Choosing Your Tube Laser Cutter: Why Quality from MZBNL Beats Price Alone?

Choosing a new tube laser cutter is a major decision. Focusing only on the price tag can lead to costly problems down the line. The right machine should be a long-term asset, not a short-term liability.

A quality tube laser cutter is the best investment because it guarantees higher efficiency, superior reliability, and a lower total cost of ownership. Innovations in automation and material use from a quality-focused brand like MZBNL deliver a return that far outweighs the initial price difference of a cheaper machine.

I've been in this industry for a long time, and I've seen firsthand how the decision between price and quality plays out on the factory floor. A low upfront cost can be tempting, but it often hides the true expense of a machine. In this article, I want to walk you through the critical factors to consider, show you what genuine quality looks like, and explain why a strategic investment in the right equipment is the smartest move for your business's future.

What are the Key Factors to Consider When Choosing a Tube Laser Cutter?

You need a new machine, but the technical specifications can be overwhelming. How do you look past the marketing and identify the factors that truly matter for your production line and your bottom line?

Key factors include cutting precision, processing speed, software usability, automation level, material utilization, and after-sales support. Evaluating these elements ensures you select a machine that meets your production needs and delivers long-term value, not just a low initial cost.

When I consult with clients, I always tell them to think of the machine as a new member of their team. You wouldn't hire an employee based on the lowest salary demand alone; you'd look for skill, reliability, and the ability to contribute to your company's growth. The same logic applies here. A cheap machine that is constantly down for repairs or produces inaccurate parts is a drain on resources. A quality machine becomes a profit center. To make an informed decision, you need to dive deeper into what defines a high-performance tube laser cutter.

The Anatomy of a Smart Investment

Here are the core elements I urge every potential buyer to scrutinize:

- Precision and Repeatability: Can the machine consistently produce identical parts within tight tolerances? Ask for sample cuts using your own files and materials. Poor precision leads to rejected parts and wasted material, which costs you money every single day.

- Overall Throughput: This isn't just about the maximum cutting speed listed on a brochure. It's about the entire process, from loading raw material to unloading finished parts. A machine with slower cutting speed but smarter automation can often outperform a "faster" machine with clumsy manual processes.

- Software and Usability: How complex is the software? How long will it take to train an operator? Complicated systems create a bottleneck and increase your dependency on highly skilled (and often hard-to-find) technicians. The future is in systems that are powerful yet intuitive.

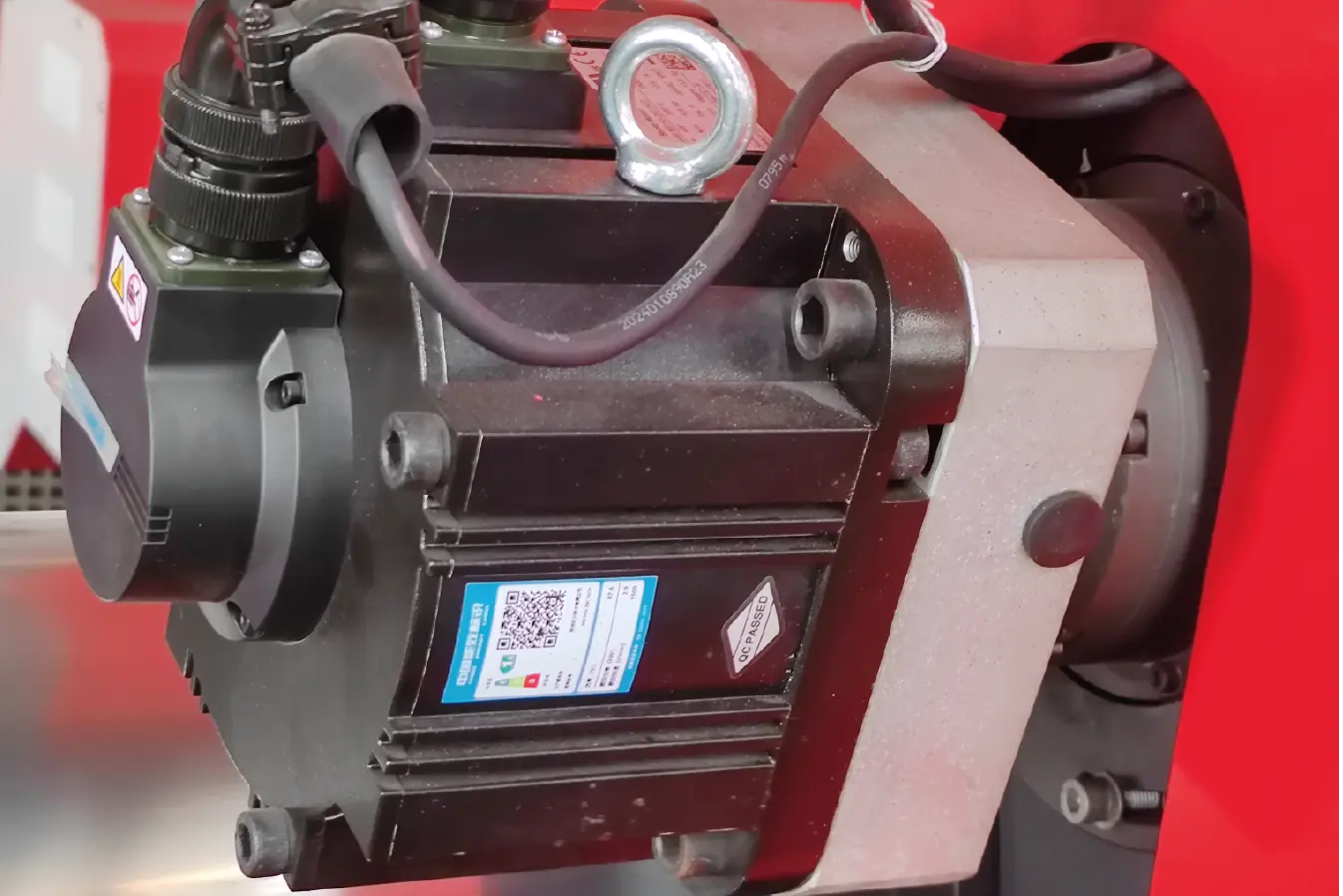

- Reliability of Core Components: The quality of the laser source, cutting head, and servo motors[^1] directly impacts the machine's lifespan and performance. Don't be afraid to ask which brands are used for these critical components. Reputable manufacturers don't cut corners here.

- After-Sales Support: What happens when you need a spare part or have a technical question? A low price often means non-existent support, leaving you stranded during a critical production run. A quality partner provides responsive service and training.

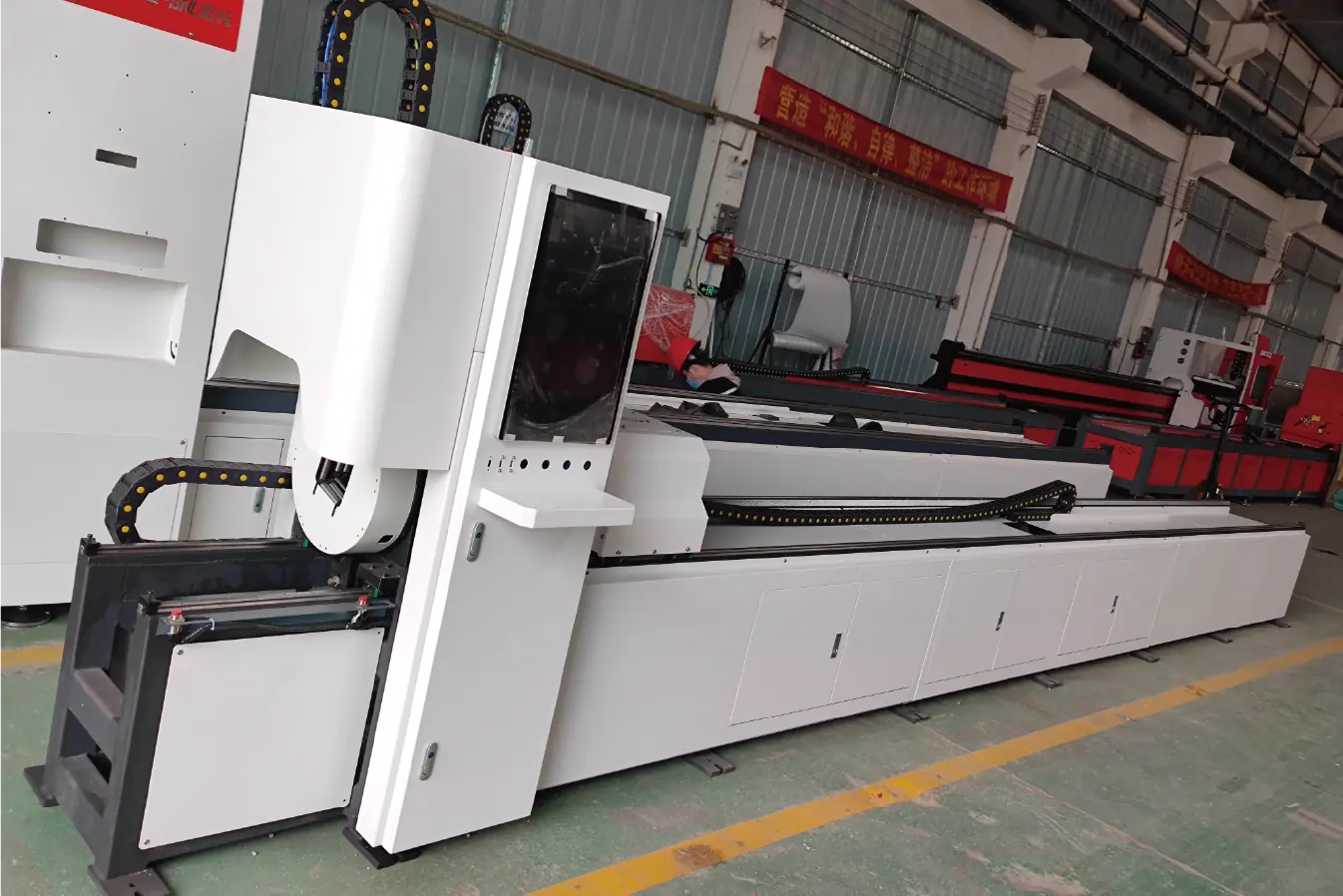

How Does MZBNL Ensure High Quality in its Tube Laser Cutters?

Every manufacturer will tell you they build quality machines. But how can you separate a genuine claim from an empty promise? For me, the proof is in the practical, problem-solving innovations.

MZBNL ensures quality through patented innovations that solve real-world problems. Our No-CAD System simplifies operation, our Front-Feeding mechanism boosts efficiency by 40%, and our Zero-Waste design maximizes material use. These are not just features; they are strategic engineering solutions.

At MZBNL, we don't just assemble machines; we engineer solutions. Our R&D is driven by the challenges I see our clients facing every day on their factory floors. High labor costs, a shortage of skilled operators, rising material prices, and the constant pressure to produce more, faster. Our definition of quality is a machine that directly addresses these pressures. We build equipment that makes our clients more competitive and more profitable. It’s that simple. Here’s how our core innovations deliver on that promise.

No-CAD System: Reducing the Skill Barrier

The traditional process requires a skilled technician to create detailed 3D CAD drawings for every job, which is time-consuming and creates a bottleneck. We saw this and developed our No-CAD System. An operator can now walk up to the machine, input basic parameters like length and hole position for standard tubes, and start cutting immediately. This innovation reduces on-site training from 15 days to just one day, empowering a wider range of employees to operate the machine and freeing up your engineers for more complex work.

Front-Feeding Innovation: Boosting Productivity

Traditional side-loading or rear-loading systems are often slow and labor-intensive. Our patented Front-Feeding mechanism automates the loading process from the front, increasing feeding efficiency by about 40% and reducing operator labor intensity by a similar margin. For industries like automotive parts or furniture manufacturing where cycle time is critical, this is a game-changer. It means more parts per shift with less physical strain on your team.

Zero-Waste Tail Material: Maximizing Profitability

Material is one of the biggest costs in metal processing. Every inch of wasted tube is money lost. We redesigned the cutting logic so the final cut is handled by the rear chuck, completely eliminating the tail material that is typically discarded. This Zero-Waste innovation maximizes your material utilization, directly improving your profit margin on every single tube you process.

What are the Potential Drawbacks of Choosing a Laser Cutter Based Solely on Price?

That low price on the quote looks very attractive. But I always ask my clients to consider the hidden costs that come with it. What is the real price of a "cheap" machine over five years?

Choosing a laser cutter based on price alone often leads to higher long-term costs. Drawbacks include frequent downtime, poor cutting accuracy, high material waste, limited software capabilities, and inadequate technical support. These issues directly impact productivity and profitability, negating any initial savings.

I once visited a factory that had purchased a very low-cost machine a year earlier. The manager was proud of the deal he got. But during my visit, the machine was down. He admitted it was a common occurrence. They were losing production days, falling behind on orders, and spending a fortune on service calls and wasted material from inaccurate cuts. The initial "savings" had evaporated within the first six months. This story is unfortunately very common. A low price tag is often a warning sign for compromises in areas that are vital for industrial production.

The Hidden Costs of a "Bargain"

| Area of Compromise | The Immediate "Saving" | The Long-Term Cost |

|---|---|---|

| Component Quality | Lower initial purchase price. | Frequent breakdowns, expensive repairs, and costly production downtime. |

| Software & Control | Basic, non-intuitive software. | Longer setup times, operator errors, and inability to handle complex jobs. |

| Build & Precision | Lighter frame, less precise assembly. | Inaccurate cuts, high scrap rates, and the need for secondary finishing work. |

| Efficiency Features | No automation or material-saving tech. | Higher labor costs per part and significant material waste, eroding margins. |

| Service & Support | Minimal or non-existent support plan. | Long waits for help, inability to get spare parts, and extended downtime. |

When you add up the costs of lost production, wasted material, and constant maintenance, the "cheap" machine quickly becomes the most expensive piece of equipment on your floor.

How Can Investing in Quality Lead to Long-Term Benefits for Your Business?

Shifting your mindset from cost to investment can feel like a leap. So, let's talk about the tangible returns. How does a quality machine pay for itself and continue to generate value for years to come?

Investing in a quality tube laser cutter delivers significant long-term benefits, including higher throughput, reduced material waste, lower labor costs, and increased operational flexibility. This leads to a stronger competitive edge, improved profit margins, and a more sustainable and adaptable manufacturing process.

A quality machine is not an expense; it's a strategic tool for growth. It allows you to take on more complex jobs, deliver them faster, and do so with greater profitability. It transforms your production floor from a cost center into a competitive advantage. The benefits extend far beyond simply cutting tubes; they impact your entire business operation, from the shop floor to your financial statements. By investing in quality, you are investing in predictability, efficiency, and the capacity to scale.

The Compounding Returns of a Quality Investment

- Higher Throughput and Profitability: With features like our Front-Feeding system, you can produce more parts in the same amount of time. This means you can take on more orders without increasing overhead, directly boosting your revenue and profit margins.

- Drastically Reduced Operating Costs: Our Zero-Waste innovation is a perfect example. If you save even 5-10% on raw material costs, that saving goes directly to your bottom line, year after year. Add in lower energy consumption and reduced maintenance needs, and the operational savings become substantial.

- Increased Business Agility: The MZBNL No-CAD system allows you to switch between jobs with incredible speed. This means you can easily handle small-batch, high-mix orders and respond to urgent customer requests. In today's market, this agility is a massive competitive advantage, allowing you to serve customers that your slower competitors cannot.

- Improved Employee Satisfaction: A machine that is easy to use and reliable reduces operator frustration and stress. An efficient, automated workflow creates a safer and more productive work environment, helping you attract and retain valuable talent.

What are the Best Practices for Evaluating Tube Laser Cutter Quality Before Purchase?

You're convinced that quality is the right path. Now, how do you properly assess it? How can you cut through the sales pitches and perform a thorough, objective evaluation before you sign a purchase order?

To evaluate quality, request live demonstrations with your specific materials and designs. Scrutinize sample cuts for precision and finish. Inquire about the brand of core components like the laser source and cutting head. And most importantly, speak with existing customers for honest feedback.

Making the right choice requires doing your homework. A reputable manufacturer will be transparent and welcome a deep dive into their technology and processes. They should be proud to show you their machines in action and connect you with happy customers. I always encourage potential clients to be skeptical and demanding during the evaluation phase. This is a major investment, and you deserve to have complete confidence in your decision. Here is a practical checklist I recommend to everyone.

Your Pre-Purchase Quality Checklist:

- Demand a Live, Custom Demonstration: Don't settle for a pre-recorded video or a standard demo part. Send the supplier your own drawings (including your most challenging ones) and your own material. Watch the machine cut your parts, either in person or via a live video call.

- Scrutinize the Sample Parts: Once you receive the samples, inspect them carefully. Is the cut edge smooth? Is there any dross? Are the dimensions accurate to your drawing? This is the ultimate proof of the machine's precision.

- Ask About Core Components: Inquire about the manufacturers of the laser source, cutting head, servo motors, and control system. Are they from globally recognized, top-tier brands? The quality of these parts is a strong indicator of the machine's overall reliability.

- Test Drive the Software: Get a demonstration of the software. Is it intuitive? Does it support the features you need? Ask the operator to show you how to set up a new job from start to finish. A simple, powerful system like our No-CAD interface can save you hundreds of hours per year.

- Talk to Existing Customers: Ask the manufacturer for references—specifically, companies in your industry or region. Call them and ask about their experience with the machine's performance, reliability, and the quality of the after-sales support. This is often the most valuable insight you can get.

Conclusion

The choice is clear: the initial price of a tube laser cutter is just a small part of its true cost. A quality machine from a partner like MZBNL is an investment in efficiency, profitability, and long-term growth, delivering value that far exceeds any initial savings from a cheaper alternative.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.