How to Choose a Reliable Tube Laser Cutter Manufacturer: Look for Patents and Global Clients?

Choosing a new tube laser cutter is a high-stakes decision. A wrong move means production delays and wasted capital. But you can de-risk your investment by focusing on two clear signals: innovation and reputation.

To choose a reliable tube laser cutter manufacturer, verify their R&D commitment through patents and their market-proven reliability through a diverse global client base. Patents signal unique, problem-solving technology, while a global presence confirms adaptability, quality, and robust after-sales support for a secure investment.

I’ve spent over a decade in this industry, and I’ve seen firsthand how these two factors separate the true partners from the mere suppliers. They are not just items on a checklist; they are powerful indicators of a manufacturer's stability, vision, and commitment to your success. Let's explore why they matter so much.

Why are patents so important in the tube laser cutter industry?

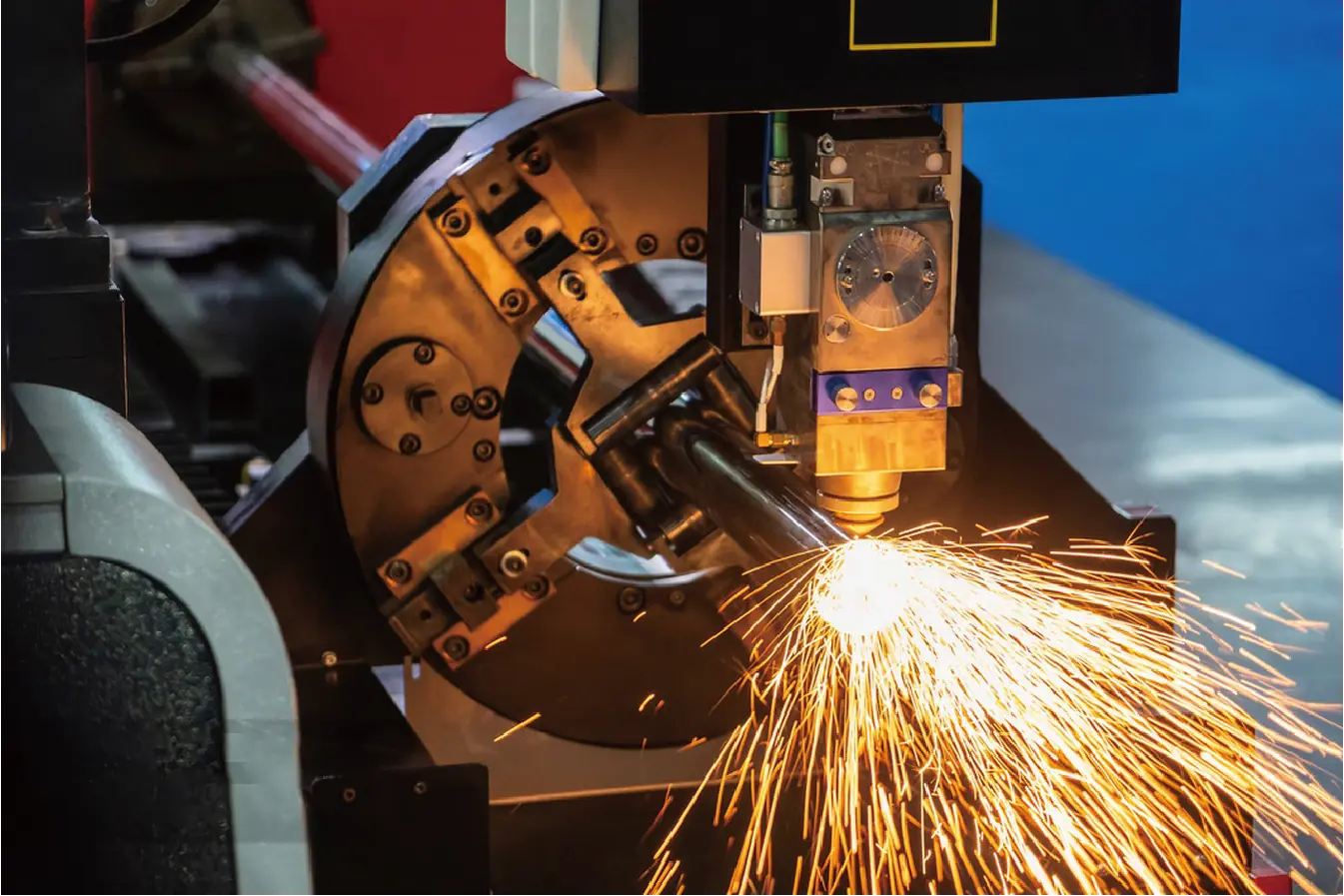

Many machines on the market look functionally identical. But this surface-level similarity can hide critical design flaws that halt production. Patents are your window into a company’s true engineering depth and problem-solving capabilities.

Patents are crucial because they represent legally protected, unique solutions to real-world manufacturing problems. They prove a company invests heavily in R&D to move beyond imitation, offering tangible benefits like reduced waste, faster setup, or simplified operation that directly boost your profitability.

At MZBNL, we've secured over 30 patents since we started in 2010. I don't say this to brag, but to illustrate a point. We don't file patents for the sake of it. Each one represents a solution to a problem a client brought to us. I remember visiting a furniture factory where they were struggling with complex cutting designs. Their operators, who were skilled workers, still needed weeks of training on traditional CAD-CAM software. This bottleneck was costing them money every single day.

From R&D to ROI

This experience led us to develop our patented No-CAD System[^1]. We wanted to make powerful technology accessible. The goal was to empower any operator to run the machine confidently after just a single day of training. By simplifying the software interface and automating complex toolpaths, we turned a multi-week training ordeal into a simple, one-day process. This isn't just a convenience; it's a direct impact on labor costs and operational flexibility.

Solving Real-World Problems

Another key innovation is our Zero-Waste cutting technology[^2]. Material cost is a huge factor in profitability. Our patented system optimizes the nesting and cutting path to maximize the use of every single tube, often reducing tailing material to a minimum. For a high-volume producer of automotive parts, this can translate into tens of thousands of dollars in savings annually. When you evaluate a manufacturer, ask them to explain the problems their patents solve. The answer will tell you everything you need to know about their focus.

What are the current trends in global client acquisition for manufacturers?

Relying on a local supplier might feel safe and convenient. But they often lack the breadth of experience a global manufacturer gains. Today, the best manufacturers prove their value by competing and winning on the world stage.

The trend is a clear shift towards manufacturers with a proven, diverse global client base. This demonstrates that their machines are robust and adaptable enough to meet different international standards, climates, and production demands, ensuring you receive a world-class, reliable product with a strong support network.

Serving over 4,000 clients across the globe has been one of our greatest teachers. It has forced us to build machines that are not just powerful, but also incredibly reliable and versatile. A machine that works perfectly in a climate-controlled facility in Germany must also perform flawlessly in the heat and humidity of a workshop in Southeast Asia. This real-world testing ground is something you can't replicate in a lab.

I recall a project with a client in Brazil who manufactured institutional furniture. They needed to process a specific type of locally sourced metal alloy that was causing issues for their existing equipment. Because we had already solved a similar challenge for a client in India, our engineering team was able to quickly adjust the machine's parameters and provide a software update that resolved the problem in days, not months. This is the power of a global knowledge base. A manufacturer with a wide client base offers more than a machine; they offer a wealth of experience.

Here’s what a global footprint really means for you:

- Proven Reliability: Their equipment has been tested in a wide range of industrial environments.

- Adaptability: They understand different production standards and can tailor solutions accordingly.

- Robust Support: They have the infrastructure for international logistics and after-sales service.

- Continuous Innovation: Feedback from a global base drives faster and more meaningful product improvements.

What challenges do buyers face when identifying reliable manufacturers?

Every sales brochure and website makes bold promises. But when you're making a significant capital investment, you know that glossy marketing materials can hide poor quality and non-existent service, creating a real challenge for buyers.

The primary challenge for buyers is cutting through the noise to distinguish genuine innovators from assemblers or imitators. It's difficult to verify claims of "high precision" or "easy operation" and to gauge the quality of post-purchase support without clear, objective evidence like patents and global case studies.

I speak with business owners and plant managers every week, and I hear the same frustrations repeatedly. They are navigating a crowded market where many suppliers simply assemble generic parts and compete on price alone. This creates several problems for the buyer.

First, there is the challenge of verifying technical claims. A manufacturer might claim a positioning accuracy of ±0.05mm, but can they sustain that precision over years of multi-shift production? Without a deep investment in R&D for a rigid machine frame and quality components—things often protected by design patents—that initial accuracy can quickly degrade.

Second is the fear of being abandoned after the sale. This is the biggest risk, especially when buying from an overseas company. A low price is no comfort when a machine is down and you can't get a technician or a spare part for weeks. This is where a company’s global reputation becomes critical. A history of successfully supporting thousands of clients worldwide is a strong indicator that they have the processes and infrastructure in place to support you, too. The real test of a partner isn't the sales process; it's how they respond when you have a problem.

What are the best strategies for evaluating manufacturers based on their patents and client base?

You understand the importance of patents and global clients. But you need a practical way to dig deeper and use this information to make a confident decision. The key is to connect their credentials directly to your operational needs.

The best strategy is to ask targeted questions. Instead of just counting patents, ask how a specific patent solves your biggest production problem. Instead of just seeing a client count, ask for case studies or references from your specific industry and region to verify their real-world performance and support.

When you engage with a potential supplier, you should lead the conversation with purpose. Move beyond the surface-level features and dive into the proof behind their claims. Here is a simple framework I recommend to all potential buyers.

How to Evaluate Patents

- Request a list of core patents: Ask for the patents that relate directly to the machine you are considering.

- Connect patents to pain points: Frame your questions around your problems. For example: "You mentioned a patent on your chuck design. How does that help reduce tube deformation on thin-walled materials, which is a major issue for us?"

- Inquire about software patents: The machine's "brain" is just as important as its hardware. Ask about patents related to software, ease of use, and system integration, like our No-CAD system. This shows a commitment to the total user experience.

How to Evaluate a Client Base

| Evaluation Step | What to Ask | Why It Matters |

|---|---|---|

| Industry Relevance | "Can you provide case studies from the furniture/automotive/etc. industry?" | This confirms they understand the unique demands of your business. |

| Regional Support | "What is your after-sales support structure in my country/region?" | This verifies their ability to provide timely service and parts. |

| Global Credibility | "Which international trade shows do you participate in?" | Presence at major global shows like those in Germany or the US signals a serious, long-term commitment to the global market. |

What are the key technical recommendations for choosing a trustworthy tube laser cutter manufacturer?

Technical specifications can be overwhelming. Focusing on the wrong details can lead to buying an underpowered machine or overpaying for capacity you don't need. A trustworthy manufacturer will be transparent about the core components that truly drive performance.

Technically, you should prioritize manufacturers who develop and control their own core software and control systems. A proprietary, patent-protected system ensures seamless hardware-software integration, simplified operation, and better long-term support. Also, verify the quality of critical components like the laser source and cutting head.

After all the strategic evaluation, the decision also comes down to the machine itself. As an engineer at heart, this is where I get passionate. A great machine is a system where every component works in harmony. Here are the three areas I tell every buyer to scrutinize.

The Brain: Control System and Software

This is the most critical element. A machine with a generic, third-party control system is just an assembly of parts. We invested heavily in developing our own system because it allows us to unlock the full potential of the hardware. It's how we deliver on our promise of one-day training. It ensures that when you need a software update or a new feature, you are dealing directly with the people who wrote the code.

The Heart: The Laser Source

The laser source is the engine of your machine. While many manufacturers use sources from reputable third-party brands, a trustworthy partner will help you select the right power and brand (like IPG or Maxphotonics) for your specific applications and budget. They should be transparent about the pros and cons of each, rather than just pushing one option.

The Body: The Machine Bed and Structure

A laser cutter's precision is entirely dependent on the stability of its foundation. We use a heavy, stress-relieved, welded plate structure for our machine beds. It’s more expensive and time-consuming to manufacture than a simple tube-welded frame, but it ensures rock-solid stability and accuracy for a decade or more. A manufacturer who cuts corners here is not a long-term partner.

Conclusion

Choosing the right manufacturer is a strategic business decision, not just a purchase. By looking beyond the price tag and focusing on a company's patent portfolio and global client base, you can find a true partner—one committed to innovation, reliability, and your ultimate success.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.