Как правильно выбрать станок для лазерной резки труб для вашего завода

Choosing a new tube laser cutting machine for your factory can feel like navigating a maze. You're faced with numerous options, technical jargon, and the pressure to make a significant investment wisely. The wrong choice can lead to production bottlenecks, wasted resources, and missed growth opportunities. As someone who's been in the metal fabrication industry for over two decades with MZBNL, I'm here to guide you through this crucial decision-making process, ensuring you select a machine that truly transforms your operations.

Selecting the ideal tube laser cutting machine involves a careful assessment of your specific production needs, including material types, desired precision, and operational efficiency. Key factors include cutting capabilities, system ease of use, overall budget including total cost of ownership, and the reliability of after-sales support and service.

Making an informed decision on your next tube laser cutting machine isn't just about acquiring new equipment; it's about unlocking new levels of productivity, precision, and profitability for your business. It’s about future-proofing your factory. I've seen firsthand how the right technology can revolutionize a workshop, and I want to share that insight with you. Let's explore the critical aspects you need to consider to ensure your investment pays dividends for years to come.

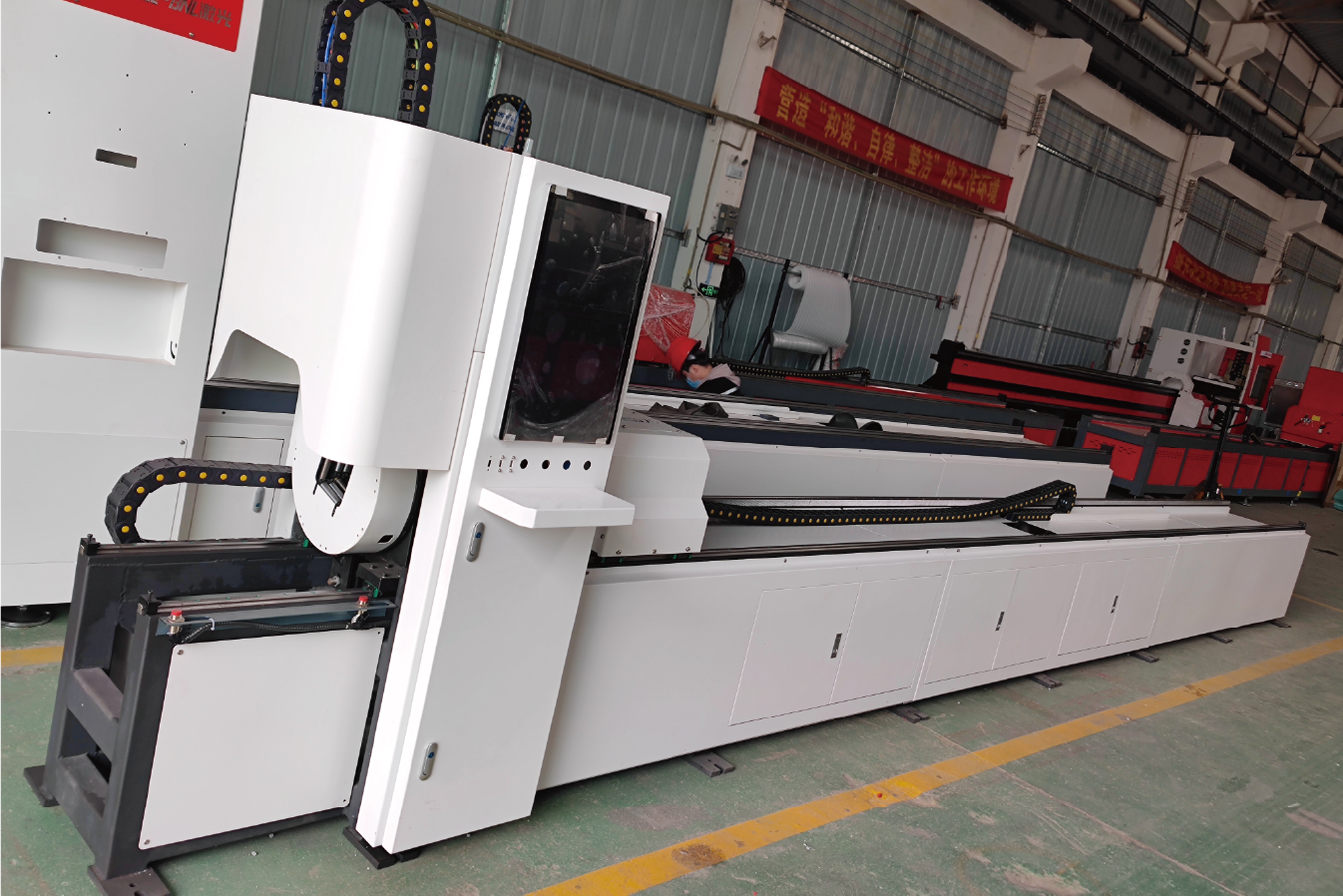

The landscape of metal fabrication is constantly evolving, driven by demands for higher precision, faster turnaround times, and greater automation. Tube laser cutting machines are at the forefront of this transformation, offering unparalleled capabilities in processing complex tube and pipe profiles. At MZBNL, we've dedicated ourselves to innovation, understanding that businesses like Ahmed Al-Farsi's in the UAE, who seek automated solutions to upgrade production, need more than just a machine; they need a comprehensive solution. For Ahmed, who is expanding his architectural metalwork and vehicle parts supply, the ability to efficiently process diverse materials with minimal human intervention is paramount. This means looking beyond basic specifications to understand how features like our No-CAD system, front-feeding innovation, and zero-waste tail material can directly address the pain points of traditional manufacturing, such as reliance on skilled CAD operators and material wastage.

What are the key factors to consider when selecting a tube laser cutting machine?

Are you feeling overwhelmed by the sheer number of features and specifications while trying to pick the right tube laser cutting machine? It's a common challenge, and it's tough to discern what truly matters for your specific needs. Focusing on the wrong aspects can lead to an ill-suited machine, causing operational inefficiencies and significant buyer's remorse. I've seen businesses make this mistake, and I want to help you prioritize the essential factors for a smart, strategic investment.

Snippet paragraph: Key factors for selecting a tube laser cutting machine include the types and thicknesses of materials to be processed, required production volume and speed, desired cutting precision and quality, level of automation, software ease-of-use (like No-CAD systems), machine footprint, available budget, and crucial after-sales support and training.

Transition paragraph: Understanding these fundamental factors is the crucial first step towards making a sound investment. However, it's not just about ticking boxes; it's about how these factors interrelate and apply to your unique operational context. For instance, a client like Ahmed Al-Farsi, who runs a mid-sized fabrication business in the UAE supplying architectural metalwork and vehicle parts, needs a machine that can handle diverse materials and profiles with high efficiency. His engineering background means he'll appreciate a deep dive into the technical nuances, but his primary goal is an automated solution that boosts productivity. Let's delve deeper into how to practically assess these factors, especially concerning the machine's core function – its ability to cut efficiently and precisely, and the support structure that keeps it running. We also need to consider the human element: how easy is it for your team to operate and maintain the machine? This is particularly important given Ahmed's previous struggles with high operator turnover and the retraining burden.

Selecting the right tube laser cutting machine requires a holistic approach, moving beyond just one or two standout features. It's about finding a synergistic fit between the machine's capabilities and your factory's specific demands. Ialways advise clients to start with a thorough internal audit of their current and anticipated needs. What types of tubes are you cutting most frequently? What's your average batch size? What are your growth projections for the next five years? Answering these questions will lay the groundwork for a more targeted search. Remember, a machine that's perfect for a high-volume automotive supplier might be overkill for a smaller workshop specializing in custom furniture, and vice-versa. The goal is to find the sweet spot where technology meets practical application and financial viability. For example, Ahmed's factory, with over 100 staff and plans to automate manual workflows, will have different priorities than a startup. He's looking for a robust, reliable machine that integrates smoothly into his existing operations and can handle the demands of both architectural and automotive component manufacturing. This means versatility in material handling and processing power is key. At MZBNL, we've seen many businesses like Ahmed's thrive by carefully matching machine capabilities to their distinct production profiles.

Material Compatibility and Range: The Foundation of Your Choice

The first technical aspect to scrutinize is material compatibility. What metals will you be processing? Common materials include mild steel, stainless steel, aluminum, and sometimes copper or brass. Each has different reflective properties and requires specific considerations for laser cutting. For instance, cutting highly reflective materials like aluminum or copper typically necessitates a источник волоконного лазера1 with appropriate safeguards. You need to define the range of tube diameters and wall thicknesses you'll encounter. A machine optimized for thin-walled small-diameter tubes might struggle with thick-walled large-diameter pipes, and vice-versa. For Ahmed, who produces railings (often stainless steel or aluminum) and automotive parts (often mild steel or specialized alloys), this versatility is critical. He needs a machine that can seamlessly switch between different material types and profiles – round, square, rectangular, and potentially L-beams or C-channels for architectural elements.

Consider the maximum and minimum tube sizes the machine can handle. Our MZBNL machines, for example, are designed to process a wide spectrum, from small intricate tubes for furniture to larger structural pipes. Data shows that a 2kW fiber laser can typically cut mild steel up to 16mm thick and stainless steel up to 8mm, while a 6kW laser can handle significantly greater thicknesses and speeds. However, it's not just about raw power; the quality of the cut edge, the minimal heat-affected zone, and the ability to maintain precision across different materials are equally important. I recall a client in the fitness equipment industry who initially underestimated the variety of tube profiles they'd need to process; upgrading later was more costly than choosing a more versatile machine upfront.

The shape of the tube is another crucial factor. While round, square, and rectangular tubes are standard, many industries, including architectural decoration and automotive, require processing of oval, L-shaped, H-shaped, or other special profiles. Ensure the machine's chucking system and software can handle these non-standard shapes effectively. For Ahmed's business, which supplies both architectural metalwork and vehicle parts, the ability to process diverse profiles without extensive changeover times is a significant advantage. A machine that can automatically identify and adjust to different tube shapes, supported by robust software, will dramatically improve workflow efficiency. This adaptability prevents bottlenecks and allows for a wider range of projects to be undertaken.

Production Volume, Speed, and Precision Requirements: Balancing Output and Quality

Your anticipated production volume will heavily influence the level of automation and cutting speed you require. For low-volume, high-mix environments, a machine with quick setup and manual or semi-automatic loading might suffice. However, for mid-to-high volume operations like Ahmed's, which aims to automate existing workflows, features like automatic bundle loaders, front-feeding mechanisms (like MZBNL's, which increases feeding efficiency by about 40%), and automated unloading systems become essential for maximizing throughput and reducing labor costs. Cutting speed, often quoted in meters per minute, is important, but it should be evaluated in the context of the specific materials and thicknesses you process. Don't be swayed by maximum speed figures; look for practical, achievable speeds that maintain cut quality.

Precision is non-negotiable in many applications, especially for automotive parts or intricate architectural designs. Evaluate the machine's positioning accuracy (e.g., ±0.05mm) and repeatability. These figures are determined by the quality of the motion system (servo motors, ball screws, linear guides) and the rigidity of the machine frame. For Ahmed, producing parts for the automotive sector, tight tolerances are a must. Any deviation can lead to assembly issues and rejected components. Therefore, a machine with a robust construction and high-precision components is vital. The integration of advanced nesting software also plays a role here, not just for material utilization but for ensuring parts are cut accurately according to the design.

To illustrate, consider the following comparison for different production volumes:

| Характеристика | Low Volume | Mid Volume (e.g., Ahmed's) | High Volume |

|---|---|---|---|

| Обработка материалов | Manual loading/unloading | Semi-automatic/Automatic loading (e.g., MZBNL front-feed) | Fully automatic loading/unloading systems |

| Мощность лазера | 1-2 kW | 2-4 kW (versatile for varied tasks) | 4 kW+ (for speed and thick materials) |

| Скорость резки | Moderate, focus on flexibility | High, balanced with quality | Very High, optimized for throughput |

| Программное обеспечение | Basic nesting, CAD import | Advanced nesting, No-CAD options, production management | MES integration, full automation suite |

| Typical Output | Custom jobs, prototypes, small batches | Diverse parts, moderate batch sizes | Mass production, repetitive parts |

| Focus | Versatility, quick setup for variety | Efficiency, reliability, cost-performance | Max throughput, minimal downtime |

This table helps visualize how different operational scales demand distinct machine configurations. Ahmed's mid-sized business falls squarely into the middle category, needing a balance of automation, speed, and versatility without the extreme specialization of a mass-production facility.

After-Sales Support, Training, and Local Presence: Ensuring Long-Term Success

The best machine in the world is only as good as the support behind it. This is a lesson many, including Ahmed, have learned the hard way, especially when dealing with equipment from suppliers lacking local service support. Before committing, thoroughly investigate the manufacturer's after-sales service. What does the warranty cover and for how long? What is the typical response time for service requests? Are spare parts readily available, and what are their costs? At MZBNL, we understand that downtime is incredibly costly, which is why we have built a robust global distributor network to provide timely support and spare parts in regions like Southeast Asia, the Middle East, Europe, and North America.

Training is another critical component. A complex machine with a steep learning curve can lead to underutilization or errors, negating its benefits. Look for suppliers who offer comprehensive training programs. For example, MZBNL's No-CAD system is designed for ease of use, allowing operators to become proficient with just one day of on-site training, a stark contrast to the traditional 15 days often required at the equipment factory. This significantly reduces the training burden, a key concern for Ahmed who has faced high operator turnover. Consider if the supplier offers ongoing training, дистанционная диагностика2, and readily accessible technical documentation.

A local agent or distributor presence, as Ahmed prioritizes, can be invaluable. They can provide faster on-site support, understand local market conditions, and often stock common spare parts. For a business owner like Ahmed, who is also considering becoming a regional distributor if the machine performs well, a strong supplier partnership built on reliable technology and support is fundamental. The peace of mind that comes from knowing expert help is readily available cannot be overstated. It transforms the purchase from a simple transaction into a long-term strategic alliance. This is why we at MZBNL focus on building lasting relationships with our 4000+ global enterprise clients.

Material compatibility is crucialПравда

Different metals like aluminum and stainless steel require specific laser cutting considerations.

Higher laser power means better cutsЛожь

While higher power can cut thicker materials, cut quality depends on multiple factors including motion system and software.

How to evaluate the cutting capabilities of different machines?

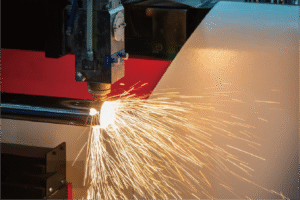

Every manufacturer will tell you their machine offers superior cutting performance. But when you're on the factory floor, how do you truly distinguish between marketing claims and actual, reliable cutting prowess? It's a critical question because investing in a machine with subpar cutting capabilities can lead to a cascade of problems: poor quality parts, excessive material waste, and frustrating production delays. I've seen businesses struggle when they've overlooked this detailed evaluation.

Evaluate cutting capabilities by requesting live demonstrations with your specific materials and typical part designs. Assess cut edge quality (dross, burr, taper), kerf width, perpendicularity, and achievable cutting speeds. Also, investigate the laser source type and power, cutting head technology, and the precision of the motion control system.

Raw laser power is just one piece of the puzzle; the finesse and consistency of the cut are what truly define a machine's capability. The quality of the laser source, the sophistication of the cutting head, and the precision of the motion systems all play vital roles in determining the final product quality and overall operational efficiency. For an engineer like Ahmed Al-Farsi, who is focused on producing high-quality vehicle parts and architectural metalwork, these technical details are paramount. He needs to be confident that the machine can consistently deliver clean, accurate cuts across a variety of materials and thicknesses. Let's dive deeper into how these components interact and what you should be looking for to ensure the machine meets your standards for speed, precision, and material utilization, such as minimizing waste, a key feature of our MZBNL machines with their zero-waste tail material innovation.

Evaluating cutting capabilities goes beyond just reading a spec sheet. It requires a hands-on approach and a keen eye for detail. I always recommend prospective buyers, especially those with an engineering background like Ahmed, to prepare their own test files and materials. This allows for a direct comparison of how different machines perform under conditions that are relevant to their actual production needs. Witnessing the machine cut your parts, feeling the edge quality, and measuring the precision yourself provides invaluable insights that brochures simply cannot convey. Furthermore, inquire about the machine's ability to handle various cutting complexities, such as intricate contours, small holes, and sharp corners, as these are often the true test of a machine's capabilities. For instance, our MZBNL machines are engineered for high-speed, high-precision cutting, and we encourage clients to push the limits during demonstrations to see these features in action. The goal is to find a machine that not only meets your current needs but also has the capacity to handle future challenges as your product designs evolve or material requirements change.

The Heart of the Machine: Laser Source and Power

The laser source is the engine of your cutting machine. For tube cutting, fiber lasers have become the dominant technology, largely supplanting CO2 lasers due to their higher energy efficiency, lower maintenance requirements, and better suitability for cutting reflective materials. When evaluating the laser source, consider its brand and reputation – major manufacturers include IPG, Raycus, and Maxphotonics. The power of the laser, measured in kilowatts (kW), directly impacts its ability to cut different materials and thicknesses at various speeds. For example, a 1kW fiber laser might be suitable for thin-walled steel tubes up to 6mm, while a 3kW source can efficiently cut stainless steel up to 10mm or mild steel up to 20mm. A 6kW or higher power source would be for very thick materials or extremely high-speed applications. Ahmed, dealing with both architectural (potentially thicker profiles) and automotive parts (often lighter but requiring precision), might look for a versatile 2kW to 4kW source.

Beam quality, often expressed as M² (M-squared)3, is another critical parameter. A lower M² value indicates a more focused beam, which translates to finer kerf widths and higher precision, especially important for intricate patterns or when cutting thinner materials. For Ahmed's automotive components, where tight tolerances are crucial, a laser source with excellent beam quality would be a significant advantage. Furthermore, the stability and longevity of the laser source are important. Reputable laser sources typically offer tens of thousands of operating hours before requiring major service, contributing to a lower total cost of ownership. We at MZBNL carefully select laser sources known for their reliability and performance to ensure our customers experience minimal downtime.

It's also important to discuss the modulation capabilities of the laser source. The ability to rapidly pulse the laser beam allows for finer control over heat input, which is crucial for minimizing the heat-affected zone (HAZ)4, reducing dross, and achieving cleaner cuts, especially on heat-sensitive materials like aluminum or certain stainless steel alloys. This level of control is vital for parts that require subsequent welding or finishing, as a smaller HAZ often leads to better weld quality and less post-processing work. For Ahmed's fabrication business, this could mean faster overall production cycles and higher quality finished products for both his architectural and automotive clients.

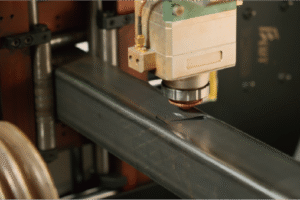

The Cutting Head: Precision and Versatility in Action

The cutting head is where the laser beam meets the material. Its design and features are critical for achieving high-quality cuts consistently. Key components include focusing lenses, nozzles, and a capacitive sensor for automatic height following. The ability of the cutting head to maintain the optimal focal distance from the tube surface, even if the tube is not perfectly straight or round, is essential for consistent kerf width and cut quality. Autofocus capabilities are now standard on most quality machines, allowing the system to automatically adjust the focal point based on the material type and thickness, which significantly simplifies setup and operation. This is a feature Ahmed, who values ease of use, would appreciate.

Consider the cutting head's versatility. Some advanced cutting heads offer features like bevel cutting (3D cutting), which can produce angled edges necessary for weld preparation or specific joint designs. This capability can eliminate secondary operations, saving time and improving accuracy. For architectural applications, such as complex truss structures or custom railings, bevel cutting can be a significant advantage. Also, look at the ease of maintenance for the cutting head – how easy is it to change nozzles and protective windows? Quick-change systems can minimize downtime. For example, our MZBNL machines incorporate cutting heads designed for both precision and robustness, capable of handling the demanding environment of a busy fabrication shop.

Furthermore, the design of the assist gas delivery system within the cutting head is crucial. The type of assist gas (oxygen for mild steel, nitrogen for stainless steel and aluminum) and its pressure significantly influence cut speed and edge quality. A well-designed cutting head ensures efficient gas flow, which helps to eject molten material effectively, resulting in a cleaner, dross-free cut. Some cutting heads also feature integrated monitoring systems that can detect issues like nozzle wear or lens contamination, prompting preventative maintenance and avoiding costly production errors. This kind of intelligent feature aligns with Ahmed's preference for turnkey solutions that are easy to operate and maintain, reducing reliance on highly skilled intervention for routine upkeep.

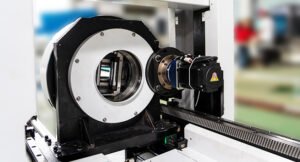

Motion Systems, Chucks, and Material Support: The Unsung Heroes of Accuracy

The precision and speed of a tube laser cutter heavily rely on its motion system. High-quality servo motors, precision-ground ball screws or helical rack-and-pinion drives, and rigid linear guideways are essential for fast acceleration, smooth movement, and accurate positioning. The overall rigidity of the machine frame also plays a critical role in absorbing vibrations and maintaining accuracy during high-speed cutting. When evaluating a machine, inquire about the specifications of these components and the manufacturer's reputation for building robust systems. For instance, MZBNL machines are built with heavy-duty frames and utilize high-precision motion components to ensure long-term reliability and consistent cutting accuracy, often achieving positioning accuracy of ±0.03mm to ±0.05mm.

The chucking system is vital for securely gripping various tube profiles (round, square, rectangular, special shapes) without causing distortion, especially with thin-walled tubes. Pneumatic chucks are common, but some high-end machines may offer hydraulic chucks for greater clamping force. Look for self-centering chucks that can automatically adjust to different tube sizes. The design of the front and rear chucks, and how they synchronize movement with the cutting head, is critical for accurate processing, especially for long tubes or when performing complex cuts near the tube ends. MZBNL’s innovation in redesigning the cutting logic to calculate from the rear chuck as the origin for our zero-waste tail material system demonstrates a sophisticated approach to chuck and motion control, maximizing material utilization and cutting efficiency, a direct benefit for cost-conscious business owners like Ahmed.

Material support systems are often overlooked but are crucial for preventing tube sag, especially with long or heavy tubes. Sagging can lead to inaccuracies in cutting as the distance between the cutting head and the tube surface changes. Effective support systems, which may include roller supports or V-supports that automatically adjust or follow the tube, ensure that the tube remains straight and stable throughout the cutting process. For Ahmed, who might be processing long sections of pipe for railings or structural elements, a reliable material support system is essential for maintaining cut quality and accuracy over the entire length of the tube. This contributes to reduced scrap and ensures that finished parts meet specifications without requiring rework.

Волоконные лазеры доминируют при резке трубПравда

Fiber lasers have largely replaced CO2 lasers in tube cutting due to higher efficiency and better performance on reflective materials.

Higher kW always means better cuttingЛожь

While higher power enables cutting thicker materials, beam quality and machine precision are equally important for optimal results.

What should you know about the machine’s operating system and ease of use?

Imagine investing in a powerful, high-tech tube laser cutting machine, only to find its operating system is so complex that it requires an engineering degree to run. This scenario can quickly turn a promising investment into a source of frustration and inefficiency, necessitating extensive training and highly skilled operators who might be hard to find or retain. The usability of a machine's control system is just as important as its mechanical capabilities.

A user-friendly operating system for a tube laser cutter should feature an intuitive interface, seamless CAD/CAM software integration, and libraries of pre-set cutting parameters. Innovations like No-CAD systems, which allow parameter-based cutting for standard shapes, drastically reduce complexity, job setup time, and operator training requirements.

A powerful machine is only truly effective if your team can harness its capabilities efficiently. The interface between the operator and the machine – its operating system and software – plays a pivotal role in daily productivity. This is particularly relevant for business owners like Ahmed Al-Farsi, who has experienced the pain of high operator turnover and the associated retraining burdens. He specifically seeks solutions that are easy to install and operate. Therefore, understanding the nuances of modern operating systems, especially advancements like No-CAD capabilities that simplify design input and machine setup, is critical. These features can transform your factory's workflow, reduce dependence on specialized skills, and significantly shorten the learning curve, directly addressing some of Ahmed’s key pain points. Let's explore what makes an operating system truly user-centric.

When I talk to factory owners, one of their biggest concerns, after cutting quality and reliability, is the ease of use of the machine's software and operating system. A complicated system can become a major bottleneck, regardless of how fast or precise the machine itself is. The goal should be to empower your existing workforce, not to create a dependency on a few highly specialized programmers or CAD experts for day-to-day operations. I recall a client who purchased a machine with a very powerful but incredibly complex German operating system; they struggled for months with productivity until they invested heavily in specialized training, a cost they hadn't initially budgeted for. This is why at MZBNL, we pioneered our No-CAD operating system, focusing on simplifying the most common tasks to make advanced laser cutting accessible to a broader range of users. Ahmed's preference for "turnkey solutions that are easy to install and operate" perfectly encapsulates this need for user-friendliness.

The Rise of No-CAD Systems: Simplifying Operations for Everyone

Traditionally, operating a laser tube cutter involved a multi-step process often requiring a skilled CAD technician. An operator would need to create or modify a 3D drawing in a separate CAD office, export it in a compatible format, and then import it into the machine's CAM software to generate the cutting program. This back-and-forth was time-consuming and inefficient, especially for standard tube types and common hole patterns. This is precisely the inefficiency that MZBNL aimed to solve with our No-CAD Operating System. With this system, operators can directly input parameters – like tube diameter, wall thickness, length, and hole type/position – into an intuitive interface on the machine itself. The system then generates the cutting program automatically for a wide range of standard profiles and operations, no separate drawing required.

The benefits are substantial. Firstly, it dramatically improves ease of use. Operators don't need to be CAD experts to produce common parts. Secondly, it significantly shortens setup time. Instead of waiting for a drawing from the design office, production can begin almost immediately. Thirdly, it lowers the skill threshold for machine operation. This is a huge advantage for businesses like Ahmed's that have faced challenges with high operator turnover and the burden of extensive retraining. As I mentioned, our system allows operators to be trained on-site in just one day, compared to the 15 days often spent at the equipment factory for traditional systems. This not only saves time and money but also increases operational flexibility, as more team members can be cross-trained to operate the machine.

For a business owner like Ahmed, who has an engineering background but also manages a workforce of over 100, the appeal of a No-CAD system is clear. It addresses his pain point regarding skilled CAD operators directly. It means his team can quickly and efficiently produce standard components for railings, shelves, or even simpler automotive brackets by simply entering a few key dimensions. This frees up his skilled CAD designers to focus on more complex, custom projects, rather than being bogged down with routine tasks. The ability to start cutting without CAD drawings for a significant portion of his work would be a major boost to his factory's overall productivity and responsiveness.

CAD/CAM Software Integration and Nesting Efficiency: Power for Complex Tasks

While No-CAD systems are excellent for standard jobs, the ability to seamlessly integrate with industry-standard CAD software is crucial for complex, custom parts. Your tube laser cutting machine's operating system should support common file formats like DXF, DWG, IGES, and STEP, allowing easy import of designs from software such as SolidWorks, AutoCAD, Inventor, or Rhino. The accompanying CAM (Computer-Aided Manufacturing) software is then responsible for processing these designs into machine-readable G-code. This software should offer features like automatic toolpath generation, collision detection, and optimization of cutting sequences. For Ahmed, who produces diverse parts for architectural metalwork and vehicles, robust CAD/CAM integration is essential for tackling bespoke designs and intricate geometries.

Nesting efficiency5 is another critical aspect of the CAM software. Good nesting software intelligently arranges parts on the tube to maximize material utilization and minimize waste. Features to look for include common-line cutting (where adjacent parts share a cut line), remnant tracking (allowing leftover material to be cataloged and used for future jobs), and the ability to prioritize parts within a nest. MZBNL's zero-waste tail material innovation, which redesigns the cutting logic to calculate from the rear chuck, complements advanced nesting by ensuring even the end piece of the tube is utilized if it's larger than the product length. This focus on material saving directly impacts the bottom line, reducing raw material costs significantly over time – a key consideration for any profit-oriented business.

The CAM software should also provide simulation capabilities, allowing the operator to visualize the entire cutting process before it begins. This helps to identify potential issues, such as collisions between the cutting head and the tube or clamps, and to verify that the cutting path is optimal. Some advanced systems even offer time and cost estimation for each job based on the nested layout and cutting parameters. For Ahmed, being able to accurately estimate job costs and lead times would be invaluable for quoting projects and managing production schedules effectively. The ability to integrate this production data with broader ERP (планирование ресурсов предприятия) или MES (системы управления производством)6 is also becoming increasingly important for larger operations seeking full factory digitalization.

User Interface, Training Resources, and Ongoing System Support

The Graphical User Interface (GUI) of the operating system is the operator's primary point of interaction with the machine. It should be intuitive, logically organized, and easy to navigate, preferably with touchscreen capabilities and clear visual feedback. Look for systems that offer customizable dashboards, on-screen prompts, and error messaging in clear, understandable language. Many modern systems also include extensive libraries of pre-set cutting parameters for common materials and thicknesses. This allows less experienced operators to achieve good cutting results quickly by selecting a proven set of parameters, while still allowing experienced users to fine-tune settings for specific applications.

Comprehensive training resources are vital. Beyond the initial operator training (like MZBNL's 1-day on-site program), inquire about the availability of detailed user manuals, video tutorials, online knowledge bases, and troubleshooting guides. The ability to get quick answers to common questions can save significant time and prevent minor issues from escalating. Furthermore, robust remote support capabilities are a huge asset. If an operator encounters a problem they can't solve, a technician from the manufacturer should be able to remotely access the machine's control system (with permission) to diagnose issues, adjust parameters, or even guide the operator through a solution. This is something Ahmed, who values after-sales service and has experienced lack of local support previously, would find highly beneficial.

Ongoing software updates and support are also important. The technology in this field evolves rapidly, and manufacturers often release software updates that include new features, performance improvements, or bug fixes. Understand the supplier's policy on software updates – are they included, or do they come at an additional cost? A supplier committed to continuous improvement and long-term support for their operating system provides peace of mind and ensures that your machine remains efficient and capable for years to come. For MZBNL, providing smart and digitalized systems is a core part of our offering, which includes ensuring our software stays current with industry needs and customer feedback.

No-CAD сокращает время обученияПравда

No-CAD systems allow operators to be trained in just one day compared to weeks for traditional CAD-based systems.

CAD is obsolete for all cuttingЛожь

While No-CAD works for standard shapes, CAD integration remains essential for complex custom parts and intricate geometries.

How does budget influence the choice of tube laser cutting machines?

Let's talk about one of the most significant factors in any major equipment purchase: the budget. It's a delicate balancing act – you want the most advanced features and capabilities, but you also have financial constraints to consider. Overspending can strain your company's finances and impact cash flow, while under-spending might mean compromising on essential features, long-term reliability, or the support you need, ultimately costing more in the long run.

Budget significantly influences the choice by setting a cap on initial machine cost, but it's crucial to consider the Total Cost of Ownership (TCO). This includes operational expenses (power, consumables, maintenance), potential financing, and the projected Return on Investment (ROI). Prioritize features offering the best long-term value for your specific production needs.

While the upfront price tag of a tube laser cutting machine is undeniably a major consideration, a truly astute financial decision looks far beyond that initial number. The concept of Total Cost of Ownership (TCO) provides a much more comprehensive view of the long-term financial implications of your investment. This is particularly important for business owners like Ahmed Al-Farsi, who explicitly prioritizes a "high cost-performance ratio over low price." He understands that a cheaper machine might end up costing more due to higher operating expenses, frequent breakdowns, or lower productivity. Let's delve into how to evaluate the true cost and value of a machine, ensuring your budgetary decisions align with your strategic goals for efficiency, quality, and profitability. This approach will help you make an investment that delivers sustained returns for your factory.

When discussing budget, it's easy to get fixated on the initial purchase price. However, as someone who has guided countless businesses through this process, I always stress the importance of looking at the bigger picture. A machine that seems like a bargain upfront might come with hidden costs or limitations that hamper your growth. Conversely, a seemingly more expensive machine could offer such significant gains in efficiency, material savings, and reliability that it provides a much faster and greater return on investment. For example, MZBNL's innovations like the No-CAD system, front-feeding, and zero-waste tail material are designed not just for performance but also for operational cost savings – reducing training time, labor intensity (by ~40% with front-feeding), and material scrap. These are tangible financial benefits that contribute to a lower TCO and a stronger ROI, aligning perfectly with Ahmed's preference for value and performance. He needs to evaluate how these features translate into savings for his specific production of railings, shelving, and auto parts.

Beyond the Sticker Price: Understanding Total Cost of Ownership (TCO)

The Total Cost of Ownership (TCO) encompasses all expenses related to the machine throughout its operational life. The initial purchase price is just the starting point. This includes the cost of the machine itself, any essential software licenses, delivery, installation, and initial operator training. However, the much larger portion of TCO often comes from ongoing operational costs. These include electricity consumption – where fiber lasers generally offer better energy efficiency than older CO2 lasers. Consider the cost and consumption rates of assist gases (like nitrogen for stainless steel or oxygen for mild steel), which can be a significant recurring expense. Also, factor in consumables such as nozzles, protective lenses, and other wear parts. While these might seem small individually, they add up over time.

Maintenance costs are another crucial element of TCO. Inquire about the recommended maintenance schedule, the cost of common replacement parts, and the availability and cost of service contracts. A well-built machine from a reputable manufacturer like MZBNL, with our 25 years of experience, is designed for durability and may have lower maintenance needs, but all machines require some upkeep. Labor costs associated with operating and maintaining the machine also contribute to TCO. Features that reduce operator intervention, simplify setup (like No-CAD), or enable faster processing (like efficient feeding systems) can lead to substantial labor savings. Don't forget to factor in potential downtime costs. A less reliable machine or one with poor support can lead to production stoppages, missed deadlines, and lost revenue – a major concern for Ahmed whose business relies on contract-based fabrication services.

Finally, consider the end-of-life costs or resale value. A high-quality machine from a well-regarded brand may retain more of its value if you decide to upgrade or sell it in the future. Calculating a comprehensive TCO provides a much more accurate basis for comparing different machine options than looking at purchase prices alone. For Ahmed, whose business is stable and has over 100 staff, minimizing these ongoing operational costs and ensuring high uptime are critical for maintaining profitability and competitiveness in the UAE market, where he sources from China, Germany, and Turkey.

Evaluating ROI and Long-Term Value: Making Your Investment Pay Off

Return on Investment (ROI) is the measure of how profitable your machine purchase will be. To evaluate ROI, you need to quantify the benefits the new machine will bring. These benefits can include increased production output (more parts per hour/day), significant material savings (e.g., through efficient nesting and features like MZBNL's zero-waste tail material innovation), and reduced labor costs (due to automation and ease of use). Improved part quality, leading to less rework and fewer rejects, also contributes positively to ROI. For Ahmed, if a new tube laser cutter allows him to take on more complex jobs, enter new markets, or reduce lead times for his clients in architectural metalwork and vehicle parts, these are all quantifiable benefits.

Consider the machine's scalability. Will it be able to handle your projected business growth over the next 5-10 years? Can it be upgraded with additional features or automation modules if needed? A machine that offers a clear upgrade path provides better long-term value than one that will quickly become a bottleneck as your business expands. The reliability and lifespan of the machine are also key. A machine built with high-quality components and backed by a reputable manufacturer is likely to have a longer operational life and require fewer major repairs, contributing to a better overall ROI. This is where MZBNL's 25 years of experience and focus on high-tech enterprise standards come into play, offering customers like Ahmed assurance of durability and performance.

Ahmed's preference for a "high cost-performance ratio over low price" directly speaks to this ROI-centric approach. He's not just looking for the cheapest machine; he's looking for the machine that will deliver the greatest value to his business in the long run. This means considering factors like cutting speed and accuracy, ease of use (especially the No-CAD system which addresses his pain point of skilled operator dependency), after-sales service, and the availability of spare parts. A machine that excels in these areas, even if it has a higher initial cost, will likely provide a much stronger ROI by maximizing uptime, productivity, and customer satisfaction.

Financing Options and Making the Investment Feasible for Your Budget

A tube laser cutting machine represents a significant capital investment, and understanding the available financing options is crucial for making it feasible within your budget. Many businesses, including stable, mid-sized ones like Ahmed's, opt for financing to preserve working capital and manage cash flow effectively. Common financing avenues include traditional bank loans, equipment leasing7, or financing programs offered directly by the machine manufacturer or their distributors. Each option has its pros and cons regarding interest rates, repayment terms, ownership, and tax implications, so it's wise to consult with your financial advisor to determine the best approach for your specific situation.

When considering leasing, you might encounter options like operating leases (similar to renting, with lower payments but no ownership at the end) or finance leases (where you typically own the machine at the end of the lease term). Leasing can be attractive as it may require a lower upfront payment and can sometimes offer tax advantages. Manufacturer-backed financing can often be competitive and may come with a better understanding of the equipment's value and lifespan. For instance, a company like MZBNL, with a global presence and numerous enterprise clients, may have established relationships with financial institutions or offer its own programs to facilitate purchases for qualified buyers.

It's also worth investigating if there are any government incentives, grants, or tax breaks available in your region (like the UAE for Ahmed) for investing in new manufacturing technology, automation, or energy-efficient equipment. Such programs can significantly reduce the net cost of the investment. Ultimately, the goal is to structure the purchase in a way that aligns with your company's financial strategy and ensures that the productivity gains and cost savings from the new machine can comfortably service any associated debt or lease payments, leading to a net positive impact on your profitability. Ahmed's stable business with 100+ staff is well-positioned to leverage financing for such a strategic upgrade, especially as he plans to automate existing manual workflows.

TCO includes operational expensesПравда

Total Cost of Ownership considers not just purchase price but also power, maintenance, and consumables over the machine's lifespan.

Cheaper machines always save moneyЛожь

Lower upfront cost may lead to higher long-term expenses through inefficiency, downtime, and maintenance issues.

What are the steps to finalize the decision and make the purchase?

You've diligently researched various tube laser cutting machines, compared specifications, and perhaps even narrowed down your choices. However, the final step – pulling the trigger on such a significant investment – can still feel daunting. Rushing these final stages or overlooking critical due diligence can unfortunately lead to post-purchase regrets, unexpected costs, or contractual misunderstandings. I've seen this happen, and it's avoidable with a methodical approach.

To finalize your tube laser cutting machine purchase, request detailed quotes and conduct live demonstrations with your materials. Thoroughly check supplier references, meticulously negotiate contract terms, and clearly understand warranty coverage and service agreements. Finally, carefully plan for the machine's installation, commissioning, and operator training for a smooth transition.

You are now on the cusp of acquiring a potentially transformative piece of technology for your factory. To ensure that this final phase proceeds smoothly and that your investment truly meets expectations, it's essential to follow a structured approach. For a hands-on decision-maker like Ahmed Al-Farsi, who has an engineering background and is looking to make a substantial upgrade to his UAE-based metal fabrication business, meticulous attention to detail in these final steps is second nature. He would want to be absolutely certain about every aspect before committing. Let's walk through the critical actions you need to take to confidently finalize your decision, ensuring a seamless purchase process and a successful integration of the new machine into your operations, paving the way for a strong, long-term supplier relationship.

The journey to acquiring the right tube laser cutting machine doesn't end with shortlisting potential suppliers. The finalization phase is where you confirm your choice, negotiate the best possible terms, and lay the groundwork for a successful implementation. This stage requires diligence and clear communication. For Ahmed, who is not just buying a machine but also considering a potential distributorship for MZBNL in the Gulf region if everything goes well, this phase is also about evaluating the supplier as a long-term partner. His previous negative experiences with suppliers lacking local service support will make him particularly cautious about the commitments made by any new vendor. Therefore, clarity on service, spare parts, and training is paramount. At MZBNL, we welcome this level of scrutiny because we are confident in our technology and our support infrastructure, backed by over 30 patents and a track record with over 4000 global enterprise clients.

Due Diligence: Demos, Samples, and Reference Checks – Seeing is Believing

Before you sign any contract, thorough due diligence is non-negotiable. The most crucial step here is to witness a live demonstration of the machine you are seriously considering, preferably cutting your own typical parts using your specific materials. This is something Ahmed, with his hands-on approach, would undoubtedly insist upon. Provide the supplier with CAD files of a few representative jobs – perhaps a complex architectural component and a precise automotive part from his portfolio. Observe the entire process: programming (especially ease of use with No-CAD features for standard items), tube loading, cutting speed, cut quality (checking for dross, taper, and accuracy), and unloading. This practical test will reveal more than any brochure or sales pitch.

Request sample parts cut on the machine during the demonstration, or ask the supplier to cut and send samples to you for inspection. Evaluate these samples meticulously for dimensional accuracy, edge quality, and consistency. Compare samples from different shortlisted suppliers. This tangible evidence is vital for confirming that the machine can meet your quality standards. Furthermore, ask for references – contact details of existing users of the same or similar machine models, ideally in your industry or region. Speaking to current users, as Ahmed does through his industry peer referrals, can provide invaluable, unbiased feedback on the machine's real-world performance, reliability, ease of use, and, critically, the quality and responsiveness of the supplier's after-sales service and technical support8. Don't hesitate to ask these references about any challenges they've faced and how the supplier addressed them.

During this due diligence phase, also assess the supplier's technical expertise. Can their team answer your in-depth questions clearly and competently? Do they understand your specific application needs? For Ahmed, who has a strong engineering background, interacting with knowledgeable sales and technical staff would be a key indicator of the supplier's capabilities. This is also an opportunity to gauge their willingness to work collaboratively to find the best solution for your factory, rather than just pushing a standard product.

Negotiation, Contractual Agreements, and Warranty: Getting the Details Right

Once you're satisfied with the machine's capabilities and the supplier's credibility, it's time to obtain detailed, formal quotations from your shortlisted vendors. Ensure these quotes are comprehensive, itemizing the machine, all included accessories (like chucks, software licenses, initial consumables), delivery, installation, training, and warranty. Carefully compare these quotes, not just on price but on the overall value and completeness of the package. Now, you can enter into negotiations. Don't be afraid to discuss price, but also consider negotiating payment terms, delivery schedules, the extent of training, and any additional services or spare parts packages. For Ahmed, ensuring favorable terms that reflect his potential as a long-term customer and possibly a future distributor would be a strategic move.

The sales contract is a legally binding document, so review it meticulously before signing. If possible, have your legal counsel review it as well. Pay extremely close attention to the warranty terms9: What is the duration of the warranty? What parts and labor are covered? What are the exclusions? What is the process for making a warranty claim? Clarify the terms of any Service Level Agreements (SLAs) offered10, which might specify guaranteed response times for service calls. Understanding the availability and cost of spare parts post-warranty is also crucial, a key point for Ahmed given his past experiences and current sourcing key points like \"spare parts availability and remote diagnostics.\" MZBNL's commitment to customer support includes ensuring a clear understanding of these terms.

Also, discuss the payment schedule. Typically, it involves a down payment upon order, another payment before shipment, and a final payment after successful installation and commissioning. Ensure these terms are clearly stipulated and acceptable to your business. The contract should also detail the responsibilities of both parties regarding site preparation, installation logistics, and acceptance criteria. Getting all these details clearly documented in the contract will prevent misunderstandings and protect your interests throughout the purchase and operational lifecycle of the machine.

Planning for Installation, Training, and a Potential Future Partnership

With the contract signed, the focus shifts to preparation and implementation. Effective planning is key to a smooth installation and a quick ramp-up to full production. The supplier should provide detailed site preparation guidelines, including requirements for floor space, foundation, electrical power supply (voltage, phase, amperage), compressed air, and assist gas lines. Ensure your facility is ready before the machine arrives to avoid delays. Coordinate closely with the supplier on the delivery schedule and the logistics for offloading and positioning the machine. Ahmed, managing a factory with over 100 staff, would likely have a dedicated team to oversee these preparations.

Confirm the training plan for your operators and maintenance staff. This should ideally be included in the purchase agreement. MZBNL's 1-day on-site training for our No-CAD system is designed to get operators proficient quickly, but ensure the scope and depth of training cover all necessary aspects, including machine operation, software usage, routine maintenance, and basic troubleshooting. Clarify who will provide the training, where it will take place (on-site is usually preferable), and if any follow-up training or resources are available. This directly addresses Ahmed's requirements for post-sales training and support, and his concern about retraining burdens due to operator turnover.

Finally, if applicable, this is also the time to discuss the potential for a deeper, long-term partnership. For Ahmed, who has expressed interest in becoming a regional distributor for MZBNL if the machine performs well and the support is reliable, this phase is an opportunity to lay the groundwork for such a collaboration. Discussing co-branding options or exclusive distribution rights for the Gulf region, as he is considering, requires open communication and a shared vision for future growth. A successful machine installation and a positive initial experience can be the foundation for a mutually beneficial strategic alliance, leveraging MZBNL's global distributor networks and Ahmed's local market expertise.

Live demonstrations are crucialПравда

Witnessing the machine cut your actual materials reveals more about its capabilities than any brochure can show.

Price is the only contract factorЛожь

Payment terms, training scope, warranty coverage and service agreements are equally critical contractual elements.

Заключение

Choosing the right tube laser cutting machine is a strategic investment that demands careful evaluation of technical capabilities, software ease of use, total cost of ownership, and robust supplier support. A well-informed decision, like the one Ahmed Al-Farsi aims for, empowers your factory to significantly boost efficiency, quality, and overall competitiveness in the demanding metal fabrication landscape.

-

Learn about fiber laser technology and its advantages for metal cutting applications. ↩

-

Explore how remote diagnostics improve uptime and reduce maintenance costs for machinery. ↩

-

Understand M² beam quality's impact on laser focus, cutting precision, and achievable kerf width. ↩

-

Discover techniques to reduce HAZ for improved material integrity and better post-processing results. ↩

-

Learn how nesting optimizes material use, cutting waste and costs in tube fabrication processes. ↩

-

Discover how ERP/MES integration enhances factory data management and operational visibility for smarter production. ↩

-

"Explore equipment leasing as a flexible financing option to acquire machinery without large upfront costs." ↩

-

Learn key factors for assessing B2B supplier after-sales service and support quality. ↩

-

Discover what to look for in industrial equipment warranty clauses for comprehensive coverage. ↩

-

Understand what Service Level Agreements (SLAs) are and their importance for timely support. ↩

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.