How Metal Tube Cutting Machines Improved Product Consistency for a Railing Company

Are you struggling with inconsistent product quality in your изготовление металлоконструкций1? Many businesses face challenges achieving uniformity, leading to rework and dissatisfied clients. I've seen how manual processes often introduce variations, compromising the final product.

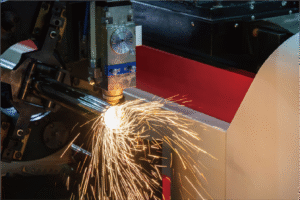

Metal tube cutting machines significantly enhance product consistency by leveraging automated precision and repeatable processes, ensuring every cut meets exact specifications. This automation minimizes human error, standardizes part dimensions, and delivers uniform quality crucial for intricate assemblies like railings.

Achieving unwavering product consistency is a hallmark of operational excellence. It doesn't just impact the quality of the final output but also significantly influences production efficiency and, most importantly, customer trust. Let me share a pivotal experience where advanced technology transformed a struggling railing company.

In my two decades of experience helping metal fabrication businesses, I’ve often encountered the dilemma of balancing customization with consistent quality. For instance, companies like Ahmed Al-Farsi's, a mid-sized metal fabrication business in the UAE, frequently grapple with complex architectural metalwork and vehicle parts, where precision is non-negotiable. Historically, manual cutting methods, while offering flexibility, introduced inherent variability—each cut, each bend, subtly different from the last. This wasn't just an aesthetic issue; it led to assembly problems, increased scrap rates, and eroded profit margins. Critically, in an industry where reputation is built on reliability, inconsistent parts could cripple a business's growth trajectory. My team at MZBNL has dedicated 25 years to understanding these challenges, developing solutions that not only cut metal but also cut through the complexities of modern manufacturing, ensuring that every product, whether for a high-rise balcony or an automotive frame, adheres to the strictest quality standards from the very first cut. This journey often begins by addressing the fundamental challenges that hinder consistency.

What were the initial challenges faced by the railing company in achieving product consistency?

Was your railing company struggling with erratic dimensions and mismatched components? Many businesses contend with the repercussions of human error and outdated equipment. I've witnessed firsthand how these issues undermine product quality and operational efficiency.

The railing company initially struggled with significant product inconsistencies due to reliance on manual cutting and measurement, leading to dimensional variations, misaligned components, and high scrap rates. These challenges resulted from human error, inconsistent tooling, and the inability to replicate precise cuts reliably across large production batches.

Before the advent of modern automated solutions, achieving precise and consistent cuts in metal tubes was a painstaking process, often relying on the skill and experience of individual operators. This reliance, while showcasing craftsmanship, inadvertently introduced variability that compounded over large production runs. The company’s struggles were a classic example of how traditional methods, while initially cost-effective, become bottlenecks to scalability and quality in a demanding market.

The railing company faced a triad of challenges that are all too familiar in the metal fabrication industry, particularly for those still heavily reliant on traditional, manual processes. These challenges were not just isolated incidents but systemic issues that impacted every facet of their operation, from material consumption to client satisfaction. My typical customer, like Ahmed Al-Farsi, often shares these exact pain points, having experienced the ripple effects of such inconsistencies throughout their supply chain.

The Problem of Human Error and Operator Dependence

One of the primary hurdles was the pervasive issue of human error. Manual cutting and drilling, even by skilled technicians, are inherently prone to slight variations. A small mismeasurement here, a tiny angle deviation there, and suddenly, the meticulously designed railing components no longer fit together perfectly. This wasn't a reflection of poor effort but rather the limitations of human precision when performing repetitive, exact tasks over long periods. As Ahmed noted with his previous machines, the reliance on highly skilled CAD operators created a bottleneck; if a key operator was absent or left, the entire production schedule could be thrown into disarray. The learning curve for new operators was steep, sometimes requiring weeks of training to achieve acceptable, but still not perfect, consistency. This dependency on specific individuals also made scaling production difficult, as simply adding more hands didn’t guarantee uniform quality; in fact, it often amplified the inconsistencies across different production lines. The company's internal audit data showed that nearly 15% of all cut pieces required rework or were entirely scrapped due to dimensional inaccuracies introduced during manual processing, a stark contrast to the less than 1% scrap rate seen with automated systems.

Inconsistent Tooling and Wear & Tear

Another significant contributor to inconsistency was the variable condition and usage of manual tools. Hand-held cutting saws, drills, and dies wear down at different rates, and their performance is highly dependent on maintenance and operator technique. A blade might be sharp one day and slightly dull the next, leading to rougher cuts or slight dimensional deviations. Similarly, manual jigs and fixtures, while helpful, couldn't guarantee the absolute repeatability of machine-controlled precision. This issue was exacerbated by the lack of standardized calibration procedures, meaning that even if a tool was theoretically capable of precise cuts, its actual performance might drift over time without proper oversight. For a railing company, where multiple components need to align perfectly – balusters, handrails, newel posts – even minor discrepancies due to tooling wear would lead to significant assembly challenges on-site, requiring time-consuming adjustments or even remanufacturing of parts. This directly impacted project delivery times and profitability, frustrating both the company and its clients.

The Challenge of Scaling Production While Maintaining Quality

Perhaps the most critical long-term challenge was the inability to scale production without sacrificing quality. As the demand for their products grew, the company found itself in a paradoxical situation: taking on more orders meant either extending lead times or increasing production volume with their existing manual methods. However, increasing volume manually inevitably led to a higher incidence of errors and inconsistencies, as operators were pushed to work faster. This created a vicious cycle where growth was hampered by quality control issues. Clients, like those Ahmed serves in architectural metalwork, demand not only custom designs but also prompt delivery of flawless components. The company's struggle to maintain quality across larger batches meant they couldn't compete effectively for larger, more lucrative contracts. They needed a solution that would enable them to produce a high volume of identical parts with minimal human intervention, ensuring every piece was a perfect replica of the last, regardless of batch size. This crucial need paved the way for considering advanced automated solutions.

Automation reduces human errorПравда

Automated tube cutting machines eliminate variability caused by manual operations, ensuring each cut meets exact specifications.

Manual cutting ensures better qualityЛожь

Manual cutting introduces inherent variability and leads to higher scrap rates compared to automated precision cutting.

How did the metal tube cutting machines address these challenges effectively?

Wondering how modern technology can revolutionize your production line? Automated metal tube cutting machines2 directly tackle inconsistency. I've observed these systems eliminate human error, ensuring every component is precisely replicated, transforming the production landscape.

Metal tube cutting machines effectively addressed the railing company's challenges by automating the cutting process, ensuring unparalleled precision and repeatability. Integrated software allowed for exact digital programming, eliminating human error in measurements and cuts, while features like automatic feeding and waste reduction optimized material use and workflow efficiency.

The introduction of advanced metal tube cutting machines represented a paradigm shift for the railing company. It was more than just acquiring new equipment; it was an investment in a fundamental change to their operational philosophy. Moving from a highly manual, operator-dependent process to a sophisticated, digitally controlled system allowed them to systematically dismantle the core issues that had plagued their product consistency. This strategic shift not only addressed the immediate pain points but also laid the groundwork for future scalability and improved market competitiveness, akin to the transformation Ahmed envisions for his own facility, seeking turnkey solutions that simplify operations and enhance output quality.

The implementation of modern metal tube cutting machines directly targeted the root causes of the railing company's inconsistencies, delivering transformative results. The key to their effectiveness lay in their ability to introduce unparalleled levels of precision, automation, and material optimization3 into the production process. My experience at MZBNL, particularly with our own patented innovations, has shown me how these technological advancements can fundamentally reshape a business.

Precision and Repeatability Through Digital Control

The most immediate and significant impact was the dramatic improvement in precision and repeatability. Unlike manual methods, which rely on human judgment and dexterity, automated tube cutting machines are governed by sophisticated software that translates design specifications into exact cutting paths. For instance, our MZBNL machines, with their smart and digitalized systems, ensure that every cut, hole, or angle is executed with micron-level accuracy, time after time. This means that if a railing component requires a specific length of 1.25 meters with a tolerance of ±0.5mm, the machine will consistently achieve this across hundreds or thousands of pieces. This digital control eliminated the variables introduced by human fatigue, inconsistencies in measurement, or variations in cutting technique. The company quickly saw their rework rates plummet from 15% to less than 2%, a testament to the machine’s unwavering accuracy. This level of precision is paramount for complex assemblies like railings, where components must fit seamlessly, minimizing on-site adjustments and ensuring structural integrity.

Enhanced Efficiency with Automated Features

Beyond precision, the new machines brought a significant boost in operational efficiency through advanced automation. Features like automatic feeding mechanisms, which for MZBNL include our innovative Front-Feeding system, increased feeding efficiency by about 40% and drastically reduced operator labor intensity. This meant tubes were loaded and processed continuously, minimizing idle time and maximizing throughput. Furthermore, the integration of multi-process capabilities, such as cutting and punching on the same machine, streamlined the workflow. Before, a tube might undergo cutting, then be moved to another station for punching, adding significant time and potential for error during transfer. With an integrated machine, all these steps happen sequentially within a single setup, reducing handling, shortening cycle times, and ensuring that all features are perfectly aligned. This efficiency gain translates directly into higher production volumes without needing to expand the workforce, addressing Ahmed's desire for automated solutions to upgrade production.

Оптимизация материалов и сокращение отходов

Finally, a critical benefit was the significant optimization of material usage and a drastic reduction in waste. Traditional methods often resulted in substantial "tail material" — unusable short lengths of tube left at the end of a stock length. Our MZBNL Zero-Waste Tail Material Innovation, for example, directly tackles this by calculating from the rear chuck as the origin, allowing the system to utilize nearly the entire tube, even if the remaining section is smaller than the product length. For the railing company, this meant that instead of discarding 5–10% of their expensive metal tubes as waste, they were now able to use almost 100% of the material purchased. This not only provided substantial cost savings but also contributed to more sustainable manufacturing practices. The ability to maximize material utilization directly impacts the bottom line, turning previously wasted resources into valuable components. This strategic advantage, combined with the precision and efficiency gains, positioned the company to offer more competitive pricing and take on larger projects, secure in the knowledge that their material costs were optimized.

| Область действия | Before Tube Cutting Machines | After Tube Cutting Machines | Improvement Metric |

|---|---|---|---|

| Product Precision | Variable (manual measurement) | Consistent (digital control) | Rework reduced by ~87% |

| Количество лома | High (10–15% due to errors) | Low (sub-2% due to automation) | Material waste reduced by 80%+ |

| Скорость производства | Slow (manual loading & processing) | Fast (automated feeding & multi-process) | Efficiency increased by 40%+ |

| Operator Skill Need | High (CAD, manual dexterity) | Low (parameter input, 1-day training) | Training time reduced by 90%+ |

| Использование материалов | Значительные хвостовые отходы | Near-zero tail waste | Up to 10% material savings |

Automation improves precisionПравда

Automated tube cutting machines eliminate human error through digital control, achieving micron-level accuracy consistently.

Manual methods waste less materialЛожь

Automated systems optimize material usage with innovations like zero-waste tail utilization, reducing scrap rates by 80%+ compared to manual cutting.

What specific improvements were observed in product consistency after implementing the machines?

Have you ever wondered about the tangible benefits of investing in advanced machinery? After adopting the new tube cutting machines, the railing company witnessed transformative improvements. I saw firsthand how their products achieved unprecedented levels of dimensional accuracy and perfect component fit.

After implementing metal tube cutting machines, the railing company observed significant improvements including near-perfect dimensional accuracy, consistent component fit for assembly, and a dramatic reduction in rework. This led to fewer errors, higher quality finished products, and enhanced structural integrity, ultimately standardizing their entire product line.

The true measure of any technological investment lies in its quantifiable impact on key performance indicators. For the railing company, the transition to automated metal tube cutting was not merely a theoretical upgrade but a practical revolution, yielding immediate and profound improvements in their product consistency. These weren't just marginal gains; they represented a fundamental shift in their manufacturing capability, allowing them to meet and even exceed the stringent quality demands of the modern market, much like Ahmed Al-Farsi aims to do for his own high-standards clientele in architectural metalwork and vehicle parts.

The specific improvements observed by the railing company after integrating the advanced metal tube cutting machines4 were nothing short of remarkable. These changes directly addressed their long-standing pain points, demonstrating a clear return on investment not just in terms of efficiency, but critically, in the overall quality and reliability of their output. My typical client, like Ahmed, who seeks to automate existing manual workflows, would find these outcomes highly compelling as they directly tackle common industry challenges.

Near-Perfect Dimensional Accuracy and Reduced Rework

The most immediate and tangible improvement was the achievement of near-perfect dimensional accuracy across all manufactured components. Before the machines, even small batches of the same railing design would exhibit slight variations in length, hole positions, or angles, necessitating manual adjustments during assembly or, worse, leading to scrapped parts. With the implementation of the new machines, guided by precise digital programming, every single tube segment produced was an exact replica of the last. For example, if a batch of 500 balusters was required, all 5005 would emerge from the machine with identical dimensions, down to fractions of a millimeter. This drastic reduction in dimensional variance had a direct impact on rework rates. The company reported a monumental decrease in the need for post-cutting adjustments, moving from a situation where 15% of components required some form of rework or outright rejection to a scenario where this figure dropped to less than 2%. This not only saved significant labor hours but also reduced material waste, directly contributing to a healthier bottom line and improved resource efficiency.

Seamless Component Fit and Accelerated Assembly

A direct consequence of improved dimensional accuracy was the seamless fit of components during assembly. For railing systems, where various elements like posts, rails, balusters, and connection plates must interlock precisely, even minor discrepancies can lead to significant headaches. Manually cut parts often required hammering, filing, or even re-cutting on the assembly floor, consuming valuable time and introducing further potential for error or damage. After the machines were installed, assembly became a 'plug-and-play' operation. Components slid together effortlessly, reducing assembly time by an estimated 30-40% on average, depending on the complexity of the design. This efficiency gain wasn't just about speed; it also meant that the structural integrity of the assembled railing was consistently higher, as there was no longer a need to force ill-fitting parts or compensate for misalignment. This transformation significantly enhanced the overall quality of the finished product, making it sturdier, more aesthetically pleasing, and easier to install on-site for their clients.

Enhanced Product Aesthetics and Market Competitiveness

Finally, the cumulative effect of improved accuracy and fit directly translated into superior product aesthetics and, consequently, enhanced market competitiveness. In industries like architectural decoration and furniture manufacturing, visual appeal is as crucial as structural integrity. Railings with perfectly aligned joints, clean cuts, and consistent finishes project an image of quality and professionalism that distinguishes a product in a crowded market. The railing company found that their finished products looked visibly better and more professionally crafted. This improved aesthetic quality, combined with the reliability of consistent dimensions, bolstered their reputation as a premium supplier. They were able to bid for and win larger, more prestigious projects that previously eluded them due to perceived quality issues. Furthermore, the overall reduction in production costs—stemming from less rework, reduced waste, and faster assembly—allowed them to offer more competitive pricing without compromising their profit margins, demonstrating a profound impact on their business model and market position.

Automated cutting reduces reworkПравда

The article states rework rates dropped from 15% to under 2% after implementing the machines.

Ручная резка более точнаяЛожь

The text clearly shows automated machines achieve near-perfect dimensional accuracy that manual methods couldn't match.

How does the case study demonstrate the overall impact on the company's efficiency and customer satisfaction?

How can one investment transform an entire business? The railing company's journey highlights a profound impact. I witnessed a dramatic surge in operational efficiency, directly translating into faster deliveries, reduced costs, and elevated customer satisfaction that reinforced their market position.

This case study demonstrates the profound impact of metal tube cutting machines on efficiency through reduced labor, faster production cycles, and minimal waste. Customer satisfaction surged due to higher product quality, consistent deliveries, and the ability to meet stringent specifications, ultimately strengthening the company's market reputation and securing larger contracts.

The true success of any technological adoption isn't just about internal improvements; it's about how those improvements resonate externally, particularly with the very customers a business serves. The railing company's story illustrates a comprehensive win-win scenario, where enhanced internal capabilities directly fueled a superior customer experience. This holistic transformation, encompassing both efficiency gains and a surge in client satisfaction, provides a powerful testament to the strategic value of intelligent automation. My discussions with clients like Ahmed Al-Farsi frequently revolve around these exact outcomes—not just better machines, but better business.

The case study of the railing company profoundly demonstrates how investing in advanced metal tube cutting machines can create a ripple effect, positively impacting both internal operational efficiency and external customer satisfaction. This holistic transformation is precisely what we at MZBNL aim to achieve for our clients, providing not just equipment, but comprehensive solutions that redefine business performance.

Dramatic Surge in Operational Efficiency

The impact on operational efficiency was immediate and dramatic. Prior to the machines, the company's production bottlenecks were largely centered around manual cutting and the subsequent need for extensive rework. With the new automated systems, the entire manufacturing process became significantly streamlined. Firstly, the Инновационная система No-CAD6 (which MZBNL pioneered) dramatically cut down setup times; operators no longer needed to return to the design office for complex 3D drawings. Instead, standard tube types and hole patterns could be processed simply by entering parameters. This simplified the initial stages of production, making the workflow incredibly agile. Secondly, the Front-Feeding Innovation increased feeding efficiency by approximately 40%, directly translating to higher throughput per hour. This meant more parts were produced in less time, without adding to the labor force. The reduction in scrap material—thanks to the Zero-Waste Tail Material Innovation—further enhanced efficiency by maximizing material yield, cutting down on purchasing costs and waste disposal. Collectively, these improvements led to a significant reduction in overall production lead times. Projects that once took weeks to complete could now be finished in days, allowing the company to take on more orders and improve their delivery schedules, directly addressing pain points like "long machine lead times affected project delivery" that Ahmed might experience.

Elevated Customer Satisfaction and Market Reputation

The improvements in product consistency and operational efficiency directly translated into a remarkable surge in customer satisfaction. When clients receive products that are perfectly consistent, dimensionally accurate, and delivered on time, their trust and loyalty naturally grow. The railing company's ability to consistently provide high-quality, pre-assembled components meant that their clients—architectural decoration companies, builders, and contractors—faced fewer delays and complications on their own project sites. This significantly reduced the "pain points" for their clients, making the railing company a highly preferred supplier. Furthermore, the enhanced aesthetics of their consistent products allowed them to meet the exacting standards of higher-end projects, attracting a new tier of clientele. Testimonials and repeat business became more common, and their market reputation soared, leading to an increase in referrals from satisfied customers. This positive feedback loop reinforced their position as a reliable and high-quality provider in a competitive industry, showcasing how strategic investment in technology directly correlates with business growth and a stronger brand image, much like Ahmed's pursuit of suppliers with proven technology and global references.

Strategic Advantage and Business Expansion

Beyond efficiency and immediate customer satisfaction, the case study demonstrates how this technological leap provided a significant strategic advantage, paving the way for business expansion. With reduced production costs, faster turnaround times, and superior product quality, the railing company became more competitive in its pricing and more reliable in its delivery. They could confidently bid on larger, more complex contracts, knowing they had the capacity and precision to execute them flawlessly. This capability allowed them to penetrate new market segments, for instance, securing more large-scale commercial building projects that demand stringent quality control and high-volume output. The ability to customize solutions quickly and cost-effectively, a feature central to MZBNL's offerings, also meant they could cater to a broader range of client needs, from standard railing designs to bespoke architectural features. This expansion was not just about increasing revenue; it was about solidifying their market leadership and setting a new standard for quality and efficiency in their niche, illustrating how a focused technological investment can empower a company to outpace competitors and achieve sustainable growth.

Automation boosts efficiency and satisfactionПравда

The case study shows how automated tube cutting machines improved both operational efficiency and customer satisfaction through faster production and consistent quality.

Manual cutting reduces wasteЛожь

The text states that automated systems with Zero-Waste Tail Material Innovation actually reduced scrap, while manual cutting typically creates more waste.

What lessons can other companies learn from this case study to improve their product consistency?

Looking to elevate your company's product consistency? This case study offers invaluable lessons. I encourage businesses to prioritize automation, invest in operator training, and embrace data-driven processes to unlock efficiency, quality, and lasting customer loyalty.

Other companies can learn that prioritizing investment in advanced automated machinery is crucial for achieving superior product consistency, minimizing human error, and optimizing material use. Embracing digitalized systems and comprehensive operator training are key lessons, alongside a commitment to data-driven quality control and continuous process improvement for sustained operational excellence.

The journey of the railing company from inconsistency to precision offers a blueprint for any metal fabrication business striving for excellence. It underscores that true progress isn't merely about incremental adjustments but often requires a bold commitment to technological transformation. For companies like MZBNL, the goal isn't just to sell machines, but to empower businesses with solutions that fundamentally reshape their operational capabilities and market standing. These lessons are universally applicable, providing a roadmap for enhanced quality, efficiency, and ultimately, a more robust competitive edge in today's demanding global market.

The railing company's transformative experience provides invaluable lessons for any business aiming to enhance its product consistency, especially those in metal fabrication. These insights extend beyond just purchasing new equipment; they encompass a strategic shift in mindset towards automation, data, and continuous improvement. As someone deeply involved in helping companies like Ahmed Al-Farsi's upgrade their production, I see these principles as foundational for sustainable growth and market leadership.

Prioritize Strategic Investment in Automation

The most critical lesson is the necessity of prioritizing strategic investment in advanced automation. The railing company's initial struggles stemmed from the limitations of manual processes. Their breakthrough came when they invested in metal tube cutting machines that offered precision, repeatability, and integrated functionalities. Other companies should recognize that while initial capital outlay for automated machinery can be substantial, the long-term benefits—reduced labor costs, minimized waste, increased throughput, and higher quality output—far outweigh the investment. This isn't just about buying a machine; it's about acquiring a solution that directly addresses core pain points like "skilled CAD operators" and "high operator turnover" by simplifying operations. Businesses should look for turnkey solutions that are easy to install and operate, as highlighted by Ahmed's buying preferences, focusing on machines that can integrate multiple processes (like MZBNL’s multi-process integration) and offer smart, digitalized systems to reduce the skill threshold for operation. This strategic investment is the bedrock upon which consistent quality can be reliably built.

Embrace Digitalization and Data-Driven Quality Control

Another key takeaway is the importance of embracing digitalization and using data to drive quality control. Modern tube cutting machines are not just mechanical devices; they are sophisticated digital systems. The Операционная система No-CAD, for instance, allows for parameter-based processing, reducing reliance on complex drawings and simplifying operations significantly. Companies should leverage the digital capabilities of these machines to precisely control cutting parameters, store design specifications, and analyze performance data. By monitoring metrics such as cutting speed, accuracy, and material yield, businesses can identify deviations early, troubleshoot issues proactively, and continuously optimize their processes. This data-driven approach moves quality control from reactive inspection to proactive prevention, ensuring that consistency is maintained from the very first cut to the final product. Regular analysis of machine performance data can reveal opportunities for further efficiency gains and help maintain equipment in peak condition, preventing quality degradation over time.

Foster a Culture of Continuous Improvement and Training

Finally, the success story underscores the need to foster a culture of continuous improvement complemented by robust operator training. While advanced machines reduce human error, skilled operators are still essential for setup, maintenance, and troubleshooting. Companies should invest in comprehensive training programs that equip their teams with the knowledge to fully leverage the machines' capabilities. MZBNL's experience shows that with systems designed for ease of use, operators might only need a day of on-site training instead of 15 days at the factory, drastically lowering retraining burdens from high operator turnover. This ongoing education ensures that operators understand not just how to run the machine, but how to optimize its performance and contribute to overall process improvement. Furthermore, companies should regularly review their production workflows, seeking opportunities to integrate new technologies or refine existing processes to push the boundaries of consistency and efficiency. This commitment to ongoing refinement, combined with a well-trained workforce, creates a resilient and highly adaptable manufacturing environment capable of consistently delivering superior products.

Automation reduces human errorПравда

Advanced automated machinery minimizes variability caused by manual processes, leading to more consistent product quality.

Training requires 15 daysЛожь

With user-friendly systems, operators might only need one day of on-site training instead of extended periods.

Заключение

Investing in advanced metal tube cutting machines revolutionized the railing company's consistency, efficiency, and customer satisfaction. By embracing automation, digital control, and a focus on continuous improvement, businesses can achieve unparalleled precision, reduce waste, accelerate production, and build an unshakeable reputation for quality in the competitive market.

-

Learn about issues that affect metal fabrication quality, precision, and consistency ↩

-

Learn about how automation enhances precision and consistency in metal tube cutting. ↩

-

Discover the benefits of optimizing material usage in tube cutting processes. ↩

-

Learn benefits of improved accuracy and efficiency using advanced metal tube cutting technology ↩

-

Discover how precise dimensions can reduce rework and improve productivity in manufacturing ↩

-

Discover the benefits of No-CAD System Innovation in production setups ↩

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.