Что такое станок для лазерной резки труб и как он работает?

Struggling with complex metal tube fabrication? Manual methods are often slow, inaccurate, and labor-intensive, eating into your profits and delaying projects. This inefficiency makes it hard to compete in today's fast-paced market. A laser tube cutting machine offers a precise, automated solution to these challenges, transforming your production capabilities.

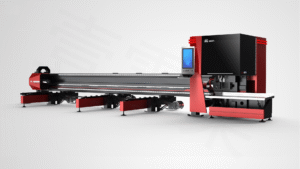

A laser tube cutting machine is an advanced manufacturing tool that utilizes a focused laser beam to cut, perforate, and shape metal tubes and pipes. It functions by directing a high-power laser through a specialized cutting head and nozzle, melting and vaporizing the material along a computer-programmed path with exceptional precision and speed.

Understanding the fundamentals of this technology is just the beginning. To truly appreciate its impact, we need to explore its capabilities, diverse applications, and the remarkable innovations that are constantly pushing its boundaries. As someone who has spent 25 years at MZBNL, helping businesses like yours adopt this technology, I want to guide you through how these machines are revolutionizing metal fabrication.

The evolution of laser tube cutting technology has been nothing short of remarkable. From its early days as a niche tool, it has grown into a cornerstone of modern metalworking, reflecting the broader manufacturing trends towards automation and unparalleled precision. Initially, these machines were complex, demanding highly skilled operators. However, continuous research and development, the kind we champion at MZBNL, has relentlessly focused on enhancing user-friendliness, operational efficiency, and overall versatility. For instance, during a visit to a client, Ahmed Al-Farsi in the UAE, he shared how his older machinery often became a production bottleneck. The constant need for intricate CAD adjustments and the availability of skilled operators were major pain points, directly impacting his ability to competitively bid on projects for architectural metalwork and automotive parts. This kind of direct feedback has been invaluable, fueling our drive towards transformative innovations like our No-CAD system, which aims to simplify operations and broaden the accessibility of this powerful technology for businesses worldwide.

What is the basic concept and functionality of a laser tube cutting machine?

Are you finding it difficult to visualize how a laser tube cutting machine transforms a simple raw tube into an intricately designed part? Without a clear understanding of its core mechanics, appreciating its profound benefits or making an informed decision when choosing the right machine can feel like a daunting task. Let's break down the fundamental concept and the precise operation of these powerful industrial tools.

The basic concept involves a high-intensity laser beam, meticulously guided by a computer numerical control (CNC) system, which precisely melts, burns, or vaporizes material from a tube. Functionally, the machine encompasses tube loading mechanisms, laser generation, sophisticated beam delivery optics, a cutting head, and material handling systems for precise, automated fabrication.

Now that we've covered the essential operational basics, you might be wondering how this sophisticated process translates into tangible results and significant advantages across a multitude of different industries. It's crucial to understand that laser tube cutting is not just about making cuts; it's about enabling entirely new design paradigms, substantially improving structural integrity through precision, and dramatically streamlining complex production workflows. The fascinating journey from a standard metal tube to a complex, finished component involves several key stages and technological components working in perfect harmony. I've seen this transformation firsthand at MZBNL, where we've helped countless clients, from furniture makers to automotive suppliers, unlock new efficiencies. Let's explore these elements in more detail to understand the true power and versatility of laser tube cutting machines.

At MZBNL, we've dedicated years to refining every aspect of laser tube cutting, and understanding these core elements is key to appreciating the technology's value. For clients like Ahmed, who are looking to automate and upgrade their production, grasping these fundamentals helps in making informed decisions about the machinery that will best suit their needs, especially when considering features like our No-CAD system or front-feeding innovations.

The Core Components: From Laser Source to Cutting Head

At the very heart of every laser tube cutting machine lies the laser source, also known as a resonator. In modern industrial applications, this is typically either a fiber laser or, less commonly now for new tube machines, a CO2 laser. We at MZBNL predominantly utilize fiber lasers in our machines due to their superior energy efficiency, significantly lower maintenance requirements, and the excellent beam quality they produce, which is ideal for cutting a wide range of metals, including reflective ones like brass and copper. This laser source is responsible for generating the high-energy, coherent beam of light that actually performs the cutting. The choice of laser source can impact cutting speed, the types of materials that can be processed, and overall operational costs, so it's a critical consideration.

Once generated, this intense laser beam is meticulously guided through a sophisticated beam delivery system. In fiber laser machines, this usually involves armored fiber optic cables that transmit the beam directly and efficiently to the cutting head with minimal power loss and without the need for complex mirror alignments often associated with CO2 lasers. The cutting head itself is a marvel of engineering, housing a series of precision lenses that focus the laser beam down to an incredibly small spot – often less than a tenth of a millimeter in diameter. This extreme concentration of energy achieves the immense power density required to melt and vaporize even thick metal. The cutting head also incorporates a nozzle that directs a stream of assist gas (such as oxygen, nitrogen, or compressed air) coaxially with the laser beam. This gas plays a crucial role in ejecting molten material from the cut kerf and, depending on the type of gas, can also participate in an exothermic reaction to aid the cutting process or protect the cut edge from oxidation. Ahmed's new machine for his architectural metalwork and automotive parts supply, for instance, specifically benefited from a high-power fiber laser for its versatility with various steels and aluminum.

Supporting these critical optical components are robust mechanical systems. A heavy-duty, stress-relieved machine frame provides the necessary stability and vibration damping to ensure high-precision cutting, even at rapid speeds. Sophisticated tube loading mechanisms, an area where MZBNL has innovated with our efficient front-feeding system, handle the intake of raw material. Powerful, precise chucks are essential for securely gripping the tube, rotating it accurately, and moving it axially under the cutting head. Many advanced systems also include automated unloading systems for finished parts and scrap management. The harmonious and precise synchronization of all these mechanical and optical components, orchestrated by the CNC controller, is what enables the machine to achieve complex cuts with tight tolerances day in and day out. A study by the Fraunhofer Institute for Laser Technology (ILT)1 highlighted that the dynamic precision of the motion system can impact cut quality attributes like perpendicularity and feature accuracy by up to 15%, underscoring the importance of a well-engineered mechanical base.

The Cutting Process: How the Laser Interacts with Material

The actual cutting process initiates the moment the highly focused laser beam impinges on the surface of the metal tube. The material absorbs the intense energy of the laser in a very localized area, causing its temperature to rise rapidly to its melting point and then, almost instantaneously, to its vaporization point. This extremely localized heating is a key advantage of laser cutting, as it minimizes the Heat-Affected Zone (HAZ)2 – the area of the material surrounding the cut that has had its microstructure and properties altered by the heat. A smaller HAZ is crucial for maintaining the material's original strength and structural integrity, which is particularly important for high-strength steels used in automotive safety components or precision parts for medical devices, sectors Ahmed is actively involved with.

Simultaneously with the laser beam, the assist gas selected for the specific material and application is expelled at high pressure through the nozzle in the cutting head. If oxygen is used as the assist gas, typically for cutting mild steel, it initiates an exothermic reaction with the hot metal. This reaction generates additional heat, which aids the cutting process, allowing for faster speeds and the ability to cut thicker sections. The oxygen also helps to vigorously eject the molten material, or slag, from the cut. Conversely, when cutting materials like stainless steel, aluminum, or other non-ferrous metals, an inert gas such as nitrogen is generally used. Nitrogen prevents oxidation of the cut edges, resulting in a clean, shiny, and dross-free finish that often requires no post-processing. The choice of assist gas, its purity, and its pressure are all critical process parameters that we at MZBNL help our clients, like a furniture manufacturer who reduced dross on their stainless steel chair frames by 70%, optimize for their specific applications.

As the laser melts and vaporizes the material and the assist gas clears the kerf, the cutting head moves along the programmed path, or the tube rotates and moves axially under a stationary or multi-axis head. This creates the desired shape, hole, slot, or complex profile. The speed of the cutting head's movement, the power output of the laser, the focal position of the beam, and the type and pressure of the assist gas are all meticulously controlled in real-time by the CNC system. This precise, multi-variable control is what allows for the creation of incredibly intricate patterns, sharp corners, and tight manufacturing tolerances that are simply unattainable with consistent quality through manual or older mechanical cutting methods. This precision directly translates into better fit-up for welded assemblies and higher quality finished products.

CNC Control and Automation: The Brains of the Operation

The Computer Numerical Control (CNC) system is, without a doubt, the sophisticated brain orchestrating the entire laser tube cutting operation. It interprets the digital design file – traditionally a CAD drawing, though our innovative No-CAD system at MZBNL significantly simplifies this for many common tasks – and translates this geometric information into precise, actionable movement commands for the machine's multiple axes (X, Y, Z, rotation, and sometimes additional axes for beveling). Simultaneously, it sends instructions to the laser source to modulate power and to the gas control system to regulate type and pressure. Modern CNC controllers are incredibly powerful, capable of managing complex, multi-axis interpolated movements at high speeds, enabling the creation of true 3D cuts and intricate features on the tube surface.

Automation in advanced laser tube cutting machines extends far beyond just guiding the cutting path. Our MZBNL machines, for example, integrate comprehensive automation features such as automatic bundle loaders and tube feeders, like the front-feeding innovation that Ahmed Al-Farsi found particularly appealing because it reduces manual labor intensity by approximately 40% and boosts feeding efficiency by a similar margin. These systems can automatically select and feed individual tubes from a storage rack. Advanced machines can also include features like automatic detection and compensation for tube straightness variations, optical seam detection for welded tubes (to orient the weld seam optimally for cutting or avoid it), and fully automated unloading systems that sort finished parts from scrap. This holistic level of automation dramatically increases machine throughput, minimizes the need for constant operator intervention, and allows for longer periods of unattended or "lights-out" operation. A report by McKinsey on automation in manufacturing suggests that such integrated automation features can boost overall productivity by 25-40% in typical metal fabrication environments.

Furthermore, cutting-edge systems, including those we develop at MZBNL, increasingly incorporate a suite of sensor technologies for real-time process monitoring and adaptive control. This can include capacitive height sensing for the cutting head to maintain the optimal focal distance from the tube surface, automatically compensating for any minor tube ovality or surface undulations. Laser power control systems can monitor the cutting process and make micro-adjustments to the laser output to ensure consistent cut quality even if material thickness varies slightly. This "smart" functionality, which we integrate into our increasingly digitalized systems, ensures optimal and consistent cut quality while minimizing waste from errors or miscuts, directly addressing concerns like those Ahmed had about material costs and rework with his previous, less sophisticated equipment. The seamless integration of these advanced control systems is paramount to achieving the high-speed, high-precision cutting performance our machines are renowned for.

| Feature Component | Function | Impact on Performance | MZBNL Innovation Focus |

|---|---|---|---|

| Источник лазерного излучения | Generates the high-energy light beam for cutting | Determines cutting speed, material capability, energy efficiency | Optimization of high-power fiber lasers |

| Cutting Head | Focuses the laser beam and delivers the assist gas to the cut zone | Governs precision, cut edge quality, and Heat-Affected Zone | Advanced nozzle design, auto-focus systems |

| CNC System | Interprets design data, controls machine movements & laser parameters | Dictates accuracy, complexity of cuts, level of automation | No-CAD system integration, intuitive HMI |

| Feeding System | Loads raw tubes and positions them for cutting | Affects overall throughput, labor efficiency, material flow | Automated front-feeding mechanism, bundle loaders |

| Chucks | Securely grip and rotate/translate the tube during processing | Ensures cutting accuracy, supports various tube profiles | High-precision, quick-change designs |

Fiber lasers are more efficient than CO2 lasersПравда

Fiber lasers offer superior energy efficiency and lower maintenance requirements compared to CO2 lasers, making them the preferred choice for modern tube cutting.

Laser cutting requires constant manual adjustmentsЛожь

Modern laser tube cutting machines are highly automated with CNC systems that precisely control all parameters without manual intervention.

How is the technology used in current industrial applications?

Wondering where laser tube cutting technology truly shines and makes a difference in the real world of manufacturing? Without seeing its practical, everyday uses, it's often hard to fully grasp the technology's transformative potential for your own specific operations and business growth. So, let's explore the diverse and expanding range of industrial applications where laser tube cutting machines are making a significant and measurable impact.

Laser tube cutting technology is widely used in industries requiring precise and complex tube fabrication. Key applications include automotive manufacturing for chassis and exhaust components, furniture production for frames, construction for structural elements and architectural features, and medical equipment manufacturing for intricate device parts, showcasing its remarkable versatility.

The adaptability of laser tube cutting is truly remarkable, extending its reach far beyond just a few niche industrial areas. From the intricate components found in advanced medical devices to the robust frames of agricultural machinery and construction equipment, its inherent precision and operational efficiency are fundamentally reshaping how products are designed, engineered, and manufactured. This technology empowers engineers and designers to create more complex geometries and stronger, lighter structures, often leading to more cost-effective and higher-performing final products. I've personally witnessed this transformative impact in numerous factories I've visited over my career. I vividly recall helping a display rack supplier in Southeast Asia completely optimize their product designs for faster assembly, thanks to the perfectly cut notches and tabs made possible by our MZBNL laser tube cutters. Let's delve into some specific sectors to see this technology in action.

At MZBNL, we've seen our machines deployed across an incredible spectrum of industries, each with unique demands. For a client like Ahmed Al-Farsi, who is expanding his UAE-based business into both architectural metalwork and automotive parts supply, the versatility of a single laser tube cutting machine to handle diverse applications is a major advantage. This adaptability, coupled with precision, is what makes the technology so compelling.

Automotive and Transportation: Precision for Performance and Safety

The automotive industry was one of the earliest adopters of laser tube cutting technology and continues to be a primary driver of its innovation and application. I've collaborated closely with numerous automotive manufacturers and Tier 1 suppliers, witnessing firsthand how they leverage this technology for a vast array of critical components. These include chassis frames and subframes, complex exhaust system components, roll cages for performance and safety vehicles, intricate seat structures, and various brackets and reinforcements. The exceptionally high precision afforded by laser cutting is absolutely critical for ensuring the tight tolerances required for vehicle safety standards, optimal performance characteristics, and streamlined assembly processes. For example, cutting accurately profiled holes and complex end-forms in hydroformed tubes for chassis components must be exact to ensure perfect fit-up during robotic welding and to guarantee the structural integrity of the vehicle during potential crash scenarios. A comprehensive study by the Center for Automotive Research (CAR)3 indicates that advanced fabrication techniques, prominently featuring laser cutting, can contribute to component weight reduction by up to 20% while simultaneously maintaining or even improving structural strength, a key factor in enhancing fuel efficiency and vehicle dynamics.

Beyond passenger cars and light trucks, laser tube cutting technology is indispensable in manufacturing parts for motorcycles (frames, handlebars), buses and coaches (structural frames, handrails), trains (carriage frames, interior fittings), and even in specialized aerospace applications where lightweighting and precision are paramount. Ahmed, my client in the UAE, is strategically expanding his fabrication business to supply components to the regional automotive aftermarket and specialty vehicle builders. His new MZBNL laser tube cutter, equipped with automatic feeding and our No-CAD system, is specifically geared towards efficiently producing these often complex, small-to-medium batch components. The machine's ability to cleanly and accurately cut high-strength steels (HSS), advanced high-strength steels (AHSS), and various aluminum alloys – materials increasingly common in modern vehicle design to meet safety and fuel economy targets – with minimal thermal distortion is a significant manufacturing advantage. This precision often reduces or eliminates the need for secondary finishing operations, saving valuable time and production costs.

Furthermore, laser cutting facilitates the creation of highly intricate joints and interlocking connections between tubular components that can significantly improve the torsional stiffness and overall strength of vehicle structures. For instance, precise "fish-mouth" cuts, copes, and other profiled ends required for tube-to-tube T-joint, K-joint, or Y-joint connections can be produced with incredible accuracy and repeatability. This leads to stronger, more consistent welds and ultimately more durable and reliable assemblies. This capability is particularly vital for safety-critical components such as Roll-Over Protection Systems (ROPS) and Falling Object Protective Structures (FOPS) in heavy machinery, agricultural vehicles, and off-road equipment, where structural integrity is non-negotiable. The precision of laser-cut components also simplifies jigging and assembly, further boosting production efficiency.

Architectural, Construction, and Furniture: Aesthetics Meets Functionality

In the realms of architecture and construction, laser tube cutting machines have unlocked new levels of design freedom, enabling the creation of complex, aesthetically pleasing, and structurally efficient elements. I recall a fascinating project where I worked with an innovative architectural firm that utilized our MZBNL machines to produce custom-designed, exposed tubular steel trusses with incredibly intricate intersecting connections for the roof structure of a new international airport terminal. The unparalleled precision of the laser-cut components ensured a perfect, gap-free fit-up on-site, which significantly accelerated the installation process and reduced the need for on-site modifications and skilled labor. The ability to cut a diverse range of tube profiles – including round, square, rectangular, elliptical, and even custom-extruded shapes – combined with 3D beveling capabilities4, opens up vast design possibilities for architects and structural engineers, allowing them to realize ambitious and visually striking designs for facades, canopies, bridges, railings, and unique decorative features.

The furniture industry has also enthusiastically embraced laser tube cutting for manufacturing high-quality frames for chairs, tables, sofas, beds, shelving units, and various other items for both residential and commercial markets. Designers can now create more ergonomic, lightweight, and visually appealing products, often incorporating complex curves and joints that were previously too costly or difficult to produce with traditional methods. One of our long-standing clients, a prominent office furniture manufacturer, transitioned from manual cutting, drilling, and grinding operations to one of our fully automated laser tube cutting lines. They subsequently reported an impressive 60% reduction in the production time required for their complex ergonomic chair frames and a dramatic improvement in overall product consistency and finish quality. Our proprietary No-CAD system proved particularly beneficial for their R&D department, as they frequently prototype new designs and greatly appreciated the ability to quickly adjust cutting parameters and hole patterns directly on the machine interface without the need for extensive CAD reprogramming. Ahmed Al-Farsi also sees significant potential in this area for his architectural metalwork projects in the UAE, where custom-designed metal railings, balustrades, and decorative screen elements are in high demand for luxury properties and commercial developments.

Display rack and shelf suppliers, another key client group for us at MZBNL, benefit immensely from the sheer speed, precision, and repeatability offered by laser tube cutting. These businesses often need to produce very large volumes of tubular components with a variety of hole patterns, slots, and end cuts to create modular and configurable display systems for retail environments, exhibitions, and warehousing. The consistent accuracy of laser-cut parts ensures easy, tool-free assembly for the end-user and contributes to a highly professional finish. For instance, producing precisely slotted tubes for adjustable shelving systems, or tubes with perfectly aligned connector holes for modular exhibition stands, becomes a simple, highly automated, and cost-effective process with a modern laser tube cutter. This efficiency allows them to be more competitive and responsive to customer demands.

Specialized Industries: Medical, Fitness, and Beyond

The medical equipment sector makes extensive use of laser tube cutting for manufacturing highly precise, often miniaturized, components for a wide range of applications, including surgical instruments, orthopedic implants, diagnostic devices, and drug delivery systems. The ability to cut extremely fine features, create intricate patterns, and achieve exceptionally clean edges with minimal burrs or thermal damage is absolutely critical in this field, where patient safety and device efficacy are paramount. Materials such as medical-grade stainless steel (e.g., 316LVM), titanium and its alloys, and Nitinol (a shape memory alloy)5 are commonly used, and laser cutting handles these advanced materials very effectively. I remember a particularly challenging application where a medical device company approached us to develop a process for cutting intricate, spiraling patterns in very small-diameter Nitinol tubes for catheters and guidewires. Our advanced laser control and fine-kerf capabilities allowed them to achieve tolerances and feature resolutions that were previously impossible with their conventional micro-machining methods.

Fitness equipment manufacturers are another significant group of users, relying on laser tube cutting for producing the robust frames and moving parts of treadmills, elliptical trainers, stationary bikes, and complex multi-station weight machines. The strength, durability, and safety of these products depend heavily on well-fabricated and accurately assembled tubular structures. Laser cutting allows for the creation of complex, interlocking joints and precise hole placements for fasteners and pivot points, which are essential for both structural integrity and ease of assembly by the end-user. The aesthetic appeal of smooth, clean laser cuts also enhances the product's perceived quality and value in a competitive consumer market. One of our clients in this sector highlighted how switching to laser-cut tubes reduced their assembly time by 15% and virtually eliminated rework due to misaligned holes.

Beyond these larger sectors, the versatility of laser tube cutting means that almost any industry working with metal tubes can potentially benefit. This includes manufacturers of agricultural machinery (for implement frames, ROPS structures, and hydraulic system components), playground equipment (for safe and durable play structures), and even artists and sculptors creating unique metal art installations. Fence and railing installation firms, for example, can dramatically improve their efficiency by having posts and rails custom-cut to length with precise notches and holes for quick, weld-free assembly on site, saving significant labor time and improving the quality of the finished installation. The ability of our MZBNL machines to handle a wide variety of tube sizes, shapes, and wall thicknesses, coupled with features like our No-CAD system for easy programming of common profiles, caters directly to this broad and diverse range of applications.

| Промышленность | Key Application Examples | Benefit from Laser Tube Cutting | Typical Material Used |

|---|---|---|---|

| Automotive & Transportation | Chassis components, exhaust systems, roll cages, seat frames | High precision, weight reduction, complex joints, improved safety | High-strength steel, AHSS, aluminum alloys |

| Architectural & Construction | Structural elements, facades, railings, decorative features | Design freedom, architectural aesthetics, on-site fit-up accuracy | Steel (mild, stainless), aluminum |

| Furniture Manufacturing | Chair/table frames, shelving units, bed frames, office furniture | Design flexibility, production speed, consistency, improved aesthetics | Mild steel, stainless steel, aluminum |

| Медицинское оборудование | Surgical instruments, implants, diagnostic device parts, stents | Miniaturization, clean cuts, biocompatibility, intricate patterns | Stainless steel (316LVM), titanium, Nitinol |

| Оборудование для фитнеса | Frames for treadmills, weight machines, elliptical trainers | Structural integrity, ease of assembly, aesthetic finish | Mild steel, aluminum |

| General Fabrication | Display racks, agricultural machinery, fencing, art installations | Versatility, customization, production efficiency | Various steels, aluminum |

Laser cutting improves automotive safetyПравда

Laser tube cutting ensures tight tolerances for critical automotive components like chassis and roll cages, directly contributing to vehicle safety standards.

Laser cutting is only for metal tubesЛожь

While commonly used for metal tubes, laser cutting technology can also process various other materials including plastics and composites in different industries.

What are the common challenges faced with laser tube cutting machines?

Thinking that laser tube cutting is an entirely flawless, plug-and-play solution? While incredibly powerful and transformative, these sophisticated machines, like any advanced technology, come with their own distinct set of operational challenges and considerations. Ignoring these potential hurdles can unfortunately lead to unexpected downtime, quality inconsistencies, and operational inefficiencies, ultimately undermining your significant investment. So, let's proactively identify and understand the common challenges users often face with laser tube cutting machines.

Common challenges include the persistent need for skilled CAD operators for programming complex or non-standard cuts, material handling difficulties with long or heavy tubes, achieving consistent cut quality across diverse materials and thicknesses, effectively managing tail material waste, and ensuring timely, expert maintenance and service support for these sophisticated systems.

While the numerous advantages of laser tube cutting are undeniably compelling, it's critically important for any business considering this technology to approach it with a clear, realistic understanding of its potential operational complexities. These aren't insurmountable obstacles by any means, but being acutely aware of them allows for much better strategic planning, more effective operator training programs, and a more informed machine selection process. Many of these very challenges are precisely what we at MZBNL have intensely focused on addressing through our ongoing research and development and resulting innovations. My countless conversations with clients worldwide, including business owners like Ahmed Al-Farsi from the UAE, frequently highlight these specific pain points stemming from their past experiences with older, less advanced, or poorly supported machinery. This direct feedback from the factory floor is what fuels our relentless development efforts to make laser tube cutting more accessible, efficient, and reliable for everyone.

At MZBNL, we believe in transparency. Understanding these challenges is the first step towards overcoming them. For Ahmed, his previous pain points regarding skilled CAD operators and local service support were key factors in his decision to partner with us, as our innovations directly address these industry-wide issues.

The Skills Gap: CAD Programming and Operator Expertise

One of the most significant and persistently voiced challenges I've encountered from clients across diverse industries over my 25 years at MZBNL is the heavy reliance on highly skilled personnel, particularly for Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) programming. Traditional laser tube cutting machines absolutely require detailed 3D models and meticulously prepared nesting programs to operate effectively and efficiently. Creating these digital files, especially for complex multi-axis cuts, unique tube profiles, or intricate joint preparations, demands considerable expertise in specialized software and a deep understanding of the cutting process itself. This design and programming stage can be very time-consuming. Ahmed Al-Farsi, my client in the UAE, candidly shared his frustration with this exact issue; with his previous machines, operators often had to interrupt production and return to the design office for even minor adjustments or to program new parts. This frequently caused significant delays if a CAD designer wasn't immediately available, directly impacting production flow, machine uptime, and project turnaround times – a critical factor in today's competitive market.

This problem is often compounded by a well-documented general shortage of skilled CAD/CAM operators and experienced machine programmers in many industrial regions globally. Finding, hiring, and retaining such talent can be difficult and expensive. Moreover, training new staff to become proficient in complex CAD/CAM software and the nuances of laser tube cutting can be a lengthy and costly process, often taking many weeks or even months. Furthermore, high operator turnover, a challenge Ahmed also unfortunately experienced with his previous setup, leads to recurring retraining burdens and the potential for inconsistencies in production quality if less experienced operators are tasked with running these sophisticated machines. This deep dependency on a small pool of specialized skills can severely limit a company's operational flexibility, its ability to respond quickly to urgent orders, and its overall growth potential. A recent Deloitte and The Manufacturing Institute skills gap study6 projected that millions of manufacturing jobs could go unfilled in the coming decade due to a lack of qualified talent, highlighting the systemic nature of this challenge.

This pervasive skills gap was, in fact, a primary motivating factor behind our dedicated effort at MZBNL to develop and perfect our proprietary No-CAD operating system. Our core goal was to significantly lower the skill threshold required for efficient machine operation for a large percentage of common tube cutting tasks. By empowering users to process a wide array of standard tube types (such as round, square, rectangular, and oval) and common hole patterns (including round, square, oblong, and slotted holes) simply by inputting key parameters like dimensions, angles, and quantities directly at the machine's intuitive control interface, we've drastically reduced the necessity for creating a separate, complex CAD drawing for many routine jobs. This revolutionary innovation not only shortens initial setup times considerably but also means that new operators, as Ahmed happily discovered, can be trained effectively and become productive in just one day of on-site training with our system, a stark contrast to the typical 15 days or more of intensive off-site training often required for traditional, CAD-dependent systems.

Material Handling and Processing Inefficiencies

Handling raw material, which often involves maneuvering long, heavy, and potentially awkward metal tubes, and then subsequently managing the processed parts and scrap, can be a significant source of inefficiency and even pose safety concerns within a fabrication environment. The manual loading of individual tubes, or even bundles of tubes, into traditional side-fed or rear-fed laser cutting machines is frequently a labor-intensive and time-consuming process, especially when dealing with larger diameter tubes, thicker wall sections, or full 6 to 8-meter stock lengths. This manual handling can easily become a bottleneck, slowing down the entire production cycle, and was another specific area Ahmed was keen to improve in his facility, actively seeking automated solutions to reduce operator fatigue, increase throughput, and enhance workplace ergonomics.

During the processing phase itself, issues related to material waste, particularly tail material, are a very common and costly problem. Conventional laser tube cutting systems, which typically initiate cutting from the tube head and utilize a rear chuck to feed the material through the cutting zone, almost invariably leave an unusable remnant or "tail" at the end of each processed tube. This tail section is the portion of the tube that remains gripped by the chuck and cannot be advanced far enough to be fully processed by the laser. Over many production runs, involving hundreds or thousands of tubes, this accumulated tail material can add up to a significant financial loss, especially when working with expensive materials like stainless steel, aluminum, brass, or other specialized alloys. I've personally visited factories where meticulously collected piles of tail material represented thousands, sometimes tens of thousands, of dollars in lost raw material value each month, a tangible hit to their bottom line.

Furthermore, achieving and maintaining consistent cut quality across different batches of material, various tube thicknesses, and diverse alloy types can present an ongoing challenge. Factors such as slight variations in material composition or surface condition, incorrect or sub-optimal cutting parameter settings (laser power, cutting speed, assist gas type and pressure, focal position), or the gradual wear and tear on crucial machine consumables (like nozzles, focusing lenses, and protective windows) can all adversely affect the final cut edge quality. This can manifest as excessive burrs, dross adhesion, thermal distortion, or dimensional inaccuracies in the cut features. Such imperfections might then necessitate secondary, labor-intensive finishing operations like grinding or deburring, adding unwelcome time and cost to the production process. Ensuring optimal cutting parameters for each specific material and thickness combination requires a good deal of operator expertise, careful machine calibration, and often, a process of trial and error if advanced adaptive control systems are not available.

Maintenance, Downtime, and Support Concerns

Laser tube cutting machines are undeniably sophisticated and complex pieces of industrial equipment, integrating numerous high-precision optical, mechanical, electrical, and electronic components that must all work in perfect synchrony. Regular, diligent preventative maintenance is absolutely essential to keep these machines running at their optimal performance levels and to proactively prevent unexpected, costly breakdowns. However, performing this maintenance can sometimes be complex, requiring specialized knowledge and tools. Moreover, finding readily available, qualified technicians for timely service and repair can be a significant challenge, especially for businesses located in remote geographical areas or for those operating machines from suppliers who lack a robust local or regional service and support infrastructure. Ahmed Al-Farsi specifically mentioned that equipment he had sourced from some previous international suppliers came with inadequate local service support in the UAE, which became a major operational pain point and a source of prolonged downtime when issues arose.

Unplanned machine downtime is, without a doubt, a manufacturer's worst nightmare. A critical breakdown in a key piece of equipment like a laser tube cutter can bring an entire production line to a grinding halt, leading to missed project deadlines, frustrated customers, and substantial financial losses. The true cost of downtime7 for such complex and high-throughput machinery can easily run into thousands, or even tens of thousands, of dollars per hour when factoring in lost production, idle labor, potential penalties, and reputational damage. Therefore, access to responsive and knowledgeable after-sales service, the ready availability of genuine spare parts, and the inclusion of modern features like remote diagnostics capabilities (which we proudly offer as standard on MZBNL machines) are absolutely critical factors for minimizing downtime and ensuring business continuity. Remote diagnostics, for instance, allow our technicians to often identify and even resolve issues remotely by accessing the machine's control system, saving valuable time and the cost of an on-site service visit.

Lead times for the delivery and installation of new laser tube cutting machines can also present a challenge for businesses planning capacity expansions or technology upgrades. Ahmed noted that long machine lead times from some suppliers had negatively affected his project delivery schedules in the past. While these lead times are often influenced by global supply chain dynamics, intricate manufacturing complexities, and high demand, it's a critical factor that businesses must carefully consider when planning their capital investments and production schedules. Choosing a supplier like MZBNL, which has integrated R&D and manufacturing processes and maintains transparent communication regarding production timelines and delivery schedules, is increasingly important for effective project management and meeting market demands.

| Зона вызова | Specific Problem | Impact on Business | MZBNL's Approach/Solution |

|---|---|---|---|

| Skills Gap & Programming | Need for highly skilled CAD operators, lengthy programming & training | Production bottlenecks, increased labor costs, operational inflexibility | No-CAD System, intuitive HMI, 1-day on-site operator training |

| Material Handling & Waste | Manual loading of heavy/long tubes, significant tail material waste | Low feeding efficiency, operator fatigue, increased raw material costs | Automated Front-Feeding, Zero-Waste Tail Material Innovation |

| Cut Quality Consistency | Variations due to material, parameters, or consumable wear | Rework, scrap, compromised part integrity, need for secondary operations | Advanced process control, smart parameter databases, high-quality components |

| Maintenance & Downtime | Complex upkeep, unexpected breakdowns, slow service response | Production halts, lost revenue, project delays, high repair costs | Remote diagnostics, robust design, global service network, readily available spares |

| Supplier Support | Lack of local technical support or spare parts availability | Prolonged downtime, frustration, inability to resolve issues quickly | Established global distributor networks, local agent support, comprehensive training |

CAD programming requires specialized skillsПравда

Traditional laser tube cutting machines require operators with expertise in CAD/CAM software for programming complex cuts, which can be time-consuming and costly to train.

Laser cutting eliminates all material wasteЛожь

Conventional systems still produce tail material waste that cannot be processed, leading to significant material loss over time, especially with expensive metals.

How have advancements like No-CAD and zero-waste innovations addressed these challenges?

Are you often frustrated by the traditional complexities inherent in laser tube cutting, such as the demanding requirement for expert CAD skills for programming or the significant financial impact of wasteful material usage? These long-standing operational challenges can severely stifle your business's productivity, eat directly into your hard-earned profits, and make it increasingly difficult to maintain a competitive edge in today's dynamic marketplace. Fortunately, truly innovative advancements, such as user-friendly No-CAD systems and ingenious zero-waste designs, are now directly tackling these critical issues head-on, revolutionizing operational efficiency and redefining what's possible with laser tube cutting.

Advancements like No-CAD systems directly address the challenge of requiring skilled CAD operators by enabling parameter-based cutting for a wide range of standard profiles, dramatically simplifying the programming process. Simultaneously, zero-waste innovations significantly minimize material scrap by optimizing cutting logic and chuck design, thereby reducing operational costs and improving sustainability in laser tube cutting operations.

The exciting journey of technological advancement in manufacturing is fundamentally about identifying and solving persistent, real-world problems to unlock new levels of performance and efficiency. In the specialized realm of laser tube cutting, the common frustrations associated with complex programming, the dependency on a limited pool of skilled labor, and the avoidable expense of material wastage have been powerful catalysts for groundbreaking innovation. At MZBNL, we've proudly championed several such advancements, many of which were born directly from listening intently to our valued clients, like Ahmed Al-Farsi, and deeply understanding their specific operational pain points and aspirations. These are not merely incremental improvements; they represent fundamental shifts in how these sophisticated machines are operated, the value they deliver, and their overall accessibility. Let's examine in more detail how these specific innovations are tangibly changing the game for manufacturers globally.

As someone who has been at the forefront of these developments at MZBNL, I've seen the transformative power of these innovations firsthand. When Ahmed decided to invest in our technology, features like our No-CAD system and Zero-Waste tail material innovation were key, as they directly solved the problems he'd faced for years with older, less advanced machines.

Streamlining Operations: The Impact of No-CAD Systems

The traditional workflow for most laser tube cutting operations has historically, and heavily, relied on the creation or meticulous modification of complex 3D CAD (Computer-Aided Design) drawings. This critical task was usually performed in a separate design office environment by a highly skilled CAD engineer or a specialized programmer. This process, as I have observed in countless factories around the world over my 25-year career, often created a significant and frustrating bottleneck in the overall production flow. If an urgent, unforeseen job came in, or if a minor design modification was needed on an existing part directly on the shop floor, the machine operator typically had to halt production and wait for the design office to provide the updated program. This frequently led to considerable idle machine time, disrupted production schedules, and delayed project completions. This was precisely the kind of scenario that Ahmed Al-Farsi described to me regarding his experiences with his older equipment, vividly highlighting the inherent inefficiency and inflexibility of such a CAD-dependent workflow.

Our proprietary No-CAD operating system at MZBNL was conceived and meticulously developed with the explicit goal of directly addressing this critical industry-wide pain point. By pioneering and continuously perfecting this innovative system, we've successfully enabled machine operators to efficiently process an extensive array of standard tube types – including common profiles like round, square, rectangular, and oval tubes – and a wide variety of frequently used hole patterns (such as round, square, oblong, and various slotted holes) simply by inputting essential dimensional and positional parameters directly at the machine's user-friendly control interface. This revolutionary approach effectively eliminates the need for a separate, time-consuming CAD drawing process for a vast majority of routine tube cutting tasks. Imagine, for instance, needing to cut a series of tubes with specific hole placements for a railing system; instead of meticulously drawing each tube and hole in a CAD program, the operator simply inputs the tube's outer dimensions, wall thickness, hole size, desired spacing, and the total quantity required. The intelligent system then automatically generates the optimal cutting path in seconds.

The positive impact of this single innovation on daily operations is truly profound and multi-faceted. Firstly, and perhaps most significantly, it dramatically improves the overall ease of use of the machine. Operators who might have previously required several weeks of intensive, often off-site, training in complex CAD software and machine-specific CAM programming8 (Ahmed specifically mentioned the common 15-day training period at the equipment factory for traditional systems) can now become highly proficient with our intuitive No-CAD system after just one single day of hands-on, on-site training. This remarkable reduction in training time significantly lowers the skill threshold required to operate the machinery, making it considerably easier for businesses to find, train, and retain proficient personnel. It also effectively mitigates the disruptive impact of high operator turnover, a common issue in the manufacturing sector. Secondly, the No-CAD system drastically shortens initial job setup times. Design modifications or adjustments to cutting parameters can be made swiftly and directly on the fly at the machine, substantially increasing valuable machine uptime and boosting overall production throughput. This heightened level of responsiveness and operational flexibility is absolutely crucial for businesses like Ahmed's, which handle a diverse portfolio of projects and need the agility to adapt quickly to changing customer demands and urgent orders.

Maximizing Material Utilization: The Power of Zero-Waste Design

Raw material cost is, without question, one of the most significant recurring expenses and a major factor in determining the overall profitability of any metal fabrication business, regardless of its size or specialty. Conventional laser tube cutting systems, which typically initiate the cutting process from the head of the tube and employ a rear chuck mechanism to feed the material through the cutting zone, almost invariably generate an unusable piece of tail material at the end of each and every processed tube. This leftover "tail" is essentially the section of the tube that remains securely gripped by the machine's chuck and, due to mechanical limitations, cannot be advanced far enough into the cutting area to be fully processed by the laser beam. For a business that processes hundreds or even thousands of tubes each week or month, this accumulated tail material can represent a very substantial and ongoing financial loss, not to mention the negative environmental impact associated with generating unnecessary scrap. I have personally visited numerous client facilities where meticulously collected bins and piles of this tail scrap served as a constant, painful reminder of thousands of dollars in lost raw material value each month – a direct drain on their profitability.

At MZBNL, we recognized this pervasive industry problem and decided to tackle it head-on by completely redesigning both the cutting logic and the chuck system of our machines to achieve what we proudly call our "Zero-Waste Tail Material Innovation." Our advanced system intelligently calculates the entire cutting path by referencing the rear chuck as the origin point, rather than the tube end. Crucially, this means that as long as the final remaining section of the tube held in the chuck is shorter than the length of the specific product being cut, the machine can continue to process it completely, effectively eliminating the traditional unusable tail remnant in most common scenarios. To illustrate, if your machine is programmed to cut 100mm long finished parts, and the piece of tube left gripped in the chuck at the end of a stock length is, say, 90mm, our system can still accurately cut that remaining 90mm piece into a final usable part (or potentially multiple shorter parts if the design allows and they fit within that remnant). This is a fundamental departure from older systems where that 90mm piece would have been automatically ejected as scrap.

This innovative zero-tail design offers an immediate and direct boost to overall material utilization, often resulting in savings of several percentage points on a company's total material consumption budget. When processing high-value materials such as stainless steel, copper, brass, or specialized alloys like titanium or Inconel, these material savings can become particularly impactful, directly improving the bottom line. For instance, one of our clients specializing in the production of high-end stainless steel furniture reported a consistent 3-5% reduction in their annual material costs shortly after adopting our zero-waste system. For them, this translated into tens of thousands of dollars in direct savings annually, significantly enhancing their competitiveness. Beyond the obvious financial benefits, this approach also makes a meaningful contribution to more sustainable and environmentally responsible manufacturing practices9 by substantially reducing the volume of scrap metal generated.

Enhancing Throughput: The Role of Feeding and Automation Innovations

Beyond the intricacies of the laser cutting process itself, the overall efficiency of material handling – both loading raw tubes and unloading finished parts – plays an absolutely critical role in determining a machine's total productivity and общая эффективность оборудования (OEE)10. Traditional laser tube cutting machines frequently rely on manual or semi-automatic side or rear loading mechanisms. These methods can be quite time-consuming, physically demanding for machine operators (especially when dealing with long, heavy, or large-diameter tubes), and can easily interrupt the smooth, continuous flow of production. This manual loading step, if not optimized, can readily become the primary bottleneck in an otherwise highly automated and efficient production cell, limiting the machine's true output potential.

Recognizing this widespread inefficiency, we at MZBNL focused significant R&D effort on developing and introducing an optimized front-feeding mechanism for our laser tube cutting machines. Instead of requiring operators to manually push, guide, or align lengthy tubes from the side or rear of the machine – a task that often requires considerable physical exertion and careful maneuvering – our innovative system automatically and precisely pulls the next tube in from a loading rack positioned at the front of the machine. This seemingly straightforward change in feeding methodology has a remarkably significant and positive impact on overall operational flow. Through extensive internal testing and client feedback, we've consistently measured that this front-feeding innovation increases raw material feeding efficiency by approximately 40% when compared to traditional manual loading methods. It effectively streamlines the entire loading process, substantially reduces the physical strain and fatigue on operators (we estimate a similar 40% reduction in labor intensity for this task), and allows for a much more continuous and reliably automated workflow. My client Ahmed Al-Farsi was particularly interested in this specific feature for his facility in the UAE, as reducing manual labor content and improving workplace ergonomics and safety were among his key strategic objectives for upgrading his equipment.

This type of intelligent automation in material handling, when combined with other advanced features such as automatic tube centering within the chucks, optical seam detection for welded tubes (allowing the machine to orient the weld seam consistently or avoid cutting through it), and efficient, automated unloading systems that can sort finished parts from scrap, contributes to a much higher OEE. When the laser tube cutting machine spends more of its available time actively cutting and significantly less time idle due to manual loading, complex programming, or time-consuming adjustments, the return on the initial capital investment is realized much more rapidly. These comprehensive automation features are an integral part of our ongoing commitment at MZBNL to providing truly smart and digitalized systems that genuinely enhance our clients' operational capabilities, competitiveness, and profitability. For businesses that are looking to significantly scale up their production volumes or substantially improve their competitive positioning in demanding markets, these tangible throughput enhancements, derived from holistic automation, are simply invaluable.

| Innovation | Традиционная проблема решена | Key Benefit | Impact Metric (Example from MZBNL) |

|---|---|---|---|

| Система No-CAD | Heavy reliance on skilled CAD operators, long and complex programming times | Simplified machine operation, dramatically reduced training time, faster job setup | Operator training reduced from ~15 days to just 1 day on-site |

| Безотходный материал хвостовой части | Generation of unusable tail material (scrap) from the end of each tube | Maximized raw material utilization, significant reduction in material costs | Potential 3-5% material savings, especially on expensive alloys |

| Инновации на переднем крае | Slow, labor-intensive, and often ergonomic-risk manual tube loading | Approximately 40% increase in feeding efficiency, ~40% reduction in operator labor | Faster cycle times, improved ergonomics, higher throughput |

| Smart Digitalized Systems | Manual parameter adjustments, potential for human error, process variability | Automated process control, consistent high-quality output, data-driven insights | Improved OEE, reduced rework, enhanced predictive capabilities |

Системы без графики сокращают время обученияПравда

No-CAD systems can reduce operator training from weeks to just one day by eliminating complex CAD programming requirements.

Zero-waste systems eliminate all material scrapЛожь

While zero-waste innovations significantly reduce scrap, they don't completely eliminate all material waste in laser tube cutting operations.

What are the future possibilities for laser tube cutting machines in manufacturing?

Are you curious about what exciting developments lie on the horizon for laser tube cutting technology? The current advancements we've discussed are undeniably impressive, but believe me, the innovation journey in this field is far from over. Staying ahead in today's rapidly evolving manufacturing landscape means proactively anticipating future trends and understanding how they could potentially reshape your production capabilities, enhance your competitive edge, and unlock new business opportunities. So, let's explore some of the thrilling future possibilities for laser tube cutting machines.

Future possibilities for laser tube cutting machines include deeper and more intuitive integration with Artificial Intelligence (AI) and Machine Learning (ML) for self-optimizing cutting processes, enhanced multi-process capabilities (e.g., incorporating welding, tapping, or marking within the same machine cycle), increased utilization of sophisticated sensor technology for truly predictive maintenance, and wider adoption in processing new and advanced materials, further revolutionizing smart and agile manufacturing paradigms.

Looking ahead, the trajectory of laser tube cutting technology is incredibly exciting and filled with potential. The robust foundations laid by current innovations, such as No-CAD interfaces and zero-waste material handling, are actively paving the way for the development of even more intelligent, versatile, integrated, and autonomous systems. As someone who is deeply involved in the research and development efforts here at MZBNL, I foresee a future where these machines become even more indispensable and central to the concept of the smart factory or Industry 4.0. The powerful convergence of advanced software algorithms, pervasive sensor technology, and new breakthroughs in laser capabilities will undoubtedly unlock operational possibilities that we are, perhaps, only just beginning to fully imagine today. This ongoing evolution will not only further enhance operational efficiency and reduce costs but will also empower engineers and designers to create entirely new product forms and enable more sustainable and agile manufacturing paradigms globally.

At MZBNL, we're not just participants in this future; we aim to be architects of it. Our ongoing R&D, fueled by insights from forward-thinking clients like Ahmed, who is already considering how these future capabilities could benefit his growing business and even his potential role as a regional distributor, focuses on making these possibilities a reality.

Smarter Machines: AI, Machine Learning, and IoT Integration

The future of laser tube cutting is undeniably and inextricably intertwined with the rapid advancements we're seeing in Artificial Intelligence (AI) and Machine Learning (ML). I confidently envision a new generation of machines that are not just highly automated in their mechanical functions but are truly intelligent and adaptive in their operational decision-making. Imagine a laser tube cutter that can continuously learn from its own operational data, automatically optimizing critical cutting parameters – such as laser power, cutting speed, assist gas flow, and focal position – in real-time. This optimization would be based on live feedback from an array of integrated sensors monitoring material characteristics (e.g., thickness variations, surface reflectivity), ambient environmental conditions (e.g., temperature, humidity), or even detecting the subtle early signs of wear on its consumable components like nozzles and lenses. This sophisticated level of self-optimization could lead to consistently perfect cuts with minimal dross or burrs, significantly reduced setup times for new jobs or unfamiliar materials, and a dramatic decrease in scrap rates. For instance, a sophisticated AI algorithm could analyze acoustic emissions, thermal imaging, or optical sensor data gathered directly from the cutting zone during operation to predict and proactively prevent potential cut quality issues before they even manifest as defects, or adjust parameters on the fly to maintain optimal performance.

The integration of these machines with the broader Industrial Internet of Things (IIoT) ecosystem will further amplify these intelligent capabilities. Machines connected to a secure factory-wide or even cloud-based network can share operational data, performance metrics, and learned optimizations, allowing for fleet-wide learning, remote performance benchmarking, and the dissemination of best practices. Predictive maintenance, already a key feature, will become far more sophisticated and accurate; a dense network of sensors will continuously monitor the health and performance of all critical machine components (such as the laser source itself, chillers, servo motors, and motion systems), and advanced AI algorithms will analyze these data streams to predict potential failures with high accuracy well in advance of an actual breakdown. This capability allows for maintenance to be scheduled proactively during planned downtimes, drastically reducing costly unplanned production stoppages – a primary concern for highly efficient operations like those run by clients such as Ahmed. A comprehensive report by Accenture on the impact of digital technologies suggests that predictive maintenance strategies can reduce overall equipment downtime by up to 70% and lower maintenance costs by as much as 25%11.

Furthermore, seamless IIoT integration will enable effortless and bi-directional communication between the laser tube cutting machine and a factory's higher-level Manufacturing Execution System (MES) and Enterprise Resource Planning (ERP) software. This means that critical production data, including job scheduling information, material consumption tracking, real-time quality control metrics, and machine status updates, can flow effortlessly and automatically between the machine on the shop floor and the broader business management systems. This profound level of connectivity and data transparency is absolutely fundamental to the realization of Industry 4.0 principles, creating truly smart factories where data-driven decisions optimize the entire production value chain, from order intake to final product shipment. We at MZBNL are already deeply committed to incorporating smart, digitalized systems into our product lines, and this deeper AI and IIoT integration represents a natural and exciting evolution of that strategy.

Expanded Capabilities: Multi-Process Integration and New Materials

While current state-of-the-art laser tube cutting machines are already incredibly versatile in their ability to handle a wide range of profiles and cutting tasks, the future will undoubtedly see an even greater degree of multi-process integration occurring within a single machine platform. I anticipate the development of next-generation machines that can not only perform high-precision laser cutting of tubes but also seamlessly execute a variety of subsequent or complementary operations – such as automated tapping of holes, precision chamfering or deburring of cut edges, robotic welding of simple sub-assemblies, or permanent part marking using the same laser source or an auxiliary one – all within the same setup and machine cycle. This consolidation of processes would drastically reduce material handling between different workstations, minimize work-in-progress (WIP) inventory, shorten overall production lead times, and further streamline complex manufacturing workflows. Our current MZBNL Automatic Punching & Cutting Integrated Machine, which combines mechanical punching with laser cutting, is already a significant step in this direction, and the potential to add even more diverse functionalities onto a single, flexible platform is immense.

The range of materials that can be efficiently and economically processed by laser tube cutters will also continue to expand significantly. While various metals (steels, aluminum, copper, brass, titanium) are the current primary focus, ongoing advancements in laser source technology – such as the development of new laser wavelengths (e.g., green or blue lasers for improved absorption in certain non-ferrous metals), ultra-short pulse lasers (picosecond or femtosecond lasers for "cold" ablation with minimal thermal effects), and higher-power, more efficient fiber lasers – could open up exciting new doors. These advancements could enable the efficient cutting, structuring, or modification of advanced composite materials, engineering ceramics, specialized polymers, or even hybrid multi-material tubes with greater precision, speed, and quality than ever before. This expanded material processing capability would directly cater to the emerging needs of highly demanding industries such as aerospace (lightweight structural components), medical devices (biocompatible and sterilisable parts), and advanced electronics (intricate conductive or insulating structures).

We will also almost certainly see more sophisticated and user-friendly 3D cutting capabilities emerge. While 5-axis laser tube cutting machines are already relatively common for producing complex bevels, weld preparations, and intricate intersecting joint profiles, future systems might offer even greater freedom of movement (e.g., 6-axis or even more), more intuitive and automated programming for highly complex three-dimensional shapes, and enhanced collision avoidance systems. This could enable the cost-effective production of components with geometries that are currently considered impossible or prohibitively expensive to manufacture using existing methods. Such capabilities would, in turn, open up entirely new design avenues for engineers and architects, allowing for more organic, structurally optimized, and functionally integrated parts. The integration of advanced vision systems and real-time metrology could also allow machines to inspect their own work and make adaptive corrections, further pushing the boundaries of precision and autonomy.

Towards Sustainable and Agile Manufacturing

Sustainability is rapidly transitioning from a desirable attribute to a fundamental business imperative in modern manufacturing, and future generations of laser tube cutting machines will undoubtedly play an increasingly significant role in supporting this global shift. Innovative features like our MZBNL zero-waste tail material system are truly just the beginning of this journey. Future machines will likely feature even more energy-efficient laser sources, optimized chiller units, and more intelligent auxiliary systems that minimize power consumption during idle periods or adapt energy use to the specific task at hand. Enhanced and potentially AI-driven nesting algorithms will be developed to further optimize the layout of parts on each stock length of tube, minimizing internal scrap beyond just the elimination of tail material. The growing global push for принципы циркулярной экономики12 will also drive demand for machines that can efficiently and reliably process recycled or reclaimed materials, potentially with integrated sensors to adapt cutting parameters to variations in recycled feedstock quality.

Agility and the capacity for rapid customization will continue to be key competitive advantages in most manufacturing sectors. The clear and accelerating trend towards mass customization, smaller batch sizes, and even lot-size-one production requires manufacturing systems that can switch between different jobs, materials, and designs quickly, efficiently, and with minimal setup cost or delay. Future laser tube cutters, equipped with AI-assisted setup routines, No-CAD principles extended even further to encompass more complex geometries, seamless integration with cloud-based digital design and collaboration tools, and perhaps even automated tool/nozzle changing, will be perfectly suited for this highly dynamic and agile manufacturing environment. Imagine a fully integrated system where a customer's unique, custom design can be uploaded, automatically analyzed for manufacturability, intelligently programmed, and then produced with minimal human intervention, enabling true rapid prototyping and on-demand production at scale. This vision aligns perfectly with the evolving needs of businesses like Ahmed Al-Farsi's, which increasingly cater to diverse, often highly customized, orders for architectural elements and specialized automotive parts.

Finally, the ongoing development of more compact, more affordable, and potentially even more modular laser tube cutting systems could further democratize access to this powerful technology. This could allow smaller businesses, job shops, and even educational institutions or maker spaces to benefit from its advanced capabilities, which were previously only accessible to larger enterprises. This wider adoption could foster innovation at a more grassroots level, enable more distributed and localized manufacturing networks, and potentially reshore some manufacturing activities. The overall direction of development clearly points towards systems that are not only more powerful and precise in their cutting capabilities but also significantly more intelligent, adaptable, user-friendly, and environmentally conscious, paving the way for a more efficient and sustainable future for metal fabrication.

| Future Trend | Anticipated Development | Potential Benefit for Manufacturing | Enabling Technologies |

|---|---|---|---|

| AI & Machine Learning Integration | Self-optimizing cutting parameters, AI-driven predictive maintenance, intelligent scheduling | Consistently higher cut quality, drastically reduced machine downtime, less reliance on operator skill | Advanced sensors, powerful edge computing, IIoT platforms, Big Data analytics |

| Expanded Multi-Process Integration | On-machine tapping, welding, chamfering, marking, automated inspection | Reduced work-in-progress, shorter overall lead times, increased process efficiency, "done-in-one" capability | Advanced robotics, integrated tooling, sophisticated CNC control, machine vision |

| New Material Processing | Efficient cutting of composites, ceramics, polymers, hybrid & recycled materials | Expanded market applications, ability to create novel products with unique properties | New laser wavelengths (e.g., green, blue, UV), ultra-short pulse lasers, adaptive optics |

| Enhanced Sustainability | Greater energy efficiency in lasers & ancillaries, advanced AI-driven scrap reduction | Lower operational carbon footprint, reduced raw material consumption, improved cost-effectiveness | More efficient laser diodes, smart energy management, advanced nesting algorithms |

| Hyper-Agility & Customization | AI-assisted rapid setup, seamless digital thread from design to production, lot-size-one | Ability to respond instantly to market demands, profitable mass customization, rapid prototyping | Cloud-based CAD/CAM, digital twin technology, automated programming |

AI will optimize laser cutting parametersПравда

Future laser tube cutters will use AI to automatically adjust power, speed and gas flow based on real-time sensor data for perfect cuts.

Laser cutters will only process metalsЛожь

Advanced laser technologies will enable cutting of composites, ceramics and polymers, expanding beyond traditional metal applications.

Заключение

Laser tube cutting machines are truly transformative tools in modern manufacturing, offering unparalleled precision, speed, and automation for metal fabrication. Key innovations like MZBNL's No-CAD systems and zero-waste designs are effectively overcoming traditional operational challenges, paving the way for an even smarter, more versatile, and sustainable future in advanced metal fabrication for businesses like yours worldwide.

-

Access research on how motion system precision affects laser cut quality attributes. ↩

-

Learn about the Heat-Affected Zone, its impact on material properties, and how laser cutting minimizes it. ↩

-

Explore research on advanced fabrication's impact on vehicle weight and fuel efficiency. ↩

-

Understand how 3D beveling enables complex cuts and joints in tube fabrication. ↩

-

Learn about Nitinol's unique properties and its critical role in medical technology. ↩

-

Access key findings from the study on the critical manufacturing skills shortage and its industry impact. ↩

-

Understand the significant financial repercussions of unplanned machine downtime in production environments. ↩

-

Understand the functions of CAD/CAM systems in design and manufacturing processes for machining. ↩

-

Discover how eco-friendly manufacturing reduces environmental impact and can improve business value. ↩

-

Learn about OEE, how it's calculated, and its role in improving manufacturing productivity. ↩

-

See data on how predictive maintenance cuts downtime and costs in industrial settings. ↩

-

Understand how circular economy models promote sustainability and resource efficiency in production. ↩

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.