time-consuming and labor-intensive. Furthermore, the burgeoning demand for custom-designed furniture and fixtures in commercial, retail, and hospitality sectors leverages laser tube cutting for its ability to produce unique shapes and perfect joints. My experience shows that the automotive and motorcycle parts producers, as well as display rack and shelf suppliers—all potential clients for MZBNL—frequently utilize laser cutting for complex tubular frames and connectors that require high strength-to-weight ratios and aesthetic finishes. This ability to produce multi-functional components with a single machine pass significantly reduces the overall manufacturing lead time and costs, making it an attractive solution for businesses like Ahmed’s that seek to diversify their offerings and expand into new markets.

| Область применения | Examples in Construction | Benefits of Laser Tube Cutting |

|---|---|---|

| Structural | Beams, Columns, Trusses, Frame Reinforcements | High precision, perfect fit-up, reduced welding, faster assembly |

| Architectural | Facades, Handrails, Balustrades, Decorative Screens | Intricate designs, complex geometries, superior finish, design flexibility |

| Mechanical | HVAC Ducting, Plumbing Conduits, Electrical Conduits | Accurate holes/angles for connections, reduced leaks, faster installation |

| Interior/Misc. | Custom Furniture, Shelving, Display Racks, Lighting Fixtures | Bespoke shapes, clean cuts, rapid prototyping, minimal post-processing |

Laser cutting ensures structural integrityПравда

Laser tube cutting provides micron-level precision for load-bearing components, ensuring perfect fit and structural safety.

Laser cutting is only for structural partsЛожь

Laser tube cutting is versatile, used for both structural elements and intricate decorative components like facades and handrails.

What challenges are faced when using laser tube cutting for construction components?

While powerful, laser tube cutting in construction isn't without hurdles. Issues like material variability and complex programming can hinder its full potential. Understanding these challenges is the first step toward effective mitigation and optimal performance7, ensuring successful project execution.

Key challenges in laser tube cutting for construction include managing material inconsistencies, handling large and heavy tube sections, complex software programming for intricate designs, and significant initial investment costs. Overcoming these requires robust machinery, advanced software integration, skilled operators, and efficient material handling systems to ensure precision and productivity.

In my two decades of navigating the metal fabrication industry, I’ve learned that no technology, no matter how advanced, is a magic bullet. While laser tube cutting offers unparalleled advantages, it's crucial to acknowledge the practical challenges that can arise, especially in the demanding construction sector. From the sheer scale of materials to the intricacies of project-specific designs, fabricators frequently encounter hurdles that, if not properly addressed, can compromise efficiency and profitability. My role at MZBNL has been to anticipate these issues and develop solutions that empower our clients. For instance, companies like Ahmed’s, looking to automate their existing manual workflows, need to be aware of potential pitfalls to ensure a smooth transition and maximize their return on investment. Let's critically examine these challenges to better understand how to navigate them effectively and unlock the full potential of laser tube cutting in real-world construction applications.

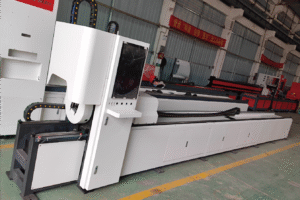

Material Handling and Logistical Complexities for Large Sections

One of the foremost challenges in applying laser tube cutting to construction components, particularly structural elements, stems from the physical characteristics of the materials8 themselves: their size, weight, and often, their raw, unrefined state. Construction projects frequently demand cutting long, heavy tubes—sometimes exceeding 12 meters in length and weighing hundreds of kilograms. Traditional laser cutting machines, often designed for smaller, lighter industrial components, struggle with the feeding, positioning, and unloading of such massive sections. This necessitates specialized material handling equipment, such as heavy-duty conveyors, automated loading systems, and overhead cranes, which add to the capital investment and require substantial factory floor space. For a mid-sized business like Ahmed Al-Farsi’s, expanding into architectural metalwork and vehicle parts, the logistical challenge of integrating such large-scale material handling can be a significant hurdle. My experience working with numerous clients has shown that inefficient material flow can negate the speed benefits of laser cutting, leading to bottlenecks and increased labor costs. For example, a fabricator undertaking a bridge project needed to cut 20-meter long steel piles. Without an automated front-feeding system, like MZBNL’s innovation that increases feeding efficiency by 40% and reduces operator labor intensity, manual handling would have required a large crew and significant time for each tube, severely impacting the project's profitability and timeline.

Complex Programming and Operator Skill Requirements

While laser tube cutting machines offer incredible precision and versatility, maximizing their potential, especially for bespoke construction components, often requires sophisticated programming. Architects and engineers frequently provide intricate 3D models with complex geometries, varying wall thicknesses, and numerous cutouts. Translating these designs into machine-readable G-code, optimizing nesting for material efficiency, and ensuring collision avoidance for multi-axis cutting can be a daunting task. This traditionally required highly skilled CAD/CAM operators, who possess a deep understanding of both design software and machine mechanics. The scarcity of such specialized talent in the workforce and the long training periods (often 15+ days at the equipment factory) contribute to significant operational costs and potential production delays. Ahmed Al-Farsi's pain point of "previous machines required skilled CAD operators" and "high operator turnover caused retraining burdens" directly reflects this industry-wide challenge. This highlights the critical need for user-friendly interfaces and simplified programming solutions. Without systems that democratize access to this technology, such as MZBNL’s pioneering No-CAD Operating System that allows operators to process standard tube types and hole patterns by simply entering parameters, businesses face a steep learning curve and reliance on a limited pool of experts.

High Initial Investment and Maintenance Considerations

Acquiring a state-of-the-art laser tube cutting machine represents a substantial capital investment. These machines, particularly those capable of handling large dimensions and high power outputs required for construction-grade materials, can cost hundreds of thousands to millions of dollars. For small to mid-sized enterprises, securing the necessary financing can be a significant barrier to entry, even if the long-term return on investment is clear. Beyond the initial purchase, there are ongoing operational and maintenance costs. Laser cutting involves high-precision optics, powerful laser resonators, and complex motion control systems, all of which require regular servicing and, occasionally, expensive spare parts. Ensuring the availability of spare parts and reliable after-sales support is crucial for minimizing downtime, as machine breakdowns can bring entire production lines to a halt, severely impacting project deadlines. Ahmed Al-Farsi's "sourcing key points" include "after-sales service and training support" and "spare parts availability9 and remote diagnostics," underscoring the real-world concerns of potential buyers. Furthermore, the energy consumption of high-power lasers, especially for cutting thick materials, can also add to the operational expenditure. Therefore, while the benefits are immense, prospective buyers must carefully evaluate the total cost of ownership, including power, gas, and cooling requirements, against their production volume and project pipeline.

| Зона вызова | Описание | Impact on Construction Projects |

|---|---|---|

| Обработка материалов | Loading/unloading large, heavy, long tubes; space reqs. | Slower cycles, increased labor costs, potential damage, floor space constraints |

| Programming Complexity | Intricate 3D designs, nesting optimization, collision avoidance | Reliance on highly skilled operators, longer setup times, higher labor costs |

| Первоначальные инвестиции | High capital cost for advanced machinery and specialized accessories | Barrier to entry for SMEs, financing challenges, long ROI period |

| Техническое обслуживание | Regular servicing, costly spare parts, potential downtime | Operational costs, project delays due to machine unavailability, need for reliable support |

Laser cutting requires specialized handling for large tubesПравда

Construction-grade tubes often exceed 12 meters and require heavy-duty conveyors/cranes for proper handling.

CAD skills aren't needed for laser tube cuttingЛожь

Traditional systems require skilled CAD operators to translate complex 3D designs into machine code (though no-CAD solutions are emerging).

What solutions exist to overcome these challenges in construction applications?

Laser tube cutting faces several hurdles in construction. These challenges can impede efficiency and adoption. Innovative technologies and strategic approaches are continuously emerging to effectively overcome these obstacles, ensuring smoother operations and maximized output.

Solutions for laser tube cutting challenges in construction include advanced automation for material handling of large sections, user-friendly No-CAD programming systems, and integrated software that streamlines design-to-production workflows. Furthermore, leveraging remote diagnostics and robust global service networks ensures minimal downtime and efficient technical support, mitigating operational risks.

Having spent 25 years in metal fabrication, I’ve learned that every challenge presents an opportunity for innovation. The issues faced in applying laser tube cutting to construction are not insurmountable; in fact, they’ve driven significant advancements in machine design and software capabilities. At MZBNL, our entire ethos revolves around identifying these pain points and engineering solutions that empower our clients to achieve unprecedented levels of efficiency and profitability. From simplifying complex operations to ensuring robust after-sales support, our commitment is to provide turnkey solutions that truly address real-world fabrication demands. For a forward-thinking business owner like Ahmed Al-Farsi, who values ease of use and reliable support, these solutions are precisely what transform a good machine into a strategic competitive advantage. Let’s explore the innovations that are effectively tackling these hurdles.

Automated Material Handling and Optimized Machine Design

The challenge of managing large and heavy tubes in construction fabrication has been significantly mitigated by advancements in automated material handling systems. Modern laser tube cutting machines are increasingly integrated with heavy-duty automatic loaders and unloaders that can manage tube lengths up to 12-15 meters and substantial weights, reducing reliance on manual labor and minimizing the risk of injury or material damage. For instance, MZBNL’s Front-Feeding Innovation automatically pulls the tube in from the front of the machine, increasing feeding efficiency by about 40% and reducing operator labor intensity by approximately 40%. This not only accelerates the loading process but also improves workplace ergonomics. Furthermore, specialized rollers and clamping systems within the machine ensure stable and precise positioning of even irregularly shaped tubes during the cutting process. Companies like Ahmed Al-Farsi’s, planning to automate existing manual workflows, find these features invaluable for scaling production without dramatically increasing their labor force. Automated systems also allow for continuous operation, enabling lights-out manufacturing shifts, which maximizes machine utilization and throughput. Industry reports indicate that automated loading systems can reduce loading times by up to 70% compared to traditional methods10, directly translating into higher output per shift.

Intuitive Software and No-CAD Operating Systems

The complexity of programming for intricate construction designs has been a significant barrier, but this is being addressed by more intuitive software solutions and revolutionary operating systems. Advanced nesting software can now automatically optimize cutting paths for multiple parts on a single tube, minimizing waste and maximizing material utilization. Crucially, the introduction of No-CAD Operating Systems, pioneered and perfected by MZBNL, has democratized access to laser tube cutting technology. Traditionally, operators needed extensive CAD/CAM training to create or modify complex 3D drawings. With our No-CAD system, standard tube types and hole patterns can be processed simply by entering parameters—no drawing required. This dramatically simplifies operation, shortens setup time, and lowers the skill threshold. For businesses like Ahmed’s, facing "high operator turnover" and "retraining burdens," this innovation is a game-changer. Operators now only need 1 day of on-site training instead of spending 15 days at the equipment factory, significantly reducing training costs and time-to-productivity. This shift from highly specialized CAD engineers to semi-skilled machine operators makes laser cutting more accessible and reduces reliance on a limited talent pool, directly impacting operational efficiency and cost-effectiveness.

Comprehensive After-Sales Support and Remote Diagnostics

Addressing the concerns of high initial investment and potential downtime, leading manufacturers are providing more robust after-sales support and advanced diagnostic capabilities. Comprehensive service packages, including on-site training, preventative maintenance programs, and readily available spare parts, are crucial. MZBNL, for example, prioritizes global support through its extensive distributor networks, ensuring that clients in Southeast Asia, the Middle East, Europe, and North America receive timely assistance. A critical innovation in this area is remote diagnostics. Modern laser tube cutting machines are equipped with sensors and connectivity features that allow manufacturers to remotely monitor machine performance, identify potential issues before they cause breakdowns, and even troubleshoot problems via a secure internet connection. This proactive approach significantly reduces downtime and the need for expensive on-site service visits. For Ahmed Al-Farsi, who values "local agent or distributor presence" and "remote diagnostics," this ensures business continuity and peace of mind. Furthermore, some suppliers offer flexible financing options or rental agreements, which can ease the initial financial burden for companies looking to integrate this technology without a massive upfront capital outlay. This comprehensive support infrastructure ensures that the advanced technology remains operational and delivers its promised benefits throughout its lifecycle.

| Challenge Addressed | Solution Implemented (MZBNL Focus) | Direct Benefit for Construction |

|---|---|---|

| Обработка материалов | Front-Feeding Innovation, Automated Loading Systems | 40% increased efficiency, reduced labor, safer operations, larger material capacity |

| Programming Complexity | No-CAD Operating System, Intuitive Software | 1-day operator training (vs. 15 days), lower skill threshold, faster setup, less errors |

| High Investment/Downtime | Global Distributor Networks, Remote Diagnostics, Comprehensive Training | Minimized downtime, rapid troubleshooting, reduced operational costs, enhanced ROI |

| Материальные отходы | Инновационный безотходный хвостовой материал | Maximized material utilization, significant cost savings, improved sustainability |

Системы без графики сокращают время обученияПравда

No-CAD systems allow operators to be trained in 1 day instead of 15 days by eliminating complex CAD/CAM requirements.

Remote diagnostics increase downtimeЛожь

Remote diagnostics actually reduce downtime by enabling proactive maintenance and remote troubleshooting.

How can laser tube cutting technology enhance efficiency in construction construction?

Construction projects constantly seek efficiency gains. Traditional methods often introduce bottlenecks and errors. Laser tube cutting provides a transformative approach to dramatically boost productivity and streamline workflows from design to assembly, ensuring superior results.

Laser tube cutting technology enhances construction efficiency by enabling rapid prototyping, precise prefabrication, and multi-process integration, significantly reducing on-site labor and material waste. Its ability to create complex, perfectly fitting components streamlines assembly, accelerates project timelines, and lowers overall costs, making construction processes faster, more accurate, and ultimately more profitable.

Over my 25 years at the forefront of metal fabrication, I've observed a fundamental truth: efficiency isn't just about doing things faster; it's about doing them smarter, with less waste and greater precision. In the construction industry, where every day of delay can cost thousands, adopting technologies that genuinely enhance efficiency is paramount. Laser tube cutting isn't merely an incremental upgrade; it represents a paradigm shift in how metal components are manufactured and integrated into buildings. From reducing reliance on manual labor to eliminating material waste, its benefits permeate every stage of a project. My client Ahmed Al-Farsi's pursuit of automated solutions to upgrade production efficiency perfectly encapsulates this drive. Let's delve into the specific mechanisms through which this technology delivers truly transformative efficiency gains across the construction lifecycle.

Accelerating Prefabrication and Off-Site Manufacturing

The future of construction heavily leans towards prefabrication and off-site manufacturing, strategies proven to reduce project timelines, improve quality control, and minimize on-site disruption. Laser tube cutting is a cornerstone technology enabling this shift. By allowing complex components like structural trusses11, modular frame sections, and even entire building facades to be fabricated with extreme precision in a controlled factory environment, it dramatically shortens the on-site assembly phase. Components produced with laser precision fit together perfectly, reducing the need for costly and time-consuming cutting, welding, or drilling adjustments on the construction site. For example, a study by McKinsey & Company on industrialized construction highlighted that projects utilizing off-site fabrication can see completion times reduced by up to 20-30%. My experience with clients who’ve transitioned to MZBNL’s laser tube cutting machines echoes this. They report a significant decrease in on-site labor hours for metalwork assembly, a crucial factor for companies like Ahmed Al-Farsi’s, which are looking to automate existing manual workflows and optimize staff allocation. The ability to mass-produce identical or highly similar components with consistent quality far from the unpredictable conditions of a construction site directly translates into unparalleled efficiency and cost savings.

Reducing Material Waste and Optimizing Supply Chain

Material waste is a perennial problem in construction, contributing to significant cost overruns and environmental impact. Traditional cutting methods often lead to substantial offcuts and scraps due to inefficient nesting and less precise cuts. Laser tube cutting, particularly with advanced features like MZBNL’s Инновационный безотходный хвостовой материал12, fundamentally transforms material utilization. By enabling the system to calculate from the rear chuck as the origin and utilize remaining tube sections smaller than the product length, it maximizes material yield. This innovation alone can reduce material waste by several percentage points, which, for large-scale projects, equates to tens of thousands of dollars in savings. For a busy metal pipe processing factory or a furniture manufacturer like Ahmed Al-Farsi's business, where profit margins can be tight, minimizing material waste directly boosts profitability. Furthermore, the precision of laser cutting allows for 'just-in-time' fabrication, where components are produced precisely when needed, reducing the need for extensive on-site storage and minimizing the risk of material damage or theft. This optimized supply chain management, from accurate material ordering based on precise cut plans to efficient delivery of ready-to-assemble components, contributes significantly to overall project efficiency and reduces logistical complexities.

Enhancing Design Flexibility and Quality Control

The integration of laser tube cutting technology empowers architects and engineers with unprecedented design flexibility, allowing for the creation of complex and aesthetically striking structures that were previously unfeasible or too expensive. From intricate curvilinear facades to elaborate support structures with complex joinery, laser technology can execute these designs with exacting precision. This capability extends beyond aesthetics; it also significantly enhances quality control. Because the laser cuts are precise and repeatable, every component produced adheres strictly to design specifications. This consistency reduces the likelihood of fit-up issues on site, leading to higher quality finished products and fewer reworks. My interactions with architectural decoration companies and elevator equipment integrators, both potential clients, consistently highlight how the ability to produce flawlessly matched components is critical for achieving high-end finishes and meeting stringent safety standards. Furthermore, the digital nature of laser cutting—where designs are directly translated from CAD/CAM software to the machine—minimizes human error. This digital workflow, combined with features like MZBNL’s No-CAD Operating System that simplifies parameter input, streamlines the entire design-to-fabrication process, ensuring that the final physical product perfectly matches the intended digital model, thereby enhancing both efficiency and the overall quality of construction projects.

| Efficiency Metric | Traditional Fabrication | Laser Tube Cutting (MZBNL Impact) |

|---|---|---|

| Assembly Time | Slower (on-site cuts/adjustments) | Up to 30% faster (prefabricated, precise fits) |

| Материальные отходы | 5-10% (offcuts, errors) | <1-2% (Zero-Waste Innovation) |

| Labor Cost | High (skilled on-site labor, multiple processes) | Reduced (less manual work, fewer trades, 1-day training) |

| Project Timeline | Longer (sequential processes, delays) | Accelerated (simultaneous operations, faster throughput) |

| Сложность конструкции | Limited, costly for intricate designs | Unprecedented flexibility, cost-effective for complex forms |

Лазерная резка уменьшает количество отходов материалаПравда

Advanced laser tube cutting with Zero-Waste Innovation can reduce material waste to 1-2%, compared to 5-10% with traditional methods.

Prefabrication increases on-site laborЛожь

Prefabrication with laser-cut components actually reduces on-site labor by 30% by eliminating manual adjustments during assembly.

Заключение

Laser tube cutting fundamentally redefines construction by boosting precision, cutting waste, and speeding up projects. It solves key challenges through automation and smart systems, empowering businesses like MZBNL to deliver tailored, efficient fabrication solutions. Embracing this technology is crucial for a future where structures are built faster, smarter, and with superior quality.

-

Learn how laser tube cutting reduces timeline and material costs in large infrastructure projects ↩

-

Discover how laser tube cutting ensures precision and efficiency in the construction industry ↩

-

Explore how precision laser cutting enhances construction with aluminum and stainless steel components ↩

-

Explore the technologies used in modern construction fabrications for precision and efficiency ↩

-

Learn how precision and automation drive efficiency in building designs and processes ↩

-

Discover the structural applications and benefits of tubular sections in construction ↩

-

Learn strategies to optimize laser tube cutting performance and increase construction project efficiency. ↩

-

Find out which equipment is essential for efficiently handling large materials in laser cutting. ↩

-

Understand the importance of spare parts availability for maintaining laser cutting machine efficiency. ↩

-

Learn about efficiency improvements in laser cutting through automation ↩

-

Gain insight into how structural trusses support buildings and optimize construction methods. ↩

-

Explore how this innovation reduces material waste improving cutting efficiency. ↩

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.